Imicu, ama- spiral ayinkimbinkimbi atholakala kumabhawodi, ezikulufini, nangaphakathi kwamantongomane, ayinkimbinkimbi kakhulu kunalokho abonakala.Ziyahlukahluka ngomklamo, usayizi, kanye nokusebenza, zibumba indlela izingxenye ezihlangana ngayo kuyo yonke into kusukela emishinini elula kuya kumasistimu onjiniyela athuthukile.Kulo mhlahlandlela, sihlola izinto eziyisisekelo zokuklama intambo, sihlola izici ezibalulekile ezihlukanisa intambo komunye.Kusukela ebulilini bezintambo kuye ekunikezeni kwazo, futhi kusukela ekuphakameni kwazo kuye kububanzi bazo, sidalula izici ezibalulekile ezenza izintambo zibe isimangaliso sobunjiniyela esibalulekile kodwa esivame ukunganakwa.

Bheka imininingwane njengokulandelayo njengoba sembula umhlaba oyinkimbinkimbi wochungechunge, sikunikeza ukuqonda okuyisisekelo okubalulekile kukho kokubili imfundamakhwela enelukuluku nochwepheshe.

Eminye imigomo ebalulekile yochungechunge

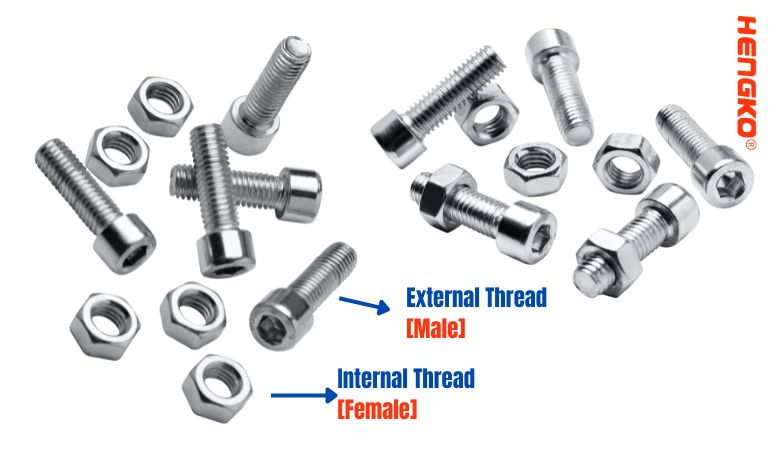

Ukusebenzisa amagama aphathelene nobulili kungaqhubeza inkolelo evamile eyingozi futhi kube nomthelela esikweni lokungabandakanywa.Ngokusebenzisa amagama angathathi hlangothi afana nochungechunge "lwangaphandle" kanye "nolwangaphakathi", singabandakanya kakhulu futhi sigweme ukuchema okungahlosiwe.

* Ukunemba:Isifaniso siqhubekela phambili lapho kucutshungulwa amafomu kanye nezicelo zentambo okungezona kanambambili.

Kubalulekile ukuthi unembe futhi ubandakanye olimini lobuchwepheshe.

* Ezinye izindlela:Sekunamagama ezobuchwepheshe acacile futhi amiswe kahle ezici zochungechunge:

* Imicu yangaphandle:Imicu engaphandle kwengxenye.

* Imicu yangaphakathi:Imicu engaphakathi kwengxenye.

* Ububanzi obukhulu:Ububanzi obukhulu bomucu.

* Ububanzi obuncane:Ububanzi obuncane bochungechunge.

* Iphimbo:Ibanga phakathi kwamaphoyinti amabili ahambelanayo emicu eseduze.

Ukusebenzisa la magama kunikeza ulwazi olunembile nolucacile ngaphandle kokuncika ekufaniseni okungase kube yingozi.

Imicu isetshenziswa ekuhlanganiseni kokuhlunga

Izihlungi ze-Sintered zisetshenziswa kabanzi ezimbonini ezahlukahlukene ngezinhloso zokuhlunga.Zenziwa ngokuhlanganisa izimpushana zensimbi ndawonye ngenqubo yokwelapha ukushisa ebizwa ngokuthi i-sintering.Lokhu kwakha isakhiwo esiqinile, esinezimbotshana esingasefa kahle izinhlayiya kuketshezi noma amagesi.

Imicu ivame ukusetshenziswa ekuhlanganiseni kwesihlungi ukuxhuma izingxenye ezihlukene ndawonye.Nazi ezinye izibonelo ezithize zokuthi imicu isetshenziswa kanjani kuma-sintered filter assemblies:

* Hlunga i-cartridge end caps:

Amakhatriji amaningi okuhlunga ane-sintered anezintambo zokuphela eziwavumela ukuthi afakwe ngezikulufu ezindlini zokuhlunga.

Lokhu kudala uphawu oluvikelekile futhi kuvimbele ukuvuza.

