I-Sintering idlala indima ebalulekile embonini yokukhiqiza, ivumela ukukhiqizwa kwezingxenye eziyinkimbinkimbi nezihlala isikhathi eside.Ukuqonda okuyisisekelo kokucula kubalulekile konjiniyela, abacwaningi, kanye nabathandi ngokufanayo.Le ndatshana ihlose ukujula emcabangweni wokucula, ukuhlola inqubo yayo, ukuxoxa ngokusetshenziswa kwayo, nokugqamisa izinzuzo nemikhawulo yayo.

Yini i-Sintering?

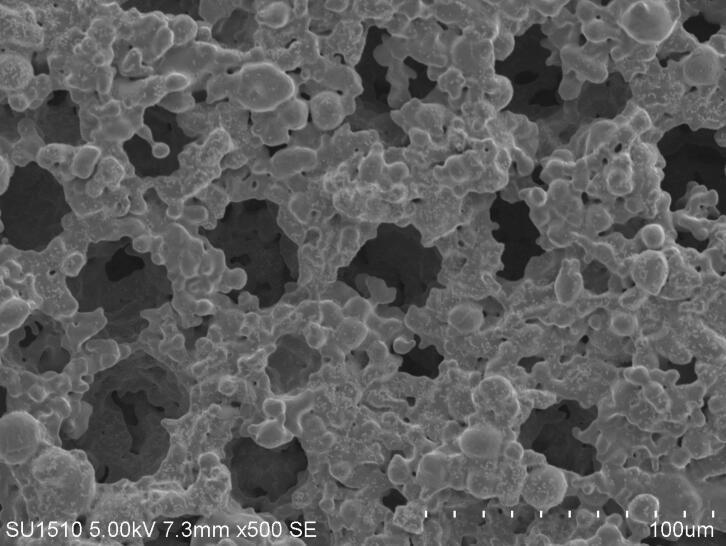

I-Sintering inqubo ehlanganisa ukuhlanganisa izinto eziyimpuphu zibe yinqwaba eqinile ngokusebenzisa ukushisa.Ngokungafani nezinqubo zendabuko zokuncibilika, i-sintering ayifinyeleli lapho kuncibilika khona.Esikhundleni salokho, isebenzisa ukusakazeka kwama-athomu kuzo zonke izinhlayiya, okuholela ekubopheni nasekuhlanganiseni.Le nqubo iphumela esakhiweni esiqinile esinezakhiwo ezithuthukisiwe zemishini.

I-Sintering nayo inomqondo obanzi futhi omncane.Ngomqondo obanzi, i-sintering iyinqubo yokuthi impushana exegayo ihlanganiswe ibe amabhulokhi ngamandla aqinile okubopha ezingeni lokushisa elithile.Kodwa i-sintering emkhakheni wokwenza i-iron kuyinqubo ehlanganisa i-iron ore powder nezinye izinto eziqukethe insimbi ibe yi-metallurgical performance block yokwenziwa ngokuhlanganisa, ukukhiqizwa kwayo yi-sinter.Zibandakanya izinqubo ezahlukene ze-physicochemical Nakuba bobabili basebenzise igama elithi sintering.

