-

Ukuhlanzwa kwe-Biopharmaceutical kanye nokuhlunga ipuleti le-porous filter 10um 20um 50um

Ipuleti lesihlungi elinezimbobo wuhlobo olusha lwesihlungi esisebenza kahle kakhulu esinezimbobo esenziwe ngempushana yensimbi engagqwali ngesisefo sempushana, ukubumba, i-sinterin...

Buka imininingwane -

I-Sintered Copper Bronze Grounding Plate

I-Deters Electrolysis kanye ne-Galvanic CorrosionYehlisa Ukuphazanyiswa kwe-RF futhi Ithuthukisa Ukusebenza Kwe-Electronics Ukwamukela okungcono kakhulu kwamadivayisi akho e-GPS, isimo sezulu ...

Buka imininingwane -

i-sintered metal round deep filter sheets yokukhiqiza uwoyela we-cannabis

Ukuhlunga Ekukhiqizeni imikhiqizo ye-cannabinoid ezinzile ukuhlunga kuyisinyathelo esibalulekile. Ukuze ususe ama-wax, amafutha kanye namafutha e-winterization a multi...

Buka imininingwane -

I-Stainless Steel Porous Metal Sheets SS316 Isihlungi Sokusakazwa Kwegesi Ye-Hydrogen

I-Stainless Steel Porous Metal Sheets SS316 Isihlungi Sokusakazwa Kwegesi Ye-Hydrogen Vula Ukuhlukahluka Kwezinto Zensimbi Ezisikiwe nge-HENGKO! Imeta yethu ehlanganisiwe...

Buka imininingwane -

Ishidi Lezendlalelo Zokusabalalisa Igesi le-MEAs, insimbi engagqwali enezimbotshana zensimbi / ezinezikhala zocingo ...

Amapuleti okuhlunga ensimbi engenasici ye-HENGKO enziwa ngokufaka i-sintering 316L powder impahla noma i-multilayer stainless stainless wire mesh emazingeni okushisa aphezulu. Sebe...

Buka imininingwane -

I-Multi-layer sintered stainless stainless steel mesh plate fluidized bed equipment Distributor bot...

Ipuleti lensimbi engenasici lombhede owuketshezi Ukulawulwa kokusatshalaliswa kwegesi, ukudluliswa kwezinto eziyimpuphu, nokusebenza kwe-fluidization sekusetshenziswe kabanzi ku-indu...

Buka imininingwane -

Ipuleti lensimbi engagqwali engu-316 304 - Imidiya yangaphandle yesihlungi esinezimbobo zensimbi

Izihlungi zamapuleti ensimbi angenasici ze-HENGKO zenziwa ngokufaka i-sintering 316L powder material noma i-multilayer stainless stainless wire mesh emazingeni okushisa aphezulu. Sebe...

Buka imininingwane -

I-Corrosion resistant microns 316L insimbi engagqwali enezimbotshana zesihlungi sensimbi amashidi / ...

I-Product Chaza Izendlalelo ze-HENGKO ze-porous metal diffusion zegesi ziyinketho ehamba phambili yokusebenza okuphezulu kwe-electrolyzer kanye nezicelo zamaseli kaphethiloli. Umfaniswano we...

Buka imininingwane -

I-Easy Clean Micron Porous SUS Sintered 316L Yensimbi Engagqwali Inline Metal Sheet Rou...

Amashidi ensimbi anezimbotshana anezimbotshana ane-porosity ephezulu atholakala kuzimpushana zensimbi ngezindlela zokusabalalisa zamahhala ezilandelwa ukucwiliswa. Isakhiwo se-sintered ...

Buka imininingwane -

0.2 5 10 40 Micron porous sintered powder insimbi engagqwali 316L metal plate isihlungi for c...

Amapuleti anezimbobo zensimbi atholwe ngezendlalelo ngokusabalalisa kwamahhala, ukuminyana, kanye nezimpushana zensimbi ezicwebezelayo asetshenziswa njengomkhiqizo omncane ukuthola...

Buka imininingwane -

Ngokwezifiso 2 10 20 60 Micron Porous Sintered Stainless Stainless Steel 316L Metal Plate Filter

Amashidi okuhlunga okujulile asetshenziselwa ukususa izinhlayiya oketshezini. Lokhu kusho ukuthi uketshezi lungacaca-, lucolise noma luhlungwe olwenziwa yinyumba. Amashidi okuhlunga alungele ...

