-

Isihlungi Se-Mesh Ye-Snow Foam Yokucindezela Okuphezulu

Isihlungi seqhwa elinomfutho ophakeme weqhwa elicindezelwe ngocingo olulukiweyo lwe-mesh Isihlungi esiphezulu segwebu kanye nokuhlanganiswa kwemibhobho ye-foam generator ku-Snow Foam Lance.Igwebu...

Buka imininingwane -

Isihlungi Sepayipi likagwayi Insimbi Engagqwali 304 316 Isihlungi Sesikrini Semeshi

Isihlungi se-cigarette mesh disc sibizwa nangokuthi i-cigarette filter mesh disc, i-bong burner mesh, isihlungi se-hookah yesi-Arabhu, noma isihlungi sokungcola kwamanzi esimpompi.Ngokuyinhloko u...

Buka imininingwane -

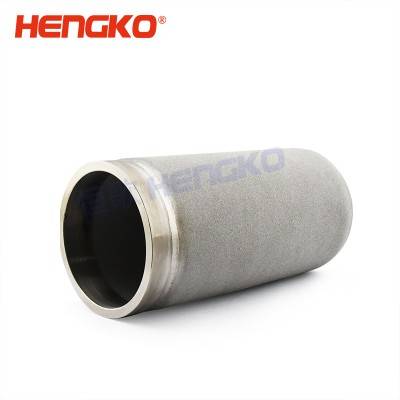

Isihlungi se-Wholesale Wire Mesh Insimbi Engagqwali engu-10 Micron Sintered Tube Yezemithi ye-M...

Izihlungi zensimbi engagqwali zilungele ukusetshenziswa ekucacisweni kobunjiniyela okufunayo okudinga ukuhlungwa ezimeni ezingezinhle zemvelo, njenge-jet en...

Buka imininingwane -

20 Micron 316 Stainless Steel Wire Mesh Filter Cartridge Inner Core 32mm Ubude M4 Thread

Isihlungi se-wire mesh i-wire mesh enwetshwa ngokusebenzisa imicu yensimbi, enezimbobo ezinhle phakathi kwemicu yensimbi eyahlukene.Lapho amanzi angcolile empompa...

Buka imininingwane -

Reverse Osmosis Stainless Steel Isihlungi Samanzi Sesihlanzi Sesistimu Yokuhlunga SS 316 M...

I-Reverse Osmosis Stainless Steel Isihlungi Sesihlanzi Samanzi Uhlelo Lokuhlunga I-SS 316 Mesh Cartridge Filter Incazelo Yomkhiqizo Wonke umuntu ufuna i-n...

Buka imininingwane -

I-RHTX Series ine-mesh-protected humidity sensor probe izindlu ezivikelwe isimo sezulu

Amagobolondo enzwa yensimbi engenasici ye-HENGKO enziwa ngokufaka i-sintering 316L powder impahla emazingeni okushisa aphezulu.Zisetshenziswe kakhulu ekuvikelweni kwemvelo, ...

Buka imininingwane -

I-HK83MCN RHT31 35 30 izinga lokushisa elingangenwa ilangabi lomswakamo inzwa enezimbotshana ze-stainless stainless...

Igobolondo lenzwa yensimbi engenasici ye-HENGKO lenziwa ngokufaka i-sintering 316L powder impahla ekushiseni okuphezulu.Zisetshenziswe kakhulu ekuvikelweni kwemvelo, p...

Buka imininingwane -

±2% umswakama ohlobene nemboni we-ultra-low-low-protected mesh-protected-proof air-proof umswakama ohlobene nemboni kanye ...

I-RHT-H serious RH&T sensor humidity probe, ekhiqizwe yi-HENGKO, iwuhlelo oluqinile, olunembile lokushisa kanye nomswakamo olulungele isikhathi eside, ...

Buka imininingwane -

I-HK20G1/8U RHT30 i2c I-mesh evikelwe izinga lokushisa elingenantambo elivikela isimo sezulu kanye nezinzwa zomswakama...

