Yini i-Sintering?

Ukusho Okulula, I-Sintering inqubo yokwelapha ukushisa esetshenziselwa ukuguqula izinto eziyimpuphu zibe yinqwaba eqinile, ngaphandle kokufinyelela eqophelweni lokuncibilika ngokuphelele.

Lokhu kuguqulwa kwenzeka ngokushisisa into engaphansi kwendawo yayo yokuncibilika kuze kube yilapho izinhlayiya zayo zinamathelana. I-Sintering isetshenziswa kakhulu ezimbonini ezahlukahlukene ezifana ne-metallurgy, i-ceramics, ngisho nokuphrinta kwe-3D ukukhiqiza izinto eziminyene neziqinile ezivela kumpushana.

Kodwa bewazi yini ukuthi umqondo we-sintering awuyona into eqanjiwe yesimanje?

Eqinisweni, imvelaphi yayo ingalandelelwa emuva cishe ku-3000 BC, lapho yayisetshenziselwa ukwenza izinto zobumba. Ukuqonda kwesayensi yesimanje kanye nokusetshenziswa kabanzi kwemboni ye-sintering, nokho, kuye kwathuthuka kakhulu phakathi nekhulu leminyaka elidlule.

Njengoba ungacabanga, ukucula kudlala indima ebalulekile ebuningini bezinhlelo zokusebenza. Kusukela ekwenzeni ama-spark plug, ama-ceramic capacitor, kanye nemiqhele yamazinyo kuya ekwakhiweni kwezingxenye zezimboni zobuchwepheshe obuphezulu, ukufaka i-sintering kubonakale kudingekile.

Izinhlobo ezahlukene ze-Sintering

Manje njengoba usuyazi ukuthi yini i-sintering nokuthi isetshenziswe kanjani kuwo wonke umlando, sekuyisikhathi sokukwazisa ngezinhlobo ezahlukene zokucula. Yebo, kunendlela engaphezu kweyodwa yokucula!

Okokuqala phezului-solid-state sintering. Lolu hlobo luwuhlobo oluyisisekelo nolujwayelekile lokucula. Lapha, izinto eziyimpuphu ziyashiswa kuze kube yilapho izinhlayiya ziqala ukuhlangana ndawonye. Kufana nokuthi ungakha kanjani i-sandcastle - izinhlamvu zesihlabathi ziyanamathelana, kodwa azincibiliki.

Olandelayo,sine-liquid phase sintering. Lolu hlobo lubandakanya ingxube yezinto ezimbili noma ngaphezulu. Ingxube iyashiselwa kuze kube seqophelweni lapho enye yezinto ezisetshenziswayo incibilika futhi yakhe isigaba soketshezi, esiza ekuhlanganiseni izinhlayiya eziqinile ezisele ndawonye.

Okwesithathuohlwini icushiwe sintering. Kulesi simo, i-additive noma i-catalyst isetshenziselwa ukusheshisa inqubo ye-sintering. Cabanga ngakho njengokwengeza imvubelo enhlama - kwenza isinkwa sikhuphuke ngokushesha.

Okokugcina,kukhona amasu okucwilisa okusizwa yingcindezi afana nokucindezela okushisayo kanye ne-spark sintering ye-plasma. Njengoba igama liphakamisa, lawa masu asebenzisa ingcindezi ngokuhambisana nokushisa ukusheshisa inqubo ye-sintering futhi akhiqize izinto eziminyene.

Uhlobo ngalunye lwe-sintering lunesethi yalo yezinzuzo futhi lusetshenziselwa izinhlelo zokusebenza ezithile. Okukhethwa kukho kuncike ezicini ezifana nempahla esetshenziswayo, izici ezifiselekayo zomkhiqizo wokugcina, nezinto ezitholakalayo. Ezigabeni ezizayo, sizocubungula ngokujulile ezintweni ezithile ezisikiwe kanye nenqubo ye-sintering ngokwayo.

