I-Porous Metal Meaning

Iyini i-Porous Metal

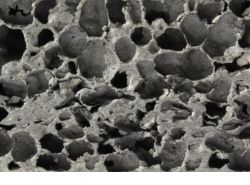

Kafushane, Izinsimbi eziyizimbotshana ziyizinto ezinohleloxhumano oluxhumene lwezinhlangothi ezintathu lwezimbotshana, noma i-voids, kusakhiwo sazo esincane esivumela uketshezi noma amagesi ukuthi ageleze kumpahla.

Lezi zimbotshana zihluka ngosayizi ukusuka kuma-nanometers kuye kumamilimitha futhi zivame ukwakhiwa ngezinqubo ezifana nokucwilisa, ukugwebulwa noma i-electroplating.Izinsimbi ezinama-Porous zinezakhiwo ezihlukile ezizenza zibe usizo ezinhlelweni ezihlukahlukene, kuhlanganise nokuhlunga, i-catalysis, ukugcinwa kwamandla, kanye nobunjiniyela be-biomedical.

I-porosity yalezi zinsimbi ingalawulwa futhi ihambisane nezidingo ezithile, njengeusayizi we-pore, umthamo we-pore, futhiindawo engaphezulu.Lokhu tunability kuvumela ukuthunga izinsimbi ezimbotshana ukuze kuhlangatshezwane nezidingo zokusebenza ezahlukene.Ngaphezu kwalokho, ukwakheka kwezimbotshana ezixhumene ezimbotsheni zezinsimbi ezimbotshana zivumela ukungena okuphezulu nokwehla kwengcindezi ephansi, okusiza ukugeleza koketshezi kanye nezinqubo zokudlulisa izinqwaba.

Namuhla,Izinsimbi ezinezimbotshanangokuvamile zenziwa ngezinsimbi ezivamile zobunjiniyela njenge-aluminium, i-titanium, i-nickel nethusi, kodwa futhi zingenziwa ngezinto ezingajwayelekile kangako njenge-magnesium noma i-zinc.Izakhiwo zezinsimbi ezinama-porous zincike ohlotsheni lwensimbi esetshenziswayo, inqubo yokukhiqiza, nobukhulu nokusabalalisa kwezimbotshana.Izinsimbi ezinama-porous zingenziwa ngezindlela ezihlukahlukene ezifana namashidi, amashubhu, amagwebu nezimpushana, okwenza kube izinto eziguquguqukayo zokusetshenziswa okuhlukahlukene.

Njengoba okulandelayo kudumileuhlu lwezinsimbi ezinama-porousUmdwebo wesakhiwo emakethe, ngethemba ukuthi uzokwenza wazi ngensimbi enezimbotshana.

Isixazululo Esimelana Nokugqwala Sokuhlunga Okuthuthukile Nezicelo Zokusabalalisa Igesi

I-Aluminiyamu enezimbotshana

I-Lightweight futhi Iguquguqukayo Yokudlulisa Ukushisa Okuthuthukisiwe kanye Nokunciphisa I-Acoustic

I-Porous Nickel

Amandla Aphezulu, Ukumelana Nokushisa Okuphezulu, Kulungele I-Catalysis Ethuthukisiwe kanye Nezicelo Zebhethri.

Isixazululo Esingabizi kakhulu se-Precision Sintering kanye ne-Porosity elawulwayo kuma-Bearings nezihlungi.

Izici Eziyinhloko Nenzuzo

I-Porosity:

Njengoba igama liphakamisa, izinsimbi ezinama-porous zibonakala ngenethiwekhi yazo yezimbotshana ezixhumene.I-Porosity ingahluka kuye ngenqubo yokukhiqiza futhi isukela kumaphesenti ambalwa ukuya ngaphezulu kwama-90%.

Indawo engaphezulu:

Izinsimbi ezinama-porous zinezinga eliphezulu lesilinganiso somthamo ngenxa yesakhiwo sazo esinezimbotshana.Le ndawo eyengeziwe engaphezulu ingasetshenziswa ezinhlelweni ezifana ne-catalysis, filtration kanye nokugcinwa kwamandla.

