I-CEMS Flue Gas Online Monitoring nge-Microporous Sintered Filter

I-flue gas monitoring element ye-stainless steel sintered microporous sintered

I-flue gas monitoring element ye-stainless steel sintered microporous sintered

Ishubhu yesihlungi sesici se-Sintered se-cems flue gas online monitoring and purification system

I-microporous stainless steel stainless steel sintered filter tube yokuhlunga kwe-molecule encane yenziwe ngempushana yensimbi engagqwali icindezelwe ngesikhunta, ifakwe emanzini okushisa aphezulu, futhi yakheke ngokuphelele.Inezinzuzo zamandla aphezulu emishini, ukumelana nezinga lokushisa eliphezulu, ukumelana nokugqwala okuhle, ukusatshalaliswa kosayizi wembotshana okufanayo, ukungena komoya okuhle, ukuvuselelwa kabusha okuhlanzekile, kanye nomshini wokushisela.Ukulungisa usayizi wezinhlayiyana zempushana kanye nezimo zenqubo kwenza kube nokwenzeka ukukhiqiza izakhi zokuhlunga ezinezimbobo zensimbi ezinohlu olubanzi lokunemba kokuhlunga.Ngenxa yezinzuzo eziningi ze-porous metal powder sintered materials, lolu hlobo lomkhiqizo lusetshenziswa kabanzi ekubuyiseleni i-catalyst, i-gas-liquid Filtration, nokuhlukaniswa emikhakheni yemboni yamakhemikhali, imithi, isiphuzo, ukudla, insimbi, i-petroleum, ukuvikelwa kwemvelo. ukuvutshelwa;amagesi ahlukahlukene, Ukususwa kothuli, ukuvala inzalo, nokususwa kwenkungu kawoyela yesitimu;ukunciphisa umsindo, ukubamba amalangabi, ukuvimba kwegesi, njll.

Izici:

Izici:

1. Umumo ozinzile, ukumelana nomthelela, kanye nomthamo womthwalo oshintshanayo kungcono kunezinye izinto zokuhlunga zensimbi;

2. Ukungena komoya, umphumela wokuhlukanisa ozinzile;

3. Amandla amahle kakhulu wokulayisha nawokuthulula, alungele ukusetshenziswa ezindaweni ezishisa kakhulu, ezicindezelayo, nasezindaweni ezigqwalile;

4. Ikakhulukazi efanelekile ukuhlungwa kwegesi ephezulu lokushisa;

5. Imikhiqizo yomumo ohlukahlukene kanye nokunemba kungenziwa ngokwezifiso ngokuya ngezidingo zomsebenzisi, futhi ukuxhumana okuhlukahlukene kungasetshenziswa ngokushisela.

Ukusebenza: ukumelana ne-asidi, ukumelana ne-alkali, ukumelana nezinga lokushisa eliphezulu, ukumelana nezinga lokushisa eliphansi, ukuvimbela umlilo, i-anti-static

Indawo yokusebenza: i-nitric acid, i-sulfuric acid, i-acetic acid, i-oxalic acid, i-phosphoric acid, i-5% i-hydrochloric acid, i-sodium encibilikisiwe, i-liquid hydrogen, i-nitrogen ewuketshezi, i-hydrogen sulfide, i-acetylene, umhwamuko wamanzi, i-hydrogen, igesi, i-carbon dioxide gas, nokunye. izindawo.Inezinhlobonhlobo ze-porosity (28% -50%), usayizi we-pore (0.2um-200um), nokunemba kokuhlunga (0.2um-100um), eneziteshi ze-criss-cross, ukumelana nokushisa okuphezulu, nokupholisa okusheshayo nokumelana nokushisa. .I-anti-corrosion.Ilungele imidiya ehlukahlukene edlayo njengama-acids nama-alkali.Isici sesihlungi sensimbi engagqwali singamelana ne-asidi-base evamile kanye nokugqwala kwemvelo, okulungele ngokukhethekile ukuhlunga amagesi aqukethe isibabule.Inamandla aphezulu kanye nokuqina okuhle.Ifanele izindawo ezinomfutho ophezulu.Ingashiselwa.Kulula ukulayisha nokukhipha.Ukuma kwe-pore okuzinzile nokusabalalisa okufanayo kuqinisekisa ukusebenza kokuhlunga okuzinzile.Ukusebenza okuhle kokuvuselela.Ngemva kokuhlanzwa okuphindaphindiwe nokuvuselelwa, ukusebenza kokuhlunga kubuyiselwa ngokungaphezulu kwama-90%.