Hlala ubukele ukuthola imininingwane eheha kakhudlwana ngomhlaba wokucula!

Ukuhlola Izinto Ezisetshenziswayo

Bese Okulandelayo sidinga ukuqonda izinhlobo ezahlukene zezinto ze-sintered.

Nginesiqiniseko sokuthi manje, usuthola i-hang yenqubo yokucula. Kodwa kuthiwani ngemikhiqizo yale nqubo ethakazelisayo?

Enye yezinto ezivame ukukhiqizwa insimbi e-sintered.Inqubo ihilela ukuhlanganisa nokwenza impushana yensimbi ngaphansi kokushisa, iyenze ibe insimbi eqinile. Umphumela uba insimbi enezinga eliphakeme lokuhlanzeka nokufana. Insimbi ene-sintered ingatholakala ezimbonini ezihlukahlukene, kusukela ezingxenyeni zezimoto kuya ekufakweni kwezokwelapha, ngenxa yokuqina kwayo nokuguquguquka.

Olandelayo,ake sikhulume ngetshe le-sintered. Itshe le-Sintered likhiqizwa ngokufaka ukushisa nokucindezela kumaminerali emvelo, ubumba, ne-feldspar, okwenza into ecishe ingapheli. Ngokuvamile uzothola itshe eline-sintered ezindaweni ezinethrafikhi ephezulu njengezindawo zokubala zasekhishini noma amathayela okugeza, lapho ukuqina kuwukhiye.

I-Sintering nayo idlala indima ebalulekile kuma-ceramics. Inqubo isenza sikwazi ukubumba i-ceramics ibe yinqwaba yomumo ngamajiyometri ayinkimbinkimbi angeke akhoneke ngezindlela zendabuko. Kusukela kumathayela e-ceramic kuya kobumba, i-sintering ibe nomthelela wenguquko kulo mkhakha.

Okokugcina,kukhona ezinye izinto ezikhethekile ze-sintered ongazihlola. Lezi zisukela ezintweni eziyinhlanganisela, njengezinhlanganisela zensimbi-ceramic, kuya ezintweni ezisezingeni elisebenzayo, lapho ukwakheka kwehluka kuyo yonke ingxenye.

Inqubo Ye-Sintering Ichaziwe

Masiqhubeke sisuka emikhiqizweni siye kwinqubo ngokwayo. Kwenzeka kanjani ukucula, futhi yiziphi izigaba ezibalulekile ezihilelekile?

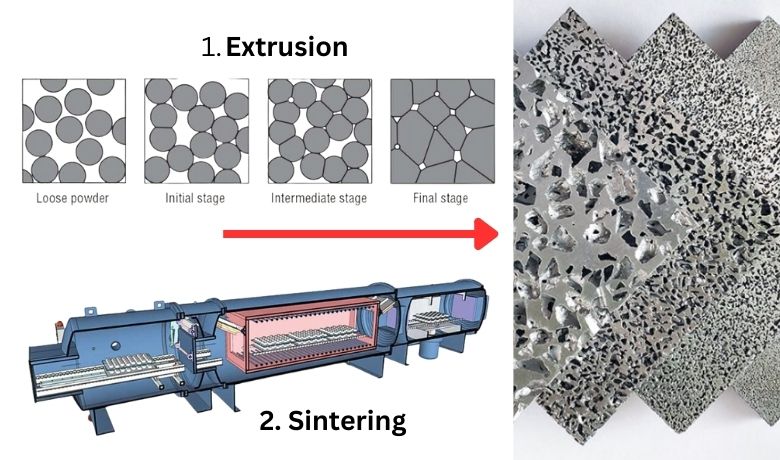

Okokuqala, izinyathelo zangaphambi kwe-sintering zibalulekile. Impahla eluhlaza, kungakhathaliseki ukuthi insimbi, i-ceramic, noma ngenye indlela, kufanele ilungiswe ngendlela yempushana. Le mpushana ibe isibunjwa ibe yifomu efunwayo, ngokuvamile ngenqubo ebizwa ngokuthi 'ukuhlanganisa okuluhlaza'.