Izakhiwo zemishini:

Izinsimbi ezinama-Porous zibonisa ububanzi bezakhiwo zemishini, kuye ngokuthi impahla kanye ne-porosity.Izakhiwo zemishini yezinsimbi zingalungiswa ngokulungisa usayizi wembotshana, umumo nokusabalalisa.

I-Biocompatibility:

Izinsimbi ezithile ezinama-porous, njenge-titanium nama-alloys ayo, ziyahambelana ne-biocompatible futhi zingasetshenziswa ezinhlelweni ze-biomedical ezifana nezimila.

Ukugeleza kwamanzi:

Izimbotshana ezixhumene ezinsimbini ezimbotshana zivumela ukugeleza koketshezi, okuzenza zibe usizo ezinhlelweni ezinjengokuhlunga nokuhlukanisa.

I-Thermal kanye ne-electrical conductivity:

I-thermal kanye ne-electrical conductivity yezinsimbi ezinama-porous zingalungiswa ngokushintshashintsha i-porosity nensimbi esetshenziswa enkambisweni yokwenziwa.

Izihlungi Ezisebenza Kakhulu Ezinosayizi Bembobo Abalawulwa kanye Nezilinganiso Zokugeleza Ezilungile Zezicelo Zegesi Noketshezi.

Izingxenye Eziqinile Nezikwazi Ukugqokwa Zama-Bearings kanye Nezinhlelo Ze-Hydraulic Ezinezici Zokugcobisa Ezithuthukisiwe.

Izixazululo Ezihlanganisiwe Zokushisa Okuthuthukisiwe Nokudluliselwa Okuningi Ezinqubweni Zamakhemikhali Neze-Petrochemical ezinobuqotho obuphezulu besakhiwo.

Isixazululo Esingcono Kakhulu Sokuklama Nobunjiniyela Bokuphezulu Kudinga Inkinga Yokuhlunga

Ngaphezulu kokuqonda kokuqala, Siyazi i-Sintered metal porous inganikeza okuhlukahlukeneukugeleza okwenziwe ngokwezifiso kanye nezakhiwo zokuhlunga.Futhi Le nto eyingqayizivele ikhiqizwa nge-sintering, okubandakanya ukushisisa impushana yensimbi ezingeni lokushisa elingaphansi nje kwephuzu layo lokuncibilika, okuvumela izinhlayiya ukuthi zihlangane ngenkathi kugcinwa i-porosity oyifunayo.Ungakwazi ukuyilolonga kalula, uyifake ngomshini, futhi ulawule ukuqina kwayo, ukwenze ibe yinto eguquguqukayo yokwakha noma iyiphi inombolo yemikhiqizo ehlukile noma izixazululo zesistimu ezibandakanya ukulawula nokulawula uketshezi namagesi.

Ake sithi Futhi Ufuna Ezinye Izinto Ezikhethekile Zohlelo Lwakho Lokuhlunga.Uma kunjalo, Sikumema ukuthiXhumana nathinamuhla ukuhlola ukuthi izixazululo zethu zemidiya yensimbi enezimbobo zingakusiza kanjani ekuxazululeni izinselele zakho zobunjiniyela bokuklama.Masihlanganyele futhi sikhombe izixazululo ezifanelana nezidingo zakho ezihlukile.

Isicelo esijwayelekile se-Porous Metal

Izihlungi zensimbi ezinama-porous zisetshenziswa ezinhlobonhlobo zezinhlelo zokusebenza ngenxa yezakhiwo zazo ezikhethekile,

kufaka phakathi ukungena okuphezulu, i-porosity elawulwayo, namandla omshini.Ngezansi ezinye izinhlelo zokusebenza ezijwayelekile:

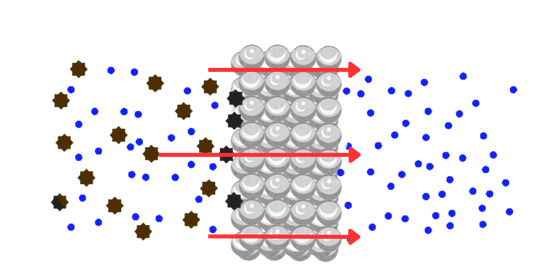

1. Ukuhlunga nokuhlukaniswa:

Izihlungi zensimbi ezinama-porous zisetshenziswa kakhulu ezinhlelweni zokuhlunga zezimboni, lapho zisiza ukuhlukanisa okuqinile noketshezi noma amagesi.