Inqubo ye-Sintering

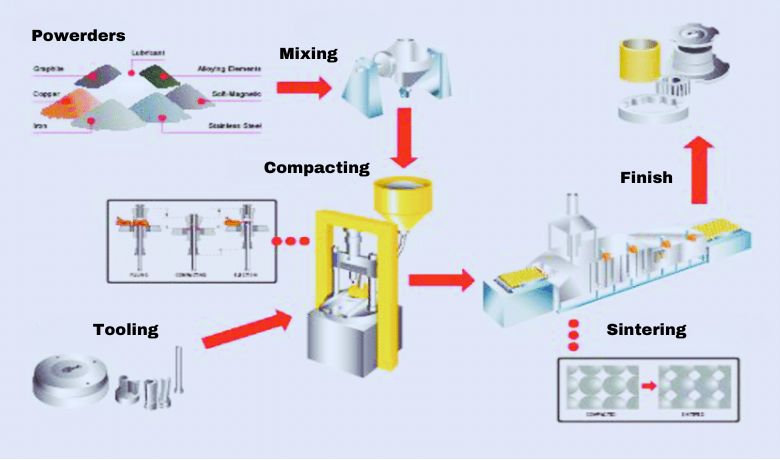

Inqubo ye-sintering inezigaba ezimbalwa.Ekuqaleni, izinto zokusetshenziswa zakhiwa ngendlela ethile, ngokuvamile ngesimo sempushana.Le powder ibe isihlanganiswa kusetshenziswa ingcindezi ukuze kuqinisekiswe ukufana nokuqeda ama-voids.Okulandelayo, izinto ezihlanganisiwe zingaphansi kokushisa okulawulwayo esithandweni somlilo.Izinga lokushisa lilawulwa ngokucophelela ukuze kube lula ukuhlangana kwezinhlayiyana ngaphandle kokubangela ukuncibilika okuphelele.Ngesikhathi sokushisa, izinhlayiya zihamba ngokusakazwa, okuholela ekwakhekeni kwentamo kanye nokuqina.Isigaba sokugcina sibandakanya ukupholisa umkhiqizo owenziwe nge-sintered, ukuwuvumela ukuba uqine ube isakhiwo esiqinile nesihlangene.

I-powder sintering besivame ukusho ukuthi impushana yensimbi noma i-powder compact.Kuyinqubo yobuciko bokuthola impahla noma umkhiqizo ngamandla adingekayo kanye nezici ezikhethekile ngenxa yesibopho esibonakalayo namakhemikhali phakathi kwezinhlayiya ezingeni lokushisa elingaphansi kwendawo yokuncibilika yengxenye eyinhloko.I-HENGKO inochungechunge lwemikhiqizo ye-powder sintering yezinhlobo ezahlukahlukene zokucaciswa nosayizi ohlanganisaisihlungi sediski, isihlungi senkomishi,isihlungi sekhandlela,isihlungi seshidinjalo njalo.Umkhiqizo wethu wensimbi engagqwali we-sintering unenzuzo yamandla aphezulu, ukukwazi ukungena kahle, ukunemba kokuhlunga okunembile kanye nokumelana nokugqwala, kulungele izindawo eziningi.Isevisi eyenziwe ngendlela oyifisayo nayo izohlinzekwa njengoba ucelile.

Isinyathelo ngasinye enqubweni ye-sintering siyasebenzisana, futhi ukugxilisa ingqondo kuyisinyathelo esibaluleke kakhulu enqubweni yokucwilisa, ngakho-ke kusho ukuthini ukugxilisa ingqondo?Ukugxilisa ingqondo kuyisinyathelo esithatha isinyathelo sokuthuthukisa impahla eluhlaza nephethiloli, ikwenze kube umthwalo wesithando somlilo esihlangabezana izidingo zokuqinisa ukucwengwa kwesithando somlilo ngaphambi kokuba impahla eluhlaza nekaphethiloli ingene esithandweni somlilo.Izinkomba eziphakeme zezobuchwepheshe nezomnotho kanye nezinzuzo zezomnotho zingatholakala ngemuva kokuthi i-concentrateis isetshenziswe ekuncibilikiseni kwesithando somlilo.Lokho okubizwa ngokuthi “sebenzisa yonke into ngendlela engcono kakhulu” futhi usebenzise izinsiza ngendlela engcono kakhulu.Futhi kuwuhlobo lokuqwashisa ngokonga nokuvikelwa kwemvelo.

Izici Ezithinta I-Sintering

Kunezici ezimbalwa ezithonya inqubo ye-sintering, okuhlanganisa izinga lokushisa, izinga lokushisa, ingcindezi, usayizi wezinhlayiyana, nokwakheka.Izinga lokushisa lidlala indima ebalulekile ekunqumeni i-sintering kinetics kanye nezakhiwo zezinto ezibonakalayo eziwumphumela.Izinga lokushisa lithinta inqubo yokuminyana, njengoba ukushisisa ngokushesha kungase kuholele ekuhlanganeni kwezinhlayiyana ezingalingani.Ingcindezi isetshenziswa ngesikhathi sokuhlanganisa ukuze kuthuthukiswe ukuhlelwa kabusha kwezinhlayiyana futhi kuqedwe i-porosity.Usayizi we-particle kanye nokwakheka kunomthelela ekuziphatheni kwe-sintering, ngezinhlayiya ezincane nokuqanjwa okufanayo okuphromotha ukuminyana okungcono.

