-

Isihlungi sokuhlola se-HENGKO se-porous metal disc sokuhlolwa kwesikali sebhentshi laseLabhorethri

Ilungele: - Ukuhlolwa kwesikali sebhentshi laselabhorethri -Izifundo ezingenzeka -Isikali esincanyana, izinqubo zohlobo lwe-batch Imiklamo ye-HENGKO futhi ikhiqiza okokuhlunga kwebhentshi-top, po...

Buka imininingwane -

I-Rugged Industrial RS-485 MODBUS RTU Temperature and Humidity Sensor Housing – Sta...

Izinzwa ezinenzwa yensimbi engagqwali yomswakamo zifaneleka ikakhulukazi ukusetshenziswa ezimeni ezinolaka. Lolu hlobo lwensimbi alunabala, okusho ukuthi ...

Buka imininingwane -

I-HENGKO Ivala Amagciwane Ibanga Lemidiya Lokuhlunga 0.2 5um Isihlungi Semidiya Sintered Porous...

Sethula Isihlungi Se-HENGKO Esenza Inzalo Yebanga Lensimbi Yezicelo Zesayensi Yezempilo Nezesayensi Yezempilo! Isihlungi sensimbi esisanda kwakhiwa sika-HENGKO si...

Buka imininingwane -

Isihlungi se-Porous Metal Metal Sintered Stainless Stainless Steel Disc Filter for Fiberf Yarn Production / P...

Izihlungi ze-Porous Metal Idizayini yesihlungi sensimbi ye-HENGKO enezimbobo ihlinzeka ngempilo eyengeziwe nokusebenza ekuhlungeni kwephakethe le-polymer spin. Isihlungi siyi-sintered,...

Buka imininingwane -

Ikhemisi Stainless Steel Sintered Isihlungi Sensimbi Enezimbotshana Ø12×20 mm

Isihlungi se-Sintered sisetshenziswa kabanzi embonini. Yenza ngokwezifiso imikhiqizo ehlukene yesakhiwo sensimbi ukuze ivumelane nendawo oyisebenzisayo! Izici: Material: SS...

Buka imininingwane -

Izihlungi Ze-Stainless Steel Sintered Porous Metal Turbine Filtration for Air Inlet Filtration ( Zisetshenziswa ...

Ukuhlunga (engeza isihlungi sensimbi enezimbotshana) kubalulekile ezinjinini ze-turbine. Uma izinhlayiya ze-sub-micron, uketshezi, nokungcola okuncibilikisiwe okufana nomoya kanye nezinhlayiya ezithwalwa amanzi...

Buka imininingwane -

I-Sintered Porous Metal Filter Cylindrical Element Yezihlungi Zenqubo YeCale Egcwele

Isihlungi sensimbi esinezimbotshana ze-HENGKO singahlukanisa izinto eziqinile kuketshezi namagesi ezinhlobonhlobo zezinhlelo zokusebenza. Ukusetshenziswa kuhlanganisa ukuhlunga kwenqubo, isihlungi samasampula...

Buka imininingwane -

Isihlungi Sesihlungi Sesampula Se-UHP Ehlanzekile Yomoya Eqinile Engagqwali Okuphezulu Kokucindezela Okuphezulu...

I-HENGKO Gas Sampling Filter ingahlukanisa izinto eziqinile kumagesi emisebenzini ehlukahlukene. Ukusetshenziswa kuhlanganisa ukuhlunga kwenqubo, izihlungi zesampula, ukupholisha...

Buka imininingwane -

Isihlungi se-Porous Disc esingu-47mm 316L SS Sintered Metal Filter for Laboratory Bench Scale Testing

Isihlungi sebhentshi esiphezulu se-HENGKO (isihlungi sokuhlola idiski esingu-47mm), isihlungi sethu sediski esingu-47mm, siyindlela elula, engabizi kakhulu yokuhlukanisa uketshezi oluqinile futhi oluqinile nge-...

Buka imininingwane -

Izihlungi Zensimbi Engagqwali E-Sintered Metal - Izicelo Zokuhlunga e-Pharma...

Ukuhlunga ngezihlungi zensimbi ezine-sintered kusetshenziswa ekwenziweni kwemithi ukususa izinto ezingafuneki kusixazululo senqwaba esakhiwe. Owokuqala...

Buka imininingwane -

I-HENGKO Yenziwe Ngokwezifiso Isihlungi Sensimbi Engagqwali ye-HENGKO 316L Sintered Sintered Porous Metal Stainless Steel With Externa...

Incazelo Yemikhiqizo I-muffler yensimbi engagqwali iyisimbozi esenziwe ngayo yonke insimbi engagqwali noma esineshubhu lensimbi engagqwali noma igobolondo langaphandle. I-HENGKO i-stainless s...

Buka imininingwane -

I-HENGKO 316L isihlungi sensimbi engenasici esinezimbotshana zensimbi

Incazelo Yemikhiqizo I-HENGKO ikhiqiza izakhi zokuhlunga zensimbi ezinama-porous ngezinto ezihlukahlukene, osayizi, kanye nezinsiza, ukuze zicaciswe kalula i-accordin...

Buka imininingwane -

I-Stainless Steel Tubeless Tyre Valve Iqinile Futhi Ihlala Eqinile Ivalve Yamathayela Induku Emfishane Yeloli Lemoto...

Incazelo Yemikhiqizo I-valve iyisisetshenziswa somzimba se-valve esizimele esivumela igesi ukuthi ingene endaweni yesondo elingenashubhu noma ishubhu lapho ivulwa, bese ...

Buka imininingwane -

Isihlungi Esine-Acid Ne-Alkali Esiqinile Kakhudlwana esingu-316L Isihlungi Sensimbi Engenasici Esingenazimbobo...

Chaza umkhiqizo we-HENGKO isihlungi se-biomedical senziwe nge-316L yensimbi eyimpushana efakwe endaweni yokushisa ephezulu, ene-porosity efanayo engu-0.2-0.5 um, ukugqwala ukumelana...

Buka imininingwane -

Isistimu Yokusampula Yesihlaziyi Segesi - Isihlungi Esiphezulu Sokucindezelwa Okusemgqeni I-UHP Ehlanzekile Ehlanzekile

I-HENGKO High-pressure gas filter ukuze uthole ukuvikelwa okuthembekile ekungcoleni. Le makethe yokuhlunga, ukuhlukaniswa kanye nokuhlanza ibuye ihambisane ne-deve...

Buka imininingwane -

I-Industry Stainless Steel Powder Sintered Metal Filter Media Yokuvikela Umlilo

Izwa Ukuphepha Okungenakuqhathaniswa Nokusebenza Kahle Ngezindlu ze-HENGKO's Gas Sensor! Uma kuziwa ekuvikeleni izinzwa zakho zegesi nokuqinisekisa indawo evikelekile...

Buka imininingwane -

I-Pre-Filter ye-Industrial Flue Gas Sampling Probe - Isihlungi Sokucindezela Okuphezulu

Isihlungi sangaphambilini sesampula segesi ye-industrial flue gas ukuze kuthathwe isampula yegesi ewuthuli oluphezulu ukugwema ukuvaleka kwendlela yegesi ngesikhathi sokusampula kweshubhu...

Buka imininingwane -

Izibophisi ze-Flashback zamasilinda owodwa ngokwezifiso ezinezimbotshana zensimbi engagqwali f...

Incazelo Yomkhiqizo Umqondo wokuklama walo mkhiqizo ukuvimbela abasebenzisi ekusebenziseni umlilo ngephutha ukuhlola ukuthi ikhona yini i-hydrogen. Umshicileli womlilo u...

Buka imininingwane -

Isihlungi Sepayipi likagwayi Insimbi Engagqwali 304 316 Isihlungi Sesikrini Semeshi

Isihlungi se-cigarette mesh disc sibizwa nangokuthi i-cigarette filter mesh disc, i-bong burner mesh, isihlungi se-Arabic hookah, noma isihlungi sokungcola kwamanzi esimpompi. Ngokuyinhloko u...

Buka imininingwane -

Isihlungi se-Wholesale Wire Mesh Insimbi Engagqwali engu-10 Micron Sintered Tube Yezemithi ye-M...

Izihlungi zensimbi engagqwali zilungele ukusetshenziswa ekucacisweni kobunjiniyela okufunayo okudinga ukuhlungwa ezimeni ezingezinhle zemvelo, njenge-jet en...

Buka imininingwane

Kungani Khetha I-SinteredInsimbi IzihlungiNgemiklamo Yakho Yokuhlunga:

Izihlungi zensimbi ezi-sinteredzenziwe ngezimpushana zensimbi ezicindezelwayo futhi zifakwe emanzini (ahlanganiswe) ukuze zakhe i-porous,

isakhiwo esiqinile. Lezi zihlungi zaziwa ngamandla azo aphezulu, ukuqina, kanye nekhono lokuhlunga izinhlayiya ezincane kakhulu.

8 Izici Eziyinhloko Zokuhlunga Kwensimbi Yensimbi

I-HENGKO inikeza uhla lwemikhiqizo yokuhlunga yensimbi, okuhlanganisa insimbi engagqwali e-sintered, ithusi elinesinki,

I-sintered mesh, nezihlungi ze-sintered titanium, izihlungi ze-metal powder, isihlungi sensimbi esine-sinteredamadiski, futhi sintered ibala

insimbiamashubhu. Izihlungi zethu zenzelwe izinhlelo zokusebenza ezidinga amazinga aphezulu e-anti-corrosion, izinga lokushisa eliphezulu,

nokusebenza ngokunemba okuphezulu.

1. Amandla Aphezulu:

Izihlungi zensimbi ze-sintered zenziwe ngezimpushana zensimbi, ezibanika amandla aphezulu

kanye nokuqina.

2. Ukumelana nezinga lokushisa eliphezulu:

Izihlungi zensimbi ezine-sintered zingamelana namazinga okushisa aphezulu, zizenze

ilungele izindawo ezinokushisa okuphezulu.

3. Ukumelana Nokugqwala:

Izihlungi zensimbi ezine-sintered zimelana nokugqwala futhi zingasetshenziswa ekonakalini

izindawo.

4. Ukumelana Namakhemikhali:

Izihlungi zensimbi ezine-sintered zimelana namakhemikhali amaningi, okuwenza afanelekele amakhemikhali

ukucubungula izinhlelo zokusebenza.

5. Ukusebenza kahle kokuhlunga:

Izihlungi zensimbi ezine-sintered zinesakhiwo esihle kakhulu se-pore, esivumela ukuba

hlunga izinhlayiya ezincane kakhulu ngempumelelo.

6. Amandla aphezulu okubamba ukungcola:

Izihlungi zensimbi ezine-sintered zinamandla aphezulu okubamba ukungcola, okusho ukuthi zingakwazi

hlunga umthamo omkhulu woketshezi ngaphambi kokuthi kushintshwe.

7. Kulula Ukuhlanza:

Izihlungi zensimbi ezine-sintered zingahlanzwa kalula futhi ziphinde zisetshenziswe, kuzenze zingabizi

ohambeni olude.

8. Ukuhlukahluka:

Izihlungi zensimbi ezi-sintered zingenziwa ngezindlela ezihlukahlukene nosayizi ukuze zihlangabezane nezidingo ezithile

kwezinhlelo zokusebenza ezahlukene.

Okuhlungayo okunezimbotshana zensimbi, insimbi engagqwali iyisinqumo esihle sokuhlungwa ekucutshungulweni kwamakhemikhali, ukucwengwa kwe-petroleum,

ukukhiqiza amandla, ukukhiqizwa kwemithi, nezinye izinhlelo zokusebenza.

Ku-HENGKO, konkeizakhi zokuhlunga ezihlanganisiwezihlolwe ikhwalithi eqinile ngaphambi kokuthunyelwa, okuhlanganisa ukusebenza kahle kokuhlunga

kanye nokuhlolwa okubukwayo. Izihlungi zethu zensimbi ezine-sintered zinokusebenza kahle okuphezulu kokususwa kwezinhlayiyana, ukumelana nokugqwala, kuncane

ukwehla kwengcindezi, ukuhlanzwa okulula, kanye nezinzuzo ze-backwash uma kuqhathaniswa nabanye abahlinzeki besihlungi sensimbi.

Uma iminikelo yethu yamanje ingahlangabezani nezidingo zakho zokuhlunga, sicelaXhumana nathingezinto zakho, ubukhulu,

kanye nezidingo zohlelo lokusebenza.

Isicelo seIsihlungi se-SinteredImikhiqizo

Izihlungi ze-Sintered zisetshenziswa ezinhlobonhlobo zezimboni, ezihlanganisa ukucubungula amakhemikhali, ukuhluzwa kwe-petroleum, ukukhiqiza amandla, kanye nokukhiqizwa kwemithi. Zilungele ukusetshenziswa ezinhlelweni lapho izinga eliphezulu lokuhlunga lidingeka khona, nalapho isihlungi kufanele sikwazi ukumelana nezinga lokushisa eliphezulu, izingcindezi, kanye nezindawo ezigqwalile. Ezinye zezinhlelo zokusebenza ezivame kakhulu zemikhiqizo yokuhlunga e-sintered zifaka:

Ukuhlunga Uketshezi

Izihlungi zensimbi ze-Sintered zivame ukusetshenziselwa ukuhlunga uketshezi ezimbonini ezihlukahlukene. Ziwusizo ikakhulukazi ezinhlelweni lapho uketshezi oluhlungwayo lune-viscous noma luqukethe izinga eliphezulu lokuqinile. Izihlungi ezi-sintered zingasusa izinhlayiya ezincane njenge-micron engu-1, zizenze zilungele ukusetshenziswa ezinhlelweni lapho kudingeka khona izinga eliphezulu lokuhlunga.

I-Fluidizing

Izihlungi zensimbi ezi-sintered nazo zingasetshenziselwa izinhlelo zokusebenza ze-fluidizing, lapho zisiza khona ukusabalalisa ngokulinganayo igesi noma uketshezi ngombhede wezinhlayiya eziqinile. Lokhu kuwusizo ikakhulukazi ezinhlelweni ezifana ne-catalysis, lapho kubalulekile ukuqinisekisa ukuthi wonke ama-reactants asatshalaliswa ngokulinganayo.

Ukubhuqa

Izihlungi zensimbi ezi-sintered nazo zingasetshenziselwa izinhlelo zokusebenza ze-sparging, lapho zisiza khona ukufaka igesi oketshezini. Lokhu kuwusizo ikakhulukazi ekufakweni okufana nokuvutshelwa, lapho kubalulekile ukuqinisekisa ukuthi uketshezi oluvutshelwayo lunomoya omuhle.

Ukusabalalisa

Izihlungi zensimbi ezi-sintered nazo zingasetshenziselwa izinhlelo zokusebenza zokusabalalisa, lapho zisiza khona ukusabalalisa ngokulinganayo igesi noma uketshezi ngolwelwesi. Lokhu kubaluleke kakhulu ezinhlelweni zokusebenza ezifana namaseli kaphethiloli, lapho kubalulekile ukuqinisekisa ukuthi ama-reactants asatshalaliswa ngokulinganayo kulwelwesi lonke.

I-Flame Arrestor

Izihlungi zensimbi ezine-sintered nazo zingasetshenziswa njengezinqamuleli zomlilo, lapho zisiza khona ukuvimbela ukusabalala kwamalangabi noma ukuqhuma. Lokhu kuwusizo ikakhulukazi ekusetshenzisweni okufana nezindawo zokucwenga noma izitshalo zamakhemikhali, lapho izinto ezivuthayo zikhona.

Ukuhlunga Kwegesi

Izihlungi zensimbi ezi-sintered nazo zisetshenziselwa ukuhlunga igesi ezinhlobonhlobo zezinhlelo zokusebenza zezimboni. Ziwusizo ikakhulukazi ezinhlelweni lapho igesi ehlungwayo iqukethe izinga eliphezulu lomswakama noma okunye ukungcola. Izihlungi ze-Sintered zingasusa izinhlayiya ezincane njengo-0.1 micron, zizenze zilungele ukusetshenziswa ezinhlelweni lapho kudingeka khona izinga eliphezulu lokuhlunga.

Ukudla Nesiphuzo

Izihlungi zensimbi ezine-sintered nazo zisetshenziswa ezinhlobonhlobo zokudla neziphuzo, okuhlanganisa ukuhlungwa kukabhiya, iwayini, nezinye iziphuzo. Ziwusizo ikakhulukazi ezinhlelweni zokusebenza lapho izinga eliphezulu lokuhlunga lidingeka khona, nalapho isihlungi kufanele sikwazi ukumelana nezinga lokushisa eliphezulu kanye nezindawo ezibolayo.

Uma udinga umkhiqizo wesihlungi se-sintered ohlangabezana nezinto ezithile, ubukhulu, noma izimfuneko zohlelo lokusebenza, sicela ukhululekeXhumana nathiukuxoxa ngezidingo zakho.

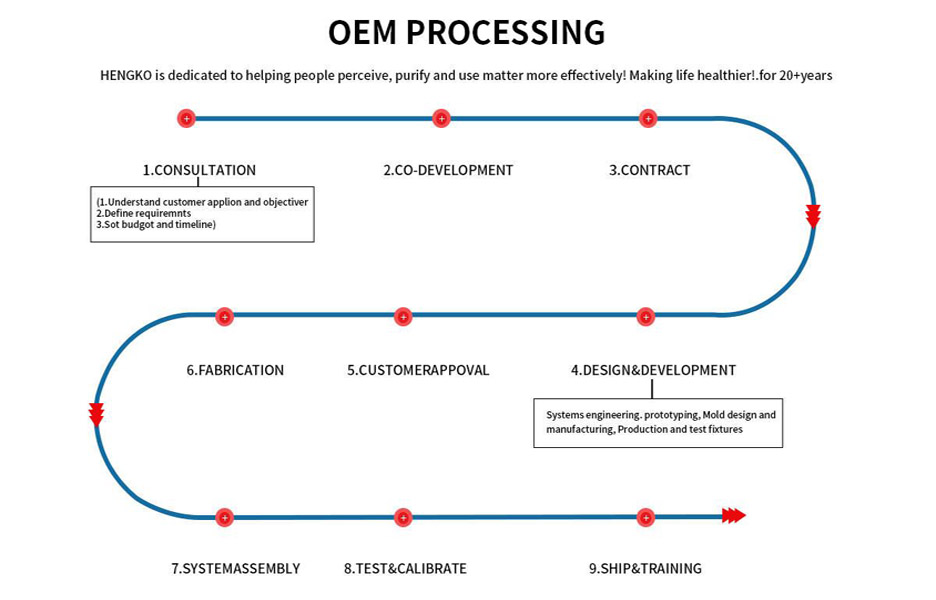

Enza ngendlela oyifisayo Inqubo yesihlungi se-Sintered Metal

Siyakwamukela ukuthatha izihlungi zakho zezidingo zomklamo okhethekile ukuze uxhumane nathi, sizothola isisombululo sokuhlunga esingcono kakhulu

izidingo zakho zokuhlunga. futhiungalandela inqubo ebanzi ukuze uqinisekise ukuthi umkhiqizo wokugcina uyahlangana

yonke imininingwane edingekayo. Inqubo ihlanganisa:

1.Ukubonisana futhi Xhumana HENGKO

2. Ukuthuthukiswa ngokubambisana

3. Yenza Inkontileka

4. Design & Development

5. Ukuvunyelwa Kwekhasimende

6. Ukukhiqiza/Ukukhiqiza Okuningi

7. Umhlangano wesistimu

8. Hlola & Linganisa

9. Ukuthumela nokufakwa

Uma udinga umkhiqizo wokuhlunga onesihlungi ohlangabezana nezinto ezithile, ubukhulu, noma izimfuneko zohlelo lokusebenza,

sicela usithinte ukuze uxoxe ngezidingo zakho.

Yini Ehlukanisa I-HENGKO Embonini Yezihlungi Zensimbi Ye-Sintered?

Kungani Khetha Izihlungi Zensimbi Ezisikiwe ze-HENGKO?

Izihlungi zensimbi ze-HENGKO ezifakwe emanzini zibhekwa kakhulu amakhasimende ethu ngomthamo wazo okhethekile wokubamba ukungcola nempilo ende.

Zakhiwe ngenqubo yokugaya elawulwa ngokucophelela, lezi zihlungi ze-OEM Sintered Metal zinikeza izimbotshana ezisatshalaliswe ngokufanayo.

ngezilinganiso ze-micronkusukela ku-0.1μ kuya ku-100μ, iqinisekisa ukuhlunga okunembile nokuthembekile.

Izinzuzo Eziyinhloko Zezihlungi Zensimbi Ezihlanganisiwe ze-HENGKO:

1.Idizayini Ezinzile futhi Eqinile:

Izihlungi zethu zigcina isimo esizinzile esinokumelana okuhle kakhulu nomthelela kanye nemithwalo eshintshanayo,

okwenza ziqine kakhulu nangaphansi kwezimo eziyinselele.

2.I-Superior Air Permeability:

Ngokusebenza kahle kokuhlunga, izihlungi zethu zensimbi ezine-sintered zihlinzeka ngokungena komoya okuhle kakhulu,

ukuqinisekisa ukusebenza kahle ezinhlelweni ezahlukene.

3.Amandla Aphezulu Nokumelana Nokugqwala:

Idizayinelwe ukumelana nengcindezi ephezulu kanye nezindawo ezonakalisa kakhulu, izihlungi zethu zinikeza amandla akhethekile okulayisha,

ukubenza balungele izilungiselelo zezimboni ezifunayo.

4.Ukusebenza Kwezinga Lokushisa Eliphezulu:

Ifaneleka kakhulu ukuhlunga kwegesi eshisa kakhulu,

izihlungi zethu zensimbi ezine-sintered zisebenza ngokuthembekile ezindaweni eziyingozi kakhulu.

5.Izinketho zokwenza ngokwezifiso:

Sinikeza izixazululo ezenziwe ngokwezifiso ezinohlu olubanzi lwezinto, izimo, nosayizi wokuxhuma ukuhlangabezana nezidingo ezithile zohlelo lokusebenza.

Njengomkhiqizi onedumela elihle e-China, i-HENGKO igxile ekukhiqizeni izihlungi zensimbi ezicwebezelayo.

Ithimba lethu lochwepheshe abaqeqeshiwe lizinikele ekuthuthukisweni nasekukhiqizeni ukusebenza okuphezulu

insimbi engagqwali ene-sintered kanye nezinto ezimbotshana.

Yaziwa ngokuziqhenya njengebhizinisi lobuchwepheshe obuphezulu, i-HENGKO isebenzisana namanyuvesi aphambili womabili ekhaya.

nakwamanye amazwe ukuze siqhubeke sisungula futhi sithuthukise imikhiqizo yethu.

Amathiphu angu-4 Uma Ukhetha & Isihlungi Sensimbi Se-OEM Sintered Okufanele Unakekele

Kunezindlela ezimbalwa zokwenza ngokwezifiso izihlungi zensimbi ezisikiwe ukuze zihlangabezane nezidingo ezithile zohlelo lokusebenza.

Ezinye izindlela ezijwayelekile zihlanganisa:

1. Ukukhetha insimbi efanele:

Izinsimbi ezahlukene zinezakhiwo ezahlukene ezingathinta iukusebenza kwe

isihlungi sensimbi esine-sintered. Isibonelo, insimbi engagqwali imelana nokugqwala futhi inephuzu eliphezulu lokuncibilika, kuyilapho

i-aluminium ayisindi futhi inokuhamba kahle kukagesi.

2. Icacisa usayizi wembotshana nokuma:

Izihlungi zensimbi ze-Sintered zingaklanywa ngama-pores osayizi abahlukene futhi

bobunjwa ukuze ivumelane nezidingo ezahlukene zokuhlunga. Isibonelo, isihlungi esinezimbotshana ezincane sizosebenza kangcono ekukhipheni

izinhlayiya ezincane, kuyilapho isihlungi esinezimbotshana ezinkudlwana singase sifaneleke kakhulu kumazinga aphezulu okugeleza.

3. Ukushintsha ukujiya kwemidiya yesihlungi:

Ugqinsi lwemidiya yokuhlunga lungabuye lulungiswe ukuze luvumelane nokuthile

izidingo zohlelo lokusebenza. Imidiya ewugqinsi ingahlinzeka ngokusebenza kahle kokuhlunga kodwa ingase ibangele ukuphakama

ukwehla kwengcindezi nokuncipha kwamazinga okugeleza.

4. Ukulungisa izinga lokushisa nengcindezi:

Izihlungi zensimbi ezi-sintered zingaklanywa ukuthi zimelane nokukhethekile

izinga lokushisa kanye nezimo zokucindezela, kuye ngokuthi isicelo. Kubalulekile ukucabangela lezi zici lapho

ukukhetha isihlungi ukuqinisekisa ukuthi singakwazi ukumelana nezimo zokusebenza zesistimu.

Ukuze wenze ngendlela oyifisayo isihlungi sensimbi esinezinsimbi ukuze sihlangabezane nezimfuneko zakho ezithile, thintana nonjiniyela onolwazi

noma uchwepheshe wezobuchwepheshe kulo mkhakha angase abe usizo. Bangakwazi ukuqondisa umklamo ofanele kanye nokukhethwa kwezinto ezibonakalayo ngokusekelwe

ezidingweni ezithile zohlelo lokusebenza.

FAQokwezihlungi ze-Sintered Metal

1. Iyini Isihlungi Sensimbi Ye-Sintered?

Incazelo emfushane yesihlungi se-sintered metal:Kuyisihlungi sensimbi esisebenzisa izinhlayiya zempushana zensimbi ezinosayizi wezinhlayiyana ezifanayo

ukubunjwa ngokugxiviza, ukushisa okuphezulu kwe-sintering kuyinqubo ye-metallurgy kusetshenziswa usayizi oyimpushana.

imizimba yezinsimbi ezahlukene nama-alloys ngemva kokunyathela.

I-Metallurgy yenzeka ngokusabalalisa emazingeni okushisa angaphansi kwendawo yokuncibilika yezithando zokushisa eziphezulu. Izinsimbi nama-alloys

okuvame ukusetshenziswa namuhla kuhlanganisa i-aluminium, ithusi, i-nickel, ithusi, insimbi engagqwali, ne-titanium.

Kunezinqubo ezahlukene ongazisebenzisa ukwenza impushana. Kuhlanganisa ukugaya, ukuzenzela, nokubola kwamakhemikhali.

Imininingwane eyengeziwe mayelanaYini isihlungi se-Sintered Metal, ngicela uhambe uyohlola lesi sihloko.

2. Kungani Usebenzisa Insimbi Engagqwali Ukwenza Isihlungi?

Ukukhetha i-Stainless Steel Metal njengezinto eziyinhloko, ngenxa nje yokuthi kunezinzuzo eziningi zensimbi engagqwali

1. Akulula ukugqwala

2. Izinga lokushisa le-sintering akudingeki libe phezulu kakhulu

3. Izimbotshana kulula ukulawula ngesikhathi sintering

4. Ukubunjwa kwe-Sintered kuhlala isikhathi eside futhi akulula ukukonakalisa

5. Kulula ukuhlanza

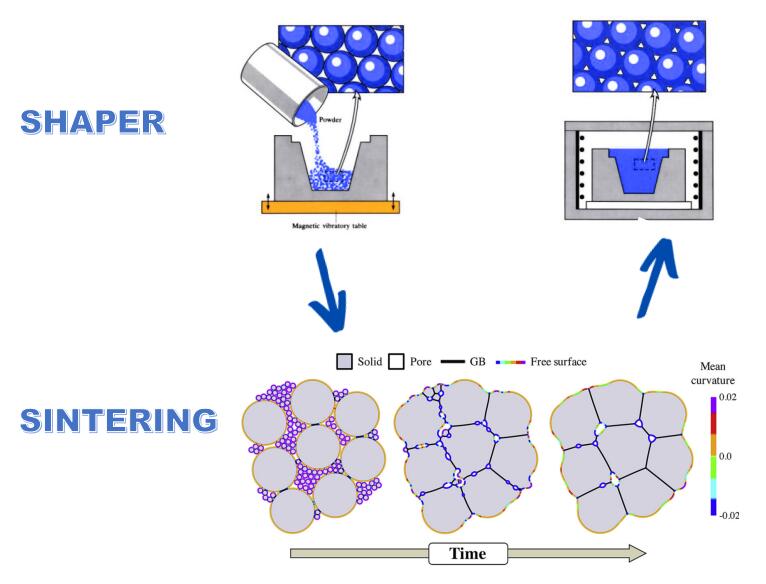

3. Senziwa kanjani isihlungi se-Sintered Metal?

Ngenqubo yokukhiqiza yesihlungi se-Sintered metal, main inezinyathelo ezi-3 kanje:

A: Isinyathelo sokuqala ukuthola insimbi yamandla.

Impushana yensimbi, Ungathola izimpushana zensimbi ngokugaya, ukuzishintshanisa, noma ukubola kwamakhemikhali. Ungakwazi ukuhlanganisa insimbi eyodwa

impushana nenye insimbi ukwenza ingxubevange ngesikhathi senqubo yokwenziwa, noma ungasebenzisa impushana eyodwa kuphela. Inzuzo yokucula yilokho

ayiguquli izinto ezibonakalayo zensimbi. Inqubo ilula kangangokuthi izakhi zensimbi aziguqulwa.

B: Ukunyathela

Isinyathelo sesibili ukuthululela i-powder yensimbi ibe isikhunta esilungiselelwe ngaphambili lapho ungabumba khona isihlungi. Ukuhlanganiswa kwesihlungi kwakhiwa ekamelweni

izinga lokushisa nangaphansi kokugxivizwa. Inani lokucindezela elisetshenzisiwe lincike ensimbi oyisebenzisayo, njengoba izinsimbi ezihlukene zinokunwebeka okuhlukile.

Ngemuva komthelela wengcindezi ephezulu, impushana yensimbi ihlanganiswa esikhunjeni ukuze yakhe isihlungi esiqinile. Ngemuva kwenqubo yomthelela wengcindezi ephezulu, ungakwazi

beka isihlungi sensimbi esilungisiwe esithandweni sokushisa okuphezulu.

C: I-sintering eshisa kakhulu

Enqubweni ye-sintering, izinhlayiya zensimbi ziyahlanganiswa ukuze zakhe iyunithi eyodwa ngaphandle kokufinyelela endaweni yokuncibilika. Le monolith iqine ngendlela efanayo,

iqinile, futhi inezimbotshana zokuhlunga njengensimbi.

Ungakwazi ukulawula i-porosity yesihlungi ngenqubo ngokusho kwezinga lokugeleza komoya noma uketshezi okufanele luhlungwe.

4. Iyini Inqubo Ye-Sintering?

Isinyathelo esisodwa esibalulekile i-Sintering, ngakho-ke iyini inqubo yokucwenga kanye nokuba izihlungi zensimbi ?

Ungahlola njengeshadi lokulandela ukuze uqonde ngokucacile.

5. Yiziphi Izicaciso Eziyinhloko Zesihlungi Sensimbi Ye-Sintered?

Ngemuva kwenqubo yokugxiviza kanye nokushisa okuphezulu kwe-sintering, singathola izihlungi zensimbi ezihlanganisiwe, bese singena

ukuze sazi ikhwalithi yezihlungi ezifakiwe, ngokuvamile, sizohlola idatha ethile yezihlungi, uma idatha ifinyelela

izidingo njengoba amakhasimende ecelile, bese singakhulula ukuze sihlele ukuthunyelwa ngaphandle.

1. I-Porosity

2. Ukuhlolwa kokucindezelwa

3. Ukuhlolwa kokugeleza (igesi noketshezi)

4. Ukuhlolwa kwesifutho sikasawoti (isivivinyo sokulwa nokugqwala)

5. Ukulinganisa ukubukeka kwe-Dimensional

Uma usathanda ukwazi okwengeziweumgomo wokusebenza kwesihlungi se-sintered, sicela uhlole imininingwane yethu yokuhlola le bhulogi.

B:IsiceloYesihlungi Sensimbi Sintered

6. Kukuphi Ukusetshenziswa Kwezihlungi Zensimbi Ze-Sintered?

Njengoba amaklayenti ethu ebhekisela ekusetshenzisweni okuyinhloko kwesihlungi se-sintered kanje:

1.) Ukuhlunga Okuwuketshezi2. Fluidizing

3. Ukubhuqa4. Ukusabalalisa

5. I-Flame Arrestor6. Ukuhlunga Kwegesi

7. Ukudla Nesiphuzo

7. Ngingakwazi Ukusebenzisa Izihlungi Zensimbi Ezisiyingi ezinezinhlobo Eziningi Zamafutha?

Yebo, kodwa udinga ukwenza ngokwezifiso usayizi wembotshana okhethekile njengamafutha, futhi nemfuneko yokulawula ukugeleza, ngakho

ungakwamukela kuXhumana nathiukuze usazise imininingwane yakho.

8. Ingabe Isihlungi Sensimbi Esiyinsimbi Singaqhubeka Sisebenza Ngisho Nalapho Izimo Kubanda?

Yebo, ngesihlungi sensimbi esine-sintered, esifana ne-316Lisihlungi sensimbi engagqwali sinteredingasebenza ngaphansi

-70 ℃~ +600℃ , ngakhongoba izihlungi eziningi ze-sintered zingasebenza ngaphansi kweqhwa. kodwa kudingeka uqinisekise

Uketshezi negesi kungageleza ngaphansi kwesimo sokubanda.

9. Iluphi Uhlobo Lwamakhemikhali Olungakwazi Ukuhlunga Ngezihlungi Zensimbi Ezisiyingi Nangaphandle Kokulimaza Umzimba Wesihlungi?

Sihlola amakhemikhali amaningi angahanjiswa ngalo mkhiqizo ngaphandle kokuwulimaza,

njenge-phenol enikezwe ukuthi zenziwa kusetshenziswa izinto eziqinile ezimelana namakhemikhali.

1. ) I-Acid

Ama-asidi aqinile: afaka i-sulfuric acid (H2SO4), i-nitric acid (HNO3), ne-hydrochloric acid (HCl).

Ama-acids abuthakathaka ekugxilweni okuphezulu, njenge-acetic acid

B Izixazululo ze-Lewis acid ezinezakhiwo zamakhemikhali ezikhethekile, njenge-zinc chloride

2.) Izisekelo Eziqinile:

kufaka phakathi i-sodium hydroxide (NaOH) ne-potassium hydroxide (KOH)

Izinsimbi ze-alkali (njenge-sodium) esimweni sazo sensimbiI-alkali kanye ne-alkaline Earth metal hydrides

Ukugxila okuphezulu kwezisekelo ezibuthakathaka njenge-ammonia

3.) I-Dehydrating agents,

kuhlanganise high-concentration sulfuric acid, phosphorus pentoxide, calcium oxide,

i-zinc chloride (okungeyona isixazululo), kanye nezakhi zensimbi ze-alkali

4.) Ama-oxidizing agents aqinile,

kufaka phakathi i-hydrogen peroxide, i-nitric acid, ne-concentrated sulfuric acid.

5.)Ama-halogen kagesi

njenge-fluorine, i-chlorine, i-bromine, ne-iodine (ama-ion of halides awagqwali),

kanye nosawoti we-electrophilic njenge-sodium hypochlorite.

6.) I-Organic halides noma i-halides yama-organic acid, njenge-acetyl chloride ne-benzyl chloroformatei-anhydride

7.)Ama-alkylating agentsnjenge-dimethyl sulfate

8.) Ezinye izinhlanganisela eziphilayo

10. Uzihlanza Kanjani Izihlungi Zensimbi Ezisikiwe?

Ukuhlanza okufanele kubalulekile ukuze kugcinwe ukusebenza nokuphila isikhathi eside kwezihlungi zensimbi ezine-sintered.

Kuye ngohlelo lokusebenza—noma ngabe okwegesi noma ukuhlunga okuwuketshezi—kungasetshenziswa izindlela ezihlukene zokuhlanza:

1.I-Blowback Yezicelo Zegesi:

*Kumasistimu okuhlunga igesi, i-blowback iyindlela evamile esetshenziselwa ukuhlanza izihlungi zensimbi ezine-sintered.

Le nqubo ihlanganisa ukubuyisela emuva ukuhamba kwegesi ngesihlungi, ukukhipha izinhlayiya ezivaleleke,

kanye nokusula imidiya yokuhlunga.

2.Ukubuyela emuva kwezicelo zoketshezi:

*Okwezinhlelo zokuhlunga uketshezi, i-backflushing iyindlela yokuhlanza esebenzayo. Le nqubo ihlehlisa ukugeleza koketshezi ngesihlungi ukuze kukhishwe ukungcola okunqwabelene futhi kubuyiselwe ukusebenza kwesihlungi.

3.Ukuhlanza kwe-Ultrasonic:

*Ukuhlanza nge-Ultrasonic kusetshenziselwa ukususa izinto ezingasebenzi ngamakhemikhali kusihlungi. Le ndlela isebenzisa amagagasi omsindo wemvamisa ephezulu ukudala amabhamuza amancane esixazululweni sokuhlanza, esikhipha futhi sikhiphe ukungcola endaweni yesihlungi.

4.Ukuhlanza Amakhemikhali:

Ukususa ukungcola okunenkani, izindlela zokuhlanza amakhemikhali zingasetshenziswa. Lokhu kungase kuhlanganise:

*Ukuhlanza i-Solvent:

Ukusebenzisa ama-solvents afanelekile ukuze kuncibilike futhi kukhishwe ukungcola kwe-organic.

*Ukugeza kwe-Caustic:

Ukusebenzisa izixazululo ze-alkaline ukudiliza nokususa izinto eziphilayo kanye ne-inorganic.

* Ukugeza nge-Acid:

Izixazululo ezine-Acidic zisetshenziselwa ukuncibilikisa amadiphozi amaminerali noma ama-oxide.

I-Water and Air Flush:

Inhlanganisela yamanzi kanye nokushaywa komoya kungasetshenziswa ukususa izinsalela nokuqinisekisa ukuthi isisefo sihlanzeke kahle.

Lezi zindlela zokuhlanza zisiza ekwandiseni impilo yezihlungi zensimbi ezine-sintered, ziqinisekisa ukuthi ziyaqhubeka nokuhlinzeka kahle

kanye nokuhlunga okuthembekile ezinhlelweni ezihlukahlukene.

C:Oda UlwaziI-Sintered Metal Filter

10. Ngingakwazi yini Ukwenza ngokwezifiso isihlungi sensimbi e-sintered lapho ngi-oda kwa-HENGKO?

Yebo, Yebo.

Singakwazi Izihlungi ze-OEM Sintered Metal njengohlu lwakho lwezidingo zokucaciswa okulandelayo:

1. Usayizi Wembotshana

2. Isilinganiso seMicron

3. Isilinganiso sokugeleza

4. Hlunga imidiya ozoyisebenzisa

5. Noma yimuphi usayizi njengomklamo wakho

11. Iyini i-MOQ kuya ku-Wholesale sintered metal filter from HENGKO?

Njengomkhiqizi Wezihlungi Ochwepheshile, sinohlobo oluthile esingalukhetha olufana ne-Sintered Filters Disc,

I-Sintered Filters Tube,I-Sintered Filters Plate, i-Sintered Filters Cup,I-Sintered Filters Mesh, Mayelana ne-MOQ

izosuselwe kwakhousayizi wokuklama nosayizi we-pore njll, okuvamile i-MOQ yethu imayelana nama-200 -1000pcs / into esekelwe ekwakhiweni.

12. Yini eyenza izihlungi zensimbi ze-HENGKO zihluke?

1.) Izihlungi zensimbi ze-HENGKO ze-sintered zihlukaniswa ngokusetshenziswa kweamasu okuphathelene

lokho kuqinisekisa usayizi wezimbotshana ezingaguquki kanye nobuqotho obukhethekile besakhiwo.

2.) Ngaphezu kwalokho, i-HENGKO inikeza okubanziongakhetha ngokwezifiso, okuvumela amaklayenti ukuthi ahlanganise

i-porosity, impahla, kanye nomklamo ukuze kufane ngokuphelele nezidingo zabo zohlelo lokusebenza.

Ucwaningo lwesigameko :

1. I-Case Study Spotlight:I-Industrial Gas Filtration

Ukusebenza Okuthuthukisiwe Ekuhlungeni Igesi Yezimboni Ngezihlungi Zensimbi Ezenziwa Ngezifiso

Inselelo:

Imboni yokucubungula igesi yezimboni ibhekane nezinkinga ngokuncipha kokusebenza kahle ohlelweni lwayo lokuhlunga,

okuholela ekunakekeleni njalo kanye nesikhathi sokuphumula esingalindelekile.

Izihlungi ezikhona azikwazanga ukuphatha ukugcwala kwezinhlayiyana eziphezulu, okuholele ekuvaleni nokuncipha kwezinga lokugeleza.

Isixazululo:

Ochwepheshe bakwa-HENGKO bancome ukuthi kushintshwe izihlungi ezikhona ngezihlungi zensimbi eziklanywe ngokwezifiso ezenziwe ngendlela efanele.

ngezinhlelo zokusebenza zokulayisha izinhlayiyana eziphezulu. Lezi zihlungi zibonise ukwakheka kwembobo okuthuthukisiwe nokuqina okuthuthukisiwe,

yakhelwe ngokukhethekile ukusingatha izidingo zokuhlunga igesi yezimboni.

Umphumela:

Izihlungi ezintsha zensimbi ezine-sintered zahlanganiswa ngaphandle komthungo ohlelweni olukhona, kunciphisa kakhulu ukuvala

izindaba kanye nokugcinwa njalo.

Izihlungi ezithuthukisiwe zinikeze ukwanda okungama-30% kwezinga lokugeleza kanye nokusebenza okuthuthukisiwe okuphelele kwesistimu.

Ngokwamukela izihlungi zensimbi ezenziwe ngokwezifiso ze-HENGKO, indawo yokucubungula igesi yezimboni yaba nokumakwa

ukuthuthukiswa kokusebenza kahle kokuhlunga, ukuphila kwesihlungi esandisiwe, nokunciphisa isikhathi sokusebenza sokunciphisa.

Isixazululo asigcinanga nje ngokuthuthukisa ukukhiqiza kodwa futhi sibe nesandla ekusebenzeni okungabizi kakhulu ngokunciphisa

izindleko zokunakekela kanye nokuqinisekisa ukusebenza kwesistimu okungaphazamiseki.

Usenemibuzo futhi uthanda ukwazi eminye imininingwane yeI-Sintered Metal Filter, Sicela uzizwe Ukhululekile Ukuxhumana Nathi Manje.

Futhi UngakwaziSithumele I-imeyiliNgokuqondile Ngokulandelayo:ka@hengko.com

Sizothumela Emuva Ngamahora angu-24, Siyabonga Ngesiguli Sakho !