Okulandelayo kuza inhliziyo yokusebenza: inqubo ye-sintering. Impushana emise okwempuphu ishiswa endaweni elawulwayo, ngokuvamile esithandweni somlilo, ezingeni lokushisa elingaphansi nje kwephuzu layo lokuncibilika. Lokhu kuvumela izinhlayiya ukuba zihlangane ndawonye ngaphandle kokuncibilika ngokugcwele, zenze inqwaba eqinile.

Uma inqubo ye-sintering isiqediwe, okokusebenza kungena esigabeni sokupholisa. Lokhu kudinga ukuphathwa ngokucophelela, njengoba ukupholisa ngokushesha kungaholela ekuqhekekeni noma kwezinye izinkinga zesakhiwo. Ukupholisa kancane kuvumela izinto ukuthi zizinze futhi ziqine ngempumelelo.

Okokugcina,asikwazi ukukhohlwa izici ezithinta i-sintering, ikakhulukazi, izinga lokushisa nesikhathi. Izinga lokushisa le-sintering lidinga ukuphakama ngokwanele ukuze kube lula ukubopha kodwa libe phansi ngokwanele ukuvimbela ukuncibilika okugcwele. Ngokufanayo, isikhathi esichithwa yi-sintering singaba nomthelela omkhulu ezimpahleni zomkhiqizo wokugcina.

Engxenyeni elandelayo yesaga yethu yokucula, sizongena sijule kuzihlungi ezifakwe emanzini futhi sembule izimo ezidingekayo zokucula. Ngakho hlala ubukele!

Izihlungi ze-Sintered: I-Spotlight yohlelo lokusebenza

Sesivele sihlanganise izinto eziyisisekelo zokucula, sahlola izinhlobonhlobo zezinto ze-sintered, futhi saxoxisana ngenqubo ye-sintering kabanzi.

Manje, ake sigxile ku-aukusetshenziswa okuqondile kwezihlungi ze-sintering.

Mhlawumbe enye yezinhlelo zokusebenza eziphawuleka kakhulu ze-sintering iwukuba ekudalweni kwezihlungi zensimbi ezine-sintered. Lezi zihlungi zikhiqizwa ngezimpushana zensimbi, zihlanganiswe futhi zifakwe i-sintered ukuze kwakhiwe isihlungi esinezimbotshana kodwa esiqinile. Ubukhulu bembotshana balezi zihlungi bungalawuleka ngokunembile, buhlinzeke ngamakhono okuhlunga aphakeme uma kuqhathaniswa nezihlungi zendabuko ezinocingo olulukiweyo.

Ungase uzibuze,kungani usebenziseizihlungi zensimbi ze-sintered?Impendulo ilele ekuqineni kwazo nasekumelaneni nezinga lokushisa eliphezulu nezingcindezi. Lezi zakhiwo zenza izihlungi zensimbi ezine-sintered zibaluleke kakhulu ezimbonini kusukela kwezokwelapha kuya kumakhemikhali e-petrochemicals kanye nokukhiqizwa kokudla nesiphuzo.

Olunye uhlelo lokusebenza oluhehayo lokucwilisa ekuhlungeni isihlungi sengilazi esine-sintered. Lokhu kwenziwa ngokuhlanganisa izinhlayiya zengilazi ezincane emazingeni okushisa aphezulu. Avame ukusetshenziswa ezindaweni zokucwaninga ukuze kuhlungwe futhi kusabalaliswe igesi ngenxa yokumelana namakhemikhali aphezulu kanye nosayizi wembotshana oqondile.

Izihlungi ze-Sintered, kungaba insimbi noma ingilazi, ziyisibonelo samakhono we-sintering ekudaleni izinto ezisezingeni eliphezulu ezinezinzuzo ezihlukile.