* Hlunga ukuxhumana kwezindlu:

Izindlu zokuhlunga zivame ukuba nezimbobo ezinentambo ezivumela ukuthi zixhunywe kumapayipi noma ezinye izinto zokusebenza.

Lokhu kuvumela ukufakwa kalula nokususwa komhlangano wokuhlunga.

* Izihlungi zangaphambili:

Ezinye izihlungi ezihlanganisayo zisebenzisa izihlungi zangaphambili ukuze zisuse izinhlayiya ezinkulu ngaphambi kokuba zifinyelele isihlungi esine-sintered.

Lezi zihlungi zangaphambili zingase zigoqwe endaweni kusetshenziswa imicu.

* Izimbobo zokudonsa amanzi:

Ezinye izindlu zokuhlunga zinezimbobo zokudonsa amanzi ezivumela ukukhishwa koketshezi oluqoqiwe noma amagesi.

Uhlobo oluthile lwentambo esetshenziswa ekuhlanganiseni kwesihlungi kuzoncika kuhlelo lokusebenza kanye nosayizi wesihlungi.Izinhlobo zochungechunge olujwayelekile zifaka i-NPT, i-BSP, ne-Metric.

Ngaphezu kwezibonelo ezingenhla, imicu ingase isetshenziselwe ezinye izinjongo emibuthanweni yesihlungi esine-sintered, njengale:

* Ukunamathisela izinzwa noma amageji

* Abakaki okufakwayo

* Ukuvikela izingxenye zangaphakathi

Sekukonke, uchungechunge ludlala indima ebalulekile ekuqinisekiseni umsebenzi ofanele kanye nokusebenza kokuhlanganiswa kwesihlungi se-sintered.

Ekugcineni, ukukhetha kwamatemu kukuwe.

Nokho, ngiyakukhuthaza ukuthi ucabangele umthelela ongaba khona wokusebenzisa ulimi lobulili kanye nezinzuzo zokusebenzisa ezinye izindlela ezingathathi hlangothi nezibandakanyayo.

Ukuphathwa Kwezintambo

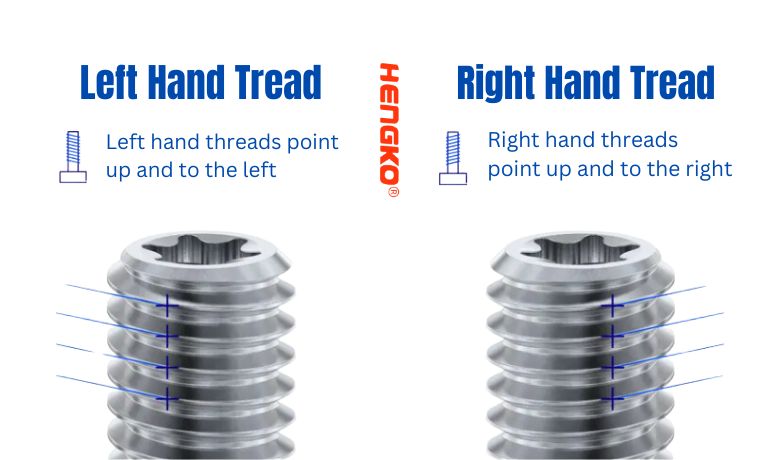

Kungani imicu engakwesokudla ivame kakhulu?

* Asikho isizathu esiqondile somlando, kodwa eminye imibono iphakamisa ukuthi kungase kube ngenxa yokuchema okungokwemvelo kwabantu abaningi abasebenzisa isandla sokudla, okwenza kube lula ukuqiniswa nokuxegisa imicu engakwesokudla ngesandla sabo esibusayo.

* Imicu yesandla sokudla nayo ijwayele ukuziqinisa uma ingaphansi kwamandla ajikelezayo endaweni efanayo nokuqiniswa (isb, ibhawudi esondweni elijikelezayo).

Izinhlelo zokusebenza zochungechunge olungakwesokunxele:

Njengoba ushilo, izintambo ezingakwesokunxele zivame ukusetshenziswa ezimeni lapho ukuxega ngenxa yokudlidliza noma amandla okuzungezisa kuwukukhathazeka,

njengokuthi: Ziphinde zisetshenziswe kumathuluzi athile namathuluzi lapho kudingeka khona ukuzungeza okuhlukile ukuze kusebenze.

* Amabhodlela egesi: Ukuvimbela ukuvuleka ngengozi ngenxa yokucindezela kwangaphandle.

* Amabhayisikili e-Pedal: Ohlangothini lwesobunxele ukuwavimbela ukuthi angaxegi ngenxa yokuzungezisa phambili kwesondo.

* Ukugxambukela kuyalingana: Ukudala ukulingana okuqinile, okuvikeleke kakhulu okumelana nokuhlakazwa.

Ukuhlonza ukuphathwa kochungechunge:

* Ngezinye izikhathi isiqondiso sentambo imakwa ngokuqondile kusixhumi (isb, "LH" yesandla sobunxele).

* Ukubuka i-engeli yezintambo ukusuka ohlangothini nakho kungaveza isiqondiso:

1.Izintambo zesandla sokudla zehlela phezulu kwesokudla (njengesikulufu esikhuphukayo).

2. Izintambo zesandla sokunxele zehlela phezulu kwesokunxele.

Ukubaluleka kokunikezwa ngesandla kuzihlungi ze-sintered kanye nokusetshenziswa okuvamile.

Ukuphatha isandla, kubhekiselwa kuhlangothi lokuzungezisa intambo (ngokuhamba kwewashi noma ngokuphambene newashi), kubalulekile ngempela ezinhlelweni zokuhlunga ezifakwe i-sintered ngezizathu ezimbalwa:

Ukuvalwa Kokuvalwa Nokuvuza:

* Ukuqiniswa kanye Nokuxegisa: Ukuphatha kahle ngesandla kuqinisekisa ukuthi izingxenye ziqina ngokuphephile lapho zijikiswa lapho kuhloswe khona futhi zixege kalula lapho kudingeka.Izintambo ezingafani zingaholela ekuqiniseni ngokweqile, kulimaze isihlungi noma izindlu, noma ukuqiniswa okungaphelele, okubangela ukuvuza.

* Ukugawula nokubamba: Ukuqondiswa kwentambo okungalungile kungadala ukungqubuzana nokubanda, kwenze izingxenye zibe nzima noma kungenzeki ukuzihlukanisa.Lokhu kungaba yinkinga ikakhulukazi ngesikhathi sokulungiswa noma ukushintshwa kwesihlungi.

Ukumisa nokuhambisana:

- Ukushintshelana: Ukunikezwa kwentambo okujwayelekile kuvumela ukushintshwa kalula kwezinto zokuhlunga noma izindlu ezinezingxenye ezihambisanayo, kungakhathaliseki ukuthi yimuphi umkhiqizi.Lokhu kwenza ukulungiswa kube lula futhi kunciphisa izindleko.

- Imithetho Yemboni: Izimboni eziningi zinemithetho ethile ephathelene nokunikezwa kwentambo ezinhlelweni zokuphatha uketshezi ngenxa yezizathu zokuphepha nokusebenza.Ukusebenzisa imicu engahambisani nakho kungaphula imithetho futhi kuholele ezingozini zokuphepha.

Ukusetshenziswa Okuvamile kanye Nesandla:

- I-Filter Cartridge End Caps: Ngokuvamile sebenzisa imicu esesandleni sokudla (ngokwewashi ukuze uqinise) ukuze uthole okunamathiselwe okuvikelekile ekuhlungeni izindlu.

- Hlunga Ukuxhumana Kwezindlu: Ngokuvamile landela izindinganiso zomkhakha, ezivame ukucacisa imicu esesandleni sokudla yokuxhunywa kwamapayipi.

- Izihlungi zangaphambili: Zingase zisebenzise imicu yesokudla noma yesokunxele kuye ngedizayini ethile kanye nendawo ehlosiwe yokugeleza koketshezi.

- Izimbobo zokudonsa amanzi: Ngokuvamile zinezintambo ezingakwesokudla ukuze zivuleke kalula futhi zivale ukuze zikhiphe uketshezi.

Sethemba ukuthi lolu lwazi lungakusiza ukuthi uqonde imininingwane yokunikezwa kwentambo!

I-thread Design

Kokubili imicu ehambisanayo kanye ne-tapered idlala indima ebalulekile ezinhlelweni ezihlukene, ngayinye inezinzuzo zayo kanye nokusetshenziswa kwayo.Ukwengeza ukujula okwengeziwe encazelweni yakho, nanka amaphuzu ongase uwacabange:

1. Izindlela Zokuvala:

* Izintambo ezihambisanayo:

Ngokuvamile zithembela kuma-seal angaphandle njengama-gaskets noma ama-O-rings ukuze kuxhunywe okungavuzi.

Lokhu kuvumela ukuhlanganisa okuphindaphindiwe nokuhlakazwa ngaphandle kokulimaza izintambo.

* Imicu eqoshiwe:

Bakha uxhumo oluqinile, oluzivalayo ngenxa yesenzo sokushadisa njengoba beboshiwe.

Lokhu kubenza balungele izinhlelo zokusebenza ezinomfutho ophezulu njengamapayipi nokufakwa.

Kodwa-ke, ukuqinisa ngokweqile kungalimaza izintambo noma kube nzima ukuzisusa.

2. Amazinga Ajwayelekile:

* Izintambo ezihambisanayo:

Lokhu kufaka phakathi amazinga afana ne-Unified Thread Standard (UTS) kanye nemicu ye-Metric ISO.

Zivamile ezinhlelweni ezijwayelekile ezifana namabhawudi, izikulufu, namantongomane.

* Imicu eqoshiwe:

I-National Pipe Thread (NPT) kanye ne-British Standard Pipe Thread (BSPT)

asetshenziswa kakhulu kumapayipi kanye nezinhlelo zamandla eziwuketshezi.

Izicelo:

* Izintambo Ezihambisanayo: Isetshenziswa ekuhlanganiseni ifenisha, izinto zikagesi, imishini, nezinye izinhlelo zokusebenza ezihlukahlukene lapho kudingeka khona ukuqaqa kanye nezigxivizo ezihlanzekile.

* Imicu Eqoshiwe: Ilungele amapayipi, ama-hydraulics, amasistimu womoya, nanoma yiluphi uhlelo lokusebenza oludinga uxhumano olungavuzi ngaphansi kwengcindezi noma ukudlidliza.

Amanothi engeziwe:

* Amanye amazinga entambo afana ne-BSPP (British Standard Pipe Parallel) ahlanganisa ifomu elihambisanayo nendandatho yokuvala ukuze kuxhunywe okungavuzi.

* Ukuphakama kwentambo (ibanga phakathi kwemicu) nokujula kwentambo nakho kudlala indima ebalulekile kumandla wentambo nokusebenza.

Ukuhambisana kohlobo ngalunye lwedizayini yochungechunge kuzihlungi zensimbi ezine-sintered.

Nakuba idizayini yochungechunge ngokwayo ingeyona imvelo ohlotsheni lwesihlungi, idlala indima ebalulekile ekusebenzeni nasekusebenzeni kokuhlanganiswa kwesihlungi sensimbi.Nansi indlela imiklamo ehlukene yochungechunge oluthinta ngayo izihlungi zensimbi ezi-sintered:

Imiklamo Yochungechunge Olujwayelekile:

* I-NPT (Uchungechunge Lwepayipi Kazwelonke): Isetshenziswa kakhulu eNyakatho Melika ekusetshenzisweni kwamapayipi okuvamile.Inikeza ukuvala okuhle futhi itholakala kalula.

* I-BSP (i-British Standard Pipe): Ivamile e-Europe nase-Asia, efana ne-NPT kodwa enomehluko omncane we-dimensional.Kubalulekile ukufanisa izindinganiso zokulingana okufanele.

* Imicu Yemethrikhi: Ilinganiswe emhlabeni wonke, inikezela ngezinketho ezibanzi zokuhlanganisa intambo ngezidingo ezithile.

* Eminye Imicu Ekhethekile: Ngokuya ngohlelo lokusebenza, imiklamo yochungechunge ekhethekile efana ne-SAE (Society of Automotive Engineers) noma i-JIS (Amazinga Ezimboni ZaseJapane) angasetshenziswa.

Ukuhambisana Kwedizayini Yochungechunge:

* Ukuvalwa Nokuvimbela Ukuvuza: Idizayini efanele yentambo iqinisekisa ukuxhumana okuqinile, ivimbela ukuvuza nokugcina ubuqotho bokuhlunga.Imicu engafani ingabangela ukuvuza, okonakalise ukusebenza futhi okungase kuholele ezingozini zokuphepha.

* I-Assembly kanye ne-Disassembly: Imiklamo ehlukene yentambo inikeza kalula ukuhlanganisa nokuqaqa.Izinto ezifana ne-thread pitch kanye nezidingo zokugcoba zidinga ukucatshangelwa ukuze zilungiswe kahle.

* Ukumiswa kanye Nokuhambisana: Imicu efana ne-NPT noma i-Metric iqinisekisa ukuhambisana nezindlu zokuhlunga ezijwayelekile kanye nezinhlelo zamapayipi.Ukusebenzisa uchungechunge olungajwayelekile kungadala izinkinga zokusebenzisana futhi kufake inkimbi ukumiselela.

* Amandla Nokuphatha Ingcindezi: Idizayini yochungechunge ithonya amandla nekhono lokusingatha ingcindezi ekuhlanganiseni kwesihlungi.Izinhlelo zokusebenza ezinengcindezi ephezulu zingase zidinge izinhlobo ezithile zentambo ngokuzibandakanya okujulile ukuze kusatshalaliswe kangcono umthwalo.

Ukukhetha Idizayini Yochungechunge Elungile:

* Izidingo Zohlelo Lokusebenza: Cabangela izici ezifana nokucindezela kokusebenza, izinga lokushisa, ukusebenzisana koketshezi, kanye nemvamisa oyifunayo yokuhlanganisa/yokuqaqa.

* Amazinga Omkhakha: Namathela kumazinga emboni afanelekile kanye nemithethonqubo yesifunda sakho esithile noma isicelo.

* Ukuvumelana: Qinisekisa ukuhambisana okungenamthungo nezindlu zokuhlunga, amasistimu wamapayipi, kanye nezingxenye ezingase zishintshe.

* Ukusebenzisa Kalula: Linganisa isidingo sesigxivizo esivikelekile ngokulungiswa kalula kanye nokushintshwa okungase kube khona esikhathini esizayo.

Khumbula, nakuba idizayini yochungechunge ingaxhumene ngokuqondile nohlobo lwesihlungi sensimbi esine-sintered, isici esibalulekile ekusebenzeni okuphelele nobuqotho bokuhlanganiswa kwesihlungi.Khetha idizayini yentambo efanele ngokusekelwe ezidingweni zakho zohlelo lokusebenza futhi ucabange ukubonisana nochwepheshe bokuhlunga ukuze uthole isiqondiso.

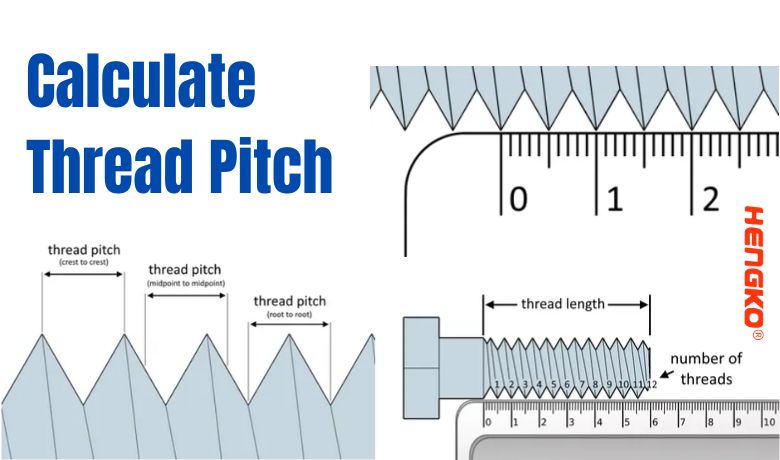

I-pitch kanye ne-TPI

* I-pitch: Ikalwa ngamamilimitha, yibanga ukusuka kwelinye intambo ukuya kwelandelayo.

* I-TPI (Imicu Ngayiyintshi): Isetshenziselwa imicu engusayizi oyintshi, ebonisa inani lemicu iyintshi ngayinye yobude.

Ubudlelwano phakathi kwe-Pitch ne-TPI:

* Bakala into efanayo (ukuminyana kwentambo) kodwa ngamayunithi ahlukene nezinhlelo zokulinganisa.

1. I-TPI iwukuzuzisana kwephimbo: TPI = 1 / Pitch (mm)

2. Ukuguqula phakathi kwabo kuqonde phambili:Ukuguqula i-TPI ibe iphimbo: Iphimbo (mm) = 1 / TPI

Ukuguqula iphimbo libe yi-TPI: TPI = 1 / Pitch (mm)

Umehluko Obalulekile:

* Iyunithi Yokulinganisa: I-pitch isebenzisa amamilimitha (uhlelo lwemethrikhi), kuyilapho i-TPI isebenzisa imicu iyintshi ngayinye (isistimu yombuso).

* Isicelo: I-pitch isetshenziselwa izixhumi zemethrikhi, kuyilapho i-TPI isetshenziselwa izixhumi ezisekelwe ngamayintshi.

Ukuqonda Ukuminyana Kwentambo:

* Kokubili iphimbo kanye ne-TPI kukutshela ukuthi imicu iqine kangakanani kusixhumi.

* Iphimbo eliphansi noma i-TPI ephezulu isho imicu eminingi ngobude beyunithi ngayinye, okuholela kuchungechunge olungcono.

* Imicu emihle ngokuvamile ihlinzeka:

1. Ukumelana okuqinile nokuxegiswa ngenxa yokudlidliza noma i-torque.

2. Ikhono lokuvala elithuthukisiwe uma lisetshenziswa nezixhumi ezifanele.

3. Ukulimala okuncane emiculweni yokuhlangana ngesikhathi sokuhlanganisa nokuqaqa

Kodwa-ke, imicu emincane ingase futhi:

* Yiba sengozini yokuphambana noma ukukhumula uma kungaqondanisiwe kahle.

* Kudinga amandla engeziwe ukuze uqinise futhi uxege.

Ukukhetha Ukuminyana Kwentambo Elungile:

* Uhlelo lokusebenza oluthile kanye nezidingo zalo zinquma iphimbo elilungile noma i-TPI.

* Izinto ezinjengamandla, ukumelana nokudlidliza, izidingo zokuvala, nokuba lula kokuhlanganisa/ukuqaqa kufanele kucatshangelwe.

* Ukubonisana namazinga afanelekile kanye nemihlahlandlela yobunjiniyela kubalulekile ekukhetheni ukuminyana kwentambo efanele ngezidingo zakho ezithile.

Ububanzi

Imicu inamadayamitha amathathu abalulekile:

* Ububanzi Obukhulu: Ububanzi obukhulu kakhulu bomucu, obukalwa kuma-crests.

* Ububanzi obuncane: Ububanzi obuncane kakhulu, obukalwa ezimpandeni.

* I-Pitch Diameter: Ububanzi bethiyori phakathi kwamadayamitha amakhulu namancane.

Ukuqonda Ububanzi Ngabunye:

* Ububanzi Obukhulu: Lona ubukhulu obubalulekile bokuqinisekisa ukuhambisana phakathi kwemicu yokukhwelana (isb, ibhawudi nenadi).Amabhawudi namantongomane anobubanzi obufanayo obukhulu azohlangana, kungakhathaliseki ukuthi iphimbo noma intambo yomucu (ihambisana noma i-tapered).

* I-Diameter Encane: Lokhu kuthinta amandla okuhlanganyela kwentambo.Ububanzi obuncane obukhudlwana bubonisa impahla eyengeziwe namandla okungenzeka aphakeme.

* I-Pitch Diameter: Lona ububanzi obucatshangelwayo lapho iphrofayili yochungechunge inenani elilinganayo lempahla ngenhla nangaphansi.Idlala indima ebalulekile ekubaleni amandla entambo nezinye izakhiwo zobunjiniyela.

Ubudlelwano phakathi kwama-Diameters:

* Amadayamitha ahlobene nephrofayili yochungechunge kanye nephimbo.Amazinga wentambo ahlukene (isb, imethrikhi ye-ISO, i-Unified National Coarse) anobudlelwano obukhethekile phakathi kwalawa madayamitha.

* Ububanzi bephimbo bungabalwa kusetshenziswa amafomula asekelwe kumadayamitha amakhulu namancane, noma atholakala kumathebula okubhekisela kumazinga athile entambo.

Ukubaluleka Kokuqonda Ububanzi:

* Ukwazi ububanzi obukhulu kubalulekile ekukhetheni izinto zokubopha ezihambisanayo.

* I-diameter encane inomthelela wamandla futhi ingase ihambisane nezinhlelo zokusebenza ezithile ezinemithwalo ephezulu.

* Ububanzi be-pitch bubalulekile ekubaleni kobunjiniyela nokuqonda izici zentambo.

Amanothi engeziwe:

* Amanye amazinga entambo achaza amadayamitha engeziwe njengokuthi "ububanzi bempande" ngezinjongo ezithile.

* Ukucaciswa kokubekezelela uchungechunge kunquma ukuhluka okuvumelekile kudayamitha ngayinye ukuze kusebenze kahle.

Ngethemba ukuthi lolu lwazi luzoqhubeka lucacisa izindima nokubaluleka kwamadayamitha entambo ahlukene!Zizwe ukhululekile ukubuza uma uneminye imibuzo.

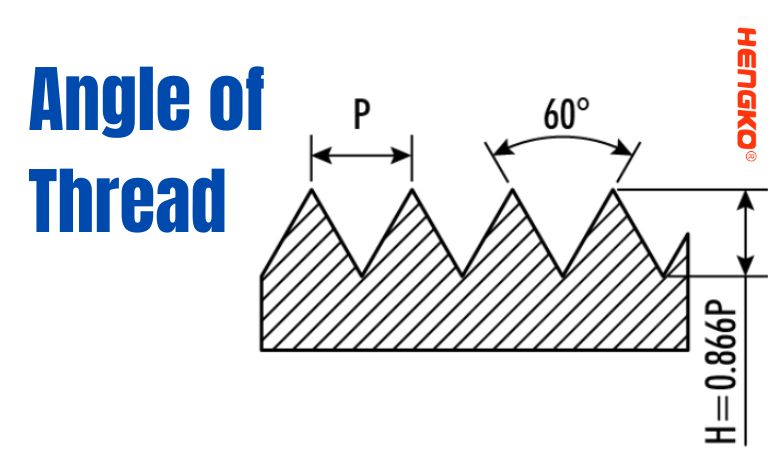

I-engeli

* I-engeli ye-Flank: I-engeli ephakathi kwe-flank yentambo kanye nomugqa we-perpendicular ku-eksisi.

* I-Taper Angle: Icaciswe kuchungechunge olucijile, i-engeli ephakathi kwe-taper ne-axis emaphakathi.

I-Flank Angle:

* Ngokuvamile, ama-engeli aseceleni ayalingana (okusho ukuthi zombili izinhlangothi zine-engeli efanayo) futhi azishintshi kuyo yonke iphrofayela yochungechunge.

* I-engeli yeflank evame kakhulu ngu-60°, esetshenziswa kumazinga afana ne-Unified Thread Standard (UTS) kanye nemicu ye-Metric ISO.

* Amanye ama-engeli e-flank ajwayelekile ahlanganisa u-55° (imicu ye-Whitworth) kanye no-47.5° (imicu ye-British Association).