Ziwusizo ikakhulukazi ezimbonini ezifana ne-petrochemical, ukucubungula amakhemikhali, kanye nowoyela negesi ngenxa yokumelana kwazo nezinga lokushisa eliphezulu nezinto ezigqwalisayo.

2. Ukusabalalisa kanye Nokusabalalisa:

Lapho i-sparging, insimbi enezimbotshana isetshenziselwa ukusakaza igesi oketshezini, ngokuvamile ukuze ikhiphe umoya oketshezini.

Lokhu kuvame ukusetshenziselwa ukwelashwa kwamanzi angcolile, ukukhiqizwa kwemithi, kanye nezinqubo zokudla neziphuzo.

3. Ukulawulwa Kwengcindezi:

Izingxenye zensimbi ezinama-porous zingasetshenziswa kumadivayisi okulawula ingcindezi njengama-valve okunciphisa ingcindezi noma iziphefumula ezimbonini ezihlukahlukene ezihlanganisa izimoto, i-aerospace, nemishini yezimboni.

4. Izinzwa:

Izinsimbi ezinezimbotshana zingasetshenziswa ezinhlotsheni ezithile zezinzwa ngenxa yekhono lazo lokuvumela amagesi noketshezi ukuba kudlule.

Lokhu kungatholakala ekuqaphelweni kwemvelo, ekucutshungulweni kwezimboni, nasezicelweni zokunakekelwa kwezempilo.

5. Ukunciphisa Umsindo:

Izinsimbi ezinama-Porous zivame ukusetshenziselwa ukunciphisa umsindo noma ukunciphisa umsindo ezimbonini ezihlukahlukene, kusukela kumasistimu wokukhipha umoya wezimoto kuya emishini yezimboni.

6. Izishintshi Zokushisa:

Izinsimbi ezinama-porous zinikeza ukuguquguquka okuhle kwe-thermal nezici zokudlulisa ukushisa, okuzenza zibe zinhle kakhulu ezinhlelweni zokushintshanisa ukushisa, ikakhulukazi ezimbonini ezisebenza ngokushisa okuphezulu.

7. I-Catalyst Isekela:

Ezinqubweni zamakhemikhali, insimbi enezimbotshana ingasetshenziswa njengendlela yokusekela i-catalyst, okuvumela indawo engaphezulu ukuze ukusabela kwenzeke.Lokhu kuvame ukubonakala embonini ye-petrochemical.

8. Ama-Electrode Ebhethri:

Izinsimbi ezinama-porous zingasetshenziswa ekukhiqizeni ama-electrode ebhethri.I-porosity ivumela indawo engaphezulu, ithuthukisa ukusebenza kahle kwebhethri.

9. Izinhlelo zokusebenza zeBiomedical:

Izinsimbi ezinezimbotshana, ikakhulukazi i-titanium enezimbotshana nama-alloys ayo, zithole ukusetshenziswa okubanzi emkhakheni wezokwelapha, njengokufakwa kwamathambo nokufakwa kwamazinyo.Imvelo yabo enezimbotshana ikhuthaza ukungena kwamathambo, okuholela ekuhlanganisweni okungcono nomzimba.

10. Fuel Cells:

Izingxenye zensimbi ezinezimbotshana zingasebenza njengama-electrode kumaseli kaphethiloli, okuvumela amagesi ukuba adlule kalula lapho kuqhutshwa ugesi.

Sicela uqaphele ukuthi imininingwane yokusetshenziswa kwensimbi enezimbotshana noma izihlungi kuncike ohlotsheni lwensimbi enezimbotshana noma ingxubevange kanye nemvelo eqondile ye-porosity (usayizi, ukusatshalaliswa, nokuxhuma kwezimbotshana).

ngakho-ke uma unemibuzo mayelana nokusetshenziswa kwesihlungi sensimbi esinezimbotshana esinezimbotshana, sicela ukhululekexhumana noHENGKOnge-imeyilika@hengko.com.

