Nge-Sintered Metal, Yini leyo?

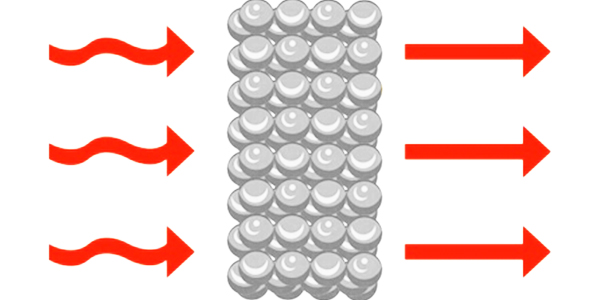

YiniIsimiso Esisebenzayo Sokuhlunga Sintered?

Kafushane ukusho, Ngenxa yohlaka oluzinzile olunembobo,izihlungi zensimbi ze-sinteredzingenye yezinto ezingcono zokuhlunga

namuhla.Futhi, izinga lokushisa eliphezulu lezinto zensimbi, umfutho ophezulu, nokumelana nokugqwala kungakusiza

qedela kalula umsebenzi wokuhlunga endaweni enzima, Ukuhlukanisa nokuhlunga ukungcola okweqile

awudingi noma ukukusiza ukuthi ukhiphe amagesi aphezulu wokuhlanzeka noma uketshezi lwephrojekthi yakho.

Mhlawumbe Akufanele uzwe leli gama kakhulu empilweni yakho yansuku zonke.

Kodwa namuhla, insimbi egxiliwe ukuze isetshenziswe ngokwengeziwe ezimbonini ezihlukahlukene, insimbi ehlanganisiwe isiqalile ukuba

iubuchwepheshe obubalulekile ekukhiqizeni okuthile.

Khona-keYini Kahle Insimbi Eyenziwe Ngensimbi?

Empeleni, igatsha lemboni ye-powder metallurgy, ngamafuphi, insimbi engagqwali engu-316L.powder ngokusebenzisa isikhunta

ukubumba, izinga lokushisa eliphezulu lingena esimeni kanye nomsebenzi wenqubo esiyidingayo.

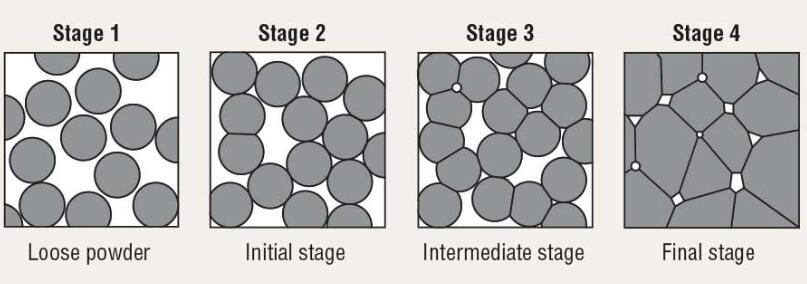

Bese, Okokuqala, sintered.Yini i-sintered?I-Sintering inqubo yokuhlanganisakanye nokwenza inqwaba eqinile yeimpahla

ngokushisa noma ngokucindezelwa ngaphandle kokuyincibilikisa kuze kube seqophelweni lokuncibilika.I-Sintering iyingxenye yeinqubo yokukhiqiza esetshenzisiwe

ngensimbi, izitsha zobumba,amapulasitiki, nezinye izinto.I-Wikipedia

Njengoba i-Wikipedia ichaza, izinhlobo eziningi zezinto zingafakwa, futhi imikhiqizo ehlukene ye-sintered inayo

ezahlukeneizicelo.Khona-ke lapha sithandaukukhuluma imininingwane eyengeziwe mayelana nensimbi e-sintered.

UmlandoyeSintering Metal

1. Ubani owasungula i-sintering futhi waqala ukusebenzisa imikhiqizo ehlanganisiwe?

Ngokusho kwamarekhodi omlando, inqubo ye-sintering yavela phakathi nenguquko yesibili yezimboni ngekhulu le-18

eSwedenkanye neDenmark.Insimbi ene-sintered kwabaezitholakala ngesikhathi sokuncibilikiswa ezimayini zamalahle.Kodwa kuze kube ngu-1980, abantu

waqala ukusebenzisainsimbi ene-sintered emafutheni okuhlunga.Futhi ngo-1985, eyokuqala yasebenzisa i-HyPulse®ubuchwepheshe bokuhlunga kwe

ukuhlunga okuqhubekayo kukawoyela we-slurry.

Kuphawula ukuqala kwezihlungi zensimbi ezisikiwe.