* I-Flank angle ithinta:**1. Amandla: Ama-engeli amakhulu ngokuvamile anikeza ukumelana netorque engcono kodwa awakubekezeleli ukuhleleka kabi.

2. Ukungqubuzana: Ama-engeli amancane adala ukungqubuzana okuncane kodwa angase abeke engozini ikhono lokuzikhiya.

3. Ukwakheka kwe-chip: I-Flank angle ithonya ukuthi amathuluzi okusika angakha kalula kanjani imicu.

I-Taper Angle:

* Le engeli ichaza izinga lokushintsha kobubanzi ngomucu ocijile.

* Ama-engeli e-taper avamile ahlanganisa u-1:16 (Uchungechunge Lwepayipi Kazwelonke - NPT) kanye no-1:19 (I-British Standard Pipe Thread - BSPT).

* I-engeli ye-taper iqinisekisa ukuxhumana okuqinile, okuzivalayo njengoba imicu icindezelana lapho iqina.

* Kubalulekile ukuthi imicu ecijile ibe ne-engeli efanelekile yokufanisa isivalo esingavuzi.

Ubudlelwano phakathi kwama-Angles:

* Emiculweni engagxiliwe, i-engeli eseceleni iyona kuphela i-engeli efanelekile.

* Ngemicu ecijile, womabili ama-engeli e-flank kanye ne-taper adlala indima:

1. I-engeli yeflank inquma iphrofayili yochungechunge oluyisisekelo kanye nezimpawu zayo ezihlotshaniswa nayo.

2. I-engeli ye-taper ichaza izinga lokushintsha kobubanzi futhi ithonya izici zokuvala.

I-Crest ne-Root

* I-Crest: Ingxenye engaphandle yochungechunge.

* Umsuka: Ingxenye engaphakathi, eyakha isisekelo sesikhala sentambo.

Ngenhla kuchazwa nje i-crest kanye nempande yomucu.

Nakuba izindawo zabo ngaphakathi kwentambo zibonakala zilula, zidlala indima ebalulekile ezicini ezihlukahlukene zokusebenza kwentambo nokuklama.

Nansi eminye imininingwane ongase ukuthole inentshisekelo:

I-Crest:

*Lolu unqenqema olungaphandle kakhulu lwentambo, lwakha iphoyinti lokuxhumana nentambo yalo yokukhwelana.

*Amandla nobuqotho be-crest kubalulekile ekuthwaleni umthwalo osetshenzisiwe kanye nokuguga kokumelana.

*Ukulimala kochungechunge, ama-burrs, noma ukungapheleli ku-crest kungalimaza amandla nokusebenza koxhumo.

Umsuka:

*Itholakala ngaphansi kwentambo, yenza isisekelo sesikhala phakathi kwemicu eseduze.

*Ukujula nokuma kwempande kubalulekile ezintweni ezifana nalezi:

1. Amandla: Impande ejulile inikeza impahla eyengeziwe yokuthwala umthwalo namandla athuthukisiwe.

2. Ukusulwa: Kudingeka imvume eyanele yezimpande ukuze kufakwe udoti, izinto zokuthambisa, noma ukuhluka kokukhiqiza.

3. Ukubekwa uphawu: Kweminye imiklamo yentambo, iphrofayili yempande inomthelela ekuqiniseni ubuqotho.

Ubudlelwano phakathi kwe-Crest ne-Root:

*Ibanga phakathi kwe-crest nempande lichaza ukujula kwentambo, okuthinta ngokuqondile amandla nezinye izici.

*Umumo othize nobukhulu bakho kokubili i-crest nempande kuncike ezingeni lentambo (isb, imethrikhi ye-ISO, i-Unified Coarse) kanye nokusetshenziswa kwayo okuhlosiwe.

Okucatshangwayo Nezicelo:

*Amazinga wochungechunge nokucaciswa kuvame ukuchaza ukubekezelela ubukhulu be-crest kanye nezimpande ukuze kuqinisekiswe ukusebenza okufanele nokushintshana.

*Kuzinhlelo zokusebenza ezinemithwalo ephezulu noma egugile, amaphrofayili entambo anama-crest aqinisiwe nezimpande angase akhethelwe ukuqina okuthuthukisiwe.

*Izinqubo zokukhiqiza kanye nokulawulwa kwekhwalithi kubalulekile ukuze kuqinisekiswe ama-crests abushelelezi, angenamonakalo kanye nezimpande ezixhunyweni.

Ngethemba ukuthi lolu lwazi olwengeziwe lungeza ukujula ekuqondeni kwakho izindima nokubaluleka kwe-crest kanye nezimpande kuchungechunge.Zizwe ukhululekile ukubuza uma uneminye imibuzo noma izihloko ezithile ezihlobene nokwakhiwa kwentambo ongathanda ukuyihlola!

Ubukhulu bezinhlobo zezintambo

Nakhu ukuhlukaniswa kobukhulu bezinye izinhlobo zochungechunge oluvamile ozishilo, kanye nezithombe zokubonwa kangcono:

I-M - ISO Thread (Metric):

*ISO 724 (DIN 13-1) (Uchungechunge Olumaholo):

1. Isithombe:

2. Ibanga lobubanzi obukhulu: 3 mm ukuya ku-300 mm

3. Ibanga le-pitch: 0.5 mm kuya ku-6 mm

4. I-engeli yochungechunge: 60°

*ISO 724 (DIN 13-2 to 11) (Uchungechunge Oluhle):

1. Isithombe:

2. Ibanga lobubanzi obukhulu: 1.6 mm ukuya ku-300 mm

3. Ibanga le-pitch: 0.25 mm kuya ku-3.5 mm

4. I-engeli yochungechunge: 60°

I-NPT - Uchungechunge Lwepayipi:

*I-NPT ANSI B1.20.1:

1. Isithombe:

2. Intambo eqoshiwe yokuxhunywa kwamapayipi

3. Ibanga lobubanzi obukhulu: 1/16 intshi ukuya kumayintshi angu-27

4. I-engeli ye-Taper: 1:16

*NPTF ANSI B1.20.3:

1. Isithombe:

2. Ifana ne-NPT kodwa enama-crest ayisicaba nezimpande zokuvaleka kangcono

3. Ubukhulu obufanayo ne-NPT

I-G/R/RP - I-Whitworth Thread (BSPP/BSPT):

*G = BSPP ISO 228 (DIN 259):

1. Isithombe:

2. Intambo yepayipi ehambisanayo

3. Ibanga lobubanzi obukhulu: 1/8 intshi ukuya kumayintshi angu-4

4. I-engeli yochungechunge: 55°

*R/Rp/Rc = BSPT ISO 7 (i-DIN 2999 ithathelwe indawo yi-EN10226):

1.Isithombe:

2. Intambo yepayipi eqoshiwe

3. Ibanga lobubanzi obukhulu: 1/8 intshi ukuya kumayintshi angu-4

4. i-engeli ye-aper: 1:19

I-UNC/UNF - Uchungechunge Lukazwelonke Oluhlanganisiwe:

*I-Unified National Coarse (UNC):

1. isithombe:

2. Ifana ne-M Coarse Thread kodwa enobukhulu obususelwe ngamayintshi

3. Ibanga lobubanzi obukhulu: 1/4 intshi ukuya kumayintshi angu-4

4. Ibanga lemicu iyintshi ngayinye (TPI): 20 ukuya ku-1

*Inhlawulo Kazwelonke Ehlanganisiwe (UNF):

1. Isithombe:

2. Ifana ne-M Fine Thread kodwa enobukhulu obususelwe ngamayintshi

3. Ibanga lobubanzi obukhulu: 1/4 intshi ukuya kumayintshi angu-4

4. Ububanzi be-TPI: 24 kuya ku-80

Ulwazi olungenhla lunikeza ukubuka konke okujwayelekile kobukhulu bohlobo ngalunye lochungechunge.kodwa ubukhulu obuthile bungase buhluke kuye ngezinga elithile kanye nokusebenza.Ungathola amathebula anemininingwane nobukhulu kumadokhumenti wamazinga afanelekile afana ne-ISO 724, ANSI B1.20.1, njll.

Zizwe ukhululekile ukubuza uma uneminye imibuzo noma udinga ulwazi olwengeziwe ngezinhlobo ezithile zochungechunge noma ubukhulu!

I-SUM

Le bhulogi sinikeza umhlahlandlela ophelele kuyointambo design, okubalulekile ekuqondeni ukuthi izingxenye zemishini nezinhlelo zobunjiniyela zihlangana kanjani.

Ihlanganisa imiqondo eyisisekelo yobulili bentambo, ukuhlonza imicu yowesilisa nowesifazane kanye nokusetshenziswa kwayo kuzihlungi ze-sintered.futhi sichaza ukunikezwa kwentambo, sigqamisa ukugqama kwemicu esesandleni sokudla ezinhlelweni eziningi.

Imininingwane enemininingwane inikezwa ekwakhiweni kwentambo, okugxile emicushweni ehambisanayo kanye ne-tapered, kanye nokuhlobana kwayo kuzihlungi ze-sintered.

Ngakho-ke lo mhlahlandlela uyisisekelo esifundwayo kunoma ngubani ofuna ukubamba ubunkimbinkimbi bokwakhiwa kwentambo kuzihlungi ezisindisiwe.Noma kunjalo, Ngethemba Kuzoba usizo kuwe

ulwazi lwentambo bese ukhetha intambo efanele esikhathini esizayo, okukhethekile embonini yokuhlunga ye-sintered.

Isikhathi sokuthumela: Jan-30-2024