Izinga lokushisa lokusebenza: ≤900°C

Ubukhulu bezindonga: ngokuvamile 3mm

Ingcindezi yangaphakathi: 3mpa

Izinto: 304, 304L, 316, 316L.

Ukuhlukaniswa kwezinhlayiyana zothuli, ukuhlanzwa, kanye ne-Filtration Stainless steel stainless sintered filter element inezinto ezinenzuzo ezifana nokumelana nokugqwala, ukumelana nezinga lokushisa eliphezulu, amandla aphezulu, ukuqinisekiswa okulula kokunemba kokuhlunga, nokuvuselela kalula.Isici sesihlungi se-titanium senziwa nge-titanium powder ngemva kokubunjwa kanye ne-high-tempering sintering, ngakho izinhlayiya ezingaphezulu akulula ukuwa;ukusetshenziswa emoyeni kungafinyelela ku-500-600 ° C;ilungele ukuhlunga imidiya eyonakalisayo ehlukahlukene, njenge-hydrochloric acid, i-sulfuric acid, i-Filtration of hydroxide, amanzi olwandle, i-aqua regia ne-chloride izixazululo ezifana nensimbi, ithusi, ne-sodium.Inezici ezinhle kakhulu zemishini, ingenziwa ngomshini wokusika, i-welding, njll., inamandla amakhulu okucindezela, futhi ukunemba kokuhlunga kwayo kulula ukuqinisekisa.I-diameter ye-pore ngeke ikhubazekile ngisho noma isebenza ngaphansi kwamazinga okushisa aphezulu nokucindezela.I-porosity yayo ingafinyelela ku-35-45%, ukusabalalisa usayizi we-pore kufana futhi umthamo wokubamba ukungcola mkhulu, futhi indlela yokuvuselela ilula futhi ingasetshenziswa kabusha ngemva kokuvuselelwa kabusha.

Ukuhlukaniswa kwezinhlayiya zothuli, ukuhlanzwa, kanye nesici sokuhlunga se-Filtration insimbi engagqwali ye-sintered sintered sisebenza kahle kakhulu.Ingasetshenziswa kabanzi emikhakheni yemboni yezemithi, imboni yokwelapha amanzi, imboni yokudla, ubunjiniyela bezinto eziphilayo, imboni yamakhemikhali, imboni ye-petrochemical, imboni ye-metallurgical, kanye nokuhlanzwa kwegesi.Yindaba entsha enamathemba entuthuko abanzi.

Ukusetshenziswa okujwayelekile kufaka:

1. Embonini yezemithi, isetshenziselwa ukuhlunga kwe-decarbonization enqubweni yokulungiselela okugxilile yezixazululo ezinkulu zokumnika, imijovo emincane, amaconsi esweni, noketshezi lomlomo kanye nokuqinisekisa ukuphepha ngaphambi kokuhlunga kwe-terminal kwinqubo yokulungiselela ehlanjululwe.

2. Ukususwa kokungcola kanye Nokuhlunga ohlelweni lokukhiqizwa kwezinto ezingavuthiwe, ukuhlungwa kwe-decarbonization, kanye nokuhlunga okuhle kwezinto.

3. Ukuhlunga Okuphephile kwezinhlelo ze-ultrafiltration, i-RO, ne-EDI embonini yokuhlanza amanzi, Ukuhlunga ngemva kokwenziwa kwe-ozone, kanye nokungenisa umoya kwe-ozone.

4. Ukucaciswa nokuhlungwa kweziphuzo, utshwala, ubhiya, amafutha emifino, amanzi amaminerali, isoso yesoya, noviniga ekudleni nasesiphuzweni.

5. Ukuhlunga kwe-Decarbonization kanye nokucwenga okunembayo kwemikhiqizo ewuketshezi, izinto zokusetshenziswa eziwuketshezi, nezimaphakathi zemithi embonini yamakhemikhali, Ukuhlunga nokubuyiselwa kwezinhlayiya ezicwebezelayo nama-catalysts, ukuhlunga okunembayo ngemva kokufakwa kwe-resin, nokususwa kokungcola kanye Nokuhlungwa kwamafutha okudlulisa ukushisa kwesistimu. nezinto zokwakha, i-catalysis Ukuhlanzwa kwegesi, njll.

6. I-Oilfield ibuyisela ukuhlungwa kwamanzi kanye nenkundla yokukhipha usawoti emanzini olwandle ngaphambi kwe-osmosis ehlehlayo ukuze kuqinisekiswe ukuhlungwa kokuphepha.

