-

I-High Purity Gas Sintered Isihlungi Sezicelo Zesilinganiso Sokugeleza Okuphansi Okukodwa

Isihlungi Esihlanganisiwe Sezihlanzi Zegesi Ezizodwa, Izicelo Zezinga Lokugeleza Okuphansi Ezidizayinelwe ukuhlanzeka okuphezulu kanye nezinhlelo zokusebenza zokuhlanzeka okuphezulu ezidinga amazinga okungcola...

Buka imininingwane -

I-Porous Metal Filter Media kanye ne-OEM Sintered Stainless Steel Filter ye-Hydrogen Gas

Imithombo yemithombo yemithombo yensimbi enezimbobo yokusungulwa kwamanje ihlanganisa iyunithi yokuhlunga esusa ukungcola kugesi ye-hydrogen, kanye nevalvu yokulawula indlela eyodwa...

Buka imininingwane -

I-Sintered In-line Metal Gas Filter Yesistimu Yokuhlanza Igesi Ye-Semiconductor

Izihlungi zegesi yensimbi e-Sintered emgqeni zisebenza ukukhipha ukungcola okuhlanganisa umswakama, umoya-mpilo, isikhutha, i-carbon monoxide, ama-hydrocarbon nama-carbonyl ensimbi nge ...

Buka imininingwane -

I-Sintered porous metal filter disc 20 micron yokuhlanza nokuhlaziya igesi

Zuza Ukwehlukana Okungenakuqhathaniswa Kwegesi/Izinsimbi NgamaDiski Okuhlunga Ensimbi Engagqwali e-HENGKO!Amasistimu ethu okuhlunga, afaka i-sintered stainless ...

Buka imininingwane -

I-Sintered metal Gas / Solids Venturi Blowback (GSV) GSP isihlungi se-OEM Services

I-Custom Sintered metal Gas/Solids Venturi Blowback (GSV) Isihlungi se-GSP se-Sintered metal sesetshenziselwe ukuhlunga igesi eshisayo ezitshalweni ezihlukahlukene...

Buka imininingwane -

I-UltraPure UHP Compressed Air Stainless Steel High Pressure Inline Isihlungi Sesampula Sesihlungi...

I-HENGKO Gas Sampling Filter ingahlukanisa izinto eziqinile kumagesi emisebenzini ehlukahlukene.Ukusetshenziswa kuhlanganisa ukuhlunga kwenqubo, izihlungi zesampula, ukupholisha...

Buka imininingwane -

I-Sintered Stainless Stainless Stainless Steel Porous Metal Powder Filter Ued For Gas Sensor Sampling

Incazelo Yemikhiqizo Ingxenye ye-pneumatic yesampula yezinzwa zegesi, esetshenziselwa ukunciphisa ukuguquguquka kwengcindezi Inhloko yesampula yegesi iyi-g ekhethekile...

Buka imininingwane -

Uhlelo Lokusampula Lokuhlaziya Igesi - Isihlungi Esiphezulu Sokucindezelwa Okusemgqeni I-UltraPure UHP

I-HENGKO High-pressure gas filter ukuze uvikeleke okuthembekile ekungcoleni.Le makethe yokuhlunga, ukuhlukaniswa kanye nokuhlanza ibuye ihambisane ne-deve...

Buka imininingwane -

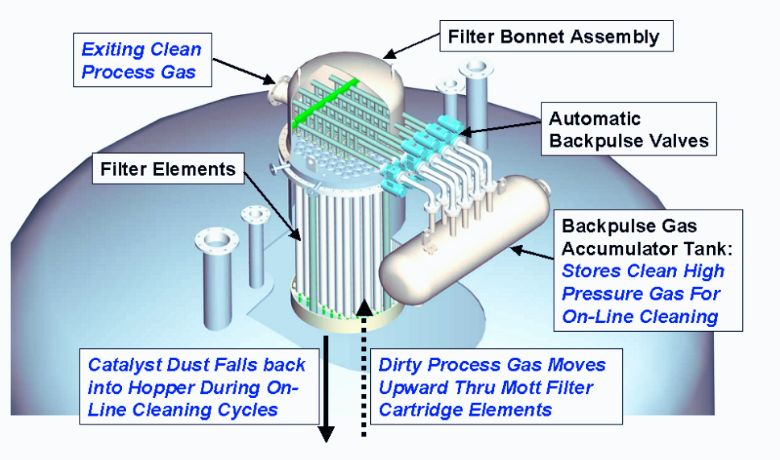

I-HENGKO Sintered Filter Cartridge for Process Gas and On-line Analysis

Ukuhlunga Kwegesi Nesampula Ukuze Kucutshungulwe Igesi Nokuhlaziywa Kwe-inthanethi Ukuhlungwa kwamagesi kubalulekile ezinhlobonhlobo zezicelo, nokho amamitha amathathu kuphela...