Buka imininingwane -

5 10 30 60 90 microns powder micro porous sintered metal sheet sheet

Amashidi okuhlunga ensimbi asetshenziswa kabanzi ukususa izinhlayiya zakwamanye amazwe ezinhlotsheni eziningi ezahlukene zokugeleza kwemidiya. Izinkambu ezisetshenziswa kakhulu: Amagesi ajwayelekile,...

Buka imininingwane -

I-HENGKO sintered insimbi engagqwali engu-316 enezingqimba zegesi yensimbi enezingqimba zokuhlunga ishidi le ...

Ipuleti lokuhlunga lensimbi engenasici le-HENGKO lenziwe ngezingqimba eziningi zephaneli enocingo olulukiweyo ihlangene kusetshenziswa inqubo yokucwilisa. Le nqubo...

Buka imininingwane -

I-Medical grade micron insimbi engagqwali 316 316L wire mesh multi-layer plate / disc filter...

Izihlungi ze-HENGKO sintered wire mesh zinezingqimba ezi-5 ze-sintered wire mesh ezinokwakhiwa okuzisekelayo kokuqina komshini nokumelana nezinga lokushisa eliphezulu...

Buka imininingwane -

Amandla afanayo anezimbotshana zensimbi ezinezimbotshana zesihlungi se-micron fluidizers zethusi zethusi ifilimu yethusi...

Amashidi okuhlunga okujulile asetshenziselwa ukususa izinhlayiya oketshezini. Lokhu kusho ukuthi uketshezi lungacaca-, lucolise noma luhlungwe olwenziwa yinyumba. Amashidi okuhlunga alungele ...

Buka imininingwane -

Ukulawula ukugeleza nokusabalalisa uketshezi ipuleti/ishidi lesihlungi esine-sintered, impushana enezimbotshana ezimbotshana...

Amashidi okuhlunga okujulile asetshenziselwa ukususa izinhlayiya oketshezini. Lokhu kusho ukuthi uketshezi lungacaca-, lucolise noma luhlungwe olwenziwa yinyumba. Amashidi okuhlunga alungele ...

Buka imininingwane -

Amapuleti/ishidi lokuhlunga lethusi elinezimbotshana elinezimbotshana lokugeleza nokulawula umsindo

Amashidi okuhlunga okujulile asetshenziselwa ukususa izinhlayiya oketshezini. Lokhu kusho ukuthi uketshezi lungacaca-, lucolise noma luhlungwe olwenziwa yinyumba. Amashidi okuhlunga alungele ...

Buka imininingwane -

Isihlungi sensimbi esinezimbobo zensimbi ishidi lesikwele lesihlungi se-micron sintered bronze

I-HENGKO ikhiqiza izinto zokuhlunga ebangeni elibanzi lezinto, osayizi, nokufakwa ukuze kucaciswe kalula ngezici kanye nokucushwa...

Buka imininingwane -

I-hepa sintered bronze steel stainless steel ishidi lokuhlunga lomoya/lomshini wokuhlunga uwoyela

I-HENGKO ikhiqiza izinto zokuhlunga ebangeni elibanzi lezinto, osayizi, nokufakwa ukuze kucaciswe kalula ngezici kanye nokucushwa...

Buka imininingwane -

Amashidi okuhlunga ensimbi enziwe ngokwezifiso e-sintered metal fitler microns porosity bronze wat...

I-HENGKO ikhiqiza izinto zokuhlunga ebangeni elibanzi lezinto, osayizi, nokufakwa ukuze kucaciswe kalula ngezici kanye nokucushwa...

