Sawubona, abathanda isikhumba!Namuhla, singena esihlokweni sosayizi wezimbotshana, nokuthi kungani kubaluleke kangaka ukuqonda.Kungenzeka ukuthi uke wezwa ngama-pores ngaphambili, kodwa uyazi ngempela ukuthi kungani usayizi we-pore ubaluleke kangaka?Qhubeka ufunda ukuze uthole!

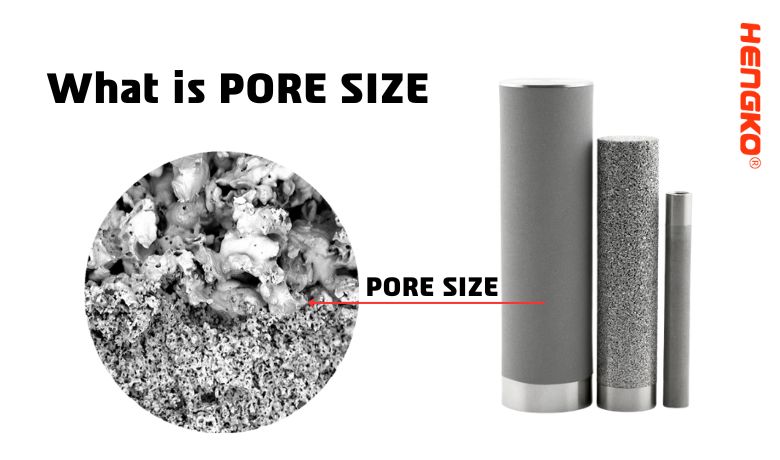

Ayini ama-pores?

Ngomongo wezakhi zokuhlunga, izimbotshana ziyizimbobo ezincane noma iziteshi ngaphakathi kwento yokuhlunga evumela ukudlula koketshezi noma amagesi ngenkathi ibamba izinhlayiya eziqinile noma ukungcola.

Izakhi zokuhlunga ziklanyelwe ukususa ukungcola nokungcola emanzini noma amagesi, futhi ukusebenza kahle kwesihlungi kunqunywa ingxenye enkulu ngosayizi nokusatshalaliswa kwama-pores ngaphakathi kwendawo yokuhlunga.

Usayizi wezimbotshana uvame ukukalwa ngama-microns, osayizi bembotshana abancane abakhombisa ikhono elikhulu lokuhlunga izinhlayiya ezincane.Kodwa-ke, isihlungi esinosayizi abancane kakhulu bezimbotshana singase sibe nezinga lokugeleza eliphansi, okungaba nomthelela ekusebenzeni kwaso kukonke.

Izinhlobo ezihlukene zezinto zokuhlunga zingasebenzisa izinto ezihlukahlukene kanye nezakhiwo zezimbotshana ukuze kuzuzwe imigomo ethile yokuhlunga, njengokususa izinhlayiya zosayizi othile noma ukuhlukanisa izinhlobo ezahlukene zoketshezi.Izinto zokuhlunga ezijwayelekile zifaka i-cellulose, i-polypropylene, nezinhlobo ezahlukene zolwelwesi noma i-mesh.

Uyini usayizi wezimbotshana?

Manje njengoba sesiyazi ukuthi ama-pores ayini, ake sikhulume ngobukhulu bawo.Usayizi we-Pore ubhekisela kububanzi bembobo esikhumbeni.Izimbotshana zingahluka ngosayizi ukusuka ngaphansi kwama-micrometer angu-0.2 ukuya ngaphezu kwamamilimitha angu-0.5.Ibanga impela lelo!Ubukhulu bezimbotshana bungalinganiswa kusetshenziswa umshini okhethekile obizwa ngokuthi i-poreometer, esebenzisa ikhamera nesofthiwe ukuhlaziya ubuso besikhumba.

Kungani usayizi wembobo ubalulekile ohlelweni lokuhlunga lwemboni?

Ubukhulu bembotshana buwukucatshangelwa okubalulekile kwezinhlelo zokuhlunga embonini ngoba inquma ukuthi yiziphi izinhlobo zezinhlayiya nokungcola okungasuswa ngokuphumelelayo oketshezini noma umfudlana wegesi.Ubukhulu bezimbotshana kusihlungi bunquma ubukhulu bezinhlayiya ezingadlula kuso.

