-

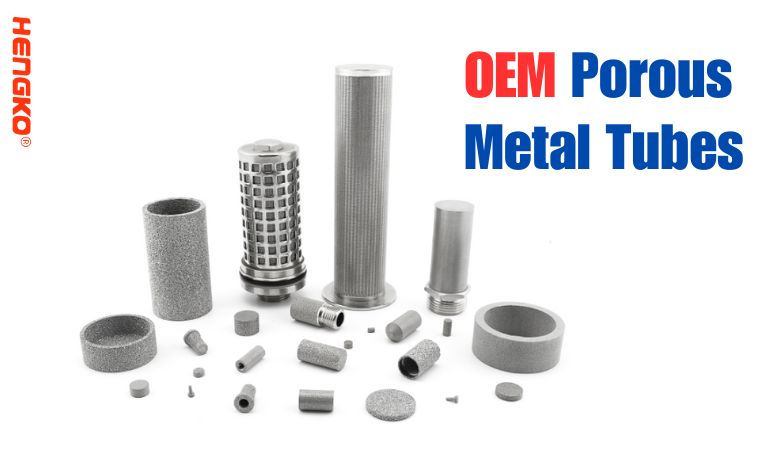

I-Stainless Steel Sintered Porous Metal Filter Tubes Porosity Down to 0.2 µm – Ku-F...

Usayizi wembotshana:0.2-100microns Izinto: SS Metal Porosity:30%~45% Ingcindezi Yokusebenza:3MPa Ithempelesha Yokusebenza:600℃ Izicelo zensimbi enezimbobo ezibomvana ...

Buka imininingwane -

Amathiphu Okushintsha Amabhamuza Amancane Ama-Sparger Okuvutshelwa / I-Bioreactor Air Aeration...

Izinzuzo ze-HENGKO Porous Metal Micro Spargers Ngenxa yokuncibilika okuphansi komoya-mpilo ezindaweni eziningi zesiko lamaseli, ukwenza kahle lokhu kudla okubalulekile kungaba ...

Buka imininingwane -

I-Stainless Steel Tubeless Tyre Valve Iqinile Futhi Ihlala Eqinile Ivalve Yamathayela Induku Emfishane Yeloli Lemoto...

Incazelo Yemikhiqizo I-valve iyisisetshenziswa somzimba se-valve esizimele esivumela igesi ukuthi ingene endaweni yesondo elingenashubhu noma ishubhu lapho ivulwa, bese ...

Buka imininingwane -

Isihlungi se-Wholesale Wire Mesh Insimbi Engagqwali engu-10 Micron Sintered Tube Yezemithi ye-M...

Izihlungi zensimbi engagqwali zilungele ukusetshenziswa ekucacisweni kobunjiniyela okufunayo okudinga ukuhlungwa ezimeni ezingezinhle zemvelo, njenge-jet en...

Buka imininingwane -

I-Sintered Porous Metal Stainless Steel Filter Tube ye-Fiber Optic Collimator HENGKO

Umkhiqizo Chaza ama-cartridge ensimbi anezimbotshana angenziwa ngokwezifiso ezinhlobonhlobo zezinhlelo zokusebenza kanye nokucaciswa futhi anganamathiselwa ku-metalic ne-non-meta...

Buka imininingwane -

Ukunemba Okuphezulu Okuphansi Ukusetshenziswa Kwe-I2C Interface Temperature & Inzwa yesihlobo somswakama...

I-HENGKO izinga lokushisa kanye ne-humidity sensor sensor eyenziwe ngebanga lokuvikela le-IP66 high-tightness steel stainless steel porous housing, ingasetshenziswa ngqo...

Buka imininingwane -

izinga lokushisa kanye nenzwa yomswakama ohlobene ne-stainless steel extension tube kanye ...

Isidluliseli se-HT-E067 somswakama/ izinga lokushisa sinikeza indlela ethembekile nengabizi kakhulu yezinhlelo zokusebenza zokuqapha ukukhweza kwe-duct.Izinzwa ze-Solid-state pr...

Buka imininingwane -

I-Sintered Sparger Tube ene-Porous Metal Stainless Steel Tank kanye nama-In-line Spargers Asetshenziswa ...