Ngokombono wangempela wegama elithi sintering, igama elithi ukuvutha liwukusebenzisa umlilo, kumele kube nelangabi elihambisana nezinga lokushisa eliphezulu.Futhi inqubo ye-sintering kufanele yenziwe emazingeni okushisa aphezulu.Ukushisa okuphezulu kwenziwa ngokushiswa kukaphethiloli.Ibanga lokushisa, isivinini esishisayo, ububanzi bebhande elivuthayo, umkhathi endaweni ye-sintered, njll kuzothinta ukuqhubeka kwenqubo ye-sintering kanye nekhwalithi yemikhiqizo yokugcina ye-sintered.Futhi lezo zakhi zihlobene nezakhiwo zomzimba kanye namakhemikhali kaphethiloli nomthamo.Ngakho-ke, izakhiwo ze-Physical and chemical of fuel ziyisici esibalulekile esithinta inqubo ye-sintering.

Isingathekiso into ayinakuba khona ngaphandle kwesisekelo abahlala kuso.Uphethiloli nezinto zokusetshenziswa ziyafana nesikhumba futhi ukhuni olunobudlelwano lubalulekile.Ngaphandle kokubili, Inqubo ye-sintering ayikwazi ukwenzeka.Kodwa uphethiloli we-Sintered ikakhulukazi ubhekisela kuphethiloli oqinile ovuthayo kungqimba lwento.Okuvame ukusetshenziswa kakhulu yimpushana ye-coke egayiwe kanye ne-anthracite, njll. Izinto zokusetshenziswa ezisikiwe, ikakhulukazi zinensimbi yensimbi, i-manganese ore, isincibilikisi, isibaseli kanye nemfucuza yezimboni.

Izinhlobo ezahlukene ze-Sintering

I-Sintering ihlanganisa amasu ahlukene ahlukaniswa ngokusekelwe kuzinqubo nezimo ezihilelekile kule nqubo.Ukuqonda izinhlobo ezahlukene ze-sintering kubalulekile ekukhetheni indlela efanele yezinhlelo zokusebenza ezithile.Nazi ezinye izinhlobo ezijwayelekile ze-sintering:

1 Solid-State Sintering

I-Solid-state sintering, eyaziwa nangokuthi i-diffusion bonding, iyindlela esetshenziswa kakhulu ye-sintering.Kule nqubo, izinto eziyimpuphu zingaphansi kwamazinga okushisa aphakeme ngaphansi kwamaphuzu azo okuncibilika.Njengoba izinga lokushisa likhuphuka, ukusabalalisa kwe-athomu kwenzeka phakathi kwezinhlayiya eziseduze, okwenza kube lula ukwakheka kwezintamo nokubopha.Ukuqedwa kwama-voids kanye nokuhlelwa kabusha kwezinhlayiya kuholela ekugxilweni nasekubunjweni kwenqwaba eqinile.

I-solid-state sintering ngokuvamile isetshenziswa ekukhiqizeni izitsha zobumba, ezifana ne-porcelain ne-alumina, kanye nokucwiliswa kwezimpushana zensimbi.Kunconywa uma kugcinwa ukwakheka kwamakhemikhali nokuhlanzeka kwempahla kubalulekile.Ngokulawula ngokucophelela imingcele ye-sintering, njengezinga lokushisa, isikhathi, nokucindezela, izinto ezibonakalayo ezifiselekayo zingafinyelelwa.

2 I-Liquid-Phase Sintering

I-Liquid-phase sintering ihilela ukungezwa kwesigaba soketshezi ukusiza ukuhlela kabusha izinhlayiyana kanye nokubopha phakathi nenqubo yokucwilisa.Isigaba se-liquid, ngokuvamile into ephansi-encibilika, sisebenza njenge-binder noma i-flux, sinciphisa izinga lokushisa le-sintering elidingekayo ukuze kuhlanganiswe.Le ndlela iwusizo ikakhulukazi lapho kuncibilika izinto ezinamaphoyinti aphezulu okuncibilika noma lapho kufiswa izinga lokuminyana.

Ngesikhathi se-liquid-phase sintering, isigaba se-liquid sisakazeka phakathi kwezinhlayiya, sikhuthaza ukuhlelwa kabusha kwezinhlayiyana futhi sithuthukise ukubunjwa kwentamo kanye nokuqina.Ukuba khona kwesigaba se-liquid nakho kwenza ukukhishwa kokungcola futhi kusize ukucwiliswa kwezinto ezinokwakheka okuyinkimbinkimbi.