Uma usayizi wembotshana mkhulu kakhulu, izinhlayiya nokungcola kungase kudlule kusihlungi futhi kuhlale kumkhiqizo wokugcina.Ngokuphambene, uma usayizi wembotshana umncane kakhulu, isihlungi singavaleka noma sonakale ngokushesha kakhulu, sinciphise ukusebenza kwaso futhi sidinge ukunakekelwa okuphindaphindiwe noma ukushintshwa.

Ngakho-ke, ukukhetha usayizi wembotshana ofanele wesistimu yokuhlunga kubalulekile ekuqinisekiseni ukuthi izinga elifiswayo lokuhlanzeka nokuhlanzeka liyafinyelelwa emkhiqizweni wokugcina.Ubukhulu bembotshana kufanele bukhethwe ngokusekelwe ekusetshenzisweni okuqondile, kucatshangelwa ubukhulu nohlobo lwezinhlayiya ezizokhishwa, izinga lokugeleza koketshezi noma igesi, nezinye izici ezifanele.

Ngakho-ke, embonini eminingi, isistimu yokuhlunga ekhethekile, iningi liyizici ezidingayo ezinosayizi wembotshana ohlukile, bese isisiza ukuthi sihlunge ukungcola okuthile ezintweni zethu.

Ungawenza kanjani usayizi we-OEM pore wezinto zokuhlunga ezinama-porous?

I-OEM (Umkhiqizi Wezinto Zoqobo) usayizi wembotshana wezakhi zokuhlunga ezimbotshana ngokuvamile uhilela ukwenza ngendlela oyifisayo usayizi wembotshana yesihlungi ukuze uhlangabezane nezidingo ezithile zohlelo lokusebenza noma imboni ethile.Izinyathelo ezilandelayo zingathathwa kusayizi wembotshana we-OEM wezinto zokuhlunga ezimbotshana:

Nquma izidingo ezithile:

Isinyathelo sokuqala kusayizi wembotshana ye-OEM yezinto zokuhlunga ezimbotshana ukunquma izimfuneko ezithile zohlelo lokusebenza, okuhlanganisa usayizi nohlobo lwezinhlayiya ezizokhishwa, izinga lokugeleza, kanye nanoma yiziphi ezinye izici ezifanele.

Khetha okokusebenza okufanele:

Izinto ezisetshenziselwa ukudala into yokuhlunga zingaba nomthelela kusayizi wayo wembotshana.Khetha into engenziwa ngokwezifiso ukuze kuzuzwe usayizi wembotshana oyifunayo.

Enza ngendlela oyifisayo inqubo yokukhiqiza:

Ngokuya ngenqubo yokukhiqiza esetshenzisiwe, usayizi wembotshana wesici sokuhlunga ungenziwa ngendlela oyifisayo.Abakhiqizi bangase basebenzise amasu ahlukene afana nokucwiliswa, ukucwiliswa, noma ukufaka umhwamuko wamakhemikhali ukuze kuzuzwe usayizi wembotshana oyifunayo.

Hlola into yokuhlunga:

Uma isici sokuhlunga senziwe ngendlela oyifisayo ukuze kufinyelele usayizi wembotshana oyifunayo, kufanele ihlolwe ukuze kuqinisekiswe ukuthi ihlangabezana nokucaciswa okudingekayo.Lokhu kungase kuhlanganise ukuhlola ukusebenza kahle kokususwa kwezinhlayiyana, ukwehla kwengcindezi, nezinye izici.

Lungiselela usayizi wembotshana:

Ngokusekelwe emiphumeleni yokuhlola, usayizi wembotshana ungase udinge ukuthuthukiswa okwengeziwe ukuze kufinyelelwe izinga elifiswayo lokuhlunga kahle nezinga lokugeleza.

Sekukonke, usayizi wembotshana we-OEM wezinto zokuhlunga ezimbotshana zidinga ukucatshangelwa ngokucophelela kwezinhlelo ezithile zohlelo lokusebenza nezinqubo zokukhiqiza ukuze kuzuzwe izinga elifiswayo lokusebenza kahle kokuhlunga kanye nokusebenza komkhiqizo.Kubalulekile ukusebenza nomkhiqizi ohloniphekile onobuchwepheshe bokukhiqiza izinto zokuhlunga ngokwezifiso ukuze uqinisekise imiphumela engcono kakhulu.