Sethula i-HENGKO sintered spagers, ikhambi lokugcina lokwethula amagesi oketshezini.Lo mkhiqizo omusha usebenzisa izinkulungwane ze...

Buka imininingwane -

Ukusebenza okuphezulu kwe-porous sintered metal stainless stainless isostatic filters tubes support ...

Amashubhu ensimbi engagqwali enziwe ngempushana yensimbi engagqwali, acutshungulwa ngobuchwepheshe be-sintering.Lo mkhiqizo ungahlanza imidiya engcolile futhi uzuze...

Buka imininingwane -

Umshini wamanzi acebile nge-Hydrogen - i-sintered SS 316L insimbi engagqwali 0.5 2 micron air o ...

Amanzi e-hydrogen ahlanzekile, anamandla, futhi ane-hydron.Kuyasiza ukuhlanza igazi futhi inyakaze igazi.Ingavikela izinhlobo eziningi zezifo futhi ithuthukise abantu...

Buka imininingwane -

Kufakiwe I-Directly Porous Metal In-Line Sparger Tube Khiqiza Amabhamuza Amancane

I-HENGKO sintered spagers yethula amagesi oketshezini ngezinkulungwane zezimbotshana ezincane, idala amabhamuza amancane kakhulu futhi maningi kakhulu kunamapayipi abhobhile ...

Buka imininingwane -

I-316L yensimbi engagqwali enezimbotshana zensimbi eqondile yesihlungi emise okwemihlangano ye-sparging

I-Sintered air stone diffuser ivamise ukusetshenziselwa ukujova igesi enezimbotshana.Zinobukhulu obuhlukahlukene bembotshana (0.5um kuya ku-100um) okuvumela amabhamuza amancane ukuthi ageleze phakathi ...

Buka imininingwane -

I-316L yensimbi engagqwali enezimbotshana zeshubhu ye-sintered yezinsiza zomkhumbi wokuvutshelwa

Inamathisele ichopho leshubhu le-sparger, leli thiphu le-stainless steel sintered elingu-316L litholakala ngosayizi abahlukahlukene bezimbotshana.I-5 10 15 50 100 i-pore frit iyona ...

Buka imininingwane -

I-Cylindrical 25 50 micron yensimbi engagqwali ama-microns ane-porous sintered filter tube for...

Amashubhu okuhlunga ensimbi engenasici e-HENGKO enziwa ngokufaka i-sintering 316L powder material noma i-multilayer stainless stainless wire mesh emazingeni okushisa aphezulu.Bake ba...

Buka imininingwane -

Ishubhu yesihlungi sensimbi enezimbotshana zokuphatha okushisayo kanye namakhemikhali akhethekile |HENGKO

Amashubhu okuhlunga ensimbi engenasici e-HENGKO enziwa ngokufaka i-sintering 316L powder material noma i-multilayer stainless stainless wire mesh emazingeni okushisa aphezulu.Bake ba...

Buka imininingwane -

Umkhiqizi ochwepheshe wenze ngokwezifiso ishubhu lesihlungi sensimbi esinezimbobo esinezimbobo esisetshenziselwa ukwelashwa...

Izihlungi ze-HENGKO sintered zivame ukusetshenziselwa ukuhlanzwa nokuhlunga uketshezi negesi, ukuhlukaniswa nokubuyiselwa kwezinhlayiya eziqinile, ukupholisa umoya...

Buka imininingwane -

I-0.2um kuya ku-90 micron 5 - 100mm ukuphakama okuyimpushana noma inetha locingo elinezimbotshana zensimbi ezinezimbotshana...

Amashubhu okuhlunga ensimbi engenasici e-HENGKO enziwa ngokufaka i-sintering 316L powder material noma i-multilayer stainless stainless wire mesh emazingeni okushisa aphezulu.Bake ba...

Buka imininingwane -

I-Sintered metal powder porous 316l SS ishubhu yesihlungi sensimbi engenasici, 2 μm 5 7 10 15 20 30 ...

Amashubhu okuhlunga ensimbi engenasici e-HENGKO enziwa ngokufaka i-sintering 316L powder material noma i-multilayer stainless stainless wire mesh emazingeni okushisa aphezulu.Bake ba...

Buka imininingwane -

2 10 20 25 microns porous SS 304/316L metal sintered insimbi engagqwali isihlungi tube for li...