FAQ Mayelana Nezimbotshana Zensimbi

1. Kungani usebenzise insimbi enezimbotshana ukwenza isisefo?

Insimbi enezimbotshana iyimpahla enesakhiwo esiyingqayizivele esiqukethe ama-pores axhumene noma ama-voids ngaphakathi kohlaka lwawo oluqinile.Usayizi wembotshana nokusatshalaliswa kungenziwa ngendlela efanele ukuze kuhlangatshezwane nezidingo ezithile zohlelo lokusebenza, kuyenze ibe yinto eguquguqukayo yohlu lwezimboni.

Ngakho njengalowo msebenzi okhethekile, izinsimbi ezinama-Porous zivame ukusetshenziswa ekwenzeni izihlungi ngenxa yezizathu ezimbalwa:

1. Usayizi Wembotshana Olawulwayo:Izinsimbi ezinezimbotshana zingakhiwa ukuze zibe nosayizi wembotshana onembe kakhulu.Lokhu kuvumela ukudalwa kwezihlungi ezinekhono elithile lokuhlunga, njengokukhipha izinhlayiya zosayizi othile.

2. Amandla Aphezulu:Izihlungi zensimbi zinamandla amakhulu okusebenza, okuzenza ziqine futhi ziqine.Angakwazi ukumelana nokucindezela okuphezulu nezimo zokushisa ezingase zilimaze ezinye izinhlobo zezihlungi.

3. Ukumelana Namakhemikhali:Izinsimbi zivame ukumelana namakhemikhali ahlukahlukene, okuwenza afanelekele ukusetshenziswa ezindaweni lapho zingachayeka khona ezinto ezonakalisayo.

4. Ukusebenziseka kabusha:Izihlungi zensimbi zingahlanzwa futhi ziphinde zisetshenziswe, okuyinto kokubili engabizi futhi evumelana nemvelo.

5. Ukuzinza Kokushisa:Izihlungi ze-metallic zingakwazi ukuqhubeka nokusebenza kwezinga lokushisa eliphezulu, okungenzeka kungabi njalo ngezihlungi ezenziwe ngezinto ze-polymer.

6. Ukuvumeleka:Ngenxa yemvelo yazo enezimbotshana, lezi zinto zivumela izinga eliphezulu lokugeleza koketshezi ngenkathi zibamba futhi zigcina izinhlayiya ngendlela efanele.

7. Amandla okugeza ngemuva:Izihlungi zensimbi zingawashwa ngemuva ukuze kukhishwe izinhlayiya eziboshiwe, okuvumela ukutholwa kwezinto ezibalulekile futhi kwandise isikhathi sokuphila sesihlungi.

Ngakho-ke, kuye ngohlelo lokusebenza kanye nohlobo loketshezi oludinga ukuhlungwa, izihlungi zensimbi ezinama-porous zingaba ukukhetha okuhle kakhulu.

2. Yenziwa kanjani insimbi enezimbotshana?

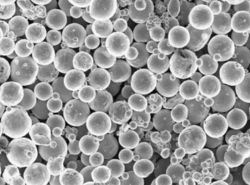

Insimbi enezimbotshana ivamise ukukhiqizwa ngenqubo ebizwa ngokuthi i-sintering, ehlanganisa ukushisisa impushana yensimbi ezingeni lokushisa elingaphansi nje kwendawo yokuncibilika, okuvumela izinhlayiya ukuthi zihlangane ndawonye kuyilapho kugcinwa i-porosity oyifunayo.

Inqubo yokwenza izinsimbi ezinama-porous ihilela ukudala ama-voids noma ama-pores ngaphakathi kwensimbi.Kunezindlela eziningana ezisetshenziselwa ukufeza lokhu, okuhlanganisa i-powder metallurgy, i-sintering, kanye nokukhiqiza okungeziwe.Ngezansi incazelo eyenziwe lula yendlela evamile, i-powder metallurgy:

1. Ukukhiqizwa Kwe-Metal Powder:Isinyathelo sokuqala sokudala insimbi enezimbotshana ukukhiqiza impushana yensimbi.Lokhu kungenziwa ngezindlela eziningana, okuhlanganisa i-atomization (ukufafaza umfudlana wensimbi encibilikisiwe egumbini lapho iqina ibe yimpushana) noma ukugaya ngemishini.

