I-Porous Metal Sintered Bearing

Izinsimbi ezinama-porous zingenye yezinto eziningi ezifanele ukukhiqiza ama-bearings.

Izinsimbi ezinama-porous zingenye yezinto eziningi ezifanele ukukhiqiza ama-bearings.

Izinzuzo Sintered Bearings

Izinsimbi eziyimpuphu zinenani elikhulu lezinzuzo nezinzuzo ezivumela ukuthi zisetshenziswe ngokuphumelelayo ukukhiqiza ama-bearings aphezulu.Ezinye zalezi zinzuzo zibalwe ngezansi.

Izindawo ezikhethekile.Enye yezinzuzo zezinsimbi eziyimpuphu ukuthi zinganikeza isiphetho esihle kakhulu se-bearings.Uma zicutshungulwa kahle, lezi zinto zingakwazi ukukhiqiza kalula ama-bearings anesiphetho esihle kakhulu, okwenza indawo engaphezulu ingakhangi nje kuphela, kodwa futhi imelana nokugqoka nokugqwala.Amandla abo aphezulu avumela ukuthi ama-bearings asetshenziswe emishinini eminingi yanamuhla.

I-porosity enhle kakhulu.Enye inzuzo yezinsimbi eziyimpuphu yi-porosity enhle kakhulu abangaba nayo.Uma izinsimbi eziyimpushana sezenziwe ngomshini, indawo yazo yonke ingaba nezimbotshana kunezinye izinto.Izinga labo elingaphezulu lizivumela ukuthi zimunce izinto zokugcoba, okwenza abakhiqizi bakwazi ukuthola ama-bearings azigcobayo.

Ukusebenza okuphezulu.Izinsimbi eziyimpuphu zingahlanganiswa nezinye izinto, ezivumela ukuthi zikhiqize ama-bearings asebenza kahle ezindaweni ezahlukene.I-microstructure yazo ingalawulwa ngokunembile, okuzivumela ukuthi zenze kangcono uma zisetshenziswa kumazinga okushisa athile.

Ukusebenza kwezindleko okuqinisekisiwe.Izinsimbi eziyimpushana azihlinzeki nje kuphela ngama-bearings anezindawo ezinhle kakhulu, i-porosity ephakeme nokusebenza okuphezulu, kodwa futhi zinikeza izinzuzo zezindleko ezinokwethenjelwa kubasebenzisi be-bearings.