Amashubhu okuhlunga ensimbi engenasici e-HENGKO enziwa ngokufaka i-sintering 316L powder material noma i-multilayer stainless stainless wire mesh emazingeni okushisa aphezulu.Bake ba...

Buka imininingwane -

I-Sintered metal 316 isihlungi sensimbi engagqwali ishubhu lesihlungi sezokwelapha esincane soketshezi negesi ...

I-Product Chaza Izinto zokuhlunga ezinama-Porous zisetshenziswe kabanzi ezinkambini ze-metallurgical, amakhemikhali, ezemithi, ze-aerospace, nezokundiza.Imithombo ye-Porous Metal...

Buka imininingwane

Kungani Kufanele Usebenzise Ishubhu Lensimbi Yezimbotshana?

Kunezizathu ezimbalwa ezibalulekile zokuthi kungani amashubhu ensimbi anezimbotshana asetshenziswa ezinhlelweni ezahlukahlukene:

Ukuhlunga:

* Umsebenzi wabo oyinhloko ukuhlunga.Usayizi wembotshana olawulwa kahle uzivumela ukuthi zikhiphe ukungcola, izinhlayiya, nokungcola oketshezini namagesi.Lokhu kungabaluleka ezimbonini ezifana nemithi, ukucubungula amakhemikhali, nokudla nesiphuzo, lapho ubumsulwa bubalulekile.

* Osayizi bezimbotshana bangasukela kuma-submicron kuye kumamilimitha ambalwa, okubenza bakwazi ukuhlunga osayizi bezinhlayiyana ezihlukahlukene.

Ukugeleza okulawulwayo:

* Isakhiwo esinezimbotshana sivumela ukugeleza okulawulwayo koketshezi namagesi.

Lokhu kungasetshenziselwa ukungena komoya, ukusatshalaliswa kwegesi, ukugeleza kwamanzi, nezinye izinhlelo zokusebenza lapho ukulawulwa okunembile kokugeleza kuyadingeka.

* Ukusatshalaliswa kwe-pore okufanayo kuqinisekisa ukugeleza okungaguquki kulo lonke ishubhu, kuvimbela umzila kanye nokusabalalisa kwengcindezi engalingani.

Ukuqina namandla:

* Eyenziwe ngezinsimbi ezifana nensimbi engagqwali, i-nickel, noma ithusi, amashubhu ensimbi anezimbobo ahlala isikhathi eside futhi angamelana nezimo zokusebenza ezinzima, okuhlanganisa izinga lokushisa eliphezulu, ukucindezela, nendawo ebolayo.

* Lokhu kubenza bafanelekele ukusetshenziswa isikhathi eside ekufuneni izicelo zezimboni.

Ezinye izinzuzo:

* Amashubhu ensimbi anezimbotshana nawo angasindi, ahlanzwa kalula, futhi asebenziseka kabusha.Zingenziwa kalula ngomshini futhi zibunjwe zibe izinhlobo ezihlukahlukene, zandise ngokwengeziwe ukuguquguquka kwazo.

Nazi izibonelo ezithile zokusebenzisa lapho kusetshenziswa amashubhu ensimbi anezimbotshana:

* Ama-air diffuser:ezindaweni zokuhlanza amanzi angcolile ukwethula umoya-mpilo emanzini ukuze kukhule amagciwane.

* Izihlungi zamafutha:ezimotweni nakwezinye izimoto ukuze kukhishwe ukungcola kuphethiloli.

* Izifakelo zezokwelapha:ukuze kungene amathambo kanye nokulethwa kwezidakamizwa.

* I-Catalyst isekela:kuma-reactor amakhemikhali ukubamba nokusabalalisa ama-catalysts.

* Izithulisi:ezinhlelweni zokukhipha umoya ukuze unciphise umsindo.

Ekugcineni, izizathu eziqondile zokuthi kungani umuntu angakhetha ithubhu lensimbi elinezimbotshana zincike ekusetshenzisweni okuqondile kanye nezidingo zalo.Kodwa-ke, inhlanganisela yabo eyingqayizivele yokuhlunga, ukugeleza okulawulwayo, ukuqina, nezinye izinzuzo kuzenza ithuluzi elibalulekile lezimboni eziningi.

Umsebenzi Oyinhloko

Iithubhu yensimbi ene-sinteredcishe umsebenzi ofanayo nomunyeizihlungi zensimbi ze-sintered or sintered metal sparger.

Umsebenzi oyinhloko wamashubhu ensimbi anezimbotshana ukuhlinzeka ngokuhlunga okusebenzayo nokuthembekile, ukuhlukaniswa nokulawula

ukugeleza kwamanzi kanye negesi.

Lawa mashubhu ensimbi anezimbobo enziwe ngezinhlayiya zensimbi ezingama-316L SS ezihlanganiswe ndawonye ngokusebenzisa i-sintering.

inqubo, ukudala isakhiwo esinezimbotshana ezixhumene.Izici eziyingqayizivele zamashubhu ensimbi anezimbotshana

zivumele ukuthi zisebenze imisebenzi eminingana ebalulekile:

1. Ukuhlunga:

Injongo eyinhloko yamashubhu ensimbi anezimbotshana iwukusebenza njengezihlungi, ukususa ukungcola, izinhlayiya, nokungcola oketshezini namagesi.Ukulawulwa okunembile kosayizi wembotshana kuzivumela ukuthi zifinyelele ukuhlungwa okuhle kuze kufike kumazinga angaphansi kwama-micron, okuqinisekisa ukuhlanzeka kwendawo ecutshungulwayo.

2. Igesi kanye Nokuhlakazwa Koketshezi:

Amashubhu ensimbi anezimbotshanazisetshenziselwa ukuhlakaza amagesi noma uketshezi ngokulinganayo nangokufana.Ngokulawula usayizi wembotshana nokusabalalisa, bangakha iphethini yokugeleza efanayo, bavimbele umzila futhi bathuthukise ukusebenza kahle kokuhlakazeka.

3. I-Fluidization:

Ekufakweni kombhede owenziwe uketshezi, lawa mashubhu asetshenziswa ukuze akhiphe izinhlayiya eziqinile, enze isimo esimisiwe esifana noketshezi.Ukusatshalaliswa okufanayo kwama-pores kusiza ekuzuzeni uketshezi olusebenzayo nokulawulwayo.

4. Ukukhipha umoya kanye nokulingana kwengcindezi:

Amashubhu ensimbi anezimbotshana asetshenziselwa ukukhipha amagesi, ukulinganisa ukucindezela, noma ukukhulula izimo ze-vacuum kumasistimu namadivayisi ahlukahlukene.Avumela ukudlula komoya noma igesi ngenkathi kuvimbela ukungena kokungcola.

5. Ukunciphisa Umsindo:

Kwezinye izinhlelo zokusebenza, amashubhu ensimbi anezimbotshana asetshenziswa njengezithulisi noma ama-mufflers ukunciphisa amazinga omsindo akhiqizwa ukuhamba kwamagesi noma uketshezi.

6. Ukusabalalisa:

Amashubhu ensimbi anezimbotshana asiza igesi noma izinqubo zokusabalalisa uketshezi ngokuvumela ama-molecule ukuba adlule ezimbotsheni zawo ezixhumene.Le ndawo ithola ukusetshenziswa emikhakheni ehlukahlukene, njenge-catalysis kanye nemisebenzi yokudlulisa abantu abaningi.

7. Ukusekela Nokusabalalisa:

Ezimbonini ezithile, amashubhu ensimbi anezimbotshana asebenza njengezakhiwo zokusekela ama-catalysts noma ezinye izinto, ahlinzeke ngohlaka oluzinzile futhi asize ekusabalaliseni okufanayo.

Ngenxa yokuqina kwawo okuphezulu, ukuqina, ukumelana namakhemikhali, kanye nezakhiwo ze-pore ezilawulekayo, amashubhu ensimbi anezimbotshana asetshenziswa kakhulu ezimbonini ezifana nemithi, amakhemikhali e-petrochemicals, ukwelashwa kwamanzi, izimoto, i-aerospace, nokunye okuningi, lapho ukuhlunga okusebenzayo kanye nezinqubo zokugeleza okulawulwayo kubalulekile. ukusebenza kahle nokuphepha.

Isimiso esisebenzayo samashubhu ensimbi anezimbotshana ezinazimbotshana ezisikiwe

Isimiso sokusebenza samashubhu ensimbi anezimbotshana ezinezimbotshana sisekelwe ezintweni eziyingqayizivele zesakhiwo sensimbi esinezimbotshana, esivumela ukuhlunga okuphumelelayo nokugeleza okulawulwayo koketshezi namagesi.Nakhu okufingqiwe kwesimiso sokusebenza:

1. Inqubo ye-Sintering:

Amashubhu ensimbi anezimbotshana akhiqizwa ngenqubo ebizwa ngokuthi i-sintering.Kubandakanya ukuhlanganisa izinhlayiya zensimbi, ngokuvamile insimbi engagqwali noma amanye ama-alloys ensimbi, abe yisimo esithile, njengeshubhu.Izinhlayiya zensimbi zishiselwa ezingeni lokushisa ngaphansi nje kwendawo yazo yokuncibilika, okuzenza zihlangane, zenze inethiwekhi eqinile nexhumene yezimbotshana.

2. Isakhiwo sezimbotshana:

Amashubhu ensimbi ane-sintered anesakhiwo se-pore esichaziwe ngenxa yokuhlelwa kwezinhlayiya zensimbi phakathi nenqubo yokucwilisa.Usayizi, umumo, kanye nokusatshalaliswa kwalezi zimbotshana kungalawulwa ngokunembile ngesikhathi sokukhiqiza ukuze kuhlangatshezwane nezidingo ezithile zokuhlunga.

3. Ukuhlunga:

Umsebenzi oyinhloko wamashubhu ensimbi anezimbotshana ezinezimbotshana ukuhlunga.Lapho uketshezi noma igesi idlula epayipini, ukungcola, izinhlayiya, nokungcola kuthathwa ngaphakathi kwezimbotshana.Usayizi wembotshana uklanyelwe ukuvumela uketshezi olufunayo noma igesi ukuthi idlule ngenkathi kuvinjwa izinto ezingafuneki.

4. Ukusebenza kahle kokuhlunga:

Ukusebenza kahle kokuhlunga kwamashubhu ensimbi anezimbotshana ezinezimbotshana ezinezimbotshana kuncike kusayizi wembotshana kanye nengqikithi yendawo etholakalayo ukuze ihlungwe.Osayizi abancane bezimbotshana bangathwebula izinhlayiya ezicolekile, banikeze ukusebenza kahle kokuhlunga okuphezulu.

5. Ukulawula Ukugeleza:

Isakhiwo sembotshana esixhumene samashubhu ensimbi ane-sintered sinika amandla okulawula okunembile kokugeleza koketshezi noma kwegesi.Ubukhulu nokusabalalisa kwama-pores kuthonya izinga lokugeleza kanye nokwehla kwengcindezi kulo lonke ishubhu.Lesi sakhiwo sibalulekile lapho kudingeka khona ukusatshalaliswa kokugeleza okufanayo noma uketshezi olulawulwayo.

6. Ukuqina Nokumelana:

Amashubhu ensimbi ane-sintered aqinile futhi amelana nengcindezi yemishini, amakhemikhali, namazinga okushisa aphezulu.Inqubo ye-sintering iqinisekisa ukuthi izinhlayiya zensimbi ziboshwe ngokuqinile, zihlinzeka ngobuqotho besakhiwo ngisho nangaphansi kwezimo zokusebenza eziyinselele.

7. Ukusebenziseka Kabusha Nokuhlanzeka:

Amashubhu ensimbi anezimbobo ezinezimbotshana angahlanzwa kalula futhi asetshenziswe kabusha.Bangakwazi ukumelana nezindlela ezihlukahlukene zokuhlanza, njengokuwashwa ngemuva, ukuhlanzwa nge-ultrasonic, noma ukuhlanza amakhemikhali, ngaphandle kokuphazamisa ukusebenza kahle kokuhlunga.

Umgomo wokusebenza wamashubhu ensimbi anezimbotshana ezinezimbotshana ezisikiwe uwenza abe nezinto ezihlukahlukene kakhulu futhi afanelekele uhla olubanzi lwezicelo ezimbonini ezifana namakhemikhali e-petrochemicals, imithi, ukwelashwa kwamanzi, i-aerospace, nokuningi.Zikhethelwe ukuhlunga kwazo okusebenzayo, ukuqina, kanye nekhono lokumelana nezindawo ezinokhahlo, zinikeze ukusebenza okuthembekile ezinqubweni nasezinhlelweni ezibalulekile.

Yini Okufanele Uyinakekele Lapho I-OEM Special Porous Metal Tubes yephrojekthi yakho yokuhlunga?

Uma ucubungula amashubhu ensimbi akhethekile e-OEM anezimbobo zensimbi ohlelo lwakho lokuhlunga noma amaphrojekthi, kunezici ezimbalwa ezibalulekile okufanele zicatshangelwe ukuze kuqinisekiswe ukusebenza kahle nokuqaliswa ngempumelelo.Nazi ezinye izinto ezibalulekile ezicatshangelwayo:

1. Izidingo zokuhlunga:

Chaza ngokucacile izimfuneko ezithile zokuhlunga zohlelo lwakho lokusebenza.Nquma ukusebenza kahle kokuhlunga okufunayo, usayizi wembotshana, nezinga lokugeleza elidingekayo ukuze kuzuzwe imiphumela oyifunayo.

2. Izimpawu zoketshezi noma zegesi:

Qonda izici zoketshezi noma igesi okufanele ihlungwe, okuhlanganisa izinga lokushisa, ingcindezi, i-viscosity, nokuhambisana kwamakhemikhali.Qinisekisa ukuthi insimbi ekhethiwe enezimbotshana ingakwazi ukumelana nezimo zokusebenza ezihlosiwe.

3. Usayizi Wezimbotshana Nesakhiwo:

Sebenza nomkhiqizi we-OEM ukwenza ngendlela oyifisayo usayizi wembotshana nokwakheka kwamashubhu ensimbi anezimbotshana ukuze kufane nezidingo zohlelo lwakho lokusebenza.Cabangela usayizi wezinhlayiyana zokungcola okufanele zisuswe kanye nezici zokugeleza ezifiselekayo.

4. Ukukhethwa Kwezinto:

Khetha impahla yensimbi efanele ngokusekelwe ekumelana namakhemikhali ayo, izici zemishini, kanye nokuhambisana nendawo ehlungwayo.Izinto ezijwayelekile zifaka insimbi engagqwali, ithusi, i-nickel, ne-titanium.

5. Idizayini neJiyomethri:

Hlanganyela nomkhiqizi we-OEM ukuze udizayine umumo nobukhulu beshubhu ukuze kulingane isistimu noma iphrojekthi yakho.Cabangela izici ezifana nobude, ububanzi, nokuxhumana kokugcina ukuze kuhlanganiswe kalula.

6. Ukusebenza kahle Kokuhlunga kanye Nokwehla Kwengcindezi:

Linganisa ukusebenza kahle kokuhlunga kanye nokwehla kwengcindezi kumashubhu ensimbi anezimbotshana.Ukusebenza kahle kokuhlunga okuphezulu kungase kuholele ekwehleni kwengcindezi eyengeziwe, okungase kuthinte ukusebenza kwesistimu.

7. Ukuhlanzeka Nokunakekela:

Xoxa ngokuhlanzeka kanye nezidingo zokunakekelwa kwamashubhu ensimbi anezimbotshana.Qinisekisa ukuthi zingahlanzwa kalula futhi ziphinde zisetshenziswe ukuze kuthuthukiswe ubude bempilo kanye nokunciphisa isikhathi sokuphumula.

8. Ukwenza ngendlela oyifisayo nobungcweti:

Sebenza nomkhiqizi we-OEM onerekhodi elifakazelwe ekukhiqizeni amashubhu ensimbi ayisipesheli.Kufanele babe nobuchwepheshe bokwenza amashubhu ngokwezifiso ngokwezidingo zakho ezihlukile.

Ngokucabangela lezi zici ngokucophelela nokusebenzisana eduze nomkhiqizi we-OEM, ungaqinisekisa ukuthi amashubhu ensimbi akhethekile e-OEM anezimbobo adizayinelwe futhi enzelwe ukuhlangabezana nesistimu yakho yokuhlunga noma izidingo ezihlukile zephrojekthi, ekugcineni okuholela ekusebenzeni okuthuthukisiwe, ukwethembeka, nokusebenza.

FAQ

1. Yiziphi izici eziyinhloko zamashubhu ensimbi anezimbotshana ezinezimbotshana?

Amashubhu ensimbi anezimbotshana anezimbotshana anikeza izici ezimbalwa ezibalulekile eziwenza ahluke futhi abe nenzuzo enkulu ezinhlelweni ezihlukahlukene.Lezi zici zifaka:

- Ukusebenza kahle Kokuhlunga Okuphezulu: Ukulawulwa okunembile kosayizi wembotshana kuvumela ukuhlungwa okuphumelelayo kwehle kuze kufike kumazinga angaphansi kwama-submicron, okuqinisekisa ukususwa kokungcola nokungcola oketshezini namagesi.

- Ukuqina Nokuqina: Inqubo ye-Sintering ibopha izinhlayiya zensimbi, inikeze amandla emishini kanye nokumelana nokuguqulwa, ngisho nangaphansi kwezimo ezinzima.

- I-Wide Temperature kanye ne-Pressure Range: Amashubhu angasebenza ezindaweni ezeqisayo, agcine ubuqotho besakhiwo kanye nokusebenza kahle kokuhlunga kulo lonke uhla olubanzi lwamazinga okushisa nezingcindezi.

- Ukuvumelana Kwamakhemikhali: Awenzi amakhemikhali futhi amelana nokugqwala, okuwenza afanelekele ukuhlunga amakhemikhali anolaka kanye nemidiya egqwalayo.

- Ukuhlanzeka Nokusebenziseka Kabusha: Amashubhu ensimbi anezimbobo ezinezimbobo angahlanzwa kalula futhi aphinde asetshenziswe izikhathi eziningi, kuncishiswe izindleko zokulungisa nokwelula isikhathi sokuphila sesihlungi.

2. Asebenza kanjani amashubhu ensimbi anezimbobo njengezihlungi?

Ukusebenza kwamashubhu ensimbi anezimbotshana anezimbotshana njengezihlungi kusekelwe esakhiweni sawo sezimbotshana ezixhumene.Lapho uketshezi noma igesi igeleza ngeshubhu, ukungcola nezinhlayiyana zibanjwa ngaphakathi kwezimbotshana kuyilapho kuvumela okuphakathi okufunayo ukuba kudlule.Ubukhulu, ukusatshalaliswa, nokuhlelwa kwezimbotshana kunquma ukusebenza kahle kokuhlunga kanye nohlobo lwezinhlayiya ezingasuswa.I-sintered metal's high porosity nezimbotshana ezinhle zinika amandla ukuhlunga okusebenzayo, okwenza lawa mashubhu alungele izinhlelo zokusebenza ezibucayi lapho kudingeka khona ukuhlunga okunembayo nokuthembekile.

3. Yiziphi izinto okufanele zicatshangelwe ngokufaka amashubhu ensimbi anezimbobo ezinezimbobo ohlelweni?

Ukufakwa ngendlela efanele kubalulekile ukuze kuqinisekiswe ukusebenza kahle kwamashubhu ensimbi anezimbotshana ezinezimbotshana.Okunye okucatshangelwayo kuhlanganisa:

- Ukuvalwa Okufanelekile: Qinisekisa ukuxhumana okuvikelekile nokungavuzi kuzo zombili iziphetho zeshubhu ukuze uvimbele ukudlula nokugcina ukusebenza kahle kokuhlunga.

- Umumo: Misa ishubhu ngendlela efanele ukuze uqinisekise ukuthi isiqondiso sokugeleza sihambisana nomsebenzi oklanyiwe, kungakhathaliseki ukuthi okokuhlunga, ukukhipha umoya, noma ukugeleza kwamanzi.

- Ukusekela Nokuvikelwa: Nikeza ukwesekwa okwanele nokuvikela ukuvimbela ukulimala kwamashubhu ngesikhathi sokufakwa nokusebenza.

4. Yiziphi izinhlelo zokusebenza ezingasetshenziswa kuzo amashubhu ensimbi anezimbotshana?

Amashubhu ensimbi anezimbotshana ezinezimbotshana athola ukusetshenziswa kuzo zonke izimboni ezihlukahlukene, okuhlanganisa:

- Amakhemikhali kanye Nokucwengisiswa:Ukuze uthole ukwesekwa kwe-catalyst, ukuhlungwa koketshezi olucutshungulwayo, nezinhlelo zokusebenza zokusabalalisa igesi.