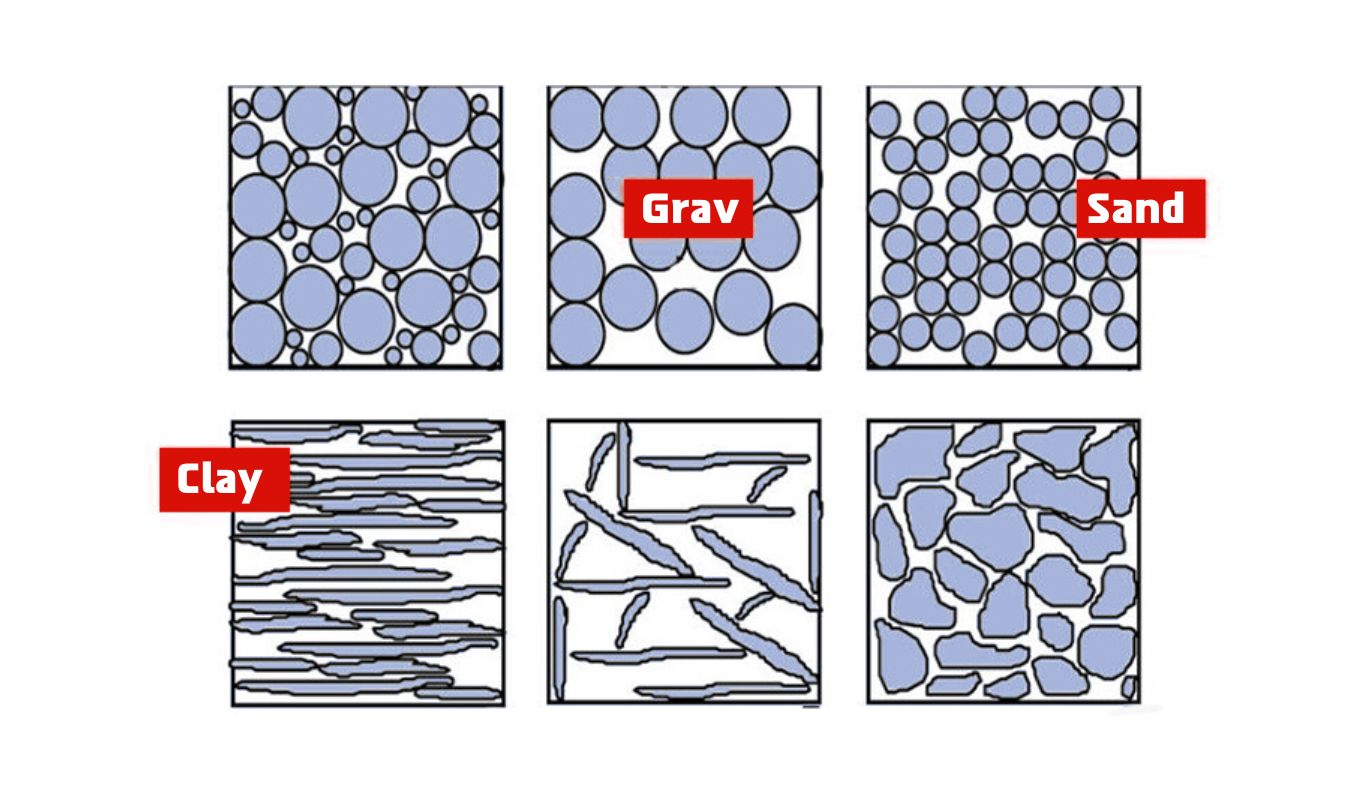

hlobo luni lomumo wembotshana olungcono lokuhlunga?

Umumo wembotshana osebenza kahle kakhulu wesihlungi uncike ohlelweni oluthile kanye nezinhlayiya ezihlungwayo.Ngokuvamile, ukuma kwezimbotshana kufanele kukwazi ukubamba kahle futhi kugcine izinhlayiya kuyilapho kuvumela ukugeleza okwanele koketshezi noma igesi.

Isibonelo, ezinhlelweni zokusebenza ze-microfiltration lapho inhloso kuwukukhipha izinhlayiya ezinkulu kuno-0.1 microns, ama-asymmetric pore pores afana nama-tapered noma ama-conical pores asebenza kangcono ngoba angakha indlela ehlukumezayo ekhulisa ithuba lokubanjwa kwezinhlayiyana.

Ngakolunye uhlangothi, ezinhlelweni zokusebenza ze-nanofiltration lapho umgomo uwukukhipha izinhlayiya ezincane kune-microns engu-0.001, ama-pores angama-cylindrical noma aqondile asebenza kangcono ngoba avumela izinga lokugeleza eliphakeme kanye nokuqoqwa kwezinhlayiyana ezincane.