I-Liquid-phase sintering ivame ukusetshenziswa ekukhiqizeni i-carbides enosimende, lapho izinhlayiya ze-tungsten carbide zihlanganiswa kusetshenziswa i-cobalt-based binder.Iphinde isetshenziswe ekucwiliseni izitsha ezithile zobumba kanye nama-alloys ensimbi, njengensimbi engagqwali.

3 I-Sintering ecushiwe

I-activated sintering, eyaziwa nangokuthi i-field-assisted sintering noma i-spark plasma sintering, iwuhlelo olusha lwe-sintering olusebenzisa imithombo yamandla yangaphandle ukukhuthaza ukuminyana.Kubandakanya ukusetshenziswa kwenkundla kagesi, amandla kagesi, noma imisebe ye-electromagnetic ukuthuthukisa inqubo ye-sintering.

Umthombo wamandla wangaphandle usheshisa ukusakazeka kwe-athomu, okuholela ekwakhekeni kwentamo ngokushesha kanye nokuminyana.Ukusetshenziswa kwamandla kagesi kukhiqiza ukufudumeza kwendawo, ukunciphisa isikhathi se-sintering futhi kuvumela ukucwiliswa kwezinto emazingeni okushisa aphansi.Le nqubo ihlinzeka ngezinzuzo ezinjengokuminyana okuthuthukisiwe, ukunciphisa ukukhula okusanhlamvu, nokulawula okuthuthukisiwe phezu kwesakhiwo esincane nezakhiwo.

I-sintering ecushiwe ithola izinhlelo zokusebenza emikhakheni eyahlukene, okuhlanganisa ukukhiqizwa kwezitsha zobumba ezithuthukisiwe, izinto ezisebenzayo, nezinhlanganisela.Izuzisa kakhulu ezintweni ezincibilikayo ezinamaphoyinti aphezulu, ukwakheka okuyinkimbinkimbi, noma ukuhlangana okulinganiselwe.

4 Ezinye Izinhlobo Zokucula

Ngaphandle kwezinhlobo ezishiwo ngenhla, kunezindlela ezimbalwa ezikhethekile zokucobelela ezenzelwe izinhlelo zokusebenza ezithile.Lokhu kuhlanganisa i-microwave sintering, lapho amandla e-microwave asetshenziselwa ukushisa nokushisisa okokusebenza, kanye nokucwiliswa kwe-pressure-assisted, okuhlanganisa ukucindezela nokushisa ukuze kuthuthukiswe ukuminyana.

Ukwengeza, i-selective laser sintering (SLS) kanye ne-electron beam sintering (EBS) amasu okukhiqiza okungeziwe asebenzisa imishayo yamandla ukuze akhethe izinto eziyimpushana ze-sinter, ungqimba ngongqimba, ukukhiqiza izinto eziyinkimbinkimbi ezinezinhlangothi ezintathu.

Uhlobo ngalunye lwe-sintering lunikeza izinzuzo ezihlukile futhi lukhethwa ngokusekelwe ezintweni ezibonakalayo, imiphumela efiselekayo, nezinhlelo zokusebenza ezithile.

Izicelo ze-Sintering

I-Sintering ithola ukusetshenziswa okubanzi kuzo zonke izimboni ezahlukahlukene ngenxa yekhono layo lokuguqula izinto eziyimpuphu zibe izingxenye eziqinile ezinezakhiwo ezithuthukisiwe.Ake sihlole ezinye zezindawo ezibalulekile lapho i-sintering isetshenziswa kabanzi:

1 - Ceramics

I-Ceramics ingenye yezinkambu eziyinhloko lapho i-sintering isetshenziswa kakhulu.I-ceramics ye-Sintered ibonisa amandla emishini athuthukisiwe, ubulukhuni, nokuzinza kwe-thermal.I-Sintering isetshenziswa ekukhiqizeni amathayela e-ceramic, i-sanitaryware, amathuluzi okusika, izinto eziphikisayo, nezinsimbi zikagesi.Ngokulawula ngokucophelela amapharamitha we-sintering, izinto ze-ceramic zingafinyelela ukuminyana okufunayo, i-porosity, kanye ne-microstructure yezinhlelo zokusebenza ezithile.