Imojula yokushisa yedijithali ye-HENGKO wifi kanye nomswakamo yamukela inzwa yochungechunge lwe-RHT enembayo ephezulu efakwe igobolondo lesihlungi sensimbi esine-sintered ye-air permeab enkulu...

Buka imininingwane -

I-4-20mA Infrared CH4 CO2 inzwa yegesi (i-carbon dioxide sensor) umtshina we-aluminium alloy...

Izindlu zensimbi engagqwali ezinokuvikela okungenakuphazamiseka.Ukuze kusetshenziswe namabhokisi okuhlanganisa aqinisekisiwe ngokwehlukana, asezingeni lomkhakha noma izindawo ezivalekile zesitholi segesi ye-OEM....

Buka imininingwane -

Izindlu zesihlungi zensimbi engagqwali e-sintered/wire mesh ezingaqhumeki ze-carbon monoxide L...

Izindlu zenzwa yokuqhuma kwe-HENGKO zenziwe ngensimbi engagqwali engu-316L ne-aluminium ukuze kuvikelwe ukugqwala okuphezulu.I-sinter-bonded flame arrestor inikeza ...

Buka imininingwane -

Isihlungi Sensimbi Engagqwali Yensimbi Engenasici Izihlungi Zethuba lokugcina Zomkhakha Wokuphrinta

I-HENGKO ikhiqiza izinto zokuhlunga ezinezikhala zensimbi ezinhlobonhlobo zezinto zokwakha, osayizi, nokufakwa ukuze zicaciswe kalula ngezici ze...

Buka imininingwane -

Izihlungi ze-Sintered Metal Stainless Steel Porous Mesh ze-High Pressure Enviroments Ma...

Izihlungi zezindwangu zebanga lokudla ze-Hengko zenziwa ikakhulukazi ngendlela yezinkomishi, izinkomishi ezinentambo, amadiski, namaphakethe endawo anwetshiwe.Lezi zihlungi zibalulekile...

Buka imininingwane -

Ishidi Lezendlalelo Zokusabalalisa Igesi le-MEAs, insimbi engagqwali enezimbotshana zensimbi / ezinezikhala zocingo ...

Amapuleti okuhlunga ensimbi engenasici ye-HENGKO enziwa ngokufaka i-sintering 316L powder impahla noma i-multilayer steel stainless wire mesh emazingeni okushisa aphezulu.Sebe...

Buka imininingwane -

Izihlungi ze-Precious Metal Catalyst - Ikhandlela lesihlungi se-mesh yensimbi engagqwali enezingqimba eziningi

I-HENGKO ikhiqiza izinto zokuhlunga ebangeni elibanzi lezinto, osayizi, nokufakwa ukuze kucaciswe kalula ngezici kanye nokucushwa...

Buka imininingwane -

Isihlungi sekhwalithi ephezulu y, isihlungi se-sintered mesh sokuhlunga igesi

y I-strainer filter mesh isetshenziswa ekufakweni kwamapayipi ukuvikela imfucumfucu ukuthi ingagelezi ngamapayipi.Uketshezi ludlula kusihlungi esine-sintered, esihluza ama...

Buka imininingwane -

I-0.2um kuya ku-90 micron 5 - 100mm ukuphakama okuyimpushana noma inetha locingo elinezimbotshana zensimbi ezinezimbotshana...

Amashubhu okuhlunga ensimbi engenasici e-HENGKO enziwa ngokufaka i-sintering 316L powder material noma i-multilayer stainless stainless wire mesh emazingeni okushisa aphezulu.Bake ba...

Buka imininingwane -

5 10 25 micorns porous 316L insimbi engagqwali powder/wire mesh sintered metal refillable kabusha ...

Amashubhu okuhlunga ensimbi engenasici e-HENGKO enziwa ngokufaka i-sintering 316L powder material noma i-multilayer stainless stainless wire mesh emazingeni okushisa aphezulu.Bake ba...