Ukusetha kubonise ukufaneleka kwemidiya yensimbi ene-sintered yokuhlunga ukushisa kwamafutha aludaka ku-carbon fiber.

inqubo yokukhula.

Isihlungi sisebenze ngokunembile iminyakaukudala uwoyela ohlanzekile ngezinto eziqinile ezingaphansi kuka-20 ppm okuqinile futhi kwaba

ekugcineni yavalwaphansi ngenxa yesidingo esiphansi sento.Kusukela lapho, izindawo zokuhluza emhlabeni wonke ziye zasebenzaqaphela i

izinzuzo filtration usebenzisaimidiya yensimbi ye-sintered yokuqedwa kwezinhlawulo ze-catalyst kuzixazululo zikawoyela oludaka.

Kusukela ngo-1997, izindawo zokucwenga eziningi e-China zifake amasistimu okuhlanza i-LSI ukuze kuqedwe ukuvuselela ku-resid.

i-fluid catalyticamasistimu e-fracturing (RFCC).Setha u-Aisistimu yokuhlunga enezihlungi ezingu-(2) 24" LSI yamiswa ku-RFCC

uhlelo nge-1.4 millionizibalo (mt) amandla onyaka ngamunye kanye nomphumela wamafutha aludaka we-180 mt/ngosuku.I

uwoyela slurry has an evamile 3,000 ukuze5,000 ppm okuqinile ukugxila.Isikhathi somjikelezo siyahlukahluka kusuka emahoreni ama-2 kuye kwayi-8.I-filtrate solids

impahla ingaphansi kuka-50 ppm.Isihlungi siyalawulwange-PLC yendawo exhumana nendawo yokucwenga esabalalisiwe

control system (DCS) ukuze umshayeli akwazi ukuqaphaukuhlanzwa endaweni yokulawula.Uhlelounayo

ibisebenza njalo, ihlinzeka ngebhizinisi lendawo nge-filtrate ehlanzekile kukhiqiza i-carbon black.Ngakho njengoba

isicelo, i-Sintered Metal, Isetshenziswa kakhulu ukuhlunga noma ukuhlukanisa okuqinile noma omagazinikusuka oketshezini noma

amagesi ngenhloso yokuhlanza.

2. Ngakho-ke Iyini I-Sintered Metal Filter?

Incazelo elula yesihlungi se-sintered metal:Kuyisihlungi sensimbi esisebenzisa izinhlayiya zempushana zensimbi ezifanayo

usayizi wezinhlayiyanaukubunjwa ngesitembu,high-temperature sintering inqubo.I-Sintering yinqubo ye

i-metallurgy kusetshenziswa i-powder-sizeimizimba yezinsimbi ezahlukene nama-alloys ngemva kokunyathela.

I-Metallurgy yenzeka ngokusabalalisa emazingeni okushisa angaphansi kwendawo yokuncibilika yezithando zokushisa eziphezulu.

Izinsimbi nama-alloysesetshenziswa kakhulu namuhlazihlanganisa i-aluminium, ithusi, i-nickel, ithusi, insimbi engagqwali,

kanye ne-titanium.

Kunezinqubo ezahlukene ongazisebenzisa ukwenza impushana.Zihlanganisa ukugaya, i-atomization,

kanye nokubola kwamakhemikhali.

3. Yini iSintering Inqubo Yokukhiqiza Isihlungi Sensimbi

Bese, ngakho-ke lapha, sithanda ukuhlola imininingwane yenqubo yokukhiqiza isihlungi se-Metal.uma uthanda, sicela uhlole ngezansi:

1.) Kuyini i-Sintering, Kungani Usebenzisa I-Sintering?

Incazelo elula i-sintering iyimpushana yensimbi ihlanganiswa ngokushisa okuphezulu nezinye izindlela zibe

module oyifunayo.Ebangeni le-micron, akukho ukulinganiselwa ngokomzimba phakathi kwezinhlayiya zempushana yensimbi,

yingakho singakwazi ukulawula ibanga le-pore

ngenqubo yokukhiqiza.

I-cartridge ene-porous yenqubo ye-sintering inikeza ukuma okuzinzile kwensimbi futhi inikeza

impahla ngeukusebenza kokuhlunga okuqinile.