Ukuqonda Imibandela Ye-Sintering

Manje, ake siphendulele ukunaka kwethu ezimeni ze-sintering. Uma sikhuluma ngenqubo ye-sintering, izimo ezenzeka ngaphansi kwazo zibaluleke kakhulu.

Okokuqala,izinga lokushisa le-sintering lidlala indima ebalulekile kule nqubo. Kudingeka ibe ngaphansi nje kwendawo yokuncibilika yezinto, ukuze izinhlayiya zihlangane ngaphandle kokuncibilika ngokugcwele. Ibhalansi ethambile engathinta kakhulu ikhwalithi yomkhiqizo wokugcina.

Khona-kekukhona indaba kagesi. Ungase uzibuze, "Iyiphi igesi esetshenziswa ekushiseni?" Ngokuvamile, ukucwilisa kwenziwa endaweni elawulwayo ukuze kuvinjelwe ukusabela okungafuneki phakathi kwezinto namagesi azungezile. Ngokuvamile, amagesi angenayo njenge-nitrogen noma i-argon asetshenziswa, nakuba ukukhetha okuqondile kuncike ezintweni ezifakwayo.

Ingcindezi iphinde ibe khona, ikakhulukazi kumasu okusiza ingcindezi. Ukucindezela okuphezulu kungabangela izinto eziminyene, njengoba izinhlayiya ziphoqelelwa ukusondelana ndawonye.

Ekugcineni,izinto ezibonakalayo nezinto zokusebenza ezisetshenziswayo ziyizici ezibalulekile. Izinto ezisetshenziswayo ezihlukene zisabela ngendlela ehlukile ekushiseni nasekucindezelweni, okudinga izimo ezihlukahlukene zokucwilisa kahle. Uhlobo lwesithando somlilo noma umshini wokucwilisa amanzi lungaphinde lube nomthelela ohlelweni, njengoba sizoxoxa ngalo esigabeni esilandelayo.

Hlala ubukele njengoba sihlola kabanzi mayelana nemishini yokucwilisa kanye neqhaza layo enqubweni yokucula!

Izisetshenziswa ze-Sintering: Ukubheka Imishini Ye-Sintering

Kuze kube manje, besihlola kahle umqondo wokucutshungulwa, okokusebenza kwe-sintered, kanye nenqubo ngokwayo.

Manje ake sikhanyise umdlali oyinhloko ngemuva kwezigcawu:umshini wokusika.

Umshini we-sintering uyitshe legumbi lenqubo ye-sintering. Kodwa uyini ngempela umshini wokuthunga? Empeleni, kuyisithando somlilo esikhethekile esiklanyelwe ukwenza inqubo yokucwilisa ngaphansi kwezimo ezilawulwa ngokucophelela.

Banguizinhlobo ezahlukene zemishini yokugezelaetholakalayo, ngayinye ifanele izinto ezahlukene kanye nezindlela zokugcoba.

1. Lezi zihlanganisaImishini ye-sintering eqhubekayo(esetshenziswa ezimbonini ezidinga ukukhiqizwa kwevolumu ephezulu),

2.Imishini yokugcwalisa i-batch(okuvame kakhulu kumalebhu noma ukukhiqizwa kwevolumu ephansi), kanye

3. Imishini yokuhlanza i-vacuum(okuvumela ukucwilisa endaweni engenalutho noma emkhathini olawulwayo).

Indlela umshini we-sintering osebenza ngayo iqondile kodwa iyathakazelisa. Ishisisa ngokulinganayo into eyimpushana ezingeni lokushisa elithile, igcine leli zinga lokushisa isikhathi esinqunyiwe, bese ipholisa izinto kancane kancane, konke lokhu iqinisekisa ukuthi umoya ongaphakathi uyalawulwa.

