Izihlungi ze-Sintered ziyingxenye ebalulekile ezinqubweni eziningi zezimboni.

Ziyizihlungi zensimbi ezidalwe ngokuhlanganisa izinhlayiya zensimbi ezincane ndawonye, ngenqubo ebizwa ngokuthi i-sintering,

emazingeni okushisa angaphansi kwendawo yokuncibilika. Lesi sakhiwo esiyingqayizivele sibanika izinzuzo eziningana:

* I-porosity ephezulu:

Aqukethe ingxenye enkulu yesikhala esingenalutho, okuvumela uketshezi ukuba ludlule kuyilapho ucupha izinhlayiya ezingafunwa.

* Amandla nokuqina:

Izihlungi ze-Sintered zinamandla futhi zingamelana nezingcindezi eziphezulu namazinga okushisa.

* Ukuhlukahluka:

Zingenziwa ngezinsimbi ezihlukahlukene futhi ziza ngobukhulu obuhlukahlukene be-pore ukuze zivumelane nezinhlobonhlobo zezidingo zokuhlunga.

Lezi zimfanelo zenza izihlungi ze-sintered zibalulekile ezinhlelweni ezihlukene zezimboni. Asetshenziswa kakhulu ku:

* Ukucutshungulwa kwamakhemikhali:

Ukuhlunga ama-catalyst, ukuhlukanisa imikhiqizo efunwayo kuzingxube zokusabela, nokususa ukungcola.

* Ukudla nesiphuzo:

Ukucacisa uketshezi, ukususa amagciwane, nokuhlunga izinhlayiya ezingadingeki.

* Imithi:

Ukuhlanza izixazululo, ukuhlunga ukungcola, nokulawula usayizi wezinhlayiyana emithini.

*Ezezimoto:

Ukuhlunga izinto zokubasa, okothambisa, noketshezi olusebenza ngehydraulic.

* Ukuhlunga komoya negesi:

Ukukhipha uthuli, izinhlayiya, nokungcola emoyeni negesi.

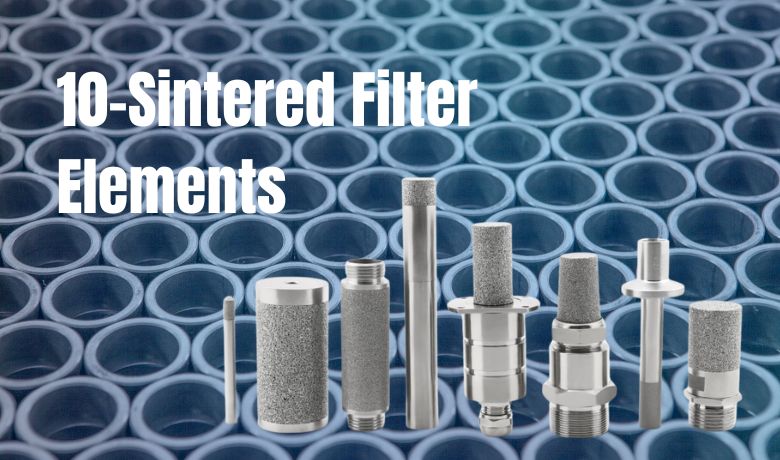

Bese njengokulandelayo , ngizoqala ukukwethulela izinto zokuhlunga eziyi-10 ezidumile ezisetshenziswa emakethe.

1. Izihlungi Zezihlungi Zensimbi Engagqwali

Izihlungi ze-stainless steel sintered ziwuhlobo oluguquguqukayo noluthembekile lwesihlungi semidiya esetshenziswa kakhulu kwigesi yezimboni.

kanye nezinhlelo zokusebenza zokuhlunga uketshezi. Akhiqizwa ngokuhlanganisa izinhlayiya zensimbi engagqwali ndawonye ngokusebenzisa i-sintering

inqubo ekushiseni okuphezulu, ngaphansi kwendawo yokuncibilika yensimbi. Le nqubo ye-sintering idala insimbi eqinile, enezimbotshana

isakhiwo esinikeza izici ezimbalwa ezibalulekile:

* Amandla aphezulu nokuqina:

Izihlungi ezine-stainless steel sintered zingamelana nezingcindezi eziphezulu namazinga okushisa, zizenze zifanelekele izindawo ezifunwa kakhulu zezimboni.