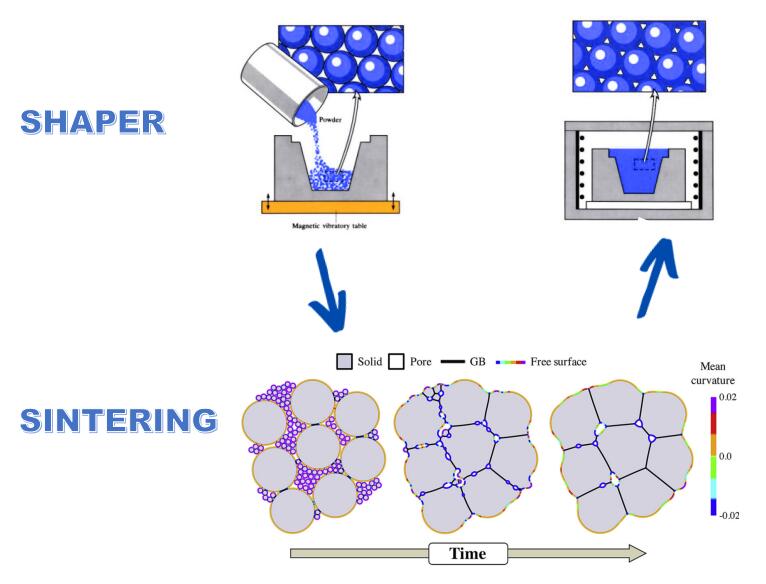

2.)3-OkubalulekileIzinyathelo Zokukhiqiza Isihlungi Sensimbi Yensimbi

A: Isinyathelo sokuqala ukuthola i-Power Metal.

Impushana yensimbi, Ungathola izimpushana zensimbi ngokugaya, i-atomization, noma ukubola kwamakhemikhali.

Ungakwazi ukuhlanganisa insimbi eyodwaimpushana nenye insimbi ukwenza ingxubevange ngesikhathi senqubo yokwenziwa,

noma ungasebenzisa impushana eyodwa kuphela.Inzuzo yokucula yilokhoakushintshi ngokomzimba

izakhiwo zensimbi.Inqubo ilula kangangokuthi izakhi zensimbi aziguqulwa.

B: Ukunyathela

Isinyathelo sesibili ukuthululela i-powder yensimbi ibe isikhunta esilungiselelwe ngaphambili lapho ungabumba khona isihlungi.

Ukuhlanganiswa kwesihlungi kwakhiwa ekamelweniizinga lokushisa nangaphansi kokugxivizwa.Inani lokucindezela elisetshenzisiwe

kuncike ensimbi oyisebenzisayo, njengoba izinsimbi ezihlukene zinokunwebeka okuhlukile.

Ngemuva komthelela wengcindezi ephezulu, impushana yensimbi ihlanganiswa esikhunjeni ukuze yakhe isihlungi esiqinile.Ngemva kwe

inqubo yomthelela womfutho ophezulu, ungakwazibeka isihlungi sensimbi esilungisiwe esithandweni sokushisa okuphezulu.

C: I-High-temperature Sintering

Enqubweni ye-sintering, izinhlayiya zensimbi ziyahlanganiswa ukuze zakhe iyunithi eyodwa ngaphandle kokufinyelela endaweni yokuncibilika.

Le monolith iqine ngendlela efanayo,iqinile, futhi inezimbotshana zokuhlunga njengensimbi.

Ungakwazi ukulawula i-porosity yesihlungi ngenqubo ngokusho kwezinga lokugeleza komoya noma uketshezi okufanele luhlungwe.

Isikhundla sebanga lemidiya ehlanganisiwe silingana nembotshana yokugeleza emaphakathi, noma usayizi omaphakathi wesihlungi.

Sintered metal media kukhonakunikezwa ngamabanga 0.1, 0.2, 0.5, 1, 2, 5, 10, 20, 40 kanye ne-100. Isilinganiso sokuhlunga

uketshezi lwamabanga emidiya 0.2 kuya ku-20 luphakathi kuka-1.4 no-35 µmngokuphelele.Isilinganiso sokuhlunga kububanzi begesi

kusuka ku-0.1 kuye ku-100 µm ngokuphelele.

4. Kungani Kufanele Usebenzise I-Metal Sintering Ukwenza Isihlungi?

Lona umbuzo omuhle, kungani usebenzise insimbi ukwenza isisefo?

Impendulo ilula, futhi nakuba kunezizathu eziningi, izindleko zibaluleke kakhulu.

Kungani Izindleko?

Yebo, insimbi ecwilisiwe inesakhiwo esizinzile futhi ingasetshenziswa kabusha, ihlanzeke futhi isetshenziswe izikhathi eziningi.

Futhi futhi, izinsimbi ezahlukene zinezakhiwo ezizinzile zomzimba namakhemikhali futhi azilinyazwa kalula.

Kungakho Izihlungi eziningi ze-Sintered zisetshenziswa ezimbonini ezahlukahlukene.

5. Zithini Izinto EzikhethwayoIzihlungi ze-Sintered?

Ngokuqhubeka okuqhubekayo kobuchwepheshe be-powder metallurgy, kunezinketho eziningi

izinto zokuhlunga zensimbi ezine-sintered,

Ungakhetha kwezinye izinsimbi eziningi nama-alloys ukuze uhlangabezane nezidingo ezikhethekile eziphakeme

izinga lokushisa nokucindezela, ukugqwalaukumelana njll, Izinto eziyinhloko zensimbi ezifana:

-

Isihlungi Sensimbi Engagqwali;316L, 304L, 310, 347 kanye no-430

-

Ibhulonzi

-

I-Inconel® 600, 625 kanye ne-690

-

I-Nickel200 ne-Monel® 400 (70 Ni-30 Cu)

-

I-Titanium

-

Ama-alloys

Insimbi eyengeziwe izosetshenziswa esikhathini esizayo.

6. 8-Izinzuzo Eziyinhloko Zesihlungi Sensimbi Sensimbi

1. ) Ukumelana nokugqwala

Izinsimbi eziningi azikwazi ukumelana nokugqwala, njengama-sulfide, ama-hydrides, i-oxidation, njll.

2. ) Ukususwa okusebenzayo kokungcola

Ukulungisa i-porosity ye-cartridge ku-fluid kusho ukuthi ungakwazi ukufeza okuphelele

ukuhlunga okufunayo futhi uthole auketshezi olungangcolisi.Futhi, njengoba isihlungi singagqwali,

ukusabela kwesihlungi akuholeli ebukhonenikokungcola oketshezini.

3. ) I-High Thermal Shock

Phakathi nenqubo yokukhiqiza, ukushisa okuphezulu kukhiqizwa, kanye nezakhiwo ezibonakalayo ze

lezi zinsimbi zisiza ukumuncaukushaqeka okukhulu kokushisa kwesihlungi.Ngenxa yalokho, ungasebenzisa lezi

izihlungi ezinhlobonhlobo zezinhlelo zokusebenza kuye ngokuthiuhla olushisayo lohlelo lokusebenza.

Ukushaqeka okukhulu okushisayo kuqinisekisa ukuhlunga okusebenzayo koketshezi ngaphandle kokukhathazeka ngakho

ukushisa kwesicelo.

4,) Ukwehla Kwengcindezi Okunengqondo

Aisihlungi sensimbi esine-sinteredungagcina umfutho we-fluid kuhlelo lwakho lokusebenza, ngaleyo ndlela uqinisekise

ukusebenza okuphezulu.

Ukwehla kwengcindezi encane kungalimaza uhlelo lwakho lokusebenza.

5. ) Izinga lokushisa kanye nokumelana nokucindezela

Ungasebenzisa lesi sihlungi ezinhlelweni ezinamazinga okushisa aphezulu nezingcindezi ngaphandle

ukukhathazeka mayelana nesici sakho sokuhlunga.

Ukusebenzisa izihlungi zensimbi ezine-sintered ekukhiqizeni ukusabela kwamakhemikhali negesi

izitshalo zokwelapha ziyakuqinisekisathola imiphumela engcono kakhulu yokuhlunga.

6. ) Iqinile futhi Imelana Nokwephuka

Enye inzuzo yokusebenzisa isihlungi sensimbi esine-sintered ukuthi sinamandla futhi amelana kuso

ukuphuka.

Phakathi nenqubo yokukhiqiza, ukuhlangana kwezinsimbi kwenzeka emazingeni okushisa kahle

ngaphansi kwendawo yokuncibilika.

Umkhiqizo owumphumela uyisihlungi sensimbi esiqinile esingakwazi ukumelana nezinhlobonhlobo

izindawo ezinokhahlo.

Isibonelo, ungayisebenzisa ezinhlelweni ezidinga ukungqubuzana ngaphandle kokwesaba ukuphuka.

7.) Ukubekezelelana Okuhle

Ukubekezelela okuhle kusho ukuthi isihlungi sakho sensimbi esine-sintered singasefa uketshezi lwakho ngaphandle kokusabela.

Uma ukuhlunga kwakho sekuqediwe, isihlungi se-sintered metal sizogcina izici zaso ezibonakalayo.

Nokho, kungasiza uma wenza isiqiniseko sokuthi insimbi oyikhethayo yesihlungi sakho ngeke

sabela ngoketshezi oluhluzayo

8.) Uhlu Lwamathuba EJiyomethri

Ama-cartridges ahlanganisiwe akuvumela ukuthi ujabulele izinhlobonhlobo zezinketho zejometri.Ungakwazi ukufeza

lokhu ngenkathi efaka impushanakudayi ngesikhathi sokukhiqiza.

Isikhunta yisona okufanele siklame isihlungi sakho.

Ngakho-ke, ukhululekile ukusebenzisa umklamo ngokuya ngemininingwane yakho.

Isibonelo, uma uhlelo lwakho lokusebenza ludinga isihlungi esincane, ungakwazi ukukhohlisa idizayini kalula

ukuthola okuncane

isihlungi sensimbi esine-sintered.Ngokufanayo, uma uhlelo lwakho lokusebenza lunomklamo ohlukile, ungakwazi kalula

phatha umklamo kuisikhunta ngesikhathi sokukhiqiza.

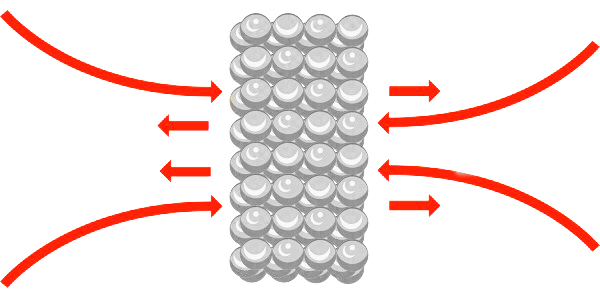

7. Zisebenza kanjani izihlungi ze-Sintered Metal?

Le nkinga ingabuye ishiwo ukuthi iyisimiso sokusebenza sezihlungi zensimbi ze-sintered.Abantu abaningi bayacabanga

ukuthi lo mbuzokunzima kakhulu ukuphendula, futhi akunjalo.Ungase umangale ngalokhu, kodwa mhlawumbe wena

ngeke kube ngemva kokufunda incazelo yami.

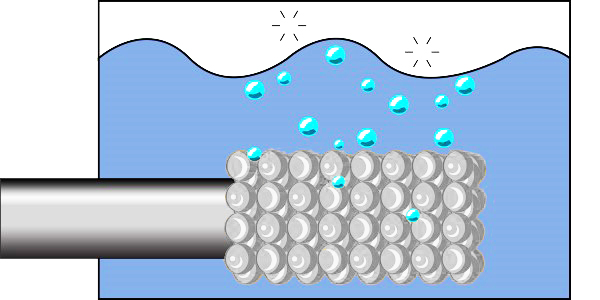

Izihlungi zensimbi ezi-sintered ziyizihlungi eziwusizo kakhulu.Ukuqoqwa kokungcola kwenzeka ebusweni be

uketshezi;lapho iuketshezi ludlula ngesihlungi sensimbi, iizinhlayiya ezinkulu kanye ukungcola kuyoba

kwesokunxele ngakolunye uhlangothi i-cartridge, kodwa niniukukhetha izinga lokuhlunga elisebenzayo loketshezi lwakho, wena

kudingeka uqiniseke ukuthiingakwazi ngisho nokuhlunga izidingo.

Lezi Zimfuneko zihlanganisa

1. Ukugcinwa Okungcolile Amandla Wokugeza Ungemuva

2. Ukwehla Kwengcindezi

Ukuze unciphise ingcindezi, udinga ukucabangela izici eziningana.

Lezi zici zihlanganisa

AI-viscosity ye-Fluid, isivinini soketshezi njengoba igeleza kusici sokuhlunga, nezici ezingcolisayo.

BIzici ezingcolile zifaka umumo wezinhlayiyana, ukuminyana, nosayizi.

Uma ukungcola kuqinile futhi kusesimweni esivamile, kwakha ikhekhe eliminyene, khona-ke ukuhlunga kwendawo kufanelekile.

Ukusebenza Kwe-Sintered Metal Filtration kuncike

1.ukucindezela okwenyuka kwehla kuze kufike lapho ukucindezela okuphelele kufinyelelwa khona.

2.ukugeleza njalo koketshezi.

Ungakwazi ukufeza izimo zokugcina ngokuqinisa ukungcola okukhuphuka kuze kufike lapho ukucindezela koketshezi kwehla khona.

Lokhu kucindezela kwehla ngokuqhubekayo kuze kube yilapho ukwehla okuphezulu kwe-viscosity enikeziwe kanye nemfuneko yezinga lokugeleza kufinyelelwa.

Enye indaba ebalulekile ukugeza emuva kwesihlungi, okwenziwa ngokucindezela igesi esikrinini futhi ngokushesha.

ukuvula i-valve yokukhipha i-backwashnjengoba kwenzeka i-backwash.

Umehluko ophezulu wengcindezi esheshayo ehlanekezelwe yikukhiqizwa.Isusa ngokuphumelelayo ukungcola kusihlungi

indawo yesici.Okuphambeneukugeleza koketshezi oluhlanzekile ngokusebenzisa isici sokuhlunga kususa ukungcola futhi kuqondise

ngaphandle kwesihlungi.

