-

I-Micron replacement sintered steel stainless porous metal filter disc

Sethula Izihlungi Zensimbi Engagqwali Yezinga eliphezulu ze-HENGKO ze-HENGKO I-HENGKO ingumkhiqizi oholayo wensimbi engagqwali enezimbobo zensimbi...

Buka imininingwane -

I-D9.5*H9.5 60-90um idiski yesihlungi sensimbi ene-sintered esetshenziselwa ukuhlunga uketshezi

Sethula izihlungi ze-HENGKO sintered disc, ikhambi elikhulu kuzo zonke izidingo zakho zokuhlunga! Izihlungi zethu ze-sintered disc zenzelwe ukucupha izingxenye eziqinile...

Buka imininingwane -

insimbi engagqwali isihlungi disc umphakeli esikhundleni microns sintered porosity metal powder...

I-Sintered Porous Metal Discs. okufana nesipontshi sensimbi. Izihlungi ze-Porous Sintered Metal zihlanganisa amanethiwekhi afanayo kakhulu, axhumene ezimbotshana ezinezimbotshana...

Buka imininingwane -

I-Porous metal ss sintered filter disc enezinga lokugeleza okusheshayo lokuhlunga okunosayizi omncane we-ap...

Sethula Izihlungi Zedisc Ezisikiwe ze-HENGKO: Khipha Amandla Okuhlunga Okuphezulu! Uma kukhulunywa ngokuhlunga okusebenzayo, izihlungi ze-HENGKO's sintered disc ...

Buka imininingwane -

Sintered 0.2-120 micron 316L insimbi engagqwali powder isihlungi disc

Chaza umkhiqizo we-HENGKO i-stainless steel filter disc yenziwa ngokufaka i-sintering 316L powder material noma i-multilayer stainless stainless wire mesh emazingeni okushisa aphezulu. T...

Buka imininingwane -

Usayizi owenziwe ngokwezifiso ongenamthungo wensimbi enezimbobo zensimbi engagqwali 304/316L powder sinterin...

Sethula I-HENGKO's Sintered Filter Disc for Helium Leak Detectors: Ukusebenza Okungenakuqhathaniswa Nokusebenza Kahle! Izici Zomkhiqizo:- I-High Filtration Effi...

Buka imininingwane -

Umkhiqizi ochwepheshe 5 20 microns metal porous sus 316l ss insimbi engagqwali sintere...

I-HENGKO Stainless Steel Filter Disc - Isixazululo Sokuhlunga Okuphezulu Okusebenza Kakhulu

Buka imininingwane -

Ukunikezwa okuthandwayo okungu-0.2-120um sintered 316 insimbi engagqwali yohlobo lwe-backwash yensimbi...

Sethula i-HENGKO Stainless Steel Filter Disc, ikhambi lokugcina lakho konke ukuvikelwa kwemvelo yakho, uphethiloli, igesi yemvelo, amakhemikhali, indawo ezungezile...

Buka imininingwane -

Ukuthengiswa okuqondile kwasefekthri sintered microporous metal stainless steel 316L filter strainer dis...

Chaza umkhiqizo we-HENGKO i-stainless steel filter disc yenziwa ngokufaka i-sintering 316L powder material noma i-multilayer stainless stainless wire mesh emazingeni okushisa aphezulu. T...

Buka imininingwane -

Ukukhiqiza okudayisiwe kanye nentengo yefekthri 0.2 0.5 2 5 10 15 20 40 60 90 100 micron porosity ...

I-HENGKO i-stainless steel filter disc yenziwa nge-sintering 316L powder material noma i-multilayer stainless stainless wire mesh emazingeni okushisa aphezulu. Baye babanzi...

Buka imininingwane -

Impushana eyenziwe ngokwezifiso i-SS 316L ye-stainless steel filter disc, 0.2 5 7 10 30 40 50 70 ...

I-HENGKO i-stainless steel filter disc yenziwa nge-sintering 316L powder material noma i-multilayer stainless stainless wire mesh emazingeni okushisa aphezulu. Baye babanzi...

Buka imininingwane -

Yenza ngokwezifiso ama-microns afakwe i-porous steel stainless diski engu-316L esetshenziselwa ind...

I-Product Chaza I-HENGKO iyaziqhenya ngokunikeza izinto eziningi zokuhlunga ezihlangabezana nezidingo ezihlukile zekhasimende ngalinye. Ithimba lethu lochwepheshe lingakha cus...

Buka imininingwane -

isihlungi esincane se-sintered stainless stainless mesh disc esizosetshenziswa kumaPrinta we-inkjet

Izihlungi ze-Sinter wire mesh zivame ukusetshenziselwa ukuhlanzwa nokuhlunga uketshezi negesi, ukuhlukanisa kanye nokubuyiselwa kwezinhlayiya eziqinile, i-coolin yokuphefumula...

Buka imininingwane -

Ukuhlunga Kwe-Catalyst Ngezihlungi Zeqabunga I-Sintered Metal Mesh Filter Disc Yokubuyisela ...

I-HENGKO ikhiqiza izinto zokuhlunga ngenani elibanzi lezinto, osayizi, nokufakwa ukuze kucaciswe kalula ngezici kanye nokucushwa...

Buka imininingwane -

I-Medical grade micron insimbi engagqwali 316 316L wire mesh multi-layer plate / disc filter...

Izihlungi ze-HENGKO sintered wire mesh zinezingqimba ezi-5 ze-sintered wire mesh ezinokwakhiwa okuzisekelayo kokuqina komshini nokumelana nezinga lokushisa eliphezulu...

Buka imininingwane -

Impilo ende yensizakalo yezingxenye zediski yesihlungi sensimbi engenasici - ukwelashwa kwamanzi ahlanzekile...

Idiski yokuhlunga ye-Sintered Mesh isebenzisa uhlaka olunezingqimba eziyisihlanu oluhlanganisiwe lwe-sintered mesh ukwenza isihlungi esihlanganisa ukusebenza kahle kokuhlunga namandla. Ama-mes ajwayelekile...

Buka imininingwane -

2 5 50 100 150 300 Microns Porous 304 316L SS insimbi engagqwali wire sintered mesh isihlungi...

Insimbi engagqwali ene-sintered mesh yenziwe ngensimbi engagqwali elukiwe, futhi inqubo yokushisela i-argon-arc ijoyina izindawo zokuvala zesici sokuhlunga. ...

Buka imininingwane -

Round 25 50 100 micron sintered steel stainless wire mesh disc disc

Izihlungi ze-HENGKO sintered disc ziqukethe amanethiwekhi afanayo kakhulu, axhumene ezimbotshana anezindlela ezihlukumezayo ezibamba izinhlayiya eziqinile kugesi noma uketshezi. Exce...

Buka imininingwane -

I-Sintered 304 316l yensimbi engagqwali ye-multilayer wire mesh micron filter screen disc

Incazelo Yomkhiqizo I-Sintered wire mesh iyisendlalelo esiningi se-wire mesh / indwangu yesihlungi sensimbi efakwe njengepuleti lonke ngenqubo yokucwilisa noma yokusabalalisa...

Buka imininingwane -

I-5 10 20 90 120 microns sintered metal porous bronze insimbi engagqwali 316L multi-purpose ...

I-HENGKO ikhiqiza izinto zokuhlunga ngenani elibanzi lezinto, osayizi, nokufakwa ukuze kucaciswe kalula ngezici kanye nokucushwa...

Buka imininingwane

Ukusetshenziswa Okuyinhloko kwama-Sintered Metal Discs

Izicelo ezi-5 eziyinhloko zamadiski ensimbi e-sintered:

* Ukuhlunga:

Amadiski ensimbi e-Sintered asetshenziswa kakhulu ezinhlelweni zokuhlunga ngenxa yobukhulu bawo bezimbotshana eziqondile, ukungeneka okuhle, namandla aphezulu. Angasetshenziselwa ukuhlunga izinto ezihlukahlukene, okuhlanganisa uketshezi, amagesi, ngisho nezinsimbi ezincibilikisiwe. Ngokwesibonelo, asetshenziselwa ukuhlunga iziphuzo, imithi, amakhemikhali, umoya namanzi ezimbonini ezihlukahlukene. Angenziwa ngendlela oyifisayo ukuze abe nosayizi abahlukene bezimbotshana, kuye ngohlelo oluthile lokuhlunga.

*I-Fluidization:

Ama-disc ensimbi e-sintered asetshenziswa ezinhlelweni zemibhede ezinoketshezi, ezisetshenziswa ezinkambisweni ezahlukahlukene zezimboni, njengokumisa, ukuhlukaniswa, nokumboza. Ehlelweni lombhede omanzi, igesi idlula embhedeni wezinhlayiya, okwenza izinhlayiya ziziphathe njengoketshezi. Amadiski ensimbi ane-sintered asetshenziselwa ukusabalalisa igesi ngokulinganayo kuwo wonke umbhede nokuvimbela izinhlayiya ukuba zingaphunyuki.

* Izishintshi Zokushisa:

Ama-disc ensimbi e-sintered angasetshenziswa njengezishintshi zokushisa ngenxa ye-thermal conductivity ephezulu kanye nendawo enkulu. Izishintshi zokushisa zisetshenziselwa ukudlulisa ukushisa kusuka kolunye uketshezi kuya kolunye. Amadiski ensimbi e-sintered angasetshenziswa ezinhlelweni ezihlukahlukene zokushintsha ukushisa, njengezinhlelo zokupholisa umoya, ama-radiator, nama-boilers.

* Izingxenye ze-Friction:

Amadiski ensimbi e-sintered asetshenziswa ezinhlobonhlobo zezingxenye zokungqubuzana, njengamapuleti e-clutch nama-brake pads. I-Sintered metal discs ingenziwa ngezinto ezihlukahlukene, kuhlanganise nensimbi, ithusi, nethusi. Impahla ethile esetshenzisiwe izoncika kuzakhiwo ezifiswayo zokungqubuzana. Isibonelo, ama-sintered iron discs avame ukusetshenziswa kuma-clutch plate ngoba aqinile futhi awagugi.

* Ukunciphisa umsindo:

Amadiski ensimbi e-sintered angasetshenziswa ukudambisa umsindo. Zingasetshenziswa ezinhlelweni ezahlukahlukene, njengezinjini zezimoto, izinto zikagesi, nemishini yezimboni. Amadiski ensimbi ane-sintered angakwazi ukumunca amaza omsindo futhi anciphise amazinga omsindo.

Izici Eziyinhloko zama-Sintered Metal Discs

Amadiski ensimbi e-Sintered anikeza inhlanganisela eyingqayizivele yezakhiwo ezenza zibe yigugu ezinhlelweni ezihlukahlukene zezimboni. Nazi ezinye zezici zabo eziyinhloko:

1. I-Porosity Ephezulu kanye Nokuqina:

*Amadiski ensimbi ane-sintered akhiwa kusuka kumpushana yensimbi ecindezelwe bese eshiselwa ekushiseni okuphezulu ngaphansi kwendawo yokuncibilika, okubangela ukuthi izinhlayiya zihlangane ndawonye. Le nqubo idala inethiwekhi yezimbotshana ezixhumene kuyo yonke i-disc, evumela uketshezi noma amagesi ukuba adlule ngenkathi ithwebula izinhlayiya ezinkulu kunosayizi wembotshana.

*I-porosity yediski ingalawulwa ngokunembile phakathi nenqubo yokukhiqiza, okuvumela ukwenziwa ngokwezifiso kwezidingo ezithile zokuhlunga. Lokhu kuvumela ukuhlukaniswa okuphumelelayo kwezinto ezifunwayo kusuka kukungcola okungafuneki.

2. Amandla Aphakeme Nokuqina:

*Ngaphezu kwemvelo yawo enezimbotshana, amadiski ensimbi ane-sintered abonisa amandla amangalisayo nokuqina. Ukuhlangana phakathi kwezinhlayiya zensimbi kudala isakhiwo esiqinile esingakwazi ukumelana nezingcindezi eziphezulu kanye nokucindezeleka kwemishini.

*Lokhu kubenza bafanelekele izicelo ezifunwayo ezindaweni ezinokhahlo, njengokuhlunga uketshezi olubolayo noma ukusebenza ngaphansi kwengcindezi ephezulu.

3. Ukumelana Nokushisa Okuhle Kakhulu:

*Izinto ezisetshenziswa kumadiski ensimbi ane-sintered, njengensimbi engagqwali noma ithusi, amelana ngokwemvelo namazinga okushisa aphezulu. Zingasebenza ngempumelelo ezindaweni ezishisayo ngaphandle kokuphazamisa ubuqotho bazo besakhiwo noma ukusebenza kokuhlunga.

Lesi sici sizenza zilungele ukusetshenziswa okubandakanya uketshezi olushisayo, amagesi, noma izinsimbi ezincibilikisiwe.

4. I-Corrosion and Wear Resistance:

*Izinto ezisetshenziswa kumadiski ensimbi ane-sintered ngokuvamile zikhombisa ukumelana okuhle nokugqwala nokuguga. Lokhu kuyiqiniso ikakhulukazi kumadiski ensimbi engagqwali, akwazi ukumelana nokuchayeka kumakhemikhali anonya kanye nezindawo ezilimazayo.

*Lokhu kumelana nokugqwala nokuguga kuqinisekisa impilo ende yesevisi yamadiski, kunciphisa isidingo sokushintshwa njalo.

5. Ukusebenziseka Kabusha Nokuhlanzeka:

*Amadiski ensimbi ane-sintered ayasebenziseka kabusha, anikeza inzuzo engabizi futhi enobungani bemvelo. Zingahlanzwa kalula futhi ziwashwe ngemuva, okuvumela ukusetshenziswa okuphindaphindiwe ezinhlelweni zokuhlunga.

*Lokhu kuphinda kusetshenziswe kunciphisa udoti kanye nezindleko zokuyilungisa uma kuqhathaniswa nemidiya yesihlungi esilahlwayo.

6. Ukuhlukahluka kanye Nokwenza Ngokwezifiso:

*Amadiski ensimbi ane-Sintered angenziwa ngezindlela ezihlukahlukene, osayizi, nosayizi wezimbotshana ukuze ahlangabezane nezidingo ezithile zezinhlelo zokusebenza ezahlukene. Angabuye enziwe ngezinto ezahlukahlukene, ngayinye inikeze izakhiwo ezihlukile ngezidingo ezithile zokuhlunga.

*Lokhu kuguquguquka kubenza babe yisixazululo esivumelana nezimo kakhulu kuhlu olubanzi lwezinqubo zokuhlukanisa izimboni.

FAQ

1. Yiziphi izinhlobo ezahlukene zezihlungi ze-disc zensimbi ze-sintered?

Izihlungi ze-Sintered metal disc zingahlukaniswa ngokusekelwe ezicini ezimbalwa:

* Material:

Insimbi engagqwali iyinto evame kakhulu ngenxa yokumelana nokugqwala okuhle kakhulu, amandla,

kanye nebanga lokushisa elibanzi lokusebenza. Ezinye izinto zifaka ithusi, i-nickel, ngisho nezinto ezingavamile

njenge-Hastelloy yezindawo ezonakalisa kakhulu.

* I-Porosity kanye nosayizi we-pore:

I-porosity ibhekisela kumaphesenti wesikhala esingenalutho kusihlungi, kuyilapho usayizi wembotshana

inquma izinhlayiya ezincane kakhulu isihlungi esingathwebula. Izihlungi zitholakala ezinhlobonhlobo zama-porosities

kanye nosayizi wezimbotshana, ukusuka kuma-microns kuya kumamilimitha, ukuze ivumelane nezidingo zokuhlunga ezihlukene.

* Inombolo yezendlalelo:

Amadiski ongqimba olulodwa anikeza amazinga okugeleza aphezulu kodwa umthamo olinganiselwe wokubamba ukungcola. Izendlalelo eziningi

ama-discs anosayizi we-pore ahlelwe ngokwezinga, ahlinzeka ngokuhlunga okucolisekile kanye namandla aphezulu okubamba ukungcola ngenkathi egcina.

amazinga okugeleza amukelekile.

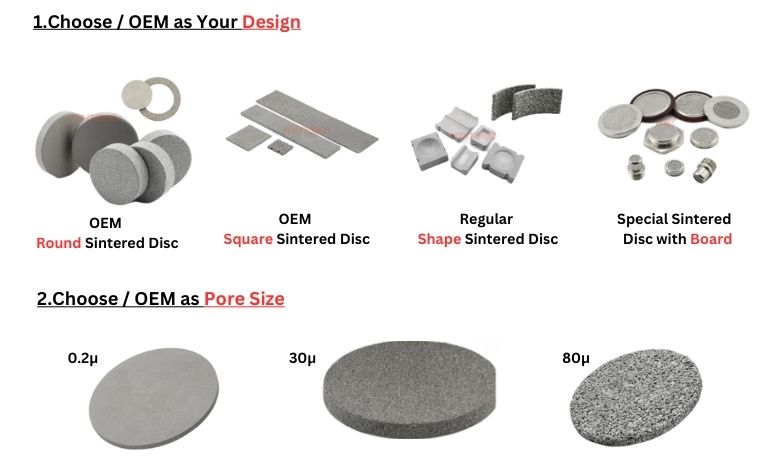

* Isimo:

Nakuba ama-discs kuyisimo esivame kakhulu, izihlungi zingenziwa ngokwezifiso ngezindlela ezihlukahlukene

njengezikwele, onxande, amasilinda, noma umumo othize wejometri wezinhlelo zokusebenza ezithile.

2. Yiziphi izinzuzo nezingozi zokusebenzisa izihlungi ze-sintered metal disc?

Izinzuzo:

* Amandla aphezulu nokuqina: Angakwazi ukumelana nezingcindezi eziphezulu, amazinga okushisa, nezindawo ezinokhahlo.

* Ukuhlunga okunembile nokungaguquguquki: Osayizi bembotshana abangaguquguquki baqinisekisa ukwehlukaniswa okuthembekile kwezinto ezifiselekayo ekungcoleni okungafunwa.

* I-Versatility: Itholakala ngezinto ezahlukahlukene, ama-porosity, osayizi bembotshana, kanye nokwakheka ukuze kuhlangatshezwane nezidingo ezahlukahlukene zohlelo.

* Ukusebenziseka kabusha nokuhlanzeka: Angahlanzwa kalula futhi asetshenziswe kabusha, kuncishiswe udoti kanye nezindleko zokuwulungisa.

* Ukusebenza okuphezulu kwe-thermal: Ifanele izinhlelo zokusebenza ezibandakanya ukudluliswa kokushisa.

Ububi:

* Izindleko zokuqala eziphakeme uma ziqhathaniswa nezinye izihlungi ezilahlwayo.

* Ingavala ngezinhlayiya ezinhle kakhulu, ezidinga ukuhlanzwa njalo noma ukuwashwa ngemuva.

* Ayilufanele uketshezi olunamehlo aphezulu ngenxa yemikhawulo engaba khona yesilinganiso sokugeleza.

3. Ngisikhetha kanjani isihlungi sediski sensimbi esine-sintered esifanele sohlelo lwami lokusebenza?

Ukukhetha isihlungi esifanele kudinga ukucabangela izici ezimbalwa:

* Izakhiwo zika-Fluid: Uhlobo loketshezi oluhlungwayo (uketshezi, igesi, njll.) kanye ne-viscosity yalo.

* Usayizi we-particle kanye nohlobo: Usayizi nezici zezinhlayiya ofuna ukuzithwebula.

* Izinga lokugeleza elifiselekayo: Izinga elidingekayo lokugeleza koketshezi ngesihlungi.

* Ingcindezi yokusebenza nezinga lokushisa: Ingcindezi nezinga lokushisa isihlungi esizohlangabezana nalo ngesikhathi sokusebenza.

* Ukuhambisana kwamakhemikhali: Ukuhambisana kwezinto zokuhlunga noketshezi oluhlungwayo.

* Izidingo zebhajethi nokusetshenziswa kabusha: Izindleko zokuqala uma ziqhathaniswa nokonga izindleko zesikhathi eside ngokusebenzisa ukuphinda kusetshenziswe.

Ukubonisana nochwepheshe bokuhlunga noma umenzi wokuhlunga kuyanconywa ukuze uqinisekise ukuthi ukhetha isihlungi sediski yensimbi ene-sintered esifanelekile sohlelo lwakho lokusebenza oluthile.

4. Ngizihlanza futhi ngizigcine kanjani izihlungi zediski yensimbi ene-sintered?

Indlela yokuhlanza incike ohlotsheni lwesihlungi, ukungcola okuhlungwayo, kanye nezincomo zomenzi. Izindlela zokuhlanza ezijwayelekile zihlanganisa:

* I-backwashing: Ukuphoqa uketshezi oluhlanzekile ngesihlungi siye emuva ukuze kukhishwe izinhlayiya ezivaleleke.

* Ukuhlanza kwe-Ultrasonic: Ukusebenzisa amaza omsindo ukukhipha izinhlayiya ezimbotsheni zokuhlunga.

* Ukuhlanza amakhemikhali: Ukusebenzisa izixazululo ezithile zokuhlanza ezihambisana nezinto zokuhlunga futhi ziphephile ukusetshenziswa okuhlosiwe komkhiqizo ohlungiwe.

Kubalulekile ukulandela imiyalelo yomkhiqizi yokuhlanza nokugcinwa okufanele ukuze kuqinisekiswe ukusebenza kahle nokuphila isikhathi eside kwesihlungi sediski yensimbi ehlanganisiwe.

5. Ngingalutholaphi ulwazi olwengeziwe mayelana nezihlungi ze-sintered metal disc?

Izinsiza ezimbalwa ziyatholakala ukuze ufunde kabanzi mayelana nezihlungi ze-sintered metal disc:

* Hlunga amawebhusayithi abakhiqizi:

Abakhiqizi abaningi bahlinzeka ngemininingwane enemininingwane mayelana nemikhiqizo yabo, okuhlanganisa imininingwane, imihlahlandlela yohlelo lokusebenza, nezinsiza zobuchwepheshe.

* Ukushicilelwa kwemboni namawebhusayithi:

Ukushicilelwa kohwebo namawebhusayithi agxile kubuchwepheshe bokuhlunga avame ukuqukatha ama-athikili nezinsiza ezidingida izinhlobo zokuhlunga ezihlukene, okuhlanganisa namadiski ensimbi ane-sintered.

* Izinhlangano zobunjiniyela nokuhlunga:

Izinhlangano zobungcweti ezifana ne-American Filtration & Separations Society (AFSS) zinikeza izinsiza zemfundo nolwazi olumayelana nobuchwepheshe bokuhlunga obuhlukile.

Ngokucabangela le-FAQ kanye nokufuna ulwazi olwengeziwe, ungenza isinqumo unolwazi mayelana nokuthi izihlungi ze-sintered metal disc ziyisixazululo esifanele sezidingo zakho zokuhlunga.

XHUMANA NATHI

Vula amandla edivayisi yakho ngamadiski ensimbi e-OEM sintered avela ku-HENGKO.

Sithumele i-imeyili namuhla kuka@hengko.comukuhlola amakhono ethu okukhiqiza athuthukile kanye

thatha isinyathelo sokuqala ekufezeni ukusebenza okuphezulu kanye nekhwalithi.

Masidale okuthile okukhethekile ndawonye. Xhumana nathi manje!