Buka imininingwane -

I-Multi-layer sintered stainless stainless steel mesh plate fluidized bed equipment Distributor bot...

Ipuleti lensimbi engenasici lombhede owuketshezi Ukulawulwa kokusatshalaliswa kwegesi, ukudluliswa kwezinto eziyimpuphu, nokusebenza kwe-fluidization sekusetshenziswe kabanzi ku-indu...

Buka imininingwane -

isihlungi esincane se-sintered stainless stainless steel mesh disc esizosetshenziswa kumaPrinta we-inkjet

Izihlungi ze-Sinter wire mesh zivame ukusetshenziselwa ukuhlanzwa nokuhlunga uketshezi negesi, ukuhlukanisa kanye nokubuyiselwa kwezinhlayiya eziqinile, i-coolin yokuphefumula...

Buka imininingwane

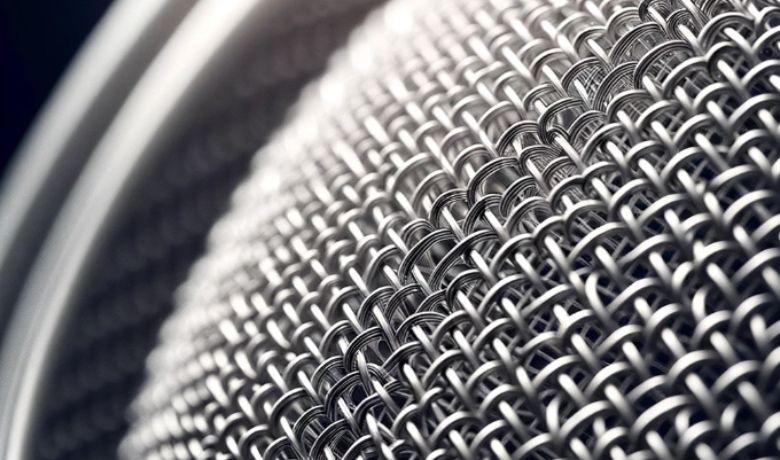

Yini i-sintered mesh?

Kulula ukusho, I-Sintered mesh isihlungi sensimbi esenziwe ngokuhlanganisa ndawonye izendlalelo eziningi ze-wire mesh elukiwe ngenqubo ebizwa ngokuthi i-sintering.Ngesikhathi se-sintering, izingqimba ze-mesh ziyashiswa futhi zicindezelwe ndawonye, zakha isakhiwo esiqinile nesizinzile.Umkhiqizo ovelayo unosayizi ofanayo we-pore futhi unikeza amandla amahle kakhulu okuhlunga, okuwenza ulungele izinhlelo zokusebenza ezihlukahlukene ezimbonini lapho ukuhlunga okunembile nokuthembekile kuyadingeka.

Kungani Kufanele Usebenzise I-Sintered Mesh?

Empeleni, ziningi izizathu zokuthi abantu basebenzise izihlungi ze-sintered mesh, kodwa ngokuphelele, kungenxa

izici zezihlungi ze-sintered mesh.

* Ukuqina:

Inqubo ye-sintering idala isibopho esiqinile phakathi kwezingqimba ze-mesh, okwenza isihlungi siqine futhi simelane nokuguga.

* Ukuhlukahluka:

I-Sintered mesh ingenziwa ngokwezifiso ngezinombolo ezihlukene zezendlalelo kanye nobukhulu obuhlukahlukene be-pore, iyenze ifaneleke uhla olubanzi lwezinhlelo zokusebenza.

* Ukunemba okuphezulu kokuhlunga:

Usayizi wayo wembotshana ongaguquguquki uqinisekisa ukuhlungwa okunembile, ukuhlukanisa izinhlayiya eziyimizuzu emincane ngokuphumelelayo.