Ukukhetha umshini wokugcwalisa ofanele kubalulekile futhi kuncike ezintweni ezimbalwa, okuhlanganisa okokusebenza okuzofakwa esiteringini, umthamo ofunekayo, kanye nezimo ezithile zokucwilisa ezidingekayo.

Ukubaluleka Nekusasa Lokucula

Manje sekuyisikhathi sokuzindla ngesithombe esikhulu:Yini i-sintering esetshenziselwa, futhikungani kubalulekile?

Iiziceloof sintering ziningi futhi ezihlukahlukene. Isetshenziselwa ukwakha imikhiqizo eminyene, eqinile enejiyometri eyinkimbinkimbi, kusukela ezingxenyeni zezimboni kuya ezimpahleni zabathengi. I-Sintering isivumela ukuthi sikhiqize izinto zekhwalithi ephezulu, njengezihlungi zensimbi ene-sintered, ezinezakhiwo ezihlukile ezifana nosayizi wembotshana olawulwayo nokuqina okuthuthukisiwe.

Kodwalibukeka kanjani ikusasa lokucula?Amathrendi asafufusa asikisela ukwanda kokusetshenziswa kwezindlela ze-sintering esiza ukucindezela ukukhiqiza izinto ezithuthukisiwe. Ukuthuthukiswa kwemishini esebenza kahle kakhulu yokucwilisa kanye nokusetshenziswa kwe-sintering ekukhiqizeni okungeziwe (ukuphrinta kwe-3D) amanye amathrendi athembisayo.

Ngaphandle kwalezi ntuthuko, i-sintering iphinde ibhekane nezinselele, njengokuthola ukulawula okukhulu phezu kwenqubo kanye nokunciphisa ukusetshenziswa kwamandla. Ukubhekana nalokhu kuzoba ukhiye ekuvuleni amandla aphelele okucula ngokuzayo.

Isiphetho:I-Sintering, kuyilapho kuyinqubo eyinkimbinkimbi, inomthelela omkhulu ezimbonini ezihlukahlukene. Ikhono layo lokuguqula izimpushana ezilula zibe izinto eziqinile, eziyinkimbinkimbi kwenza kube inqubo eyigugu. Njengoba sibheke phambili ekusaseni, inguquko kanye nokucwengwa kwe-sintering kuthembisa amathuba ajabulisayo wezinto ezintsha nezinhlelo zokusebenza.

FAQ

1. Iyini inqubo ye-sintering?

I-Sintering inqubo yokwelapha ukushisa eguqula izinto eziyimpuphu zibe yinqwaba eqinile ngaphandle kokuncibilika ngokuphelele. Kubandakanya ukushisa izinto eziyimpuphu ngaphansi kwendawo yayo yokuncibilika kuze kube yilapho izinhlayiya ziqala ukunamathela komunye nomunye, zakha isisindo esiqinile. Le nqubo isetshenziswa ezimbonini ezahlukahlukene ezifana ne-metallurgy, i-ceramics, kanye nokukhiqiza okungeziwe ukuze kukhiqizwe izinto eziminyene neziqinile ezivela kumpushana.

2. Kusebenza kanjani ukucula?

Inqubo ye-sintering ihilela izigaba ezintathu eziyinhloko: ukushisa, ukubamba, nokupholisa. Impahla eyimpushana iqala ihlanganiswe futhi yakheke ibe yisimo esifiswayo, bese ishiselwa endaweni elawulwayo ibe izinga lokushisa elingaphansi nje kwendawo yayo yokuncibilika. Ukushisa kubangela ukuthi izinhlayiya zihlangane, zenze inqwaba eqinile. Ngemuva kokugcina leli zinga lokushisa isikhathi esinqunyiwe, okokusebenza kuyapholiswa kancane ukuze kuvinjelwe ukuqhekeka noma ezinye izinkinga zesakhiwo.