2. Ukuxuba kanye Nokuhlanganisa:Impushana yensimbi ixubene ne-ejenti ebophayo noma into yesibambi sesikhala ukusiza ukugcina isakhiwo ngesikhathi sokucubungula.Ingxube ibe isihlanganiswa ngaphansi kwengcindezi ephezulu ku-die ukuze yakhe i-compact "green".Ukuma kwe-die kuzonquma ukuma kokugcina kwengxenye yensimbi enezimbotshana.

3. Ukucula:Ucwecwe oluluhlaza lube selushiswa esithandweni lube ngaphansi kwezinga lokushisa elingaphansi kwendawo yokuncibilika kwensimbi.Le nqubo, eyaziwa ngokuthi i-sintering, ibangela ukuthi izinhlayiya zensimbi zihlangane ndawonye.Izinga lokushisa eliphezulu liphinde libangele ukuthi i-binder noma into yesibambi-mkhathi ishise noma ihwamuke, ishiye izimbotshana.

4. Ukupholisa nokuqeda:Ngemuva kokucwiliswa, ingxenye yensimbi ivunyelwe ukupholisa, khona-ke ingase ibhekane nezinqubo ezengeziwe njengokuqeda noma ukuhlanganisa ukuze kuthuthukiswe izici zayo ezingaphezulu.

Enye indlela ukusebenzisa ukukhiqiza okungeziwe (okuvame ukwaziwa ngokuthi ukuphrinta kwe-3D), lapho impushana yensimbi ikhethwa ngokukhetha ungqimba ngongqimba olusekelwe kumodeli yedijithali.Lokhu kungakha ubujamo obuyinkimbinkimbi kanye nezakhiwo zangaphakathi ze-pore ezingaba nzima noma ezingenakwenzeka ukufeza ngezindlela zendabuko.

Ubukhulu bembotshana, ukusatshalaliswa, kanye nokuxhumana kungalawulwa kakhulu phakathi nenqubo yokukhiqiza, okwenza izinsimbi ezinezimbotshana zilungele uhla olubanzi lwezinhlelo zokusebenza, okuhlanganisa ukuhlunga.

3. Yiziphi izinzuzo zezinsimbi ezinama-porous?

Izinzuzo zezinsimbi ezinama-porous zihlanganisa isilinganiso esiphezulu sendawo-to-volume, amandla emishini, ukuqhutshwa kwe-thermal kanye nogesi, kanye nekhono lokuthunga usayizi wembotshana nokusatshalaliswa.Lezi zakhiwo zikwenza kube usizo ezinhlelweni ezifana ne-catalysis, ukuhlunga, nokugcinwa kwamandla.

4. Iyini imikhawulo yezinsimbi ezinama-porous?

Izinsimbi ezinezimbotshana zingase zibe namandla aphansi wenqwaba uma ziqhathaniswa nezinsimbi ezingenazo izimbotshana ngenxa yobukhona bezikhala ngaphakathi kwento.Ukwengeza, inqubo yokukhiqiza ingaba yinkimbinkimbi futhi ibize.

5. Uyini umehluko phakathi kwe-open-cell kanye ne-closed-cell-porous metals?

Ama-open-cell porous metals anezimbotshana ezixhumene ezifinyeleleka kusukela phezulu kwento, kuyilapho izinsimbi ezimbotshana zamaseli avaliwe zinezimbotshana ezivalekile ezingafinyeleleki ukusuka phezulu.

6. Yiziphi izinhlobo zezinsimbi ezingasetshenziswa ukwenza izinsimbi ezinezimbotshana?

Izinsimbi ezinama-porous zingenziwa kusuka kuhlu lwezinsimbi, kufaka phakathi i-aluminium, i-titanium, i-nickel, ithusi, nensimbi engagqwali, phakathi kokunye.