* Izinga Lokushisa Eziphakeme kanye Nokumelana Nokucindezela:

I-Sintered mesh ingamelana namazinga okushisa aphezulu nezingcindezi kunezinye izinhlobo eziningi zezihlungi, okuyenza ilungele izindawo zezimboni eziyinselele.

*Ukuhlanza Okulula Nokunakekela:

Ngenxa yesakhiwo sayo esiqinile, i-sintered mesh ingahlanzwa futhi isetshenziswe kabusha izikhathi eziningi, okuholela ekwehleni kwezindleko ngokuhamba kwesikhathi.

* Ukugeleza komoya Okufanayo:

Ivumela ukusatshalaliswa okulinganayo komoya noma uketshezi, okubalulekile ezinhlelweni ezifana nemibhede exutshiwe noma ama-aerators.

Ngokunikezwa kwalezi zinzuzo, i-sintered mesh iyinketho ekhethwayo ezimbonini ezihlukahlukene, kusukela kwezokwelapha nokucubungula ukudla kuya kumakhemikhali kaphethiloli kanye ne-aerospace.

Izinhlobo zesihlungi se-Sintered Mesh ?

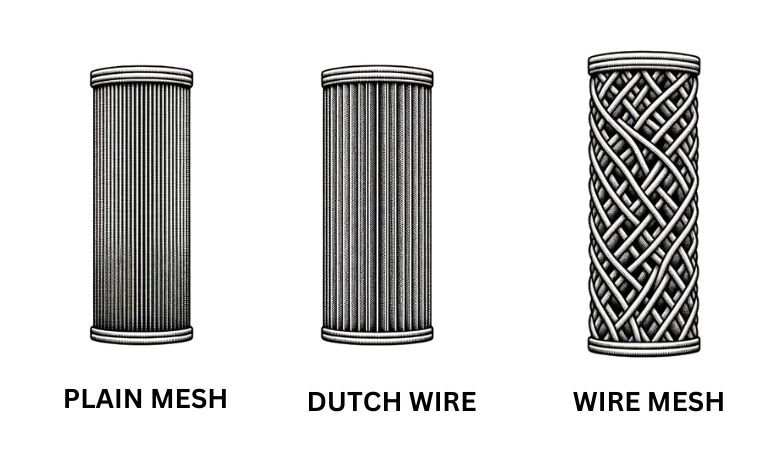

Izihlungi ze-Sintered mesh ziza ngezinhlobo ezahlukahlukene ngokuya ngesakhiwo sazo, izendlalelo, nezinhlelo zokusebenza ezithile.Ezinye zezinhlobo ezijwayelekile zihlanganisa:

1. Ungqimba Olulodwa Sintered Mesh:

Yenziwe ngesendlalelo esisodwa se-wire mesh ephothiwe ukuze kuthuthukiswe amandla nokuqina kwayo.

2. I-Multi-layer Sintered Mesh:

Lokhu kuhilela ukupakisha izendlalelo ezimbalwa zocingo olulukiweyo bese uzihlanganisa ndawonye.Isakhiwo esinezendlalelo eziningi sithuthukisa amandla emishini kanye nokunemba kokuhlunga.

3. I-Sintered Square Woven Mesh:

Yenziwe ngezingqimba zocingo olulukiweyo oluyisikwele ezihlanganiswe ndawonye, lolu hlobo lunikeza osayizi bembotshana obufanayo futhi luvame ukusetshenziswa ezinhlelweni zokuhlunga ezahlukahlukene.

4. I-Dutch Woven Sintered Mesh:

Lokhu kuhlanganisa izingqimba eziningi zezintambo zocingo ezilukiwe zase-Dutch, ezibe sezifakwe i-sintered.Umphumela uba isihlungi esinekhono elihle lokuhlunga.

5. I-Perforated Metal Sintered Mesh:

Lolu hlobo luhlanganisa ungqimba olulodwa noma ngaphezulu lwe-mesh yocingo olulukiweyo nongqimba lwensimbi enezimbobo.Insimbi enezimbobo inikeza amandla engeziwe, kuyilapho izendlalelo ze-wire mesh zinikeza ukuhlunga.