Ukwenyuka okuqhubekayo kwezinga lokwehla kwengcindezi kubonisa ukusabalalisa okungaguquki nokufana kosayizi wokungcola.To

ukuzuza okungaguqukiukusebenza, kufanele uqinisekise ukuthi ukwehla kokucindezela kwesici sokuhlunga kuzinzile.Uma izinga lokushisa

izinguquko uketshezi, kuyathintai-viscosity yoketshezi.Kulesi simo, ingcindezi yehla kuso sonke isihlungiisici sizokwenza

ukwandisa futhi ungatholi umphumela wokuhlunga.

Ngakho-ke, udinga ukugcina izinga lokushisa lokusebenza kwesihlungi ngesikhathi senqubo yokuhlunga futhi

uqinisekise iizinga lokushisa loketshezi nomfutho.Lapho uhlanza isihlungi, udinga ukulandela i-

inqubo yokuwasha umhlane efanele.

Zisebenza kanjani izihlungi ze-Sintered Metal?

Ungaqonda kalula uma uhlola okulandelayoUmdwebo wesimiso sokusebenza

Njengoba okulandelayo kuyinhloko8-IzinhlobokweTheisimiso sokusebenza sokuhlunga kwensimbi, ngethemba ukuthi kuzoba usizo kuwe

qonda okwengeziwekanjaniIsihlungi se-sintered metal singasizangoba fiteration liquit, igesi kanye nezwi.

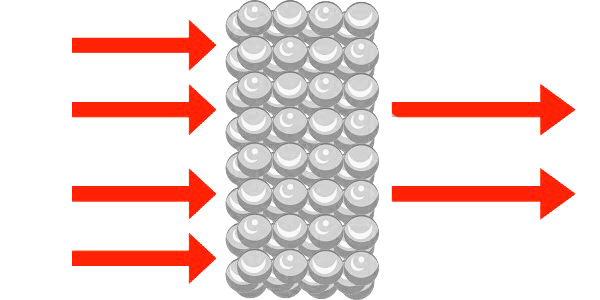

1.) Ukuhlunga/Ukuhlukanisa Uketshezi Negesi

Izihlungi ze-Sintered Metal zinganciphisa noma zisuse ngokuphelele i-particle kugesi noma i-liquid medium.

I-particle canzihlanganisa kodwa azikhawulelwe ezinhlayiyeni ezimisiwe (intlenga, ama-metal chips, usawoti, njll.),

ulwelwe, amabhaktheriya, isikhunta spores, futhi okungafunwaukungcola kwamakhemikhali/kwebhayoloji.Izimbotshana zesihlungi zensimbi

ingenza kube ibanga ukusuka ku-0.2 µm - 250 µm.

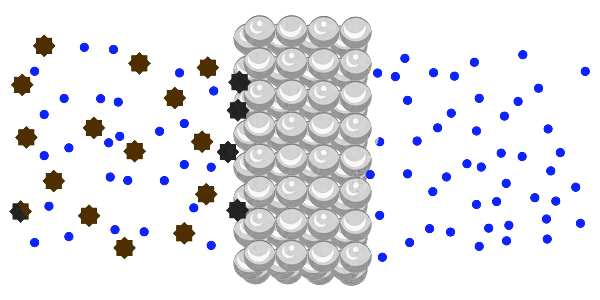

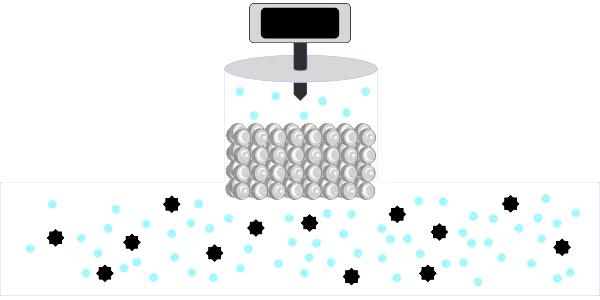

2.)Sparger

Ezinye ze-Sparing Applications:

I-Soda Carbonization

I-Beer Carbonization

Umoya-mpiloUkuchithwa Kwamafutha Adliwayo

I-Sparging ukwethulwa kwegesi oketshezini.Isetshenziselwa ukususa igesi encibilikisiwe engadingeki

(ukukhipha umoya-mpilo) nomauketshezi oluguquguqukayo oluncibilikisiwe.Ingasebenzisa futhi ukwethula igesi ibe uketshezi (carbonization).

Ukwehlukana kwendabuko kwakha amabhamuzaububanzi obuyi-6 mm.Ukuhlunga kwe-PM kuvumela okuncane nakakhulu

bubble ububanzi, ngaleyo ndlela ukwandisa indawo engaphezuluamabhamuza adala ukuqhuma okuphumelelayo

isicelo ngokunciphisa isikhathi senqubo.

3.) Izimbobo zokuphefumula

Izihlungi zensimbi ezi-sintered nazo zisetshenziswa njengama-vents okuphefumula kumasilinda, ama-gearbox, ama-manifolds, amasistimu we-hydraulic,

amadamu, nokunyeizinhlelo.Izikhala zokuphefumula zivumela ukulinganisa kwengcindezi nomoya/igesi ukungena nokuphuma ohlelweni

ngenkathi ivimba i-particle matterukungena ohlelweni.Izihlungi zensimbi zingabuye ziwashwe ukuze kukhishwe izinhlayiya

okubalulekile, okubanika isikhathi eside sokuphila njengokuphefumulavula kunenye imidiya yokuhlunga.

4.) Ukuvikelwa Kwenzwa

Izihlungi ze-Sintered Metal nazo zingavikela izingxenye ze-elekthronikhi njengesembozo, njengama-thermometers,

izinzwa ezahlukahlukene,ukhiyeizingxenye zezinhlelo zezokwelapha, neminye imikhiqizo ebucayi evela emanzini,

uketshezi, inzika, uthuli, kanyeukushintshashintsha kwengcindezi.

5.) Ukulawula Ukugeleza (Ukudonsa / Ukudambisa)

Isihlungi esikhethekile se-sintered singalawula ukugeleza ngaphakathi komoya, igesi, i-vacuum, nesistimu yokugeleza koketshezi.I

iyunifomu yesihlungipore osayizivumela ukulawulwa kokugeleza okungaguquki, okuphindaphindekayo nokuvikela ama-valve, izinzwa,

kanye nanoma yini enye engaphansiohlelweni kusukaukungcola.Ukulawula ukugeleza kusetshenziswa kulokho

izinhlelo zokusebenza njengezibali sikhathi ze-pneumatic, ukulawulwa kokuhlinzekwa kwegesiizici, nokubambezeleka kwesikhathiizakhi ku

izicelo zezimoto.

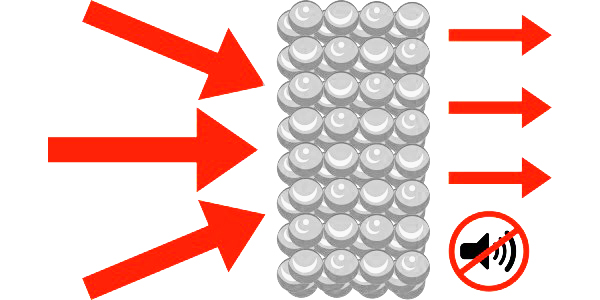

6.) Ama-Air Exhaust Silencers

Izihlungi ze-Sintered zingashiselwa noma zihlanganiswe ne-sinter kunoma yikuphi ukufakwa okudingekayo, okuzivumela ukuthi zisebenze njenge-

exhaust silencer.Isihlungi asikwazi ukuvikela kuphela ama-solenoid nama-manifolds ekungcoleni ngaphakathi

uhlelo kodwa futhi inciphisa umsindoizinga lokuqeda amandla ohlelweni.Izihlungi ze-air exhaust silencer

futhiyehlisa umoya ovunguzayo ophuma ohlelweni, okuthikunciphisa ukungcola, Ukuvikela

imvelo.

7.) Ukugeleza / Ukulinganisa Kwengcindezi

Izihlungi ze-Sintered zingalingana futhi zilawule izinga lokugeleza kwesistimu nengcindezi.Ukulinganisa kuyavikela

amasistimu ngokumelene nokuhlinzwayoketshezi futhi idale ukugeleza okufanayo njengoba igesi noma uketshezi ludlula

i-uniform pores.

8. Yiziphi Izihlungi ze-Sintered ezisetshenziselwa?

Kulo mbuzo, Empeleni abantu abaningi bazobuza Yini ukusetshenziswa kwezihlungi zensimbi ezine-sintered?

Ngemva kwenqubo eyinkimbinkimbi kangaka, azosetshenziswa kuphi amakhatriji okuhlunga ensimbi?

Iqiniso liwukuthi ungathola lezi zihlungi ezimbonini ezihlukahlukene.

Izinhlelo zokusebenza ezijwayelekile zihlanganisa okulandelayo.

1) Ukucubungula kwamakhemikhali

Ungathola izihlungi zensimbi ezine-sintered embonini ye-solvent yamakhemikhali kanye ne-gas processing, kuhlanganise

imboni yenuzi.Ukugqwala, izinga lokushisa eliphezulu, nokungasabelani kumakhemikhali kwenza insimbi ene-sintered

ihlunga inzuzo ehlukile kuyo

imboni yokucubungula amakhemikhali.