7. I-high-temperature decarbonization kanye nokuhlunga kobumba olumhlophe embonini yokudaya.

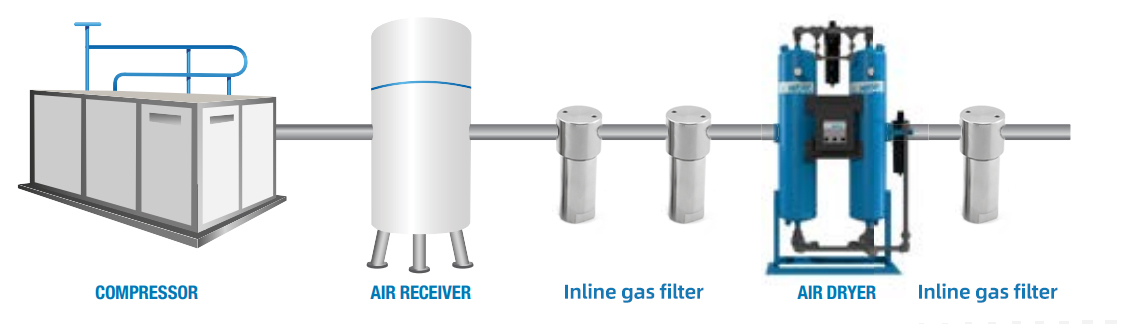

8. Mayelana nokuhlanzwa kwegesi, ikakhulukazi kuhlanganisa ukuhlanzwa kanye noHluzo lwesitimu, umoya ocindezelweyo, kanye negesi ye-catalytic.

FAQ

1. Siyini isihlungi segesi se-semiconductor ephezulu yokuhlanzeka?

Isihlungi segesi se-semiconductor ehlanzekile siwuhlobo olukhethekile lwesihlungi esiklanyelwe ukususa ukungcola emagesini asetshenziswa ekwenzeni izingxenye ze-elekthronikhi.Lezi zihlungi zenziwe ngezinto ezikwazi ukumelana namazinga okushisa aphezulu namakhemikhali abolayo, futhi zenzelwe ukususa izinhlayiya zehle ziye ezingeni le-nano-scale.

2. Kungani izihlungi zegesi ze-semiconductor ezihlanzekile zibalulekile?

Ekukhiqizeni ama-semiconductors, ngisho namanani amancane okungcola angabangela amaphutha futhi anciphise ikhwalithi yomkhiqizo wokugcina.Izihlungi zegesi ze-semiconductor ezihlanzekile zisiza ekuqinisekiseni ukuthi amagesi asetshenziswa ezinqubweni zokukhiqiza awanakho ukungcola, okuholela ezingxenyeni ze-elekthronikhi zekhwalithi ephezulu.

3. Yiziphi izinhlobo zamagesi ezingahlungwa ngezihlungi zegesi ze-semiconductor ezihlanzekile?

Izihlungi zegesi ze-semiconductor ezihlanzekile zingasetshenziswa ukuhlunga amagesi anhlobonhlobo, okuhlanganisa i-hydrogen, i-nitrogen, umoya-mpilo, kanye nezinhlobonhlobo zamagesi ezinqubo.Kuye ngenqubo ethile yokukhiqiza, izinhlobo ezahlukene zokuhlunga zingadingeka ukuze kuzuzwe izinga elifiswayo lokuhlanzeka.

4. Zenziwa kanjani izihlungi zegesi ze-semiconductor ezihlanzekile?

Izihlungi zegesi ze-semiconductor ezihlanzekile zenziwe ngezinto ezifana nensimbi engagqwali, nezinye izinsimbi eziqine kakhulu.Izinto zokuhlunga ngokuvamile zincane kakhulu, ezinosayizi wezimbotshana ukusuka ku-0.1 ukuya ku-1 micron.Izihlungi zivame ukumbozwa ngezinto ezikhethekile zokuthuthukisa izakhiwo zazo ezingaphezulu futhi zithuthukise ukusebenza kwazo kokuhlunga.

5. Zihlala isikhathi esingakanani izihlungi zegesi ye-high purity semiconductor?

Ubude besikhathi sokuphila kwesihlungi segesi ye-semiconductor ehlanzekile kakhulu bungahluka kuye ngezinto ezimbalwa, okuhlanganisa uhlobo lwesihlungi, igesi ehlungwayo, kanye nenqubo ethile yokukhiqiza.Ngokuvamile, lezi zihlungi zenzelwe ukusetshenziswa isikhathi eside futhi zingahlala izinyanga ezimbalwa noma ngisho neminyaka ngaphambi kokudinga ukushintshwa.Ukunakekelwa okuvamile nokuhlanza kungasiza ukwandisa isikhathi sokuphila kwalezi zihlungi futhi kuqinisekise ukusebenza okuhle ngokuhamba kwesikhathi.