6. I-Sintered Fiber Felt Mesh:

Esikhundleni socingo olulukiwe, lesi sihlungi sisebenzisa umata wemicu yensimbi.Amafayibha ahlanganiswe ndawonye ukuze kwakheke indawo enezimbotshana elungele izinga lokushisa eliphezulu kanye nezinhlelo zokusebenza ze-viscosity ephezulu.

7. I-Sintered Metal Powder Mesh:

Lolu hlobo lwenziwa ngokufaka izimpushana zensimbi ukuze kwakheke indawo yokuhlunga enezimbotshana.Ivamise ukusetshenziswa lapho kudingeka ukuhlunga okuhle kanye namandla okubamba ukungcola okuphezulu.

Ngayinye yalezi zinhlobo inezinzuzo zayo futhi yakhelwe izinhlelo zokusebenza ezithile.Lapho ukhetha isihlungi se-sintered mesh, kubalulekile ukucabangela uhlobo lwento ehlungwayo, usayizi wembotshana oyifunayo, izimo zokusebenza, nezinye izici ezifanele.

Ungazikhetha Kanjani Izihlungi Ze-Sintered Mesh Ezilungile Zedivayisi Yakho Yokuhlunga?

Ukukhetha isihlungi semeshi esine-sintered esilungile sedivayisi yakho yokuhlunga kubalulekile ukuze usebenze kahle.Nansi inkomba yesinyathelo ngesinyathelo ukukusiza wenze isinqumo unolwazi:

1. Nquma Izidingo Zokuhlunga:

*Usayizi Wezinhlayiyana: Qonda usayizi wezinhlayiyana ezincane kakhulu ozidingayo ukuze uzihlunge.Lokhu kuzokuqondisa ukuthi ukhethe usayizi wembotshana olungile wemeshi ene-sintered.

* Izinga Lokugeleza: Cabangela izinga lokugeleza olifisayo ngesihlungi.Ezinye izinhlobo zemeshi zivumela amazinga okugeleza asheshayo ngaphandle kokuphazamisa ukusebenza kahle kokuhlunga.

2. Hlola Izimo Zokusebenza:

Izinga lokushisa: Qinisekisa ukuthi i-sintered mesh ekhethiwe ingakwazi ukumelana namazinga okushisa okusebenza enqubo yakho.

Ukucindezela: Ezinye izinqubo zokuhlunga zibandakanya ukucindezela okuphezulu.Khetha i-mesh engakwazi ukubhekana nalezi zingcindezi ngaphandle kokukhubazeka.

Ukuvumelana Kwamakhemikhali: Qinisekisa ukuthi i-material yemeshi iyahambisana nezinto ezihlungwayo, ikakhulukazi uma kubandakanyeka amakhemikhali noma izinto ezibolayo.

3. Ukukhetha Okubalulekile:

Insimbi engagqwali iyinto ejwayeleke kakhulu ye-sintered mesh ngenxa yokuqina kwayo kanye nokumelana nokugqwala.Kodwa-ke, ezinye izinto ezifana ne-titanium noma i-Monel zingase zilungele izinhlelo zokusebenza ezithile.

4. Khetha Uhlobo lwe-Sintered Mesh:

Isendlalelo Esilodwa vs. Izendlalelo Eziningi: Amameshi anezendlalelo eziningi anikeza amandla aphakeme nokuhlunga okunembe kakhudlwana kodwa angase adle ngokweqile kwezinye izinhlelo zokusebenza.

I-Woven vs. Non-Woven (I-Fiber Felt): Nakuba izimbotshana ezilukiweyo zinikeza osayizi bembotshana abafaniswayo, abangalukiweyo, njengefayibha ezwakalayo, bahlinzeka ngokuhlunga okujulile.

