-

I-HENGKO® High Purity Semiconductor Gas Filter

Izihlungi zochungechunge oluhlanzekile ziklanyelwe ukuhlunga amagesi e-semiconductor.Lo mhlangano oshiselwe ngokugcwele uzoletha ukugcinwa kwezinhlayiyana eziyi-0.003 micron.Semi...

Buka imininingwane -

I-Sintered In-line Metal Gas Filter Yesistimu Yokuhlanza Igesi Ye-Semiconductor

Izihlungi zegesi yensimbi e-Sintered emgqeni zisebenza ukukhipha ukungcola okuhlanganisa umswakama, umoya-mpilo, isikhutha, i-carbon monoxide, ama-hydrocarbon nama-carbonyl ensimbi nge ...

Buka imininingwane -

I-HENGKO High Purity Porous Metal Diffusers Stone yokuhlunga kwegesi ehlanzekile ...

I-HENGKO Porous Metal Diffuser ngokushesha ikhipha amagumbi e-vacuum emkhathini okwehlisa isikhathi somjikelezo futhi andise ukuphuma.Insimbi yethu engagqwali i-diffu...

Buka imininingwane -

Inzwa yezinga lokushisa kanye nomswakamo yeSemiconductor Clean Room Temperature Humidity Contr...

Umbukiso Womkhiqizo Izinga lokushisa kanye nomswakama wendawo ehlanzekile kunqunywa ngokuyinhloko ngokwezidingo zenqubo, kodwa ngaphansi kwesimo sokuhlangabezana...

Buka imininingwane -

I-Sintered SS 316L yensimbi engagqwali engenasici sokuvikela isihlungi sezindlu zezimboni...

Izinzwa ezivikela ukuqhuma zenziwe ngensimbi engagqwali engu-316 ukuze kuvikeleke ukugqwala okuphezulu.I-sinter-bonded flame arrestor ihlinzeka ngokusabalaliswa kwegesi...

Buka imininingwane -

316L isihlungi esivikela ilangabi lendlu ye-co2 semiconductor microns modbus sensor filter probe ho...

Izindlu zenzwa yokuqhuma kwe-HENGKO zenziwe ngensimbi engagqwali engu-316L ne-aluminium ukuze kuvikelwe ukugqwala okuphezulu.I-sinter-bonded flame arrestor inikeza ...

Buka imininingwane

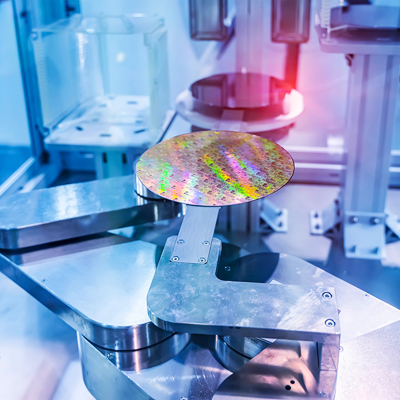

Izihlungi Zegesi Ye-Semiconductor:

Ukuqinisekisa Ukuhlanzeka Kwegesi Okungenasici ku-Chipmaking

Ezweni eliyinkimbinkimbi yokukhiqiza i-semiconductor, lapho ukunemba nokuhlanzeka kubaluleke kakhulu, ikhwalithi ye

amagesi asetshenzisiwe adlala indima ebalulekile ekunqumeni impumelelo yenqubo.Ukungcola, ngisho nasezingeni elilinganiselwe,

kungadala umonakalo ekujikelezeni okuntekenteke kwama-microchip, kuwenze abe namaphutha futhi angasebenziseki.Ukuze uvikele

le nqubo ebucayi, izihlungi zegesi ye-semiconductor zime njengabaqaphi abangagodli, zisusa ngokucophelela ukungcola.

kanye nokuqinisekisa ikhwalithi emsulwa yamagesi ageleza emigqeni yokukhiqiza.

Kunezici eziningi ezinhle kakhulu kanye nezinzuzo zezihlungi zensimbi ze-sintered

1. Iklanywe endaweni ye-State-of-the-Art Cleanroom

Lezi zihlungi zizalelwa endaweni ehlanzekile yesimanjemanje, indawo lapho izimo ezimsulwa zigcinwa khona ngokucophelela ukuze kuncishiswe noma yikuphi ukungcola okungaba khona.Abhekana nenqubo yokukhiqiza eqinile, eqala ngokushisela ngokunemba ngaphansi kwesimo somoya ohlanzekile.Ukugungiswa kwamanzi okulandelanayo okwenziwe yi-deionized, okulandelwa ukucindezela okukhulu, ukuhlanzwa kwe-nitrogen ehlungiwe, kuqeda noma yiziphi izinhlayiya ezihlala isikhathi eside futhi kunciphisa ingozi yokuchitheka kwezinhlayiyana.