Buka imininingwane -

Ubufakazi Bokuqhuma Kwesihlungi Sesihlungi Sezindlu Zenzwa Yegesi Yenqubo Nokusebenza Kwegesi Yokuhlaziya...

Izindlu zezinzwa zegesi zingamathuluzi okuphepha avumela ukugeleza kwamagesi avuthayo kuyilapho kuvimbela ukuthungela.I-(sintered metal filter media) inzwa yezindlu...

Buka imininingwane -

Izihloli Zegesi Yezimboni Zezohwebo ezinama-alamu eGesi Yemvelo

Londoloza Imizuzwana - Ukwehluleka Kokuvikela Izimpilo Kuholela emiphumeleni edabukisayo.Ekutholeni igesi, isekhondi ngalinye libalulekile, nokukhetha isisombululo esifanele sokuthola igesi i...

Buka imininingwane -

I-Smart Single Gas Detectors eku-inthanethi - GASH-AL01

Isitholi segesi esisodwa sisetshenziswa kakhulu ukuthola igesi evuzayo evuthayo noma igesi enobuthi echayeke endaweni ezungezile.Ingakwazi ukusiza imboni ye-petroleum ch...

Buka imininingwane

Izinhlobo Zokuhlunga Kwegesi

Njengoba Sazi, Kunezinhlobo eziningi ezahlukene zokuhlunga kwegesi, kuye ngohlelo oluthile.

Ezinye zezinhlobo ezivame kakhulu zokuhlunga igesi zifaka okulandelayo:

1. Ukuhlunga okuphelele:

Lolu hlobo lokuhlunga lususa zonke izinhlayiya zosayizi othile noma ezinkulu.Izihlungi eziphelele zivame ukusetshenziswa ku

izinhlelo zokusebenza ezibucayi lapho ngisho nezinhlayiya ezincane zingabangela izinkinga, njenge-semiconductor

ezimbonini nasezinsizeni zezokwelapha.

2. Ukuhlunga okuhlanganisayo:

Lolu hlobo lokuhlunga lususa amaconsi awuketshezi emfudlaneni wegesi.Izihlungi ze-coalescing zivame ukusetshenziswa ku

izinhlelo zokusebenza lapho umswakama ungabangela izinkinga, njengokukhiqizwa kukawoyela negesi kanye nokungaphakathi

amasistimu omoya acindezelwe.

3. Ukuhlunga kwe-Adsorptive:

Lolu hlobo lokuhlunga lususa amagesi nezihwamuko emfudlaneni wegesi nge-adsorption.Izihlungi ze-Adsorptive

zivame ukusetshenziswa ezinhlelweni lapho kudingeka khona ukulawula okuphumayo, njengasezimbonini zikagesi kanye naphakathi

izikhungo zokucubungula amakhemikhali.

3. Ukuhlunga kwe-Catalytic:

Lolu hlobo lokuhlunga lusebenzisa i-catalyst ukuguqula amagesi ayingozi abe amagesi angayingozi kangako.Izihlungi ze-Catalytic

zivame ukusetshenziswa ezinhlelweni lapho kudingeka khona ukulawula okuphumayo, njengezimoto nasezitshalweni zezimboni.

Ngaphezu kwalezi zinhlobo ezijwayelekile zokuhlunga kwegesi, kunezinhlobo eziningi ezikhethekile zokuhlunga kwegesi, njenge:

* Ukuhlunga kwe-HEPA (okusezingeni eliphezulu kwezinhlayiyana):

Izihlungi ze-HEPA zenzelwe ukususa izinhlayiya ezincane kakhulukusuka emfudlaneni wegesi, yehle iye kuma-microns angu-0.3 ububanzi.