- Ezemithi:Ezingeni elingenalutho, ukuhlunga kwegesi, kanye nezinhlelo zokulethwa kwezidakamizwa.

- Ukwelashwa kwamanzi:Ukuze kuhlanzwe amanzi angcolile, kufakwe umoya, futhi kuhlungwe amanzi aphuzwayo.

- I-Aerospace:Kuphethiloli kanye nezinhlelo zehydraulic zokuhlunga nokukhipha umoya.

- Ezezimoto:Ekulawuleni ukungcola, ukuhlunga uphethiloli, namasistimu okugcoba.

- Ukudla Nesiphuzo:Ukuze uthole isiphuzo carbonation, aeration, futhi umusi filtration.

5. Amashubhu ensimbi anezimbotshana anezimbotshana anesandla kanjani ekusebenzeni kahle kwesistimu nokusebenza?

Amashubhu ensimbi anezimbotshana ezinezimbotshana athuthukisa ukusebenza kahle kwesistimu nokusebenza ngoku:

- Ukuqinisekisa ukusebenza kahle kokuhlunga, okuholela ekuhlanzeni noketshezi oluhlanzeke kakhulu noma amagesi.

- Ukunikeza ukusatshalaliswa kokugeleza okufanayo, ukuvimbela umzila noma ukusatshalaliswa kwengcindezi engalingani.

- Ukumelana nezimo ezinzima, ukunciphisa isikhathi sokuphumula kanye nezindleko zokunakekela.

- Ukwenza lula ukusakazeka kwegesi kanye nezinqubo ze-fluidization, ukuthuthukisa ukusabela kwamakhemikhali nokusebenza kokudlulisa okukhulu.

6. Yiziphi izindlela zokulawula ikhwalithi ezisetshenziswayo lapho kukhiqizwa amashubhu ensimbi anezimbotshana ezinezimbotshana?

I-HENGKO njengabakhiqizi be-Top Sintered Metal Filter basebenzisa izindlela eziqinile zokulawula ikhwalithi kuyo yonke inqubo yokukhiqiza.Lokhu kuhlanganisa:

- Ikhwalithi Yezinto Ezibalulekile: Ukusebenzisa izinhlayiya zensimbi ezisezingeni eliphezulu ukuze kuqinisekiswe amandla emishini nokumelana namakhemikhali.

- Ukulawula Usayizi Wembobo: Ukulawula okunembile kwamapharamitha we-sintering ukuze kuzuzwe usayizi ofunekayo wembotshana nokusabalalisa.

- Ukunemba Kobukhulu: Ukuqinisekisa ukubekezelelana okuqinile ukuze kuhlangatshezwane nezicaciso zekhasimende.

- Ukuhlolwa kokusebenza: Ukwenza izivivinyo zokusebenza kahle kokuhlunga, ukuhlola ukwehla kwengcindezi, nokuhlola amandla emishini.

Ukuze uthole izixazululo eziqondene nawe nezisebenza kahle ze-OEM Porous Metal Tubes, xhumana no-HENGKO namuhla kuka@hengko.com.

Ithimba lethu lochwepheshe lilungele ukukusiza ekwenzeni ngendlela oyifisayo ikhambi lokuhlunga eliphelele lezidingo zakho ezithile.Ukuthi

okokuhlunga, ukuhlakazwa kwegesi, i-fluidization, nanoma yiluphi olunye uhlelo lokusebenza, sinolwazi nobungcweti bokuletha

amashubhu ensimbi asezingeni eliphezulu ahlangabezana nezidingo zakho.

Ungangabazi ukuxhumana nathi ukuze uthole ukubonisana futhiake sikusize uthuthukise isistimu yakho yokuhlunga noma iphrojekthi.

Sithumele i-imeyili kuka@hengko.commanje futhi uthathe isinyathelo sokuqalaekufezeni ukusebenza kahle okuthuthukisiwe kanye nokusebenza nge

Ikhwalithi ye-HENGKOIthubhu yensimbi ene-sintered.