3. Yiziphi izinto ezingenziwa sintered?

Izinhlobonhlobo zezinto ezisetshenziswayo zingashiswa, kufaka phakathi izinsimbi, izitsha zobumba, amapulasitiki, nezingilazi. Izinto ezihlukile zidinga izimo ezihlukile zokucwenga, njengezinga lokushisa, ukucindezela, nomoya. Ezinye izinto ezisetshenziswayo zingashiswa ngokuqondile, kuyilapho ezinye zidinga izithasiselo noma izibophezelo ukuze kube lula inqubo.

4. Siyini isisefo se-sintered, futhi kungani sisetshenziswa?

Isihlungi se-sintered wuhlobo lwesihlungi esikhiqizwa ngenqubo ye-sintering. Ingenziwa ngensimbi, i-ceramic, noma izimpushana zengilazi, ihlanganiswe futhi ishisiswe kuze kube yilapho izinhlayiya zihlangana ndawonye. Usayizi wembotshana walezi zihlungi ungalawulwa ngokunembile, unikeze amandla okuhlunga aphakeme uma kuqhathaniswa nezihlungi zendabuko. Izihlungi ze-Sintered ziqinile kakhulu futhi zimelana namazinga okushisa aphezulu nezingcindezi, zizenza zibe usizo ezimbonini ezihlukahlukene ezifana nemithi, amakhemikhali e-petrochemicals, kanye nokukhiqizwa kokudla nesiphuzo.

5. I-sintering isetshenziswa kanjani ekukhiqizeni okungeziwe (ukuphrinta kwe-3D)?

Ekukhiqizeni okungeziwe, noma ukuphrinta kwe-3D, i-sintering isetshenziswa ngezindlela ezifana ne-selective laser sintering (SLS) kanye ne-direct metal laser sintering (DMLS). Lezi zindlela zibandakanya ukusebenzisa i-laser ukwenza isendlalelo sezinto eziyimpuphu sinter ngongqimba, ukwakha into efiselekayo ye-3D. Ikhono lokulawula inqubo ye-sintering ngokunembile lenza kube nokwenzeka ukukhiqiza izimo eziyinkimbinkimbi namajiyometri okungaba nzima noma okungenzeki ukufezeka ngezindlela zokukhiqiza ezivamile.

6. Liyini ikusasa lokucula?

Ikusasa le-sintering libukeka lithembisa, nokuthuthuka kwezobuchwepheshe okuvula amathuba amasha. Isibonelo, amasu oku-sinter okusiza ingcindezi aya ngokuya ethandwa kakhulu ekukhiqizeni izinto ezithuthukile. Ukwakhiwa kwemishini esebenza kahle kakhulu nenembayo, kanye nokusetshenziswa kwe-sintering ekukhiqizeni okungeziwe, kungezinye izindlela ezithembisayo. Kodwa-ke, izinselele ezinjengokuthola ukulawula okukhulu phezu kwenqubo kanye nokunciphisa ukusetshenziswa kwamandla kumele kubhekwane nazo ukuze kuvulwe ngokugcwele amandla okusebenzisa i-sintering.

Noma ngabe ubheke ukwenza izinqubo ze-sintering emisebenzini yakho noma ufuna izinto zokwakha zekhwalithi ephezulu zephrojekthi yakho, i-HENGKO ilapha ukuzokusiza. Ithimba lethu lochwepheshe limi ngomumo ukukunikeza izeluleko, izixazululo, namasevisi ahambisana nezidingo zakho ezihlukile.

Ungangabazi ukuxhumana nathi ukuze uthole imininingwane eyengeziwe mayelana nenqubo ethokozisayo yokucula noma ukuhlola uhla lwethu olubanzi lwemikhiqizo namasevisi. Simply usithumelele i-imeyili kuka@hengko.com, futhi sizokuthinta maduze. sizimisele ukukusiza ukuthi uguqule amathuba ayimpushana abe impumelelo eqinile!

Thumela umlayezo wakho kithi:

Isikhathi sokuthumela: Jul-03-2023