Izihlungi ze-HEPA zivame ukusetshenziswa ezibhedlela nakwezinye izindawo zamagumbi ahlanzekile.

1. Ukuhlunga kwe-ULPA (umoya wokungena ophansi kakhulu):

Izihlungi ze-ULPA zisebenza kahle kakhulu kunezihlungi ze-HEPA, zisusa u-99.999%izinhlayiya 0.12 microns ububanzi

noma ngaphezulu.Izihlungi ze-ULPA zivame ukusetshenziswa ezinhlelweni ezibucayi lapho ngisho ne-izinhlayiya ezincane kakhulu zingadala izinkinga,

njengasembonini yezemithi kanye nasekukhiqizeni ama-semiconductor.

2. Ukuhlunga kwekhabhoni okucushiwe:

Izihlungi zekhabhoni ezicushiwe zisetshenziselwa ukususa umhwamuko wemvelo nokunye ukungcolaumfudlana wegesi.Yenziwe yasebenza

izihlungi zekhabhoni zivame ukusetshenziswa ezinhlelweni lapho kudingeka ukulawula iphunga, njengakuizitshalo zokuhlanza amanzi angcolile

nasezikhungweni zokucubungula ukudla.

Uhlobo lokuhlunga kwegesi olulungele uhlelo oluthile luncike ezintweni eziningi, okuhlanganisa uhlobo lwegesi ehlungwayo, ubukhulu bezinhlayiya ezizokhishwa, kanye nezinga elifiswayo lokusebenza kahle kokuhlunga.

Izici Eziyinhloko Zokuhlunga Kwegesi Yensimbi Yensimbi

Isihlungi segesi yensimbi ye-Sintered siwuhlobo lobuchwepheshe bokuhlunga igesi obusebenzisa izinto zensimbi ezine-sintered ukuhlunga amagesi.Ezinye zezici eziyinhloko zokuhlunga igesi yensimbi ene-sintered zifaka okulandelayo:

1. Ukusebenza kahle kokuhlunga okuphezulu:Izihlungi zensimbi ezine-sintered zisebenza kahle kakhulu, okusho ukuthi zingakwazi ukususa ukungcola kumagesi.

2. Ukuqina:Izihlungi zensimbi ezenziwe nge-sintered zenziwe ngensimbi, okuzenza ziqine kakhulu kunezinye izihlungi.Ziyakwazi ukumelana namazinga okushisa aphezulu nezingcindezi futhi zimelana nokugqwala.

3. Ukuhlukahluka:Izihlungi zensimbi ezine-sintered zingasetshenziswa ezinhlelweni ezahlukene, okuhlanganisa ukuhlungwa komoya, igesi, noketshezi.

4.Ukwenza ngokwezifiso:Izihlungi zensimbi ze-sintered zingenziwa ngezifiso ukuze zihlangabezane nezidingo ezithile zezinhlelo zokusebenza ezahlukene.Isibonelo, zingenziwa ngobukhulu obuhlukahlukene kanye nokwakheka ukuze zilingane nemishini ehlukene.

5. Ukumelana namakhemikhali: Izihlungi zensimbi ezi-sintered zimelana nezinhlobonhlobo zamakhemikhali, okwenza zifanelekele ukusetshenziswa ezindaweni ezinokhahlo.

6. Ukubekezelela izinga lokushisa eliphezulu: Izihlungi zensimbi ezi-sintered zingasebenza emazingeni okushisa aphezulu, zizenze zifaneleke izicelo zokushisa okuphezulu.

7. Ukwehla komfutho ophansi: Izihlungi zensimbi ezine-sintered zinengcindezi ephansi, okusho ukuthi azimelani kakhulu nokugeleza kwegesi kuzo.Lokhu kubenza bonge ugesi futhi kungasiza ekunciphiseni izindleko zokusebenza.

8. Impilo ende: Izihlungi zensimbi ezihlanganisiwe zinesikhathi eside futhi azidingi ukushintshwa kaningi njengezinye izihlungi.Lokhu kungasiza ukunciphisa izindleko zokunakekela kanye nesikhathi sokuphumula.

