-

I-Stainless Steel Porous Metal Sheets SS316 Isihlungi Sokusakazwa Kwegesi Ye-Hydrogen

I-Stainless Steel Porous Metal Sheets SS316 Isihlungi Sokusakazwa Kwegesi Ye-Hydrogen Vula Ukuhlukahluka Kwezinto Zensimbi Ezisikiwe nge-HENGKO! Imeta yethu ehlanganisiwe...

Buka imininingwane -

Ishidi Lezendlalelo Zokusabalalisa Igesi le-MEAs, insimbi engagqwali enezimbotshana zensimbi / ezinezikhala zocingo ...

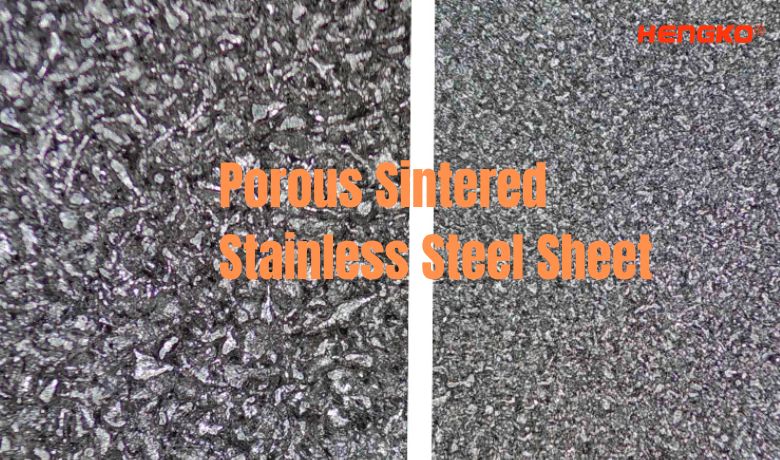

Amapuleti okuhlunga ensimbi engenasici ye-HENGKO enziwa ngokufaka i-sintering 316L powder impahla noma i-multilayer stainless stainless wire mesh emazingeni okushisa aphezulu. Sebe...

Buka imininingwane -

I-Corrosion resistant microns 316L insimbi engagqwali enezimbotshana zesihlungi sensimbi amashidi / ...

I-Product Chaza Izendlalelo ze-HENGKO ze-porous metal diffusion zegesi ziyinketho ehamba phambili yokusebenza okuphezulu kwe-electrolyzer kanye nezicelo zamaseli kaphethiloli. Umfaniswano we...

Buka imininingwane -

I-Easy Clean Micron Porous SUS Sintered 316L Yensimbi Engagqwali Inline Metal Sheet Rou...

Amashidi ensimbi anezimbotshana anezimbotshana ane-porosity ephezulu atholakala kuzimpushana zensimbi ngezindlela zokusabalalisa zamahhala ezilandelwa ukucwiliswa. Isakhiwo se-sintered ...

Buka imininingwane -

5 10 30 60 90 microns powder micro porous sintered metal sheet sheet

Amashidi okuhlunga ensimbi asetshenziswa kabanzi ukususa izinhlayiya zakwamanye amazwe ezinhlotsheni eziningi ezahlukene zokugeleza kwemidiya. Izinkambu ezisetshenziswa kakhulu: Amagesi ajwayelekile,...

Buka imininingwane -

I-HENGKO sintered insimbi engagqwali engu-316 enezingqimba zegesi yensimbi enezingqimba zokuhlunga ishidi le ...

Ipuleti lokuhlunga lensimbi engenasici le-HENGKO lenziwe ngezingqimba eziningi zephaneli enocingo olulukiweyo ihlangene kusetshenziswa inqubo yokucwilisa. Le nqubo...

Buka imininingwane -

Ukulawula ukugeleza nokusabalalisa uketshezi ipuleti/ishidi lesihlungi esine-sintered, impushana enezimbotshana ezimbotshana...

Amashidi okuhlunga okujulile asetshenziselwa ukususa izinhlayiya oketshezini. Lokhu kusho ukuthi uketshezi lungacaca-, lucolise noma luhlungwe olwenziwa yinyumba. Amashidi okuhlunga alungele ...

Buka imininingwane -

Amapuleti/ishidi lokuhlunga lethusi elinezimbotshana elinezimbotshana lokugeleza nokulawula umsindo

Amashidi okuhlunga okujulile asetshenziselwa ukususa izinhlayiya oketshezini. Lokhu kusho ukuthi uketshezi lungacaca-, lucolise noma luhlungwe olwenziwa yinyumba. Amashidi okuhlunga alungele ...