Buka imininingwane

Izici Eziyinhloko Ze-Porous Metal Plate:

Izici eziyinhloko zamashidi ensimbi anezimbotshana zifaka:

1.Ukuqina okuphezulu:

Amashidi ensimbi anezimbotshana enziwe ngezinto eziqinile njengensimbi engagqwali, i-titanium, noma ama-nickel alloys,

inikeza amandla amahle kakhulu emishini kanye nokumelana nokugqwala, ukuguga, namazinga okushisa aphezulu.

| Okubalulekile | Amandla Emishini | Ukumelana Nokugqwala | Gqoka Ukumelana | Ukumelana Nokushisa | Izinhlelo zokusebenza |

|---|---|---|---|---|---|

| Insimbi engagqwali | Phezulu | Phezulu | Phezulu | Kuhle kakhulu (kufika ku-800°C) | Ukuhlunga, ukucubungula amakhemikhali, uwoyela negesi, imithi |

| I-Titanium | Maphakathi | Phezulu kakhulu | Maphakathi | Kuhle kakhulu (kufika ku-600°C) | I-Aerospace, izindawo zasolwandle, izicelo zezokwelapha |

| I-Nickel Alloys | Phezulu kakhulu | Kuhle kakhulu | Phezulu | Okuphezulu (kufika ku-1000°C) | Ukuhlunga kwezinga lokushisa eliphezulu, ukucubungula amakhemikhali, ukukhiqiza amandla |

2.I-Precise Filtration Control:

Usayizi wembotshana olawulwayo nokusabalalisa okufanayo kuvumela ukuhlunga okunembile, okunikeza ngokungaguquki

ukusebenza ezinhlobonhlobo zezinhlelo zokusebenza.

3.Customizable Porosity:

Amashidi ensimbi anezimbotshana angenziwa ngezifiso ngokuya ngosayizi wembotshana, ukuma,

nokusabalalisa, okuhlinzeka ngokuguquguquka ukuze kuhlangatshezwane nezimfuneko ezithile zokuhlunga noma ukugeleza.

4.Ukuqina okuphezulu:

Naphezu kwamandla abo, amashidi ensimbi ane-porous avumela ukuvuthwa okuphezulu, ukuqinisekisa

amazinga okugeleza asebenzayo amagesi noketshezi kuyilapho kugcinwa ukusebenza kahle kokuhlunga.

5.Ukuhambisana Kwamakhemikhali:

Lawa mashidi ahambisana nohlu olubanzi lwamakhemikhali, awenza

ilungele ukusetshenziswa ezindaweni ezinokhahlo, okuhlanganisa ukucubungula amakhemikhali kanye nezimboni zemithi.

6.Ukumelana Nokushisa Nokucindezela:

Izinto ezisetshenziswa emashidini ensimbi anezimbotshana zingamelana ngokwedlulele

amazinga okushisa nezingcindezi, ukuqinisekisa ukuzinza nokuthembeka ezinhlelweni ezifunwayo.

7.Isondlo Esiphansi kanye Nesikhathi Sokuphila Okude:

Amashidi ensimbi anezimbotshana ahlala isikhathi eside futhi amelana nokuvala,

ukunciphisa isidingo sokunakekelwa njalo nokushintshwa, ngaleyo ndlela andise impilo yabo yesevisi.

8.I-Thermal kanye ne-Electric Conductivity:

Ngaphezu kokuhlunga, amashidi ensimbi anezimbotshana angasebenza njengokushisa

kanye namakhondatha kagesi, anweba ububanzi bezicelo zabo.

Lezi zici zenza amashidi ensimbi anezimbotshana alungele ukusetshenziswa kokuhlunga, ukulawula ukugeleza, izisekelo ze-catalyst,

kanye nezinqubo zokuhlukanisa ezimbonini ezahlukahlukene, njenge-aerospace, ukucubungula amakhemikhali, ezemithi,

nobunjiniyela bezemvelo.

Izinhlobo Zeshidi Lensimbi Enezimbotshana ?

Empeleni kunezinhlobo ezimbili eziyinhloko zamashidi ensimbi anezimbotshana ongazithola

emakethe yeshidi lensimbi enezimbotshana :

1. Amashidi ensimbi ahlanganisiwe:

Lezi zenziwa ngokuhlanganisa kanye ne-sintering metal powders. Ama-pores kulawa mashidi ngokuvamile

kuxhumene futhi kungahluka ngosayizi nokuma. Amashidi ensimbi e-sintered avame ukusetshenziswa ezinhlelweni zokusebenza

lapho kudingeka khona amandla aphezulu nokuhlunga okuhle, njengezihlungi, izishintshisi zokushisa, nezinciphisi-msindo.