Ukusetshenziswa Okuyinhloko Kwesihlungi Segesi

Isihlungi segesi sisetshenziswa ezinhlelweni ezahlukahlukene ukususa ukungcola kumagesi.Ezinye zezinhlelo zokusebenza eziyinhloko zokuhlunga igesi zifaka:

1. Izinqubo zezimboni:Ukuhlunga kwegesi kuvame ukusetshenziselwa ukususa ukungcola okufana nezinhlayiya, umswakama, namakhemikhali kumagesi acutshungulwayo.

2.Ukuhlanzwa komoya: Ukuhlunga kwegesi kusetshenziswa ezinhlelweni zokuhlanza umoya ukuze kususwe ukungcola okunjengothuli, izinto ezingezwani nomzimba, nomhwamuko wamakhemikhali.

3. Imishini yezokwelapha: Ukuhlunga kwegesi kusetshenziswa emishinini yezokwelapha njengama-ventilators kanye nemishini ye-anesthesia ukuze kukhishwe ukungcola kumagesi okuphefumula.

4. Ukucubungula ukudla nesiphuzo: Ukuhlunga kwegesi kusetshenziswa ekucubunguleni ukudla nesiphuzo ukuze kukhishwe ukungcola kumagesi asetshenziswa ekukhiqizeni nasekupakisheni ukudla neziphuzo.

5. Ukuvikelwa kwemvelo: Ukuhlunga kwegesi kusetshenziswa ezinhlelweni zokuvikela imvelo ukususa ukungcola kumagesi akhishwa izinqubo zezimboni noma izimoto.

6. Ukukhiqizwa kwamandla: Ukuhlunga kwegesi kusetshenziswa ekukhiqizeni amandla, njengasekucutshungulweni kwegesi yemvelo nasekuphehleni amandla, ukususa ukungcola kumagesi asetshenziswa njengophethiloli.

7. Imishini yaselabhorethri: Ukuhlunga kwegesi kusetshenziswa emishinini yaselabhorethri ukususa ukungcola emagesi asetshenziswa ocwaningweni lwesayensi nasekuhloleni.

8. I-Aerospace:Ukuhlunga kwegesi kusetshenziswa embonini ye-aerospace ukususa ukungcola emagesini asetshenziswa ekuqhutshweni kwezindiza kanye nezinhlelo zokusekela ukuphila.

Hlobo Luni Lwegesi Okudingeka Ulwenze Ukuhlunga Kwegesi?

Ukuhlunga igesi kuyinqubo esemqoka ezimbonini eziningi nasekufakeni izicelo.Izinhlobo ezahlukene zamagesi zidinga izindlela zokuhlunga ezihlukile, kuye ngezici zawo ezithile kanye nesicelo esiseduze.Nazi ezinye izinhlobo ezivamile zamagesi ezivame ukudinga ukuhlungwa:

1. Izihlungi Zomoya Zemvelo :Ukuhlunga komoya kungenye yezinqubo ezivame kakhulu nezidingekayo, ikakhulukazi ezindaweni lapho izinga lomoya lingaba nomthelela omkhulu empilweni yomuntu noma ikhwalithi yomkhiqizo.Ngokwesibonelo, lapho kwakhiwa amagumbi ahlanzekile, izibhedlela, noma amasistimu e-HVAC, izihlungi zomoya zisetshenziselwa ukususa izinto ezingcolisa umzimba, izinto ezingezwani nomzimba, nezinto ezingcolisa amagciwane.

2. Izihlungi Zenjini Yegesi:Ukuhlunga kwegesi yemvelo kubalulekile embonini kawoyela negesi.Le nqubo isiza ekususeni ukungcola nokungcola njengothuli, ukungcola, uwoyela, amanzi, nama-condensate okungaholela ekugqwaleni nasekulimaleni kwezinto zokusebenza namapayipi.

3. Isihlungi seHydrojeni:Ukuhlunga kwe-hydrogen kuvame ukudingeka kumaseli kaphethiloli nasezitshalweni zokukhiqiza i-hydrogen.Inqubo yokuhlunga isusa ukungcola okufana ne-carbon monoxide, carbon dioxide, ne-methane okungase kuthinte ukusebenza kwamaseli kaphethiloli noma ukuhlanzeka kwe-hydrogen ekhiqiziwe.