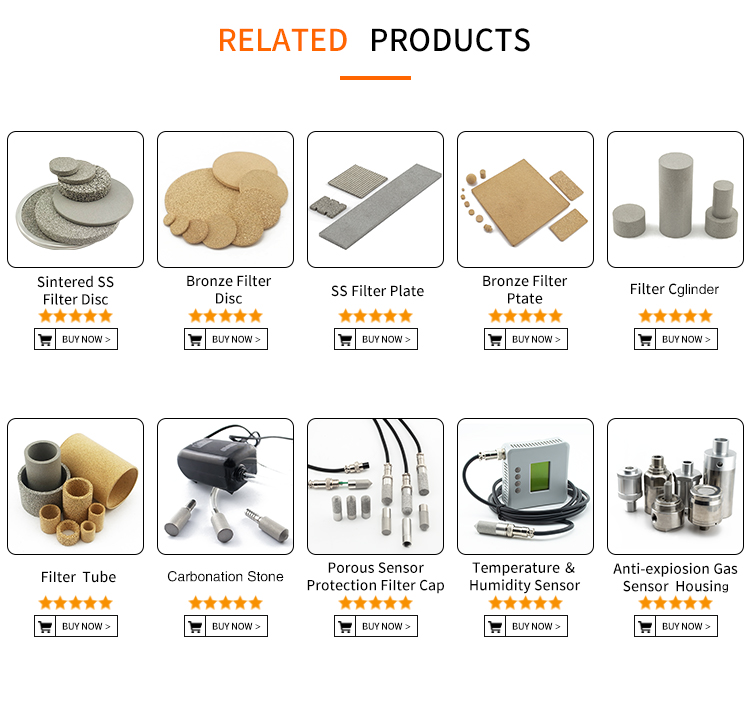

Izihlungi zensimbi ze-Sintered ziyimikhiqizo esebenza kahle kakhulu lapho izinhlayiya ziqoqwa khona endaweni yemidiya.Ukukhetha okufanele kosayizi wembotshana yesihlungi kufanele kulinganisele isidingo sohlelo lokuhlunga lokugcinwa kwezinhlayiyana, ukwehla komfutho, namandla okugeza ingemuva.Izinto ezintathu zenqubo okufanele zicatshangelwe: isivinini soketshezi ngokusebenzisa imidiya yesihlungi, i-viscosity yoketshezi, nezici zezinhlayiyana.Izici ezibalulekile zezinhlayiya wumumo wezinhlayiyana, usayizi, kanye nokuminyana.Iphumela kusihlungi esiqinile, esivamile, noma esinomumo ongajwayelekile onediski noma inkomishi engacindezeli kanye nezinye izimo.

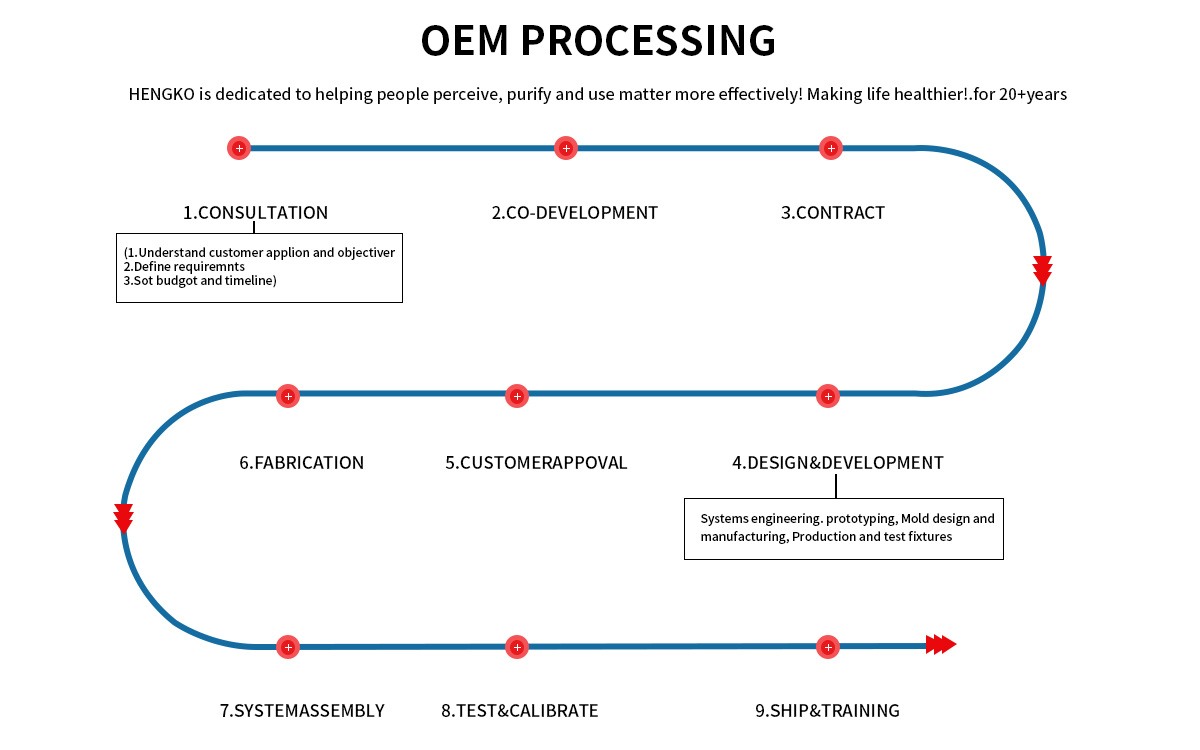

Awuwutholi umkhiqizo ohlangabezana nezidingo zakho?Xhumana nabasebenzi bethu bokuthengisa ukuze uthole Izinsizakalo zokwenza ngokwezifiso ze-OEM/ODM!