2 - Metallurgy

Ekusetshenzisweni kwe-metallurgical, i-sintering isetshenziselwa ukwakha izinhlobonhlobo zezingxenye zensimbi.Lokhu kuhlanganisa amagiya, ama-bearings, ama-bushings, izingxenye zezimoto, nezakhi zesakhiwo.Izimpushana zensimbi, njenge-iron, i-aluminium, nensimbi engagqwali, ziyahlanganiswa futhi zifakwe i-sinter ukuze kukhiqizwe izingxenye eziqinile ezinezakhiwo ezinhle kakhulu zemishini.Izingxenye zensimbi ezisikiwe zivame ukubonisa amandla aphezulu, ukumelana nokugqokwa, nokunemba kobukhulu uma kuqhathaniswa nezingxenye zabalingisi ezivamile.

3 - Izinhlanganisela

I-Sintering idlala indima ebalulekile ekukhiqizweni kwezinto eziyinhlanganisela, lapho kuhlanganiswa izinto ezimbili noma ngaphezulu ezihlukene ukuze kwakhiwe izinto ezinezici ezithuthukisiwe.Ekwenziweni kwezinhlanganisela ze-metal matrix (MMCs) kanye nezinhlanganisela ze-ceramic matrix (CMCs), i-sintering isetshenziswa ukuhlanganisa izinto zokuqinisa, njengemicu noma izinhlayiya, nokokusebenza kwe-matrix.Lokhu kuthuthukisa amandla, ukuqina, kanye nokuqina kwezinto eziwumphumela eziyinhlanganisela.

4 - I-Powder Metallurgy

I-Powder metallurgy, igatsha elikhethekile le-metallurgy, lithembele kakhulu ekufakweni.Kubandakanya ukukhiqizwa kwezingxenye zensimbi ezivela ku-metal powders.Ngezinqubo ezifana nokuhlanganisa kanye nokucwenga, izingxenye eziyinkimbinkimbi ezinobunjwa obuyinkimbinkimbi zingenziwa.I-powder metallurgy ivame ukusetshenziswa embonini yezimoto ukukhiqizwa kwamagiya, ama-camshafts, nezihlalo zamavalvu, kanye nokukhiqizwa kwamathuluzi okusika nezihlungi ezifakwe emanzini.

5 - 3D Printing/Additive Manufacturing

I-Sintering idlala indima ebalulekile kumasu okukhiqiza okungeziwe afana ne-selective laser sintering (SLS) kanye ne-electron beam sintering (EBS).Kulezi zinqubo, izinto eziyimpuphu zikhethwa ngokukhetha ungqimba ngongqimba, ngokusekelwe kumiklamo yedijithali, ukudala izinto eziyinkimbinkimbi ezinezinhlangothi ezintathu.I-Sintering ivumela ukuhlanganiswa nokuhlanganiswa kwezinto eziyimpuphu, okuholela ezingxenyeni eziminyene ngokugcwele nezisebenzayo.Lobu buchwepheshe busetshenziswa ezimbonini ezahlukahlukene, kufaka phakathi i-aerospace, ukunakekelwa kwezempilo, kanye ne-prototyping.

6 I-Electronics kanye nobunjiniyela bukagesi

I-Sintering isetshenziswa ekukhiqizeni izingxenye zikagesi nezikagesi.Ekwenziweni kwezitsha zobumba ze-elekthronikhi, njengama-capacitor, ama-varistors, nama-thermistors, i-sintering isetshenziselwa ukuhlanganisa izinhlayiya ze-ceramic, ukudala izinto ezicinene nezisebenza ngogesi.I-Sintering iphinde isetshenziswe ekwakhiweni kwezinto ezithinta ugesi, ukupakishwa kwe-semiconductor, kanye nezingxenye zebhodi lesekethe.

Lezi yizibonelo ezimbalwa zezinhlelo zokusebenza ezihlukene zokucula.Inqubo ilokhu icutshungulwa futhi icwengisiswa ukuze kuhlangatshezwane nezidingo ezithuthukayo zezimboni ezahlukene, okuvumela ukukhiqizwa kwezinto ezisebenza kahle kakhulu nezingxenye.