4. Izihlungi Zomoya-mpilo:Ezilungiselelweni zezokwelapha nezimboni, ukuhlunga kwe-oxygen kuyadingeka ukuze kukhishwe ukungcola okungahle kubeke engozini ukuphepha kwesiguli noma izinqubo zezimboni.Ukuhlunga kwegesi komoyampilo kuqinisekisa ukuthi iphephile futhi iyasebenza ezinhlelweni ezifana nempahla ye-oxygen yezokwelapha, ukusika insimbi, noma ukushisela.

5. Isihlungi seNitrojeni:Ezimbonini ezifana nokupakishwa kokudla, i-electronics, kanye nemithi, igesi ye-nitrogen ivamise ukuhlungwa ukuze kuqinisekiswe ubumsulwa nokuvimbela ukungcoliswa kwemikhiqizo.Ngokwesibonelo, emaphaketheni okudla, i-nitrogen ehlungiwe ingasiza ekulondolozeni ukusha ngokukhipha umoya-mpilo ongaholela ekoneni kokudla.

6. I-Sulfur Hexafluoride (SF6):I-SF6 iyigesi enamandla yokuvikela imvelo esetshenziswa ezintweni zikagesi njengama-breaker circuit kanye nama-switchgear.Ukuhlunga le gesi kubalulekile ngesikhathi sokululama kwayo futhi iphinde isetshenziswe ukuze kukhishwe ukungcola okungase kube nomthelela ezintweni zayo ezivikelayo noma kulimaze okokusebenza.

7. Isihlungi se-Carbon Dioxide (CO2) :Ezimbonini ezinjengokwenza utshwala nesiphuzo, ukuhlunga kwe-carbon dioxide kubalulekile ukuze kuqinisekiswe ukuhlanzeka kwe-CO2 esetshenziselwa izinqubo ze-carbonation.I-CO2 engcolile ingathinta ukunambitheka kanye nekhwalithi yomkhiqizo wokugcina.

8. Izihlungi ze-Helium:Kuzinhlelo zokusebenza ezifana nemishini ye-MRI, i-helium iyahlungwa ukuze kuqinisekiswe ukuhlanzeka kwayo nokusebenza kahle kwemishini.Ukungcola kwe-helium kungabangela ukungasebenzi kahle kokupholisa futhi kungase kulimaze okokusebenza.

Imibuzo Evame Ukubuzwa Yesihlungi Segesi

1. Siyini Isihlungi Segesi, futhi Kungani Sibalulekile?

Ukuhlunga kwegesi kusho inqubo yokukhipha ukungcola emfudlaneni wegesi.Ezinye izizathu zihlanganisa ukuthuthukisa izinga legesi, ukuvikela izinto zokusebenza emonakalweni obangelwa ukungcola, nokuqinisekisa ukuphepha kwabasebenzi.Ukuhlunga igesi kuyinqubo ebalulekile ezimbonini eziningi, okuhlanganisa ukucutshungulwa kwamakhemikhali, ukukhiqizwa kwemithi, ukukhiqizwa kukawoyela negesi, kanye nokuphehla ugesi.

2. Sisebenza kanjani isihlungi segesi yensimbi ye-sintered?

Izihlungi zegesi yensimbi ene-sintered zisebenza ezimisweni zokuhlunga ukujula nokuhlunga kwendawo.Akhiwe ngokucindezela izimpushana zensimbi zibe sesimweni esichaziwe bese zishisisa into ehlanganisiwe (ngaphandle kokufinyelela endaweni yokuncibilika) ukuze zenze izakhiwo eziqinile nezimbotshana.

Nansi incazelo eyenziwe lula yokuthi izihlungi zegesi yensimbi ene-sintered zisebenza kanjani:

-

I-Inlet:Igesi engahlungiwe yethulwa kusihlungi sensimbi esine-sintered.Le gesi ingaqukatha ukungcola okuhlukahlukene njengothuli, izinhlayiya, noma okunye ukungcola kuye ngomthombo wegesi nokusetshenziswa kwawo.

-

Inqubo yokuhlunga:Njengoba igesi idlula esisefweni sensimbi esinezimbotshana esinezimbotshana, ukungcola kuvaleleka phakathi kwenethiwekhi eyinkimbinkimbi yezimbotshana.Ukuhlunga kungenziwa ngezindlela ezimbili:

-

Ukuhlunga Ukujula:Kule nqubo, ukungcola kuyabanjwa futhi kugcinwe kukho konke ukujula kwemidiya yesihlungi.Ilungele ukususa izinhlayiya ezincane futhi inikeza umthamo ophezulu wokubamba ukungcola.