7. Yiziphi ukusetshenziswa kwezinsimbi ezinama-porous?

Izinsimbi ezinama-porous zisebenza ezimbonini ezifana ne-aerospace, ubunjiniyela be-biomedical, ukucubungula amakhemikhali, nokugcinwa kwamandla, phakathi kokunye.

8. Yiziphi izinselele ezihambisana nokukhiqiza izinsimbi ezinama-porous?

Izinselelo ezihambisana nokukhiqiza izinsimbi ezinama-porous zihlanganisa ukugcina i-porosity oyifunayo, ukuqinisekisa izakhiwo ezinhle zemishini, nokulawula usayizi wembotshana nokusatshalaliswa.

9. Iyini i-porosity yezinsimbi ezinama-porous?

I-porosity yezinsimbi ezinama-porous ingaba kusuka kumaphesenti ambalwa kuya ku-90% noma ngaphezulu, kuye ngezidingo zohlelo lokusebenza.

10. Kuyini ukubaluleka kobukhulu bembotshana nokusatshalaliswa kwezinsimbi ezimbotshana?

Ubukhulu bembotshana nokusatshalaliswa kwezinsimbi ezimbotshana kubalulekile ekunqumeni izakhiwo zezinto ezibonakalayo, njengokungena kwamanzi, amandla okusebenza, kanye nendawo engaphezulu.Lokhu kungenxa yokuthi usayizi wezimbotshana uthinta indlela uketshezi olungageleza kalula ngayo ezintweni kanye nokuthi ingakanani indawo engaphezulu etholakalayo ukuze kuvele ukusabela.

11. Ingabe izinsimbi ezinama-porous zingenziwa ngezifiso izinhlelo ezithile?

Yebo, izinsimbi ezinama-porous zingenziwa ngezifiso izinhlelo zokusebenza ezithile ngokulungisa usayizi wembotshana nokusabalalisa, kanye nohlobo lwensimbi esetshenziswayo.

12. Ingakanani impilo yezinsimbi ezinama-porous?

Ukuphila kwezinsimbi ezimbotshana kuncike ekusetshenzisweni nasekusetshenzisweni okuthile.Ngokuvamile, izinsimbi ezinama-porous zihlala isikhathi eside ngenxa yokuqina kwazo okuphezulu nokumelana nokugqwala.

13. Ingabe izinsimbi ezinezimbotshana zingagaywa kabusha?

Yebo, izinsimbi ezinezimbotshana zingagaywa kabusha ngokuncibilikisa okokusebenza phansi futhi kuphinde kusetshenziswe ezinhlelweni ezintsha.

14. Ingabe izinsimbi ezinama-porous ziphephile ukusetshenziswa ekusetshenzisweni kwe-biomedical?

Izinhlobo ezithile zezinsimbi ezinezimbobo, ezifana ne-titanium ne-tantalum, ziyasebenzisana futhi zingasetshenziswa ngokuphepha ezinhlelweni ze-biomedical.Isakhiwo se-porous singakhuthaza ukukhula kwamathambo futhi sithuthukise ukuhlanganiswa nezicubu ezizungezile.

15. Izinsimbi ezinama-porous zingahlolwa kanjani izici zazo?

Izinsimbi ezinama-porous zingahlolelwa izakhiwo ezinjengokuqina, ukuvuthwa, namandla emishini kusetshenziswa amasu afana ne-scanning electron microscopy (SEM), ukuhlolwa kokungena kwegesi, nokuhlolwa kokucindezela.

Thola amathuba angapheli ezinsimbi ezinezimbotshana!Kusukela ekudluliselweni kokushisa okuthuthukisiwe kuya ekuhlungeni okuthuthukisiwe, izinsimbi ezimbotshana zinikeza izinzuzo ezihlukile ezingaguqula imboni yakho.Xhumana nathi namuhla ukuze ufunde kabanzi futhi uqale ukuhlola amandla ezinsimbi ezimbotshana.

Konke okudingayo ukuze uxhumane no-HENGKO uthole Isixazululo

Thumela umlayezo wakho kithi: