Njengoba Sazi Kuze kube manje, ubuchwepheshe bokuhlunga budlala indima ebalulekile ezicini ezingenakubalwa zempilo yethu kanye nezimboni,

okuthinta yonke into kusukela emoyeni esiwuphefumulayo kuye emanzini esiwaphuzayo kanye nemikhiqizo esiyisebenzisayo. Kuyinqubo

ehlukanisa izinhlayiya ezimisiwe oketshezini (igesi noma uketshezi) ngokuludlulisela esivinjeni esinezimbotshana esibizwa ngokuthi isisefo.

Ukuhlunga kubalulekile ngenxa yezizathu ezihlukahlukene:

* Ukuhlanza:

Ukukhipha ukungcola oketshezini namagesi, kukwenze kuphephe ukusetshenziswa noma ukusetshenziswa ezinqubweni ezihlukahlukene.

* Ukuvikelwa:

Ukuvimbela izinhlayiya eziyingozi ukuthi zingangeni emishinini nasezinhlelweni ezibucayi, kuqinisekisa ukusebenza kwazo ngendlela efanele

kanye nokwelula isikhathi sabo sokuphila.

* Ukuvikelwa kwemvelo:

Ukukhipha ukungcola emoyeni nasemanzini, kube nomthelela endaweni ehlanzekile.

* Ukubuyiselwa kwezinsiza:

Ukwehlukanisa izinto ezibalulekile kuketshezi, okuvumela ukusetshenziswa kwazo futhi nokunciphisa ukungcola.

* Ikhwalithi yomkhiqizo:

Ukuqinisekisa ukuthi imikhiqizo ihlangabezana nezindinganiso ezifiselekayo zokuhlanzeka nokucaca.

Emkhakheni wobuchwepheshe bokuhlunga, ukugxila kwethu okuyinhloko kugxile kokuthi

izindlela ezimbili ezihlukene:Igesi kanye Noketshezi.

Kodwa-ke, kubalulekile ukuqaphela ukuthi akuwona wonke amagesi noketshezi okufanayo, futhi ngenxa yalokho, kudinga ukuhlelwa ngendlela efanele.

izindlela zokuhlungaukuqinisekisa ubumsulwa obuphelele kanye nekhwalithi. Le ndlela ehlanganisiwe iyisihluthulelo sokuthola okungcono kakhulu

kungenzeka igesi noma uketshezi kokulandelayoizinqubo zokukhiqiza.

Ngokuqonda nokusebenzisa amasu athile okuhlunga ezinhlobo ezahlukene zamagesi noketshezi,

singakwazi ngokuphawulekayoukuthuthukisa ukusebenza kahle nokusebenza ngempumelelo kwemizamo yethu yokukhiqiza.

Ukuhlunga Kwegesi

Ukuhlunga kwegesi kuyinqubo yokukhipha izinhlayiya ezingafunwa kanye nokungcola emfudlaneni wegesi. Iyadlala

indima ebalulekile ekusetshenzisweni okuhlukahlukene njengokuhlanzwa komoya, ukucutshungulwa kwegesi yezimboni, nokuvikela okubucayi

imishini. Nazi ezinye zezinhlobo eziyinhloko zobuchwepheshe bokuhlunga igesi:

1. Izihlungi zikaMechanical:

Lezi zihlungi zithwebula izinhlayiya ngokusekelwe kusayizi wazo. Ngokuvamile basebenzisa i-mesh noma i-membrane enezimbotshana

mancane kunezinhlayiya okufanele zikhishwe. Njengoba igesi idlula isihlungi, izinhlayiya zibambeke

ebusweni bolwelwesi.

Izinhlobo Zezihlungi Zemishini:

* Izihlungi zokujula:

Lezi zinesakhiwo esiwugqinsi, esine-fibrous esivalela izinhlayiya ezingaphakathi kwezingqimba zazo.

Zisebenza ngempumelelo ekususeni izinhlayiya ezinkulu kodwa zingaba nokwehla komfutho ophezulu.

* Izihlungi ze-Membrane:

Lezi zinolwelwesi oluncane, olunezimbotshana oluvumela ama-molecule egesi ukuba adlule kuyilapho egcina izinhlayiya ezinkulu.

Ngokuvamile zisebenza kahle kakhulu kunezihlungi zokujula futhi zinengcindezi ephansi yokwehla.

2. Izihlungi ze-Adsorption:

Lezi zihlungi zisebenzisa izinto ezifana nekhabhoni ecushiwe ukuze zibambe ama-molecule. Impahla ye-adsorbent inobukhulu

indawo engaphezulu enezimbotshana eziheha futhi zibambe ama-molecule egesi. Njengoba igesi idlula esihlungini,

ama-molecule angafuneki akhangiswe phezu kwe-adsorbent.

Izinhlobo zezihlungi ze-Adsorption:

* Izihlungi zekhabhoni ezicushiwe:

Lolu uhlobo oluvame kakhulu lwesihlungi se-adsorption. Ikhabhoni ecushiwe yi-a

impahla enezimbobo kakhulu ezingakhanga inhlobonhlobo yamagesi.

* Izihlungi ze-molecular sieve:

Lezi zisebenzisa izinto ze-zeolite ukuze zikhethe ama-molecule athile.

3. Izihlungi Zekhemikhali:

Lezi zihlungi zisebenzisa izinto ezisebenzayo ukuze zinciphise amagesi ayingozi. Ukusabela kwamakhemikhali kuguqula i

igesi eyingozi ibe umkhiqizo ongenangozi ongadedelwa ngokuphephile noma ulahlwe.

Izinhlobo Zokuhlunga Amakhemikhali:

* Izihlungi ze-Scrubber: Lezi zisebenzisa isixazululo esiwuketshezi ukuze zimunce futhi zisabele ngegesi engafunwa.

* Izihlungi ze-Chemisorption: Lezi zisebenzisa izinto eziqinile ukuze zisabele futhi zisuse igesi engadingeki.

Izicelo Zokuhlunga Kwegesi:

* Ukuhlanzwa komoya:

Ukususa uthuli, izinto ezingezwani nomzimba, nezinto ezingcolisayo emoyeni wangaphakathi nangaphandle.

* Ukucubungula igesi yezimboni:

Ukwehlukanisa ukungcola kuwoyela negesi ukukhiqiza izinto zokubasa ezihlanzekile.

* Ukuvikela imishini ebucayi:

Ukuvimbela izinhlayiya eziyingozi ukuthi zingangeni ezintweni ezibucayi.

* Izicelo zezokwelapha:

Ukunikeza umoya ohlanzekile wezinqubo zokwelapha.

* Ukuvikelwa kwemvelo:

Ukususa ukungcola okuvela ezimbonini.

Ukukhetha ubuchwepheshe obufanele bokuhlunga igesi kuncike ezintweni ezimbalwa, okuhlanganisa:

* Usayizi nohlobo lwezinhlayiya okufanele zikhishwe

* Izinga elifiswayo lokuhlanzeka

* Izinga lokugeleza kwegesi

* Izindleko nobunkimbinkimbi benqubo

Kubalulekile ukuthintana nochwepheshe bokuhlunga ukuze uthole uhlobo olungcono kakhulu lwesihlungi sakho

izidingo ezithile.

Ukuhlunga Uketshezi

Ukuhlunga okuwuketshezi kuyinqubo yokukhipha izinhlayiya ezingafunwa kanye nokungcola emfudlaneni owuketshezi.

Kubalulekile ekusetshenzisweni okuhlukahlukene, okuhlanganisa ukwelashwa kwamanzi, ukucubungula amakhemikhali, nokudla kanye

ukukhiqizwa kwesiphuzo. Nazi ezinye zezinhlobo eziyinhloko zobuchwepheshe bokuhlunga uketshezi:

1. Izihlungi Zobuso:

Lezi zihlungi zibamba izinhlayiya ebusweni besihlungi. Ngokuvamile basebenzisa i-mesh noma isikrini nge

izimbotshana ezincane kunezinhlayiya okufanele zikhishwe. Njengoba uketshezi ludlula isihlungi, izinhlayiya

zivaleleke phezu kwesikrini.

Izinhlobo Zokuhlunga Okungaphezulu:

* Izihlungi zesikrini:

Lezi ziwuhlobo olulula kakhulu lwesihlungi esingaphezulu. Zenziwe ngensimbi enezikhala ezinezikhala

ezinkulu ngokwanele ukuvumela uketshezi ukuba ludlule kodwa luncane ngokwanele ukubamba izinhlayiya ezinkulu.

* Izihlungi ze-Cartridge:

Lokhu kuqukethe imidiya yokuhlunga enamacembe eyenziwe ngephepha, indwangu, noma ezinye izinto.

Atholakala ngamasayizi ahlukahlukene embotshana ukuze asuse amasayizi ahlukahlukene ezinhlayiya.

2. Izihlungi zokujula:

Lezi zihlungi zithwebula izinhlayiya ngaphakathi kwe-matrix yezinto zokuhlunga. Ngokuvamile zenziwa ngogqinsi,

izinto ze-fibrous ezibamba izinhlayiya ngaphakathi kwezendlalelo zazo. Izihlungi ezijulile ziyasebenza ekususeni ezincane

izinhlayiya kodwa ingaba nokwehla komfutho ophezulu.

Izinhlobo zezihlungi zokujula:

* Izihlungi zokujula:Lezi zenziwe ngezinto ezifana ne-cellulose, imicu yengilazi, noma imicu yokwenziwa.

Zisebenza ngempumelelo ekususeni izinhlobonhlobo zosayizi bezinhlayiyana, okuhlanganisa amagciwane namagciwane.

* Izihlungi zamanxeba:Lezi zenziwa ngokusonta i-fibrous material ezungeze umgogodla.

Atholakala ngobukhulu obuhlukahlukene kanye nosayizi wezimbotshana.

3. Izihlungi ze-Membrane:

Lezi zihlungi zisebenzisa ulwelwesi oluncane olunosayizi abathile bembotshana ukuvumela ama-molecule amancane kunezimbotshana

ukudlula. Zisebenza ngempumelelo ekususeni izinhlayiya ezincane kakhulu, kufaka phakathi amabhaktheriya, amagciwane,

nama-molecule ancibilikisiwe.

Izinhlobo zezihlungi ze-Membrane:

* Ukuhlunga okuncane:

Izimbotshana ezinosayizi we-0.1 kuya ku-10 microns futhi zisetshenziselwa ukususa amagciwane, ama-parasites, nezinye izinhlayiya ezinkulu.

*Ukuhlunga:

Izimbotshana ezinosayizi we-0.01 kuya ku-0.1 microns futhi zisetshenziselwa ukususa amagciwane, amaprotheni, nezinye izinhlayiya ezincane.

*Nanofiltration:

Izimbotshana ezinosayizi we-0.001 kuya ku-0.01 microns futhi zisetshenziselwa ukususa ama-molecule ancibilikisiwe njengosawoti noshukela.

* Reverse osmosis:

amasayizi amancane wembotshana azo zonke izihlungi zolwelwesi (ama-microns angu-0.0001) futhi asetshenziselwa ukususa cishe

wonke ama-molecule ancibilikile emanzini.

Izicelo Zokuhlunga Kwe-Liquid:

* Ukwelashwa kwamanzi:

Ukukhipha ukungcola emanzini okuphuza, ukuhlanza amanzi angcolile.

* Ukucutshungulwa kwamakhemikhali:

Ukuhlukanisa ama-reactants, imikhiqizo, nama-catalyst ngesikhathi sokusabela kwamakhemikhali.

* Imboni yokudla neziphuzo:

Ukucacisa nokuhlanza iziphuzo, ukususa okuqinile emafutheni,nokuhlukanisa izingxenye

ekulungiseni ukudla.

* Ukukhiqizwa kwemithi:

Imithi yokubulala inzalo nokuhlanza imikhiqizo yezinto eziphilayo.

* Ukucubungula uwoyela negesi:

Ukuhlukanisa amanzi nokunye ukungcola kuwoyela negesi.

Ukukhetha ubuchwepheshe obufanele bokuhlunga uketshezi kuncike ezintweni ezimbalwa, okuhlanganisa:

* Usayizi nohlobo lwezinhlayiya okufanele zikhishwe

* Izinga elifiswayo lokuhlanzeka

* Izinga lokugeleza koketshezi

* Ukuhambisana kwamakhemikhali koketshezi kanye nokokuhlunga

* Izindleko nobunkimbinkimbi benqubo

Ngakho-ke kubalulekile ukuthintana nochwepheshe bokuhlunga abaqeqeshiwe ukuze uthole uhlobo olungcono kakhulu lwesihlungi sakho

izidingo ezithile.

Amagesi Akhethekile kanye Nokuhlunga Okukhethekile Koketshezi

Ukuhlunga amagesi akhethekile noketshezi kuveza izinselelo eziyingqayizivele ngenxa yezakhiwo eziyingozi,

izidingo zokuhlanzeka okuphezulu, noma izingoma eziyinkimbinkimbi. Nakhu ukuhlukaniswa kwezinselelo kanye

izixazululo ezihilelekile:

Izinselelo:

* Amagesi abolayo noma asebenzayo noketshezi:

Lokhu kungalimaza izinto zokuhlunga zendabuko, ezidinga izinto ezikhethekile njenge-Hastelloy noma i-PTFE.

* Izidingo zokuhlanzeka okuphezulu:

Ezimbonini ezifana nezamakhemisi nama-semiconductors, ngisho nokungcola kungalandelela ngokuphawulekayo

nomthelela kwikhwalithi yomkhiqizo.

Ukufeza nokugcina amazinga anjalo okuhlanzeka kudinga izindlela zokuhlunga eziqinile.

* Izingoma eziyinkimbinkimbi:

Olunye uketshezi lunezingxenye eziningi ezinobukhulu obuhlukahlukene kanye nezakhiwo,

ukwenza ukuhlukana nokuhlunga kube nzima kakhulu.

Izixazululo:

* Izinto eziyisipesheli:

Izihlungi ezenziwe ngezinto ezikwazi ukumelana nokugqwala njengama-alloys ensimbi, ama-polymers afana ne-PTFE (Teflon), noma izitsha zobumba

ingamelana namakhemikhali anonya kanye nezindawo ezinolaka.

* Izindlela zokuhlunga eziqinile:

Amasu afana nokuhlunga okunezigaba eziningi, i-ultrafiltration, ne-nanofiltration angafinyelela amazinga aphezulu okuhlanzeka

ngokukhipha ngisho nezinhlayiya ezincane nezingcolisayo.

* Imiklamo yokuhlunga ethuthukisiwe:

Izihlungi ze-Membrane ezinosayizi we-pore abanembile noma ama-cartridges akhiwe ngokukhethekile zingasusa ngokukhetha

izingxenye ezithile ezisuselwe kusayizi nezakhiwo zazo.

* Ukulawulwa kwenqubo nokuqapha:

Ukuqapha ngesikhathi sangempela ingcindezi, izinga lokugeleza, namazinga okuhlanzeka kusiza ukuqinisekisa ukusebenza kahle kanye

ukungenelela okufika ngesikhathi uma kuba khona ukuchezuka.

* I-Adsorption kanye nokuhlunga kwamakhemikhali:

Ezimeni lapho ukuhlukaniswa okuyinkimbinkimbi kuyadingeka, amasu engeziwe afana ne-adsorption ecushiwe

Izihlungi zekhabhoni noma zamakhemikhali zingasetshenziswa ukususa ukungcola okuthile.

Ubuchwepheshe Bokuhlunga Okuthuthukile:

* I-Chromatography yegesi:

Ihlukanisa futhi ihlonze izingxenye eziguquguqukayo kuzingxube zegesi kusetshenziswa ikholomu egcwele into ekhethekile ye-adsorbent.

* I-High-Performance Liquid Chromatography (HPLC):

Isebenzisa ingcindezi ephezulu ukuze ihlukanise izakhi oketshezini ngokusekelwe ekusebenzelaneni kwazo nesigaba esimile.

* Ukukhishwa kweMembrane:

Isebenzisa ulwelwesi ukuhlukanisa izingxenye ngokusekelwe ekuguquguqukeni kwazo, okuvumela ukuhlukaniswa okuwonga kwamandla koketshezi oluhlanzeke kakhulu.

* Imvula ye-Electrostatic:

Isebenzisa indawo kagesi ukuze ishaje izinhlayiya, izihehe ekuqoqeni amapuleti futhi iwasuse ngokuphumelelayo emfudlaneni wegesi.

Izibonelo Zamagesi Akhethekile Noketshezi:

* I-Hydrofluoric acid:

Igqwala kakhulu, idinga izihlungi ezikhethekile ze-PTFE.

* Amakhemikhali enqubo ye-semiconductor:

Kudingeka ukuhlanzeka okuphezulu kakhulu, okudinga ukuhlungwa kwezigaba eziningi ngokuqapha okuqinile.

* I-Biopharmaceuticals:

Izwela ukungcola futhi idinga izihlungi ezikhethekile ukuze zihlanzwe.

* Amagesi anobuthi:

Kudingeka izihlungi ezikhethekile kanye nezinqubo zokuphatha ukuqinisekisa ukuphepha.

Ukubaluleka:

Ukuhlunga ngokuphumelelayo amagesi akhethekile noketshezi kubalulekile ukuze kuqinisekiswe ukuphepha, ikhwalithi, nokusebenza.

zezinqubo ezahlukene kuzo zonke izimboni. Ukuhlunga okungalungile kungaholela ekungcoleni komkhiqizo,

ukulimala kwemishini, izingozi zokuphepha, kanye nezingozi zemvelo.

Ukuhlunga Kwezinga Lokushisa Okuphezulu Nokucindezela Okuphezulu Kwamagesi

Ukuhlunga kwegesi okunezinga lokushisa eliphezulu kanye nomfutho ophezulu (i-HTHP) kubangela izinselele eziyingqayizivele ngenxa yokweqisa

izimo ezidinga ukwakheka okukhethekile nokucatshangelwa kwempahla.

Nakhu ukuhlukaniswa kwezici ezibalulekile:

Ukucatshangelwa kwedizayini:

* Ukumelana nengcindezi:

Izindlu zokuhlunga nezinto kufanele zimelane nokucindezela okukhulu ngaphandle kokuguqulwa noma ukuphuka.

* Ukubekezelela izinga lokushisa:

Izinto ezisetshenziswayo zidinga ukugcina amandla nobuqotho bazo emazingeni okushisa aphezulu ngaphandle kokuncibilika noma ukwehliswa.

* Ukumelana nokugqwala:

Izingxenye zokuhlunga kufanele zimelane nokugqwala okuvela kugesi elithile elihlungwayo.

* Ukusebenza kahle kokugeleza:

Idizayini idinga ukunciphisa ukwehla kwengcindezi ngenkathi igcina ukusebenza kahle kokuhlunga okuphezulu.

* Ukuhlanzeka kanye nokuvuselelwa:

Ezinye izihlungi zidinga ukuhlanzwa noma ukuvuselelwa ukuze kugcinwe ukusebenza, futhi idizayini kufanele ihambisane nalezi zinqubo.

Ukucatshangelwa kwezinto:

* Ama-alloys ensimbi:

Insimbi engagqwali, i-Hastelloy, ne-Inconel yizinketho ezivamile ngenxa yamandla azo aphezulu, ukumelana nezinga lokushisa, nokumelana nokugqwala.

* I-Ceramics:

I-Alumina, i-zirconia, ne-silicon carbide ilungele amazinga okushisa aphakeme kakhulu futhi inikeza ukumelana kwamakhemikhali okuhle kakhulu.

* Imicu yengilazi:

Imicu yengilazi ye-Borosilicate inikeza ukumelana nokushisa okuphezulu kanye nokusebenza kahle kokuhlunga.

* Ama-polymer akhethekile:

I-PTFE namanye ama-polymers asebenza kahle kakhulu angasetshenziselwa izinhlelo zokusebenza ezithile ezidinga ukumelana namakhemikhali kanye nokuguquguquka.

Okusunguliwe Kwezobuchwepheshe:

Kuvele ubuchwepheshe obusha obuningana ukuze kubhekwane nezinselelo zokuhlunga kwegesi ye-HTHP:

* Izinto zokuhlunga ze-Ceramic:

Lezi zinikeza ukumelana nokushisa okuphezulu (kufika ku-1800 ° C) futhi zingaklanywa ngosayizi othize wezimbotshana

ukufeza ukusebenza kokuhlunga okufunayo.

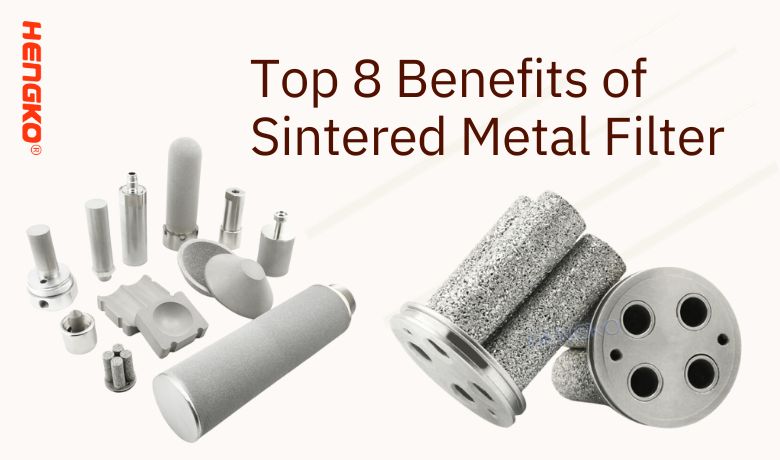

* Izihlungi zensimbi ezi-sintered:

Zenziwe ngezimpushana zensimbi ezinezimbotshana, lezi zihlungi zinikeza amandla aphezulu, ukumelana nokushisa okuhle,

futhi ingahlanzwa futhi ivuselelwe kahle.

* Izihlungi zokuzihlanza:

Lezi zihlanganisa izindlela ezifana nokushaya emuva noma ukugeleza okuhlehlayo ukuze kukhishwe ngokuzenzakalelayo okunqwabelene

ukungcola, ukunciphisa izidingo zokulondoloza.

* Izihlungi ze-Membrane:

Ulwelwesi olumelana nezinga lokushisa eliphezulu olunosayizi wezimbotshana ezinembile lungasetshenziselwa ukusebenza kahle okuphezulu

ukuhlunga izingxenye ezithile zegesi.

Izibonelo Zezihlungi ze-HTHP:

- Izihlungi zensimbi ezihlanganisiwe:

- Izinto zokuhlunga ze-Ceramic:

- Izihlungi ze-membrane ezinezinga lokushisa eliphezulu:

Izicelo:

Ukuhlunga kwegesi ye-HTHP kubalulekile ezimbonini ezahlukahlukene:

* Ukukhiqiza amandla:

Ukukhipha i-particle emoyeni ongenisa umoya we-turbine ukuze kuvikelwe izinjini zomoya futhi kuthuthukiswe ukusebenza kahle.

* Ukucutshungulwa kwamakhemikhali:

Ukuhlunga amagesi ashisayo kanye nomhwamuko ekuphenduleni kwamakhemikhali ukuze kukhishwe ukungcola nokuqinisekisa ikhwalithi yomkhiqizo.

* Imboni ye-Petrochemical:

Ukuhlukanisa izingxenye emifudlaneni yegesi kusukela emisebenzini yokucwenga nokucubungula.

* Imboni yensimbi nensimbi:

Ukuhlunga amagesi e-hot flue asuka ezithandweni naseziko ekushiseni ukuze kulawulwe ukungcoliswa komoya.

*I-Aerospace:

Ukuvikela okokusebenza okuzwelayo othulini nasekungcoleni ezindaweni ezinezinga lokushisa eliphezulu.

Isiphetho:

I-High-temperature ne-high-pressure gas filtration idinga ukuklanywa ngokucophelela nokukhetha

izinto zokuqinisekisa ukusebenza okuphephile nokusebenza kahle.

Ngokuqonda izinselele nokusebenzisa ubuchwepheshe obuphambili, izimboni zingakwazi ngempumelelo

hlunga amagesi e-HTHP wezinhlelo zokusebenza ezahlukahlukene,ukufaka isandla ekwenzeni ngcono, imvelo

ukuvikelwa, nokuphepha kokusebenza.

Ukuhlunga Kwezinga Lokushisa Okuphezulu kanye Nokuhlunga Okuphezulu Koketshezi Lwengcindezi

Uketshezi olunokushisa okuphezulu nomfutho ophezulu (i-HTHP) luletha izinselelo eziyingqayizivele zokuhlunga ngenxa

izimo ezimbi kakhulu ezingathinta kakhulu inqubo.

Nakhu ukuhlukaniswa kobunzima obuyinhloko nezisombululo:

Izinselelo:

* Izinguquko ze-viscosity:

Njengoba izinga lokushisa likhuphuka, i-viscosity yoketshezi iyancipha, okwenza kube lula kwezinye izinto ezingcolisayo

ukuze udlule kusihlungi.

* Ukunwetshwa kwe-thermal:

Kokubili uketshezi kanye nezingxenye zokuhlunga kunwebeka ngamanani ahlukene ngenxa yokushintsha kwezinga lokushisa, okungenzeka

okuthinta ukusebenza kokuhlunga futhi kubangele ukuvuza.

* Imiphumela yokucindezela:

Ukucindezela okuphezulu kungahlanganisa imidiya yesihlungi, kunciphise i-porosity yayo nokusebenza kahle kokuhlunga. Ngaphezu kwalokho,

kungabangela ukucindezeleka ezindlini zokuhlunga kanye nezimpawu, okuholela ekuhlulekeni okungenzeka.

* Ukuhambisana kwamakhemikhali:

Amazinga okushisa aphezulu nezingcindezi kungakhuphula ukusebenza kabusha kwamakhemikhali oketshezi, okudinga okukhethekile

izinto zokuhlunga ukuze kuqinisekiswe ubuqotho baso nokuvimbela ukungcola.