-

Ukuhlunga Okungaphezulu:Kule nqubo, ukungcola kubanjwe ebusweni besihlungi.Isebenza kahle kakhulu ezinhlayiyeni ezinkulu futhi izivimbela ukuthi zingadluli esihlungini.

-

-

I-Outlet:Igesi ehlanziwe, engenakho ukungcola, bese iphuma kusihlungi futhi iqhubekele ekusebenzeni kwayo okuhlosiwe, noma ngabe leyo inqubo yokukhiqiza, idivayisi ethile, noma isistimu yezimboni.

Izihlungi zensimbi ezi-sintered zaziwa ikakhulukazi ngokuhlala kwazo isikhathi eside, amandla aphezulu okusebenza, kanye nokumelana nezinga lokushisa eliphezulu.Angahlanzwa futhi aphinde asetshenziswe izikhathi eziningi, okunomthelela ekongeni kwazo izindleko kanye nokusimama kwemvelo.Bayakwazi futhi ukuphatha ukuhluka kwengcindezi ephezulu, okubenza bafanelekele izinhlelo zokusebenza eziyinselele ezihlukahlukene.

Ingabe udinga isisombululo sokuhlunga esisebenza kahle kakhulu sohlelo lwakho lokusebenza oluthile?Xhumana nethimba lethu e-HENGKO kuka@hengko.com.Silungele ukukunikeza iseluleko sochwepheshe nezixazululo ezifanelana nawe ukuze sihlangabezane nezidingo zakho.

3. Yiziphi izinzuzo zokusebenzisa insimbi ene-sintered yesihlungi segesi?

Kunezinzuzo ezimbalwa zokusebenzisa insimbi ene-sintered ukuhlunga igesi:

1.) Amandla aphezulu nokuqina:Izihlungi zensimbi ezine-sintered ziqinile futhi zimelana nokulimala, zizenza zifanelekele izinhlelo zokusebenza ezinomfutho ophezulu kanye nezinga lokushisa eliphezulu.

2.)Indawo ephezulu:Isakhiwo esinezimbotshana sezihlungi zensimbi ezine-sintered sinikeza indawo enkulu engaphezulu ukuze ukungcola kubanjwe, okwandisa ukusebenza kahle kokuhlunga.

3.)Ukumelana namakhemikhali:Izihlungi zensimbi ezine-sintered zimelana namakhemikhali amaningi futhi zingasetshenziswa namagesi agqwalayo.

4.)Ukwenza ngokwezifiso:Izihlungi zensimbi ezine-sintered zingenziwa ngosayizi abahlukahlukene, umumo, nokucushwa ukuze kuhlangatshezwane nezidingo ezithile zokuhlunga.

5. Yiziphi izimboni ezivame ukusebenzisa i-sintered metal gas filtration?

I-Sintered metal gas filtration ivame ukusetshenziswa ezimbonini ezihlukahlukene, okuhlanganisa ukucubungula amakhemikhali, ukukhiqizwa kwemithi, ukukhiqizwa kukawoyela negesi, ukukhiqiza amandla, nokuhlanzwa komoya.Kulezi zimboni, izihlungi zensimbi ezine-sintered zisetshenziselwa ukususa ukungcola emifuleni yegesi ukuvikela izinto zokusebenza, ukuthuthukisa ikhwalithi yomkhiqizo, nokuqinisekisa ukuphepha kwabasebenzi.

6. Usayizi nokuma kwesihlungi sensimbi esine-sintered kuthinta kanjani ukusebenza kwaso?

Usayizi nokuma kwesihlungi sensimbi esine-sintered kungathinta kakhulu ukusebenza kwaso.Isihlungi esikhulu sizoba nendawo enkulu futhi singakwazi ukuhlunga ukungcola okwengeziwe, kodwa singase sibe nokwehla kwengcindezi ephezulu, okungase kwehlise izinga lokugeleza kwegesi.Ngokufanayo, ukwakheka kwesihlungi nakho kungathinta ukusebenza kwaso.Isibonelo, isihlungi esinama-pleated singase sibe nendawo ephezulu futhi sisebenze kahle ekucupheni ukungcola, kodwa futhi singase sibe nokwehla kwengcindezi ephezulu kunesihlungi esingenasici.

7. Ingabe izihlungi zegesi yensimbi ene-sintered zingasetshenziswa namagesi abolayo noma abrasive?

Izihlungi zegesi yensimbi ene-sintered zingasetshenziswa namagesi abolayo noma abrasive.Izihlungi zensimbi ezine-sintered zimelana namakhemikhali amaningi futhi zingamelana namazinga okushisa aphezulu, zizenze zifanelekele izindawo ezinokhahlo.Nokho, kubalulekile ukukhetha isihlungi sensimbi esine-sintered esihambisana namagesi athile asetshenziswayo kanye nokugcina isihlungi ngendlela efanele ukuze kuqinisekiswe ukuphila kwaso isikhathi eside.

8. Uzigcina kanjani futhi uzihlanze kanjani izihlungi zegesi yensimbi ene-sintered?

Ukugcinwa kahle nokuhlanza izihlungi zegesi yensimbi e-sintered kubalulekile ukuqinisekisa ukusebenza kwazo nokuphila isikhathi eside.Nayi eminye imihlahlandlela ejwayelekile yokugcina izihlungi zensimbi ezine-sintered:

Landela izincomo zomkhiqizi zokulungisa nokuhlanza izihlungi.

Hlola izihlungi njalo ukuze uthole izimpawu zokulimala noma ukungcoliswa ngokweqile.

Sebenzisa umoya ocindezelwe ohlanzekile, owomile ukuze ufuthe.

9. Yiziphi izinhlobo ezahlukeneizihlungi zegesi yensimbi ene-sinterediyatholakala?

Kunezinhlobo ezimbalwa zezihlungi zegesi yensimbi ene-sintered etholakalayo, okuhlanganisa:

1. Izihlungi eziboshiwe:Lezi zihlungi zinendawo enkulu futhi zenziwe ngemibimbi noma ukugoqa kumidiya yokuhlunga.Zivame ukusetshenziswa ezinhlelweni zokugeleza okuphezulu futhi zingenziwa ngobukhulu obuhlukahlukene kanye nokwakheka.

2. Izihlungi zokujula:Lezi zihlungi zenziwe ngongqimba lwempushana yensimbi ene-sintered egqitshwayo noma esongwe ngesakhiwo sokusekela.Izinto ezingcolisayo zibambeke phakathi kokujula kwesihlungi kunaphezu komhlaba.

3. Izihlungi zesikrini:Lezi zihlungi zenziwe nge-mesh yezintambo zensimbi ezine-sintered noma imicu futhi zisetshenziselwa ukususa izinhlayiya ezinkulu emifudlaneni yegesi.

4. Izihlungi ze-Membrane:Lezi zihlungi zinongqimba oluncane lwensimbi ene-sintered esakhiweni sokusekela futhi zisetshenziselwa ukususa izinhlayiya ezincane emifudlaneni yegesi.

10. Usikhetha kanjani isihlungi segesi yensimbi esine-sintered esifanele sohlelo lwakho lokusebenza?

Kunezici ezimbalwa okufanele zicatshangelwe lapho ukhetha isihlungi segesi yensimbi ene-sintered, okuhlanganisa:

*Uhlobo lwegesi ehlungwayo:

Amagesi ahlukene angase adinge izihlungi ezihlukene noma imidiya yokuhlunga.

* Ukungcola kuyasuswa:

Usayizi nohlobo lokungcola kuzonquma usayizi wembotshana nendawo engaphezulu yesihlungi esidingekayo.

* Izinga lokugeleza kwegesi:

Isihlungi kufanele sisingathe izinga lokugeleza elidingekayo ngaphandle kokubangela ukwehla kwengcindezi ngokweqile.

* Izinga lokushisa lokusebenza nengcindezi:

Isihlungi kumele sikwazi ukumelana nezinga lokushisa lokusebenza nokucindezela kwesistimu.

* Ukuhambisana kwamakhemikhali kwesihlungi:

Isihlungi kufanele simelane namakhemikhali asemfudlaneni wegesi.

11. Yimiphi imikhawulo yokuhlunga igesi yensimbi ye-sintered?

Eminye yemikhawulo yokuhlunga igesi yensimbi ene-sintered ihlanganisa okulandelayo:

1. Ukwehla kwengcindezi ephezulu:Izihlungi zensimbi ezine-sintered zingaba nokwehla komfutho ophezulu, okwehlisa izinga lokugeleza kwegesi.