Ekugcineni, umumo wembotshana osebenza kahle kakhulu uzoncika ezidingweni ezithile zohlelo lokuhlunga kanye nosayizi nohlobo lwezinhlayiya ezihlungwayo.

I-Porous Metal Filter Ingcono noma Izihlungi ze-PE ?

Ukuthi isihlungi sensimbi esinezimbotshana noma isihlungi se-PE (i-polyethylene) singcono kuya ngezidingo ezithile zohlelo lokusebenza kanye nezakhiwo zezinto ezihlungwayo.Nazi ezinye izici ezibalulekile okufanele uzicabangele lapho ukhetha phakathi kwezihlungi zensimbi ezinama-porous nezihlungi ze-PE:

Ukuhambisana kwamakhemikhali:

Izihlungi zensimbi ezinezimbobo ngokuvamile zimelana kakhulu namakhemikhali kunezihlungi ze-PE, okuzenza zifaneleke kangcono ukuhlunga amakhemikhali anolaka noma adlayo.Kodwa-ke, izihlungi ze-PE zingenziwa ngamamaki ahlukahlukene e-polyethylene ukuthuthukisa ukuhambisana kwazo kwamakhemikhali.

Ukumelana nezinga lokushisa:

Izihlungi zensimbi ezinezimbotshana zingamelana namazinga okushisa aphakeme kangcono kunezihlungi ze-PE, ezingase zithambe noma zonakale emazingeni okushisa aphakeme.Lokhu kwenza izihlungi zensimbi ezinezimbotshana zibe ukukhetha okungcono ezinhlelweni ezifaka uketshezi olunezinga lokushisa eliphezulu noma amagesi.

Amandla omshini:

Izihlungi zensimbi ezinezimbotshana ngokuvamile zinamandla futhi zihlala isikhathi eside kunezihlungi ze-PE, zizenza zifaneleke kangcono izinhlelo zokusebenza ezidinga ukuhlungwa komfutho ophezulu noma ukuhlungwa kwezinto ezihuquzelayo.

Ukusebenza kahle kokuhlunga:

Izihlungi ze-PE zingaba nokusebenza kahle okuphezulu kokuhlunga kwezinhlelo zokusebenza ezithile, njengoba zingenziwa ngosayizi abancane bezimbotshana kunezihlungi zensimbi ezinezimbotshana.Nokho, izihlungi zensimbi ezinezimbotshana zingenziwa ngendlela oyifisayo ukuze zibe nosayizi abathile bembotshana namajiyometri ukuze kuzuzwe ukusebenza kahle kokuhlunga okufunayo.

Izindleko:

Izihlungi zensimbi ezinezimbobo ngokuvamile zibiza kakhulu kunezihlungi ze-PE, ikakhulukazi kumadizayini ngokwezifiso noma ukukhiqiza okuncane.Izihlungi ze-PE, ngakolunye uhlangothi, zibiza kakhulu futhi zitholakala kabanzi.

Kafushane, zombili izihlungi zensimbi ezinezimbotshana nezihlungi ze-PE zinezinzuzo kanye nokubi kwazo kuye ngezidingo ezithile zohlelo lokusebenza.Kubalulekile ukucabangela ngokucophelela ukuhambisana kwamakhemikhali, ukumelana nezinga lokushisa, amandla emishini, ukusebenza kahle kokuhlunga, kanye nezindleko lapho ukhetha phakathi kwalokhu kokubili.

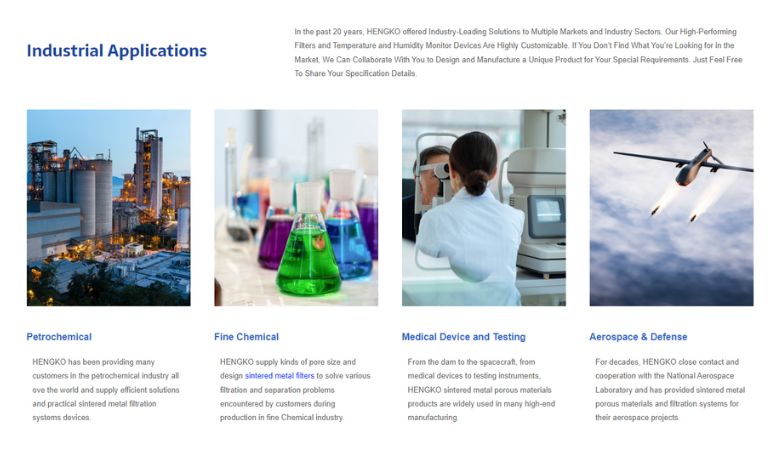

Ukusetshenziswa kwezihlungi ezinama-porous ? Izihlungi ze-Metal Sintered ?