5.Cabangela Ukunakekela Nokuhlanza:

Uzodinga kangaki ukuhlanza noma ukushintsha isihlungi?Amanye ama-meshes ane-sintered angawashwa kalula ngemuva, kanti amanye angase adinge ukushintshwa ngemva kwesikhathi esithile.

6. Hlola Izilinganiso Zokuhlunga:

Ukusebenza kahle kokuhlunga, isilinganiso somfutho wokuqhuma, kanye nokungeneka yizilinganiso ezibalulekile okufanele zicatshangelwe.Qinisekisa ukuthi i-mesh ekhethiwe ihlangabezana noma idlula izilinganiso ezidingekayo zohlelo lwakho lokusebenza.

7. Xhumana Nabakhiqizi noma Ochwepheshe:

Ukusebenzelana nomkhiqizi wesihlungi se-sintered mesh noma uchwepheshe kunganikeza imininingwane ebalulekile.Bangaphakamisa imikhiqizo ethile noma izixazululo ezenziwe ngokwezifiso ngokusekelwe ezidingweni zakho.

8. Izindleko zokucatshangelwa:

Nakuba kubalulekile ukuthola isihlungi esihlangabezana nezidingo zakho, kubalulekile futhi ukulinganisa ikhwalithi nezindleko.Cabangela kokubili ukutshalwa kwezimali kokuqala kanye nezindleko zokusebenza zesikhathi eside.

9. Izitifiketi Nokuqinisekiswa Kwekhwalithi:

Qinisekisa ukuthi umkhiqizi unamathela kumazinga ekhwalithi afana nezitifiketi ze-ISO.Lokhu kuqinisekisa ukwethembeka nokusebenza kahle kwezihlungi ze-sintered mesh.

Ngokuhlola ngokucophelela izidingo zakho nokuxhumana nochwepheshe, ungakhetha isihlungi esilungile se-mesh esiqinisekisa kokubili ukuhlunga okusebenzayo nokuphila isikhathi eside.

Isicelo

Nazi ezinye izinhlelo zokusebenza ezidumile zezihlungi ze-sintered mesh, kanye nezincazelo ezinemininingwane ngayinye:

1. Ukukhiqizwa Kwemithi kanye Ne-Biotech:

* Incazelo: Embonini yezemithi neye-biotech, ukuhlanzeka komkhiqizo kubaluleke kakhulu.Izihlungi ze-Sintered mesh zidlala indima ebalulekile ekuqinisekiseni lobu bumsulwa ngokususa ukungcola nokungcola.Asetshenziswa ezinhlelweni ezifana nokuhlunga komoya oyinyumba, ukungena, nokulungiselela imidiya yesiko lamaseli.Izakhiwo zazo ezingasebenzi kanye nekhono lokuvalwa inzalo kuzenza zilungele lezi zinhlelo zokusebenza ezizwelayo, ziqinisekise ukuhambisana komkhiqizo nokuphepha kwesiguli.

2. I-Petrochemical Processing:

* Incazelo: Imboni ye-petrochemical icubungula uketshezi oluhlukahlukene, oluningi lwazo olune-viscous noma oluqukethe ukungcola.Izihlungi ze-Sintered mesh zihlukanisa ngempumelelo izinhlayiya ezingafuneki, okuvumela ukukhiqizwa kwezibaseli zekhwalithi ephezulu, izinto zokuthambisa, neminye imikhiqizo yamakhemikhali.Uma kubhekwa izinga lokushisa eliphezulu nokumelana nokucindezela, lezi zihlungi nazo zilungele izimo zokucubungula ngokwedlulele ezijwayelekile kulo mkhakha.

3. Ukukhiqizwa Kokudla Neziphuzo:

* Incazelo: Ukuqinisekisa ukuhlanzeka nokuphepha kwezinto ezisetshenziswayo kuyinto ehamba phambili ekukhiqizeni ukudla neziphuzo.Izihlungi ze-Sintered mesh zisiza ekuhlungeni izinhlayiya ezingafuneki, amagciwane, nokunye ukungcola oketshezini olufana namajusi, amawayini, namasyrups.Zibuye zisetshenziswe ekufakeni umoya izinhlelo zokusebenza ukuqinisekisa ukuthi umoya oyinyumba ungena emathangeni okuvutshelwa noma emikhunjini yokugcina.