2. Ukususwa okulinganiselwe kwezinhlayiya ezincane:Izihlungi zensimbi ezine-sintered kungenzeka zingasusi ngempumelelo izinhlayiya ezincane, njengalezo ezincane kunezimbotshana ezisesihlungini.

3. Ukuhambisana kwamakhemikhali okunomkhawulo:Nakuba izihlungi zensimbi ezine-sintered zimelana namakhemikhali amaningi, zingase zingawafanele wonke amagesi.

12. I-sintered metal gas filtration iqhathaniswa kanjani nezinye izinhlobo zokuhlunga kwegesi?

I-Sintered metal gas filtration inezinzuzo ezimbalwa ngaphezu kwezinye izinhlobo zokuhlunga kwegesi, okuhlanganisa:

1. Amandla aphezulu nokuqina:Izihlungi zensimbi ezine-sintered ziqinile futhi zimelana nokulimala, zizenza zifanelekele izinhlelo zokusebenza ezinomfutho ophezulu kanye nezinga lokushisa eliphezulu.

2. Indawo ephezulu:Isakhiwo esinezimbotshana sezihlungi zensimbi ezine-sintered sinikeza indawo enkulu engaphezulu ukuze ukungcola kubanjwe, okwandisa ukusebenza kahle kokuhlunga.

3.Ukwenza ngokwezifiso:Izihlungi zensimbi ezine-sintered zingenziwa ngosayizi abahlukahlukene, umumo, nokucushwa ukuze kuhlangatshezwane nezidingo ezithile zokuhlunga.

Kodwa-ke, ukuhlunga kwegesi yensimbi ye-sintered kungase kungabi yisinqumo esingcono kakhulu.Isibonelo, ezinye izihlungi, njengezihlungi ze-carbon activated, zingasebenza kangcono ekususeni ukungcola okuthile noma zifaneleke kakhulu ukusetshenziswa namagesi athile.

13. Ingabe kukhona ukucatshangelwa kokuphepha okufanele ukuqaphele lapho usebenzisa izihlungi zegesi yensimbi ene-sintered?

Yebo, kunezinto ezimbalwa ezicatshangelwayo zokuphepha okufanele uziqaphele lapho usebenzisa izihlungi zegesi yensimbi ene-sintered:

Landela imiyalelo yomkhiqizi yokuphatha nokufaka izihlungi.

Qaphela lapho uphatha izihlungi, njengoba zingaba bukhali noma zibe nemiphetho emagebhugebhu.

Lapho uphatha izihlungi, gqoka izinto zokuzivikela, njengamagilavu nezibuko zokuphepha.

Vikela kahle izihlungi ukuze uvimbele ukuthi zingaxegi noma zikhishwe ngesikhathi sokusetshenziswa.

Hlola izihlungi njalo ukuze uthole izimpawu zokulimala noma ukungcoliswa ngokweqile bese uzishintsha njengoba kudingeka.

Landela izinqubo ezifanele zokuhlanza nokugcina izihlungi ukuze uqinisekise ukusebenza kwazo nokuphila isikhathi eside.

Qaphela ukuhambisana kwamakhemikhali kwezihlungi futhi uzisebenzise kuphela ngamagesi eziklanyelwe ukuwaphatha.

Ngethemba ukuthi lolu lwazi luwusizo!Ngazise uma uneminye imibuzo eyengeziwe.

Are you interested in our sintered metal gas filters and have questions about our products? We'd love to help! Email us at ka@hengko.com, and we'll assist you. Our team of experts is here to answer any questions and help you find the right solution for your gas filtration needs. Don't hesitate to reach out – we look forward to hearing from you!

Ukuze uthole Imikhiqizo Eminye Yezihlungi Zegesi, Ungaphinda Uhlole Njenge Landela Ividiyo.

Izihlungi Zensimbi Ezihlanganisiwe Zingakusiza Ukuhlunga Igesi Eningi Kangcono, Mhlawumbe Ungabheka Imininingwane bese U-oda Amanye Amasampula Okuhlola,

Any more questions for the Gas Filtration and Custom Service, Please feel free to contact us by email ka@hengko.com or send

isicelo ngendlela elandelayo.Siyabonga!