2. I-Exceptional Particle Ukususwa Ngempumelelo

Ngokusebenza kahle okumangalisayo kokuhlunga kwe-9 LRV yezinhlayiya ezingu-0.003μm, kubambelela ezindinganisweni eziqinile ezibekwe yi-SEMI F38 kanye nezindlela zokuhlola ze-ISO 12500, lezi zihlungi zisusa ngempumelelo noma yiziphi izinhlayiya ezikhiqizwe ukugqwala nezinhlayiya ezikhiqizwe ezingxenyeni ezihambayo, ziqinisekisa ukuhlanzeka okumsulwa amagesi.

3. Amandla Emishini Ephakeme

Zihlolwe ngokuqinile ukuze kuqinisekiswe ukukhuthazela okukhethekile ezinqubweni zokukhiqiza ezifunwayo kanye nezindawo ezivame ukusebenzisa umfutho wegesi ophakeme, lezi zihlungi zihlinzeka ngokusebenza okungantengantengi kuyo yonke impilo yazo.

4. Ukudlula Amazinga Emboni Aphakeme Kakhulu

Ukudlula izidingo eziqinile zokuphathwa kwegesi zokuhlunga ukuze kucutshungulwe i-semiconductor, lezi zihlungi zihlolwa ngokuqinile ukuze kuqinisekiswe ukuthi zihlangabezana nokusebenza kahle kokuhlunga, ukulawula ukugeleza okunembayo, namazinga okuphepha afunwa amasistimu okulethwa kwegesi ekukhiqizeni ama-semiconductor.

5. Ukuzibophezela Okungantengantengi Ekuphepheni

Ukuze kuvikelwe ekuchayekeni kumagesi ezinqubo ezivuthayo, ezibolayo, ezinobuthi, kanye ne-pyrophoric, izindlu zokuhlunga zihlolwa ngokucophelela ukuvuza, okuqinisekisa ukuthi zithola izinga lokuvuza elimangalisayo elingaphansi kuka-1x10-9 atm scc/sesekhondi.Lokhu kuzibophezela okungantengantengi kwezokuphepha kuqinisekisa ukuthi amagesi ayingozi aqukethwe futhi avinjwe ukuthi angalimazi.

6. Ukuhlanzeka Okungayekethisi Kwe-Chipmaking Excellence

Ngamandla azo akhethekile okuhlunga, ukuzibophezela okungantengantengi kwezokuphepha, kanye nokuhambisana nezindinganiso eziphakeme kakhulu zemboni, lezi zihlungi zegesi zidlala indima ebalulekile ekuvikeleni inqubo eyinkimbinkimbi yokukhiqiza ama-semiconductor.Zimi njengabaqaphi bokuhlanzeka, ziqinisekisa ukuthi amagesi ahlanzekile kuphela ageleza emigqeni yokukhiqiza, evula indlela yokwakhiwa kwama-microchips asebenza kahle kakhulu anika amandla umhlaba wethu wesimanje.

Izinhlobo Zezihlungi Ze-Semiconductor

Izihlungi ze-Semiconductor zisetshenziswa ezinhlelweni ezahlukahlukene, kufaka phakathi:

* Ukukhiqizwa kwe-elekthronikhi:

Izihlungi ze-Semiconductor zisetshenziselwa ukususa izinhlayiya emanzini aphezulu, amagesi, namakhemikhali asetshenziswa ekwenzeni ama-semiconductors.

* I-Chemical mechanical planarization (CMP):

Izihlungi ze-semiconductor zisetshenziselwa ukususa izinhlayiya kuma-slurries e-CMP, asetshenziselwa ukupholisha ama-wafers we-semiconductor.

* I-Biomedical:

Izihlungi ze-Semiconductor zisetshenziselwa ukususa izinhlayiya kuketshezi olusetshenziswa ekuxilongeni nasekwelashweni.

*Ezemvelo:

Izihlungi ze-semiconductor zisetshenziselwa ukususa izinhlayiya emoyeni nasemanzini.

Kunezinhlobo ezine eziyinhloko zezihlungi ze-semiconductor:

1. Izihlungi ze-Membrane:

Izihlungi ze-membrane zenziwe ngefilimu elincanyana, elinezimbotshana elivumela uketshezi ukuba ludlule ngenkathi ibamba izinhlayiya.

2. Izihlungi zokujula:

Izihlungi ezijulile zenziwe ngombhede owugqinsi, ohlukumezayo obamba izinhlayiya njengoba zigeleza kusihlungi.

3. Izihlungi ze-Adsorbent:

Izihlungi ze-Adsorbent zenziwe ngezinto ezihehayo futhi ezibambelela ezinhlayiyeni.

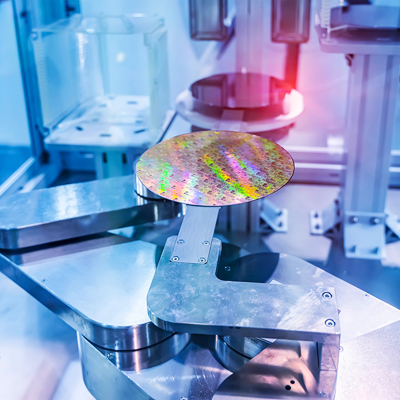

4. Izihlungi zensimbi ezine-sintered

Izihlungi zensimbi ze-Sintered ziwuhlobo lwesihlungi sokujula esivame ukusetshenziswa ekwenzeni i-semiconductor.Zenziwa ngokucwilisa impushana yensimbi ibe yizimbotshana.Izihlungi zensimbi ze-Sintered zaziwa ngokuhlala kwazo okuphezulu, ukusebenza kahle kokuhlunga okuphezulu, kanye nekhono lokumelana namazinga okushisa aphezulu nezingcindezi.

Izinzuzo zezihlungi zensimbi ezine-sintered zokukhiqiza i-semiconductor:

* Ukuqina okuphezulu:

* Ukusebenza kahle kokuhlunga:

*Impilo ende:

* Ukuhambisana kwamakhemikhali:

Izicelo zezihlungi zensimbi ezine-sintered ekwenzeni i-semiconductor:

* Ukuhlanzwa kwegesi:

Izihlungi zensimbi ezi-sintered ziyingxenye ebalulekile yenqubo yokukhiqiza i-semiconductor, okusiza ukuqinisekisa ukukhiqizwa kwamadivayisi we-semiconductor wekhwalithi ephezulu.

Uhlobo lwesihlungi se-semiconductor esisetshenziswa ohlelweni oluthile luncike kusayizi wezinhlayiya ezikhishwayo, uhlobo loketshezi oluhlungwayo, kanye nezinga elifiswayo lokuhlunga.

Nali ithebula elifingqa izinhlobo ezahlukene zezihlungi ze-semiconductor:

| Uhlobo Lwesihlungi | Incazelo | Izinhlelo zokusebenza | Isithombe |

|---|---|---|---|

| Izihlungi ze-membrane | Yenziwe ngefilimu elincanyana, elinezimbotshana elivumela uketshezi ukuba ludlule ngenkathi ibamba izinhlayiya. | Ukukhiqizwa kwe-elekthronikhi, i-CMP, i-biomedical, imvelo | |

| Izihlungi ezijulile | Yenziwe ngombhede owugqinsi, ohlukumezayo obamba izinhlayiya njengoba zigeleza kusihlungi. | I-CMP, i-biomedical, imvelo | |

| Izihlungi ze-Adsorbent | Kwenziwe ngezinto ezihehayo futhi ezibambelela ezinhlayiyeni. | Ukukhiqizwa kwe-elekthronikhi, i-CMP, i-biomedical, imvelo | |

| Izihlungi zensimbi ezi-sintered | Kwenziwe ngokucwilisa impushana yensimbi ibe yizimbotshana. | Ukuhlanzwa kwegesi, ukuhlungwa kwamakhemikhali, ukuhlungwa kwamanzi okunamandla, ukuhlunga kwe-CMP slurry | Izihlungi zensimbi ze-Sintered ze-semiconductor |

Isicelo

Izihlungi zegesi ze-Sintered semiconductor zensimbi zisetshenziswa kabanzi ezinhlelweni ezahlukahlukene embonini ye-semiconductor.Izakhiwo zabo eziyingqayizivele, ezifana nokusebenza kahle kokuhlunga okuphezulu, ukuqina, kanye nekhono lokumelana nezinga lokushisa eliphezulu nezingcindezi, kubenza babe yingxenye ebalulekile yezinhlelo zokulethwa kwegesi ekukhiqizeni ama-semiconductor.

Nazi ezinye zezinhlelo zokusebenza ezithile zezihlungi zegesi ye-sintered semiconductor yensimbi:

1. Ukukhiqizwa kwe-wafer:

Izihlungi zensimbi ezine-sintered zisetshenziselwa ukuhlanza amagesi asetshenziswa ekukhiqizweni kwe-wafer, njenge-nitrogen, i-hydrogen, nomoya-mpilo.Lawa magesi abalulekile ezinqubweni ezifana nokukhula kwe-epitaxial, etching, kanye ne-doping.