Izihlungi ze-Porous zisetshenziswa ezinhlobonhlobo zezinhlelo zokusebenza lapho uketshezi noma igesi idinga ukuhlungwa ukuze kukhishwe ukungcola noma izinhlayiya.Nazi ezinye izinhlelo zokusebenza ezivamile zezihlungi ezinama-porous:

Ukwelashwa kwamanzi:

Izihlungi ezinama-porous zivame ukusetshenziswa ezinhlelweni zokuhlanza amanzi ukuze kukhishwe ukungcola okufana nenhlabathi, amagciwane, namagciwane.Angasetshenziswa ezilungiselelweni ezihlukahlukene ezihlanganisa izindawo zokuhlanza amanzi zikamasipala, amasistimu okuhlunga amanzi asezindaweni zokuhlala, kanye nemishini yokuhlunga indawo yokusetshenziswa.

Ukucutshungulwa kwamakhemikhali: Izihlungi ezinembobo zisetshenziswa ezinhlelweni zokucubungula amakhemikhali ukuze zisuse ukungcola noma ukungcola oketshezini namagesi.Lokhu kufaka phakathi izinhlelo zokusebenza ezifana nokuhlunga kwe-solvent, ukutholwa kwe-catalyst, nokuhlanzwa kwegesi.

Ukudla nesiphuzo:

Izihlungi ezinama-porous zisetshenziswa embonini yokudla neziphuzo ukuze kukhishwe ukungcola, amagciwane, nokunye ukungcola oketshezini olunjengamajusi, ubhiya, newayini.

I-pharmaceutical and biotechnology: Izihlungi ezinama-porous zisetshenziswa embonini yezemithi kanye ne-biotechnology ukuvala inzalo uketshezi namagesi, ukuhlunga izinhlayiya, nokuhlukanisa amaprotheni namanye ama-biomolecules.

Izimoto kanye ne-aerospace:

Izihlungi ezinama-porous zisetshenziswa embonini yezimoto kanye ne-aerospace ezinhlelweni ezifana nezihlungi zokungenisa umoya wenjini kanye nezihlungi zomoya ze-cabin.

Izihlungi ze-Metal sintered ziwuhlobo oluthile lwesihlungi esinezimbotshana esenziwe ngempushana yensimbi eye yashiswa (yashisisa futhi yacindezelwa) ukuze kwakhiwe into eqinile enezimbotshana ezixhumene.Nazi ezinye izinhlelo zokusebenza ezivamile zezihlungi ze-metal sintered:

Uwoyela negesi:

Izihlungi ze-Metal sintered zivame ukusetshenziswa embonini kawoyela negesi ukususa ukungcola nokungcola oketshezini olufana nowoyela ongahluziwe, igesi yemvelo, noketshezi olusebenza ngamanzi.

I-Aerospace:

Izihlungi ze-Metal sintered zisetshenziswa ezinhlelweni ze-aerospace ezifana nokuhlunga uphethiloli, ukuhlungwa kwesistimu ye-hydraulic, nokuhlunga komoya.

Imishini yezokwelapha: Izihlungi ze-metal sintered zisetshenziswa emishinini yezokwelapha njengama-ventilators nezigxilisa komoyampilo ukuze kuhlungwe izinhlayiya namagciwane.

Ukuhlunga kwezimboni: Izihlungi ze-Metal sintered zisetshenziswa ezinhlelweni ezahlukahlukene zokuhlunga ezimbonini ezinjengokuhlanza amanzi, ukucutshungulwa kwamakhemikhali, nokuhlanza amanzi angcolile.

Ezezimoto:

Izihlungi ze-Metal sintered zisetshenziswa ezinhlelweni zezimoto ezifana nokuhlunga uphethiloli kanye nokuhlunga uwoyela.

Ngakho-ke ngosayizi wezimbotshana owaziwa abantu abaningi ngokwengeziwe kanye nesistimu yokuhlunga eyengeziwe sebenzisa izihlungi zensimbi ezihlanganisiwe ngenxa yesakhiwo esingcono sosayizi wembotshana.

Yazi imininingwane eyengeziwe mayelana nosayizi wembotshana, sicela ukhululeke ukusithinta nge-imeyilika@hengko.com, sizoyithumela phakathi namahora angu-48.

Isikhathi sokuthumela: Mar-02-2023