Izinzuzo ze-Sintering

I-Sintering inikeza izinzuzo ezimbalwa eziyenza ibe yindlela yokukhiqiza ekhethwayo ezimbonini ezihlukahlukene.Ake sihlole ezinye zezinzuzo ezibalulekile:

1 Izimo Eziyinkimbinkimbi Nemiklamo Eyinkimbinkimbi

Enye yezinzuzo ezibalulekile ze-sintering yikhono layo lokukhiqiza izingxenye ezinobunjwa obuyinkimbinkimbi kanye nemiklamo eyinkimbinkimbi.Ngokusebenzisa izinto eziyimpuphu, i-sintering ivumela ukwakheka kwezingxenye ezinamajiyometri ayinkimbinkimbi okungaba inselele ukufeza kusetshenziswa amasu emishini yendabuko.Lokhu kuvumelana nezimo ekubumbeni kwenza kube lula ukukhiqizwa kwezingxenye ezenziwe ngezifiso eziklanyelwe izinhlelo zokusebenza ezithile.

2 Izakhiwo Zemishini Ethuthukisiwe

I-Sintering ithuthukisa izakhiwo zemishini yezinto zokwakha, okuholela ezingxenyeni ezinezici zokusebenza ezisezingeni eliphakeme.Phakathi nenqubo ye-sintering, izinhlayiya zibopha futhi ziminyene, okuholela ekuthuthukisweni kwamandla, ubulukhuni, nokumelana nokugqoka komkhiqizo owenziwe nge-sintered.Izindlela zokushisisa nokusabalalisa ezilawulwayo ezihilelekile ekushiseni zinomthelela ekuthuthukisweni kwesakhiwo esiminyene nesihlangene, okuthuthukisa ubuqotho bemishini bengxenye.

Izinto Ezingu-3 Ezihlanganisiwe

I-Sintering ivumela ukuhlanganiswa kwezimpushana ezinezingoma ezihlukene, okuvumela ukukhiqizwa kwezinto ezinezici ezihambisanayo.Ngokuhlanganisa izinhlobo ezahlukene zezimpushana noma ukufaka izithasiselo, kungenzeka ukuguqula izici zezinto ezibonakalayo ngokwezidingo ezithile.Lokhu kuvumelana nezimo ekwakhiweni kuvula amathuba okudala izinto ezithuthukisiwe ngokusebenza okuthuthukisiwe, njengama-alloys aphezulu noma izinto ezinezici ezithile zikagesi noma ezishisayo.

4 Ukusebenza Kwezindleko

I-Sintering iyindlela yokukhiqiza engabizi kakhulu uma kuqhathaniswa nezinqubo zokuncibilika ezingokwesiko nokuphonsa.Ukusetshenziswa kwezinto eziyimpuphu kunciphisa imfucuza yezinto ezibonakalayo, njengoba i-powder eyengeziwe ingaqoqwa futhi isetshenziswe kabusha.Ukwengeza, inqubo ye-sintering idinga ukusetshenziswa kwamandla okuphansi njengoba isebenza emazingeni okushisa angaphansi kwendawo yokuncibilika yezinto.Ikhono lokukhiqiza izingxenye ezicishe zifane nenethi liphinde linciphise isidingo sokusebenza komshini okulandelayo, okuholela ekongeni kwezindleko ngokuya ngokusetshenziswa kwempahla, ukusetshenziswa kwamandla, kanye nokucubungula ngemva kokucubungula.

5 Ukuhlukahluka Ekukhetheni Okubalulekile

I-Sintering inikeza ukuguquguquka ekukhetheni impahla, ehlanganisa inhlobonhlobo yezinto zokusetshenziswa ezihlukahlukene.Ilungele izitsha zobumba, izinsimbi, nezinhlanganisela.Izinhlobo ezehlukene zezinto ezisetshenziswayo, okuhlanganisa ama-oxide, ama-carbides, ama-nitrides, nama-alloys, zingacutshungulwa ngokufakwa kwe-sintering.Lokhu kuhambisana okubanzi kwempahla kuvumela ukukhiqizwa kwezingxenye ezahlukahlukene ezinezakhiwo ezithile ezibonakalayo, okwenza i-sintering ibe yinketho ekhangayo ezimbonini eziningi.