*Ukugqwala:

Inhlanganisela yamazinga okushisa aphezulu, ukucindezela, noketshezi olungase lube ukugqwala kungasheshisa ukugqwala

zezingxenye zokuhlunga, ezinciphisa ukuphila kwazo futhi zibe sengozini yokusebenza kwazo.

Izixazululo Namasu:

Ukuze unqobe lezi zinselelo, kusetshenziswa izixazululo namasu amaningana ekuhlungeni uketshezi lwe-HTHP:

* Imidiya yesihlungi esikhethekile:

Izinto ezimelana nezinga lokushisa eliphezulu njengensimbi engenasici, impushana yensimbi ehlanganisiwe, ne-ceramic

imicu isetshenziselwa ukumelana nezimo ezimbi kakhulu.

* Ukuhlunga kwezigaba eziningi:

Ukusebenzisa izihlungi eziningi ezinobukhulu obuhlukahlukene bembobo kungabhekana nosayizi abahlukahlukene bezinhlayiyana futhi kuzuzwe

high ukusebenza kahle jikelele.

* Ukulawula izinga lokushisa:

Ukugcina izinga lokushisa elizinzile kuyo yonke inqubo yokuhlunga kusiza ukunciphisa imiphumela yokushisa

ukunwetshwa kanye nezinguquko ze-viscosity.

* Izindlu ezimelana nokucindezela:

Izindlu eziqinile ezenziwe ngezinto eziqinile njengensimbi engagqwali noma i-titanium zenzelwe ukwenza kanjalo

ukumelana nomfutho ophezulu futhi uvimbele ukuvuza.

* Izimpawu ezimelana namakhemikhali:

Izigxivizo ezikhethekile ezenziwe ngezinto ezifana neTeflon noma iViton zisetshenziselwa ukuqinisekisa ukuhambisana ne

uketshezi oluthile futhi uvimbele ukuvuza ngisho namazinga okushisa aphezulu kanye nezingcindezi.

* Izihlungi zokuzihlanza:

Lezi zihlanganisa izindlela ezifana nokushaya emuva noma ukugeleza okuhlehlayo ukuze kususwe ukungcola okunqwabelene

ngokuzenzakalelayo, ukunciphisa izidingo zokunakekela kanye nokuqinisekisa ukusebenza okungaguquki.

Izibonelo zezihlungi ze-HTHP Liquid:

* Izihlungi zensimbi ezihlanganisiwe:

* Izinto zokuhlunga ze-Ceramic:

* Izihlungi ze-Metal mesh:

* Izihlungi ze-membrane ezinokushisa okuphezulu:

Izicelo:

Ukuhlunga uketshezi lwe-HTHP kudlala indima ebalulekile ezimbonini ezahlukahlukene:

* Ukucutshungulwa kwamakhemikhali:

Izingxenye ezihlukanisayo ekusebenzeni kwamakhemikhali, ukuhlunga okuqinile nokungcola.

* Imboni ye-Petrochemical:

Ukucubungula uwoyela ongahluziwe negesi yemvelo, ukuhlunga ukungcola ngaphambi kokuqhubeka nokucutshungulwa.

* Ukukhiqiza amandla:

Ukuhlunga isitimu namanzi kuma-boilers nama-turbines ukuze kuthuthukiswe ukusebenza kahle nokuvikela ukulimala kwemishini.

* Imboni yensimbi nensimbi:

Ukuhlunga izinsimbi ezincibilikisiwe nama-alloys ukususa ukungcola futhi kuzuzwe izakhiwo ezifiselekayo.

* Imboni yokudla neziphuzo:

Ukufaka inzalo uketshezi kanye nokususa ukungcola ukuze kuqinisekiswe ukuphepha komkhiqizo kanye nekhwalithi.

Isiphetho:

Ukuhlunga uketshezi olunezinga eliphezulu lokushisa nomfutho ophezulu kudinga ubuchwepheshe obukhethekile nokucophelela

ukucatshangelwa kwezimo ezimbi kakhulu ezihilelekile. Ngokusebenzisa izixazululo ezifanele kanye namasu,

Ukuhlunga kwe-HTHP kungenziwa ngempumelelo ezimbonini ezahlukahlukene, kuqinisekiswe ikhwalithi yomkhiqizo, ukuphepha, kanye

ukusebenza kahle.

Futhi ekugcineni, sibala isidingo esikhethekile segesi kanye noketshezi ukwenza ukuhlunga

Amagesi Akhethekile kanye Noketshezi Okudinga Ukuhlunga Embonini Yokukhiqiza

Amagesi Akhethekile:

I-Hydrofluoric acid (HF):

Igqwala kakhulu ezintweni eziningi, idinga izihlungi ezikhethekile ezenziwe nge-Teflon (PTFE) noma ezinye.

ama-polymers aqinile.