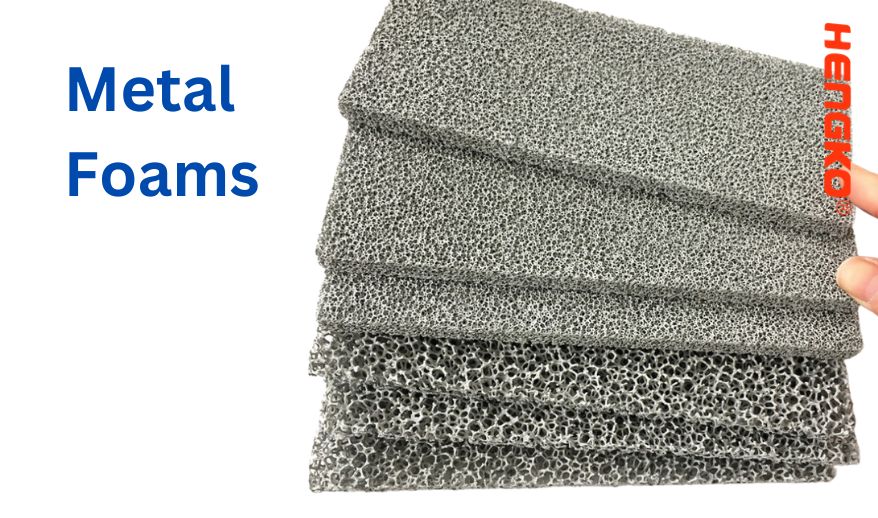

2. Amagwebu Ensimbi:

Amagwebu ensimbi enziwa ngokwethula amabhamuza egesi ensimbi encibilikisiwe futhi ayivumele ukuthi iqine.

Izimbotshana kulawa mashidi ngokuvamile amaseli avaliwe, okusho ukuthi awaxhumene. Amagwebu ensimbi

evame ukusetshenziswa ezinhlelweni lapho kudingeka amandla angasindi namandla aphezulu, njengase-aerospace kanye

izicelo zezimoto.

Nazi ezinye izinhlobo zamashidi ensimbi anezimbotshana:

1. I-wire mesh elukiwe:

Lolu hlobo lwemeshi lwenziwa ngokuluka ndawonye izintambo ezincane. Usayizi wembotshana kumeshi yocingo olukiwe

ingalawulwa ubukhulu bezintambo kanye nephethini yokweluka. I-wire mesh elukiwe ivamisile

ezisetshenziswa izicelolapho kudingeka khona ukuhlunga kanye nezakhiwo ezinhle zokugeleza, njengezikrini nezihlungi.

2. Insimbi enwetshiwe:

Lolu hlobo lweshidi lwenziwa ngokusika ishidi eliqinile lensimbi ngephethini ethile bese liyayelula.

Izimbotshana zensimbi enwetshiwe zivame ukuba zinde futhi zimise okwedayimane. Insimbi enwetshiwe ngokuvamile

ezisetshenziswa izicelolapho kudingeka khona isisindo esilula namandla amahle, njengakunogada bezokuphepha nasezindleleni zokuhamba.

Ukusetshenziswa kwe-Sintered Porous Metal Sheet

Amashidi ensimbi anezimbotshana ze-Sintered ayimidiya yokuhlunga enemisebenzi eminingi ngenxa yezakhiwo zawo ezihlukile.

Nazi ezinye zezinhlelo zokusebenza ongazisebenzisa:

* Izindawo Ezinokushisa Okuphezulu:

*Izindawo Zamakhemikhali Eziqinile:

*Izicelo Zokucindezela Okuphezulu:

* Isidingo Sokulawulwa Kwezinhlayiyana Ezinembile:

* Ukusebenziseka Kabusha Nokukhiqiza Kabusha:

Futhi Nazi ezinye izimboni ezingazuza ikakhulukazi ngokusebenzisa amashidi ensimbi anezimbotshana ezisikiwe ezinhlelweni zazo zokuhlunga, wena

ungabheka ukuthi kuzoba kuhle yini kusistimu noma kudivayisi yakho?

* Ukucutshungulwa Kwamakhemikhali - Okokuhlunga uketshezi olubolayo namagesi, kanye nama-catalysts asuka ku-process stream.