Izinzuzo ze-Sintering ekubunjweni okuyinkimbinkimbi, izakhiwo ezithuthukisiwe zemishini, ukwakheka kwezinto ezifanelanisiwe, ukuphumelela kwezindleko, kanye nokuguquguquka kwezinto kuyenza inqubo yokukhiqiza ebalulekile emikhakheni eyahlukene.Ngokusebenzisa lezi zinzuzo, izimboni zingafinyelela ukukhiqiza okuphumelelayo, ukusebenza okuthuthukisiwe, nokonga izindleko ezinqubweni zazo zokukhiqiza.

Kunezinguquko eziningi ezihlanganisa izinguquko eziyinkimbinkimbi ngokomzimba namakhemikhali.Ukusabela komzimba kanye namakhemikhali ekufakweni kwempushana okuhlanganisa ukuhwamuka noma ukuhwamuka kwamanzi noma izinto eziphilayo, ukususwa kwamagesi adsorbed, ukukhululeka kwengcindezi, ukuncishiswa kwama-oxide angaphezulu ezinhlayiya zempushana, ukufuduka kwempahla, ukwenza kabusha ikristalu, ukukhula okusanhlamvu, njll. Kubaluleke kakhulu ukufunda futhi baqonde ulwazi lokucula njengomdidiyeli.Futhi njengomthengi, ukufunda lolu lwazi oluyisisekelo kungasenza sibe nombono omuhle lapho sikhetha imikhiqizo ye-sintering.

I-Sintering yinqubo yendabuko futhi eyinkimbinkimbi.Izikhathi ziyathuthuka, Futhi ubuchwepheshe bokukhiqiza kanye nemishini yokukhiqiza nakho kubuyekezwa njalo.Ukugcina ulwazi oluyisisekelo futhi ufunde ulwazi olusha kuyadingeka kubasebenzi abahlobene nomkhakha.Eminyakeni engu-18 edlule.HENGKOnjalo iphikelela ekuzithuthukiseni njalo, ukuhlinzeka amakhasimende ngemikhiqizo emihle kanye nezinsizakalo ezicabangelayo, ukusiza amakhasimende kanye nentuthuko evamile.Sithemba ukuthi uzoba uzakwethu othembekile wesikhathi eside.

Imibuzo Evame Ukubuzwa (Imibuzo Evame Ukubuzwa)

Yiziphi izinto ezingenziwa sintered?

Izinhlobonhlobo zezinto ezisetshenziswayo zingashiswa, kufaka phakathi i-ceramics, izinsimbi, nezinhlanganisela.Izibonelo zifaka izimpushana zobumba ezifana ne-alumina ne-zirconia, izimpushana zensimbi njengensimbi kanyeizihlungi zensimbi engenasici, kanye nezimpushana eziyinhlanganisela eziqukethe izinto zokuqinisa njengemicu noma izinhlayiya.

Yiziphi izinzuzo ze-sintering uma kuqhathaniswa nezinye izindlela zokukhiqiza?

I-Sintering inikeza izinzuzo ezimbalwa kunezindlela zokukhiqiza zendabuko.Ivumela ukukhiqizwa kwezingxenye ezinobumo obuyinkimbinkimbi kanye nemiklamo eyinkimbinkimbi, inikeza izakhiwo ezithuthukisiwe zemishini, yenza kube ngokwezifiso ukwakheka kwezinto ezibonakalayo, kubiza izindleko ngenxa yokunciphisa udoti wezinto ezibonakalayo, futhi ihlanganisa izinto ezihlukahlukene zezinhlelo zokusebenza ezahlukene.

Yiziphi izinhlelo zokusebenza eziyinhloko ze-sintering?

I-Sintering ithola izinhlelo zokusebenza ezimbonini ezifana ne-ceramics, i-metallurgy, i-powder metallurgy, i-electronics, kanye nokukhiqiza okungeziwe.Isetshenziselwa ukukhiqiza amathayela e-ceramic, izingxenye zezimoto, izingxenye zensimbi, amathuluzi okusika, izitsha zobumba zikagesi, nezinto eziphrintiwe ze-3D, phakathi kokunye.

Ingabe kukhona ukulinganiselwa noma izinselele nge-sintering?