*Silane (SiH4):

Ivutha kakhulu futhi i-pyrophoric, edinga izinqubo ezikhethekile zokuphatha nezihlungi eziklanyelwe

ukusebenza okuphephile.

I-Chlorine (Cl2):

Kunobuthi futhi konakala, kudinga izinto ezikhethekile ezifana ne-Hastelloy noma i-Inconel yezihlungi nezisetshenziswa zokuphatha.

I-Amoniya (NH3):

Inobuthi futhi iyagqwala, idinga izihlungi ezenziwe ngensimbi engagqwali noma ezinye izinto ezimelene.

I-Hydrogen sulfide (H2S):

Inobuthi kakhulu futhi iyavutha, idinga izihlungi ezikhethekile nezinyathelo zokuphepha.

I-Sulfur dioxide (SO2):

Igqwala futhi inobuthi, idinga izihlungi ezenziwe ngensimbi engagqwali noma ezinye izinto ezimelana nazo.

Uketshezi Olukhethekile:

* Amakhemikhali ahlanzekile kakhulu:

Isetshenziswa ezimbonini ze-semiconductor kanye nemithi, edinga amazinga aphezulu kakhulu wokuhlanzeka kanye

izihlungi ezikhethekile njengezihlungi ze-membrane noma amasistimu okuhlunga ezigaba eziningi.

* I-Biopharmaceuticals:

Izwela ukungcola futhi idinga izihlungi ezikhethekile ezidizayinelwe ukuhlanzwa nokuqinisekisa ikhwalithi yomkhiqizo.

* Izinsimbi ezincibilikisiwe nama-alloys:

Amazinga okushisa aphezulu namandla okuqiniswa adinga izihlungi ezikhethekile ezenziwe ngezinto eziphikisayo ezifana

ama-ceramics noma ama-alloys asezingeni eliphezulu.

* Usawoti oncibilikisiwe:

Igqwala kakhulu futhi idinga izinto ezikhethekile ezifana ne-Hastelloy noma i-Inconel yezihlungi nezinto zokuphatha.

* Ama-slurries nama-pastes:

I-viscosity ephezulu kanye nemvelo e-abrasive idinga imiklamo ethile yesihlungi nezinto zokwakha ukuze kuqinisekiswe ukuhlunga okuphumelelayo

futhi uvimbele ukuvala.

* Uketshezi olunobuthi noluyingozi:

Idinga izinqubo ezikhethekile zokuphatha nezihlungi eziklanyelwe ukuvimbela ukuvuza nokuchayeka ezintweni eziyingozi.

Qaphela:

Lolu akulona uhlu oluphelele, futhi uhlobo oluthile lwegesi ekhethekile noma uketshezi oludinga ukuhlungwa luzoncika

inqubo ethile yokukhiqiza yezimboni.

Ingabe Unayo Iphrojekthi Yegesi Ekhethekile noma Yokuhlunga Uketshezi?

U-HENGKO uyaqonda ukuthi yonke inselele yokuhlunga ihlukile, ikakhulukazi uma kuziwa ekuphatheni okukhethekile

amagesi noketshezi. Ubuchwepheshe bethu bokwenza izihlungi ngokwezifiso ukuze kuhlangatshezwane nezidingo ezithile busenza sihluke embonini.

Uma udinga izixazululo ezikhethekile zokuhlunga, silapha ukuze sikusize. Noma ngabe okohlelo lokusebenza oluhlukile

noma indawo eyinselele, ithimba lethu likuhlomele ukuklama nokwenza izihlungi ezihlangabezana nawe

izimfuneko eziqondile.

Ungavumeli izinselele zokuhlunga zehlise ijubane. Xhumana nathi nge-OEM (Original Equipment Manufacturer)

amasevisi enzelwe izidingo ezithile zephrojekthi yakho.

Xhumana nathi namuhla kuka@hengko.com ukuxoxa ngephrojekthi yakho nokuthi singasiza kanjani ukuletha imibono yakho ibe ngokoqobo.

Sizibophezele ekuhlinzekeni ukuhlunga kwekhwalithi ephezulu, okwenziwe ngendlela oyifisayoizixazululo ezikusiza ukuthi uzuze imiphumela emihle.

Isikhathi sokuthumela: Dec-08-2023