2) Ukucwengwa kwe-petroleum

Ukuze kucwengwe i-petroleum, ukuhlunga ngempumelelo amafutha ahlukene

Kudingeka sisebenzise izihlungi zensimbi ezihlukene ngokwezinga ledigri ukuze siqedele ukuhlunga kwe

uphethiloli othize kusukaisitoko sokuphakelayo.Yebo, izihlungi zensimbi ezine-sintered zingakusiza ukufeza lo mgomo.

Ngoba izihlungi zensimbi azisabeli ngamakhemikhali ngophethiloli.

Ngakho-ke, uphethiloli othize uzokhululeka kunoma yikuphi ukungcola ngemva kokuhlunga.

Ngaphezu kwalokho, ungayisebenzisa emazingeni okushisa aze afike ku-700 °, okuvame ukuhlanzwa kwe-petroleum.

3.) Ukukhiqiza amandla

Ukukhiqizwa kwamandla kagesi kudinga ukusebenza okuqhubekayo kwe-turbine.Noma kunjalo, i

imvelo kuokuyinto i-turbineisebenza ngokuvamile idinga ukuhlunga ukuze kuzuzwe amanzi amaningi

i-turbine engenakho ukungcola.

Uma i-turbine igcwele ukungcola, izophela futhi ivimbele i-turbine ekujikelezeni,

bese kuthi i-turbine izokwenzaungaphehli ugesi.Ungasebenzisa izihlungi zensimbi ze-sintered ukuze uqinisekise

ukukhiqiza ugesi ngendlela ephumelelayo nephumelelayo.

Lezi zihlungi zisetshenziselwa ukukhiqiza ugesi ngokuhlunga amanzi ku-turbine.

Ngenxa yokuthi azigugulwa ngamanzi, i-turbine izosebenza isikhathi eside.

4.) Ukukhiqizwa kwegesi yemvelo

Enye indawo ebalulekile yokusetshenziswa kwezihlungi zensimbi ezi-sintered ukukhiqizwa kwegesi.

Izihlungi zensimbi ezine-sintered ziwusizo kakhulu ekukhiqizeni igesi ngoba azisabeli negesi,

futhi ungazisebenzisaezindaweni ezahlukene.

5.) Ukudla nesiphuzo

Izihlungi zensimbi zikhipha imisoco ebalulekile namajusi embonini yokucubungula ukudla neziphuzo.

Izihlungi zensimbi zihlunga kahle futhi zivimbele lezi zakhi ukuthi zingakhukhuleki ngesikhathi zicutshungulwa.

Inzuzo yezihlungi zensimbi ezifanayo ukuthi aziphenduli ngokudla okuthile noma iziphuzo.

Uma usebenzisa lezi zihlungi kuqinisekisa ikhwalithi yenqubo yakho yokukhiqiza.

9. Hlobo luniIzihlungi Zensimbi EzihlanganisiweHENGKO Can Supply ?

I-HENGKO main supply 316L, 316 kanye namafayili ensimbi ane-bronze sintered.umumo oyinhloko njengohlu olulandelayo:

1.Isihlungi Sensimbi EngagqwaliIdiski,

2.IngenabalaIsihlungi SensimbiIthubhu,

3.Ingenabala Isihlungi SensimbiIpuleti,

4.Isihlungi Sensimbi EngagqwaliIzinkomishi,

njll., noma yimuphi umumo odingwa yiphrojekthi yakho.

Impela, siyanikezelaIsevisi ye-OEM

1.I-OEMIsimo:Idiski, indebe,Ithubhu, Ipuleti ect

2.Enza ngendlela oyifisayoUsayizi, Ubude, Ububanzi, OD, ID

3.Usayizi Wembobo Owenziwe Ngezifiso /Izimbobokusuka ku-0.1μm - 120μm

4.Enza ngendlela oyifisayo Ubukhulu obuhlukile

5.I-Mono-layer, I-Multi-layer, Izinto Ezixubile

6.Idizayini edidiyelwe enezindlu ezingama-304 zensimbi engagqwali

Ngemininingwane Yakho Eyengeziwe ye-OEM, sicela uthinte i-HENGKO Namuhla!

Usenemibuzo efana nokwazi imininingwane eyengeziwe Yenzwa Yokuqapha Umswakama,

Sicela uzizwe ukhululekile ukuxhumana nathi manje.

Futhi UngakwaziSithumele I-imeyiliNgokuqondile Ngokulandelayo:ka@hengko.com

Sizothumela Emuva Ngamahora angu-24, Siyabonga Ngesiguli Sakho !

Thumela umlayezo wakho kithi:

Isikhathi sokuthumela: Aug-20-2022