I-Sintering inemikhawulo nezinselele ezithile.Ukuthola ukuminyana okufanayo kuyo yonke into kungaba inselele, njengoba ukushisisa okungalingani noma ukusatshalaliswa kwezinhlayiyana kungase kubangele amaphutha.Ukulawula ukukhula okusanhlamvu nokuvimbela ukushwabana ngokweqile ngesikhathi sokucwilisa nakho kubalulekile.Ukwengeza, akuzona zonke izinto ezilungele ukucwiliswa ngenxa yokuncibilika kwazo okuphezulu noma ukuphinda kusebenze nomkhathi ozungezile.

Yiziphi izinhlobo ezahlukene zezindlela zokucula?

Kunezinhlobo ezahlukene zamasu okucula, okuhlanganisa i-solid-state sintering, i-liquid-phase sintering, i-sintering evuliwe, i-microwave sintering, i-sintering-assisted sintering, kanye namasu akhethekile afana ne-selective laser sintering (SLS) kanye ne-electron beam sintering (EBS).Inqubo ngayinye inezindlela zayo ezihlukile futhi ikhethwa ngokusekelwe ezidingweni ezithile zezinto kanye nokusetshenziswa kwayo.

I-sintering ithuthukisa kanjani izakhiwo zezinto zokwakha?

I-Sintering ithuthukisa izakhiwo zezinto ngokukhuthaza ukuhlangana kwezinhlayiyana nokuminyana.Phakathi nenqubo ye-sintering, izinhlayiya zithola ukusabalalisa, okuholela ekwakhekeni kwentamo kanye nokukhula kwabantu.Lokhu kubangela izici ezithuthukisiwe zemishini ezifana namandla, ubulukhuni, nokumelana nokugqoka.Ukwengeza, i-sintering ingaholela ekuthuthukisweni kwezakhiwo zikagesi, ezishisayo, namakhemikhali ngokuya ngezinto kanye nokwakheka kwayo.

Ingabe izingxenye ze-sintered zingenziwa ngomshini noma ziphinde zicutshungulwe?

Yebo, izingxenye ze-sintered zingacutshungulwa okwengeziwe noma ukwenziwa ngomshini, uma kudingeka.Ngenkathi i-sintering ingafinyelela izingxenye eziseduze-net-shape, kungase kube nezimo lapho ukucutshungulwa okwengeziwe noma ukucubungula ngemva kokucubungula kuyadingeka ukuze kuzuzwe ukucaciswa okufunayo.Izinqubo zokucupha ezifana nokugaya, ukubhola, noma ukugaya kungasetshenziswa ukuze kuzuzwe ubukhulu bokugcina noma ukuphela kwendawo.

Yiziphi izinto ezicatshangelwayo zemvelo ze-sintering?

I-Sintering ngokuvamile ibhekwa njengenqubo yokukhiqiza evumelana nemvelo.Idla amandla amancane uma iqhathaniswa nezindlela zokuncibilika nezindlela zokuphonsa, futhi inciphisa udoti wezinto ezibonakalayo ngokuvumela ukusetshenziswa kabusha kwezimpushana ezeqile.Kodwa-ke, kubalulekile ukucabangela umthelela wemvelo wezinto ezingavuthiwe ezisetshenziswayo, kanye nokuphathwa ngendlela efanele nokulahlwa kwanoma yimiphi imikhiqizo noma udoti okhiqizwa phakathi nenqubo.

I-sintering inegalelo kanjani ekuthuthukisweni kwezinto ezithuthukisiwe?

I-Sintering idlala indima ebalulekile ekuthuthukisweni kwezinto ezithuthukisiwe.Ngokukhetha ngokucophelela nokulawula ukwakheka, usayizi wezinhlayiyana, kanye nemingcele ye-sintering, kungenzeka ukuhlanganisa izakhiwo zezinto eziwumphumela.Lokhu kuvumela ukudalwa kwezinto ezithuthukisiwe ezinezici ezithile, njengama-alloys asebenza kakhulu, izitsha zobumba ezisebenzayo, noma izinto eziyinhlanganisela ezinenhlanganisela eyingqayizivele yezakhiwo.

Uma uneminye imibuzo noma ungathanda ukuthintana nayeHENGKO,

sicela ukhululeke ukuxhumana nathi nge-imeyili kuka@hengko.com.

Singajabula ukukusiza futhi sikunikeze noma yiluphi ulwazi olwengeziwe ongase uludinge.

Isikhathi sokuthumela: Aug-14-2020