* Ukukhiqiza Amandla - Ukuhlunga kwezinga lokushisa eliphezulu kwamagesi ezitshalweni zikagesi.

* Imboni Yemithi - Ukuqinisekisa ubunyumba kanye nokuhlanzeka kwemikhiqizo ngokususa amagciwane kanye nezinhlayiya.

* Imboni Yokudla Neziphuzo - Ukuhlunga kokucacisa uketshezi, nokukhipha izinhlayiya ezingafuneki.

* Ukuhlanza Amanzi - Ukuba negalelo ezinhlelweni zokuhlanza ngokususa ukungcola emanzini.

Sekukonke, amashidi ensimbi anezimbotshana ezinezimbotshana ayithuluzi elibalulekile lezinhlelo zokusebenza zokuhlunga ezimbonini ezidinga ukuqina, ukumelana nezinga lokushisa eliphezulu, ukuhlungwa okunembile, nokusebenziseka kabusha.

FAQ

1. Yini aishidi lensimbi elinezimbotshana, futhi yenziwa kanjani?

Ishidi lensimbi elinezimbotshana liwuhlobo lwempahla ebonakala ngesakhiwo salo esikwazi ukungena, esakhiwe

izimbotshana ezixhumene noma ama-voids kulo lonke ubuningi bayo. Lawa mashidi akhiqizwa ngokuyinhloko

inqubo eyaziwa ngokuthi sintering. I-Sintering ihlanganisa ukuhlanganisa impushana yensimbi esikhunjeni bese ushisisa

ingaphansi kwendawo yayo yokuncibilika. Lokhu kwelashwa kokushisa kubangela ukuthi izinhlayiya zensimbi zihlangane ngaphandle kokuncibilika,

ukwakha isakhiwo esiqinile esine-porosity elawulwa ngokunembile.

Inqubo ivumela ukukhiqizwa kwamashidi anobukhulu obuhlukahlukene bembotshana, ukwakheka, nokusabalalisa,

yakhelwe izinhlelo zokusebenza ezithile. Amashidi ensimbi engenasici, isibonelo, asetshenziswa kabanzi ngenxa

izici zabo ezinhle kakhulu zemishini, ukumelana nokugqwala, nokuzinza kokushisa.

2. Yiziphi izinhlelo zokusebenza eziyinhloko zamashidi ensimbi engenasici?

Amashidi ensimbi engagqwali e-Sintered asetshenziswa ezinhlobonhlobo zezinhlelo zokusebenza ngenxa yokuguquguquka kwawo nokuqina kwawo.

Ezinye zezinhlelo zokusebenza ezibalulekile zifaka:

* Ukuhlunga:

Asetshenziswa kuzo zombili izinhlelo zegesi kanye ne-liquid filtration, asusa ngempumelelo i-particle

ngenxa yobukhulu bawo obuqondile bembotshana.

* Ukusabalalisa nokusabalalisa:

Ilungele ukusabela kwe-gas-liquid, i-aeration, kanye nezinqubo zokuphisa,lapho kulawulwa khona

usayizi webhamuza ubalulekile.

*I-Fluidization:

Kuqashwe emibhedeni egcwele amanzi ngezinqubo ezahlukahlukene zamakhemikhali, esiza ekulinganeniukusatshalaliswa

amagesi ngoketshezi noma izimpushana.

* Ukuvikelwa kwezinzwa:

Ivikela izingxenye ezizwelayo ezindaweni ezinokhahlo, ivimbele ukungcola

ngenkathi ivumela ukuxhumana kwemvelo okudingekayo.

* Ukubuyiselwa Kwe-Catalyst Nokusekelwa:

Inikeza isiteji esihle kakhulu sezinto ezisebenzayo, ezisizayo

ukusabela kwamakhemikhali kuyilapho kuvumela ukutholakala kalula kwama-catalyst ayigugu.