* Ukumelana nokugqwala okuhle kakhulu:

Insimbi engagqwali ngokwemvelo imelana nokugqwala okuvela enhlobonhlobo yamakhemikhali, okuwenza alungele ukusetshenziswa noketshezi olunamandla.

* I-porosity ephezulu:

Izihlungi ze-Sintered zinephesenti elikhulu lesikhala esingenalutho ngaphakathi kwesakhiwo sazo, okuvumela ukugeleza okuphezulu koketshezi namagesi.

kuyilapho ubamba ngempumelelo izinhlayiya ezinkulu kunosayizi wembotshana.

* Ukuhlukahluka:

Angenziwa ngezinhlobo nosayizi abahlukahlukene ngohlu olubanzi lwezilinganiso ze-micron ukuze avumelane nezinhlobonhlobo zezidingo zokuhlunga.

* Ukuhlanza kalula:

Izihlungi zensimbi engagqwali zingawashwa ngemuva noma zihlanzwe ngezincibilikisi, kuzenze ziphinde zisetshenziswe isikhathi eside.

Isicelo :

Lezi zakhiwo zenza izihlungi zensimbi engagqwali zibe yinketho edumile yezinhlelo eziningi zegesi yezimboni kanye nokuhlunga uketshezi, okuhlanganisa:

* Ukuhlunga kwegesi:

Ukukhipha uthuli, izinhlayiya, nokungcola emoyeni nasemfudlaneni wegesi ezinqubweni ezehlukene zezimboni, okuhlanganisa ukuhlunga komoya okucindezelwe,

ukuhlunga kwegesi yemvelo, nokuhlunga komoya wensimbi.

* Ukuhlunga uketshezi:

Ukuhlunga izinhlayiya, amagciwane, nokunye ukungcola oketshezini olusetshenziswa ekucutshungulweni kwamakhemikhali, ukukhiqizwa kokudla nesiphuzo,

imithi, nokwelashwa kwamanzi.

* Ukuhlunga uwoyela namafutha:

Ukukhipha ukungcola nokungcola emafutheni okugcoba, uketshezi olunamanzi, namafutha ukuze kuvikelwe izinto zokusebenza nokuqinisekisa ukusebenza kahle.

Ngaphezu kwalezi zinhlelo zokusebenza ezijwayelekile, izihlungi ze-stainless steel sintered nazo zisetshenziswa ezinqubweni ezikhethekile zokuhlunga zezimboni, okuhlanganisa:

* Ukuvuselelwa kwe-Catalyst:Ukuthola ama-catalyst abalulekile ezingxubeni zokusabela ezinqubweni zokukhiqiza amakhemikhali.

* Ukuvala inzalo:Izixazululo zokuvala inzalo kanye negesi embonini yezemithi neye-biotechnology.

* Ukulawulwa kwe-Emission:Ukukhipha i-particle nokungcola emifuleni yegesi ukuze kuhambisane nemithetho yemvelo.

2. Izihlungi Zensimbi Engagqwali Sintered Mesh

Izihlungi zensimbi engenasici ziwuhlobo lwesihlungi semidiya yezimboni esisetshenziswa kakhulu embonini yokudla neziphuzo ngenxa

izakhiwo zabo ezingavamile. Akhiwe ngokuhlanganisa izingqimba zensimbi engagqwali encane enezikhala ezihambisana nezinga lokushisa eliphezulu

inqubo ye-sintering, ngaphansi kwendawo yokuncibilika yensimbi. Le nqubo idala isakhiwo sensimbi esiqinile, esinezimbotshana esinikeza izinzuzo ezibalulekile ezimbalwa:

Izici Eziyinhloko :

* Amandla aphezulu nokuqina:

* Ukumelana nokugqwala okuhle kakhulu:

* Ukuhlanza kalula:

Lezi zakhiwo zenza izihlungi zensimbi engagqwali ezine-sintered mesh zibe yinketho edumile yezinhlelo zokusebenza ezahlukahlukene ekuhlungeni ukudla nesiphuzo, okuhlanganisa:

Isicelo :

* Ukucaciswa koketshezi:

* Ukuhlunga kwangaphambili kwama-membrane:

* Ukuhlunga amanzi:

* Ukuhlunga kwama-syrups namafutha:

* Ukuhlunga komoya negesi:

3. Izihlungi Ze-Bronze Sintered

Izihlungi ze-bronze sintered zingolunye uhlobo lwemidiya yesihlungi sensimbi esetshenziswa ezinhlelweni zezimboni. Akhiqizwa ngenqubo efanayo

njengezihlungi zensimbi engagqwali, kodwa esikhundleni sempushana yensimbi engagqwali, i-bronze alloy powder isetshenziswa njengento eyisisekelo. Nakhu ukuhlukaniswa kwabo

izici kanye nenqubo yokukhiqiza:

Izici Eziyinhloko :

Izici:

* Kuqiza kahle:

2. Ukubumba:

3. Ukucula:

4. Ukukhipha imali nokuqeda:

Isicelo :

Ngenxa yezimpawu zazo, izihlungi ze-bronze sintered zithola izinhlelo zokusebenza ezivamile kumandla oketshezi kanye nezinhlelo ze-hydraulic:

* Ukuhlunga uketshezi lwe-hydraulic:

* Ukuhlunga kwesistimu yokugcoba:

* Ukuhlunga komoya:

Nakuba izihlungi zethusi zinikeza isisombululo esingabizi kakhulu samandla amaningi oketshezi kanye nezinhlelo ezisebenza ngogesi, kubalulekile

cabangela ukulinganiselwa kwazo mayelana nokumelana nokugqwala uma kuqhathaniswa nezihlungi zensimbi engagqwali zohlelo olubandakanya amakhemikhali anokhahlo noma izindawo ezizungezile.

4. Izihlungi ze-Sintered Polyethylene:

Uhlolojikelele:

Izici Nezinzuzo:

* Ukumelana namakhemikhali aphezulu kuma-organic solvents nama-asidi.

* Ilula futhi iyabiza.

* I-Biocompatible, ibenza bafaneleke kwezinye izinhlelo zokusebenza zemithi.

* Ilungele ukuhlunga komoya negesi.

Isicelo

Ukusetshenziswa Embonini Yezemithi kanye Neye-Biotechnological:

5. Izihlungi Zengilazi Ye-Sintered:

Izakhiwo ze-Sintered Glass:

Izici:

* Excellent chemical ukumelana anhlobonhlobo amakhemikhali.

* Ukuzinza okuphezulu kokushisa, okuvumela ukusetshenziswa emazingeni okushisa aphezulu.

* Inert futhi ingasetshenziselwa ukuhlunga okuyinyumba.

* Ukusebenza kahle kokuhlunga kwezinhlayiya ezinhle.

Isicelo:

Izicelo Ezijwayelekile Elabhorethri Nokuhlolwa Kwendawo:

6. Izihlungi ze-Sintered ezisuselwa ku-nickel:

Ukwakheka nezici:

Amandla okushisa aphezulu, awenza afanelekele izindawo ezidinga kakhulu.

Amandla amahle emishini yezinhlelo zokusebenza ezinomfutho ophezulu.

Izinhlelo zokusebenza

Ukusetshenziswa Ezimweni Zokushisa Eziphezulu Nezidlayo:

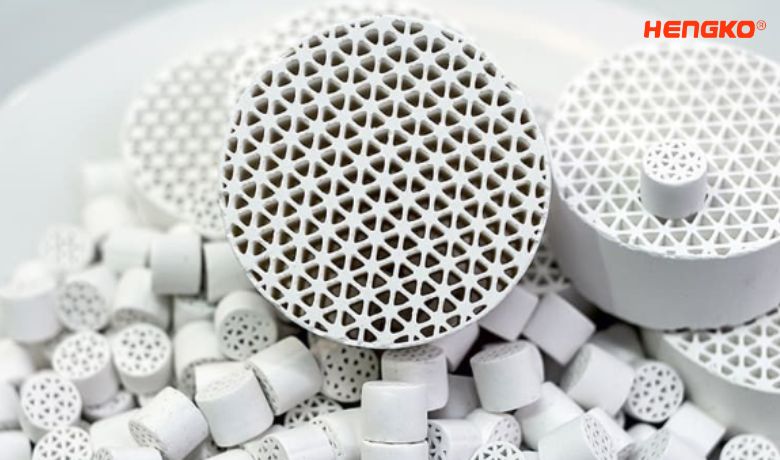

7. Izihlungi ze-Ceramic ze-Sintered:

Izici Eziyinhloko Nokuqina:

Isicelo

Izicelo ku-Metal Casting kanye Nokuhlanzwa komoya:

8. Izihlungi Ze-Titanium Sintered:

Izinzuzo, Izici, kanye Nezakhiwo Zokumelana:

Izihlungi ze-Titanium-sintered zinikeza inhlanganisela eyingqayizivele yamandla aphezulu, ukumelana nokugqwala okuhle kakhulu, kanye

Isicelo

Ukusetshenziswa Okuncanyelwayo Ekucubunguleni Amakhemikhali Nezimboni Zasolwandle:

9. Izihlungi ze-Sintered Silver:

Izakhiwo ezihlukile, izici, nokusebenza ngempumelelo:

Izihlungi zesiliva ze-Sintered ziyamangalisa ngezakhiwo zazo zemvelo ezilwa namagciwane.

Izicelo:

Sebenzisa Ekuhlanzeni Amanzi Nokuhlunga Kwamagciwane:

Lezi zihlungi zilungele amasistimu okuhlanza amanzi okusetshenziselwa iphuzu kanye nezinhlelo zokusebenza ezidingayo

10. Izihlungi Zekhabhoni Ezicushiwe:

Ukuqamba, Izici, Namakhono Okuhlunga:

Lezi zihlungi zihlanganisa isakhiwo sensimbi esine-sintered nama-carbon granules ashumekiwe.

Izicelo Ekuhlanzweni Kwegesi Nokulawula Iphunga:

Izihlungi ze-carbon activated activated zisetshenziswa ezinhlelweni zokuhlanza umoya negesi ukususa amagesi angafuneki,

5-Izici Okufanele Uzinakekele Ukukhetha OkulungileIsihlungi se-Sintered

Ukukhetha isihlungi esifanelekile sohlelo lwakho lokusebenza lwemboni kudinga ukucatshangelwa ngokucophelela kwezinto ezimbalwa:

1. Isilinganiso se-Micron:

Lokhu kubhekisela kusayizi wezinhlayiya isihlungi esingacupha. Khetha isilinganiso se-micron esincanyana kunezinhlayiya ofuna ukuzisusa.

2. Ukuhambisana kwezinto:

Izinto zokuhlunga zidinga ukuhambisana noketshezi oluzochayeka kukho. Insimbi engagqwali iyisinqumo esidumile

ngenxa yokumelana nokugqwala kwayo, kodwa ezinye izinketho ezifana nethusi noma i-nickel zingase zifaneleke ngokuya ngesicelo.

3. Izinga lokushisa nengcindezi:

Isihlungi sidinga ukumelana nezinga lokushisa lokusebenza nengcindezi yenqubo yakho.

4. Izinga lokugeleza:

Isihlungi kufanele sivumele ukugeleza koketshezi olwanele ukuze kuhlangatshezwane nezidingo zenqubo yakho kuyilapho ugcina ukuhlunga okusebenzayo.

5. Ukuhlanza nokunakekela:

Cabanga ukuthi kuzoba lula kangakanani ukuhlanza nokugcina isihlungi. Ukuwashwa emuva noma amandla okuvuselela kungenzeka

kubalulekile kwezinye izinhlelo zokusebenza.

Ngokuhlola ngokucophelela lezi zindlela zokunquma, ungakhetha isihlungi esine-sintered esithuthukisa inqubo yakho yezimboni

futhi iqinisekisa ukuhlunga okusebenzayo, okuthembekile.

Xhumana no-HENGKO

Uma udinga izeluleko ezinemininingwane eyengeziwe noma ufisa ukuxoxa ngezidingo zakho zokuhlunga,

Thumela umlayezo wakho kithi:

Isikhathi sokuthumela: Apr-26-2024