4. Ukwelapha Amanzi:

* Incazelo: Ukufinyelela emanzini ahlanzekile kubalulekile kokubili ukusetshenziswa kanye nezinqubo zezimboni.Izihlungi ze-Sintered mesh zisiza ekukhipheni izinhlayiya, amagciwane, nokunye ukungcola emithonjeni yamanzi, ukuqinisekisa ukuthi amanzi okuphuza aphephile kanye nokwelashwa kwamanzi angcolile okusebenzayo.Ukumelana nokugqwala kwazo kunenzuzo ikakhulukazi lapho zisefa usawoti omningi noma amanzi afakwe amakhemikhali.

5. Imibhede Enoketshezi Ekucutshungulweni Kwamakhemikhali:

* Incazelo: Imibhede enoketshezi isetshenziswa ezinqubweni ezihlukahlukene zamakhemikhali lapho izinhlayiya eziqinile zidinga ukumiswa oketshezini.Izihlungi ze-Sintered mesh ziqinisekisa ukugeleza komoya okufanayo noma ukugeleza koketshezi, zenza isiqiniseko sokuthi izinhlayiya zimiswe ngokulinganayo, okubalulekile ekusebenzeni okungaguquki kwamakhemikhali kanye nekhwalithi yomkhiqizo.

6. I-Aerospace kanye Nokuhlunga Kwezimoto:

* Incazelo: Izimboni ze-aerospace nezezimoto zidinga ukunemba kuzo zonke izingxenye, okuhlanganisa ukuhlunga.Izihlungi ze-Sintered mesh zisetshenziswa kumasistimu asebenza ngamanzi, amasistimu kaphethiloli, nasezinhlelweni zokungenisa umoya.Ikhono lazo lokumelana nezingcindezi eziphezulu kanye nokumelana nokugqwala kubenza babaluleke kakhulu kulezi zindawo ezinzima.

7. Ukukhiqizwa Kwezinto zikagesi kanye neSemiconductor:

* Incazelo: Njengoba ubuchwepheshe buthuthuka, isidingo samanzi acwenge kakhulu nomoya kuma-electronics kanye nokukhiqizwa kwe-semiconductor siba sibucayi kakhulu.Izihlungi ze-Sintered mesh zisiza ukufeza lobu bumsulwa ngokuhlunga izinhlayiya ze-sub-micron, ukuqinisekisa ukuthi izingxenye ze-elekthronikhi ezisezingeni eliphezulu ziyakhiqizwa.

8. Izimbobo Zokuphefumula Ezindaweni Ezibiyelwe Izisetshenziswa:

* Incazelo: Izinsimbi ezivalekile, njengalezo zezingxenye zikagesi noma amabhokisi egiya, ngokuvamile zidinga 'ukuphefumula' ukuze zilinganise ingcindezi noma zidedele ukushisa.Izihlungi ze-Sintered mesh ezimbotsheni zokuphefumula ziqinisekisa ukuthi ngenkathi umoya udlula, ukungcola okunjengothuli noma umswakama kuyagcinwa ngaphandle, kuvikela okokusebenza ngaphakathi.

Ngalunye lwalezi zinhlelo zokusebenza lubonisa ukuguquguquka nokusebenza kahle kwezihlungi ze-sintered mesh, okugcizelela ukubaluleka kwazo ezimbonini ezihlukahlukene.

Xhumana nathi

Ingabe ufuna izixazululo ezikhethekile zokuhlunga?

Finyelela ku-HENGKO ngqo ku-ka@hengko.comku-OEM izihlungi zakho ezihlukile zemeshi.

Ake sakhe ubuhle ndawonye!