3. Unquma kanjani usayizi wembotshana ofanele wohlelo oluthile?

Ukunquma usayizi wembotshana ofanele wohlelo oluthile kuhlanganisa ukucabangela

izici eziningana, kuhlanganise uhlobo uketshezi noma amagesi acutshungulwayo, izinhlobo

izinhlayiya noma ukungcola okufanele kukhishwe, kanye nezinga lokugeleza elifunekayo. Ngezinhlelo zokusebenza zokuhlunga,

usayizi wembotshana ukhethwa ukuthi ube mncane kunezinhlayiyana ezincane kakhulu ezidingayo

ukuze ihlungwe. Kuzinhlelo zokusebenza ezibandakanya ukusakazeka kwegesi noma ukukhishwa, usayizi we-pore uthinta

usayizi wamabhamuza akhiqizwayo, okungaba nomthelela omkhulu ekusebenzeni kahle kwenqubo.

Ukubonisana nabakhiqizi beshidi lensimbi elinezimbobo ezinjenge-HENGKO banganikeza imininingwane esekelwe

isipiliyoni esibanzi kanye nobuchwepheshe bezobuchwepheshe, okuqinisekisa ukukhethwa kosayizi wembotshana olungile

nganoma yisiphi isicelo esinikeziwe.

4. Yiziphi izinzuzo ezinikezwa ngamashidi ensimbi engagqwali e-sintered ngaphezu kwezinye izinto?

Amashidi ensimbi engagqwali e-Sintered anikeza izinzuzo ezimbalwa ngaphezu kwezinye izinto, azenze a

ukukhetha okuthandwayo kwezicelo eziningi zezimboni:

* Ukuqina:

Amandla abo aphezulu kanye nokumelana nokuguga kuqinisekisa impilo ende yesevisi ngaphansi kwezimo eziyinselele.

* Ukumelana nokugqwala:

Insimbi engagqwali ingokwemvelo ukumelana nokugqwala ilungele ukusetshenziswa ezindaweni zamakhemikhali ezinokhahlo noma

lapho ukuchayeka ezintweni ezonakalisayo kuvame.

*Ukuqina Kwezinga Lokushisa Okuphezulu:

Bangakwazi ukumelana namazinga okushisa aphezulu ngaphandle kokululaza, okubenza bafanelekele ukusetshenziswa kuma-heaters,

izihlungi ezinezinga lokushisa eliphezulu, nezinye izinhlelo zokusebenza ezidinga ukuzinza kwe-thermal.

* Ukuhambisana Kwamakhemikhali:

Insimbi engagqwali ihambisana nezinhlobonhlobo zamakhemikhali, inciphisa ingozi yokuwohloka kwezinto

kanye nokungcola.

* Ukuhlanzeka kanye Nenzalo:

Izindawo zabo ezibushelelezi, ezingenazimbobo zingahlanzwa kalula futhi zivalwe inzalo, okubalulekile kwezemithi.

kanye nezicelo zokudla neziphuzo.

5. Ingabe amashidi ensimbi engagqwali ane-sintered angenziwa ngokwezifiso ukuze asetshenziswe ngendlela ehlukile?

Yebo, amashidi ensimbi engenasici angenziwa enziwe ngokwezifiso kakhulu ukuze ahlangabezane nezidingo ezihlukile zohlelo lokusebenza.

Ukwenza ngendlela oyifisayo kungabandakanya ukuhluka kosayizi wembotshana, ukujiya, usayizi weshidi, nokuma, kanye nokufakwa

yezinto ezithile ze-alloying ukuthuthukisa izakhiwo ezithile ezifana ne-conductivity noma ukumelana nokushisa.

Abakhiqizi abafana no-HENGKO basebenza ngokubambisana namakhasimende ukuze baklame futhi bakhiqize insimbi e-bespoke.

izixazululo ezihlangabezana ngokunembile nezicaciso nemibandela yokusebenza edingekayo ezicelweni zabo.

Leli zinga lokwenza ngokwezifiso liqinisekisa ukuthi umkhiqizo wokugcina ungasebenza kahle endaweni ohlosiwe,

kungakhathaliseki ukuthi kuhilela izidingo zokuhlunga eziyingqayizivele, ukucubungula amakhemikhali okukhethekile, nanoma yiluphi olunye uhlelo lokusebenza oluqondene nemboni.

Xhumana no-HENGKO

Ingabe usukulungele ukuphakamisa uhlelo lwakho lokusebenza lwezimboni ngezisombululo zensimbi ezingenazimbobo ze-bespoke?

Xhumana nathi kuka@hengko.comfuthi ake siguqule izinselele zakho zibe impumelelo.