2. Ukuhlunga kwamakhemikhali:

Izihlungi zensimbi ezine-sintered zisetshenziselwa ukuhlunga amakhemikhali asetshenziswa ekukhiqizeni ama-semiconductor, njengama-acids, izisekelo, nezinyibilikisi.Lawa makhemikhali asetshenziselwa izinjongo ezihlukahlukene, okuhlanganisa ukuhlanza, ukucwiliswa, nokupholisha.

3. Ukuhlunga kwamanzi okuhlanzekile:

Izihlungi zensimbi ze-Sintered zisetshenziselwa ukuhlunga amanzi e-ultrapure (UPW) asetshenziswa ekwenzeni i-semiconductor.I-UPW ibalulekile ekuhlanzeni nasekuwasheni amawafa, kanye nasekulungiseleleni amakhemikhali.

4. Ukuhlunga kwe-CMP slurry:

Izihlungi zensimbi ezihlanganisiwe zisetshenziselwa ukuhlunga ama-slurries e-CMP, asetshenziselwa ukupholisha amawafa e-semiconductor.I-CMP iwuhlelo olubalulekile ekwakhiweni kwama-microchips.

5. Ukuhlunga kwephoyinti lokusebenzisa (POU):

Izihlungi zensimbi ezine-sintered zivame ukusetshenziswa njengezihlungi ze-POU, ezifakwa ngqo endaweni yokusetshenziswa ukuze zinikeze izinga eliphezulu lokuhlunga.Izihlungi ze-POU zibaluleke kakhulu ezinhlelweni zokusebenza lapho ukuhlanzeka kwegesi kubaluleke kakhulu, njengokukhiqizwa kwama-microprocessors namanye amadivaysi asebenza kahle kakhulu.

6. Ukubamba igesi ehlanzekile:

Izihlungi zensimbi ezine-sintered zisetshenziswa ezinhlelweni zokuphatha igesi ehlanzeke kakhulu ukuze kususwe ukungcola kumagesi asetshenziswa ekwenziweni kwe-semiconductor.Lokhu kungcola kungabandakanya izinhlayiya, umswakama, nezinhlanganisela eziphilayo.

7. Ukukhiqiza ama-Microelectronics:

Izihlungi zensimbi ze-Sintered zisetshenziswa ekwenzeni ama-microelectronics, njengamakhompyutha, amaphilisi, omakhalekhukhwini, izinzwa ze-IoT, namadivayisi okulawula.

8. Ukuhlunga amasistimu ama-Micro-electromechanical (MEMS):

Izihlungi zensimbi ezine-sintered zisetshenziswa ekuhlungeni kwe-MEMS, okuwuhlelo lokususa ukungcola ezinhlelweni ezincane ze-electromechanical.I-MEMS isetshenziswa ezinhlelweni ezahlukahlukene, kufaka phakathi izinzwa, ama-actuator, nama-transducer.

9. Ukuhlunga idivayisi yokulondoloza idatha:

Izihlungi zensimbi ezine-sintered zisetshenziswa ekuhlungeni idivayisi yokugcina idatha, okuyinqubo yokususa ukungcola kumadivayisi okugcina idatha, njengamadrayivu oqinile namadrayivu wesimo esiqinile.

Ngokungeziwe kulezi zinhlelo zokusebenza ezithile, izihlungi zegesi ye-sintered semiconductor yensimbi nazo zisetshenziswa kwezinye izinhlelo zokusebenza embonini ye-semiconductor.Ukuguquguquka kwazo kanye nokuthembeka kwazo kuzenza zibe ithuluzi elibalulekile labakhiqizi be-semiconductor.

Ingabe ufuna izihlungi zegesi ezisezingeni eliphezulu ze-sintered metal semiconductor?

U-HENGKO unguzakwethu ohamba naye wezixazululo ze-OEM ezinhlelweni zokukhiqiza ze-semiconductor.

Izihlungi zethu ezibunjwe ngokunemba ziqinisekisa ukwethembeka nokusebenza kahle ezinqubweni zakho, zikunikeza umkhawulo emakethe yokuncintisana.

Kungani Khetha Izihlungi zika-HENGKO?

* Ikhwalithi ephakeme nokuqina

* Izixazululo ezenziwe ngokwezifiso ukuze zivumelane nezidingo zakho ezithile

* Ukusebenza okuthuthukisiwe kokukhiqizwa kwe-semiconductor

Ungavumeli izinselele zokuhlunga zibambezele ukukhiqiza kwakho.

Xhumana nathi namuhla ukuze uhlole ukuthi izihlungi zethu zensimbi ezine-sintered zingaluguqula kanjani uhlelo lwakho lokukhiqiza.

Xhumana nathi kuka@hengko.com

Bambisana ne-HENGKO futhi uthathe igxathu eliya ebuhleni bokukhiqiza ama-semiconductor!