Buka imininingwane -

Isihlungi sensimbi esinezimbobo zensimbi ishidi lesikwele lesihlungi se-micron sintered bronze

I-HENGKO ikhiqiza izinto zokuhlunga ngenani elibanzi lezinto, osayizi, nokufakwa ukuze kucaciswe kalula ngezici kanye nokucushwa...

Buka imininingwane -

I-hepa sintered bronze steel stainless steel ishidi lokuhlunga lomoya/lomshini wokuhlunga uwoyela

I-HENGKO ikhiqiza izinto zokuhlunga ngenani elibanzi lezinto, osayizi, nokufakwa ukuze kucaciswe kalula ngezici kanye nokucushwa...

Buka imininingwane -

Amashidi okuhlunga ensimbi enziwe ngokwezifiso e-sintered metal fitler microns porosity bronze wat...

I-HENGKO ikhiqiza izinto zokuhlunga ngenani elibanzi lezinto, osayizi, nokufakwa ukuze kucaciswe kalula ngezici kanye nokucushwa...

Buka imininingwane

Izici Eziyinhloko zeshidi lensimbi engenasici

Kunezici eziningi zeshidi le-SS, lapha sibala izici ezibalulekile nethemba

ungaqonda imininingwane eyengeziwe yezici zabo:

Izici eziyinhloko zamashidi e-stainless steel stainless zifaka:

1. High Porosity:

Amashidi ensimbi engenasici e-Sintered anikeza izinga eliphezulu le-porosity, ehlinzeka ngokuhlunga okuphumelelayo

ngenkathi igcina ubuqotho besakhiwo.

2. Ukuqina namandla:

Lawa mashidi aqinile kakhulu futhi amelana nokugqokwa, okuwenza alungele ukusetshenziswa kuwo

izindawo ezinzima,okuhlanganisa umfutho ophezulu kanye nezimo zokushisa.

3.Ukumelana Nokugqwala:

Enziwe ngensimbi engagqwali, lawa mashidi amelana nokugqwala, awenze afanelekele ukusetshenziswa

enolakaamakhemikhali, amagesi, noketshezi.

4.Ukuhlunga Okunembayo:

Zivumela ukulawula okunembile kosayizi wembotshana, zinikeza ukuhlungwa kwezinhlayiya ezisuka ku

ama-microns kuya kuma-sub-microns.

5.Ukusebenziseka kabusha:

Amashidi ensimbi engagqwali e-Sintered angahlanzwa futhi asetshenziswe kabusha izikhathi eziningi, awenze

kuqiza kahlekanye nobungane bemvelo ngokuhamba kwesikhathi.

6.I-Thermal Resistance:

Bangakwazi ukumelana namazinga okushisa aphezulu ngaphandle kokwehliswa isithunzi,

okwenza zibe zilungele izicelo zokushisa okuphezulu.

7.Ukuzinza Kwemishini:

Lawa mashidi agcina ukwakheka kwawo ngaphansi kwengcindezi ehlukahlukene yemishini,

okuhlanganisa amazinga okugeleza aphezulu kanye nokwehluka kwengcindezi.

8.Ukuhambisana Kwamakhemikhali:

Amashidi ensimbi engagqwali e-Sintered ahambisana nohlu olubanzi lwamakhemikhali, aqinisekisa ukwethembeka

ukusebenza ezinqubweni ezehlukene zezimboni.

Lezi zici zenza amashidi ensimbi engenasici afanelekele izinhlelo zokusebenza ezifana nokuhlunga, igesi

nokusabalalisa uketshezi,fluidization, nokunye.

Izinhlobo zeshidi lensimbi engenasici

Kunezinhlobo ezimbalwa zamashidi ensimbi engagqwali e-sintered, ngalinye lakhelwe izinhlelo zokusebenza ezithile

kanye nezimfuneko zokusebenza ezehlukene.

Izinhlobo eziyinhloko zihlanganisa:

1.Ishidi Lensimbi Engagqwali Yesendlalelo Esilodwa Sintered

* Incazelo: Ishidi eliyisisekelo elenziwe ngongqimba olulodwa lwezinhlayiya zensimbi engagqwali elihlanganiswe ndawonye.

* Izicelo: Isetshenziselwa ukuhlunga ngokwenhloso evamile, ukufaka umoya, kanye nezinhlelo zokusebenza zokusabalalisa lapho ukuhlunga okunezindleko eziphansi nokuyisisekelo kwanele.

2.Ishidi Lensimbi Engagqwali elinezingqimba eziningi ze-Sintered

* Incazelo: Yakhiwe ngezingqimba eziningi zensimbi engagqwali enezikhala noma imicu, ehlelwe ngesakhiwo esithile ukuze kuthuthukiswe

amandla emishini nokusebenza kahle kokuhlunga.

* Izicelo: Ilungele ukuhlunga okunomfutho ophezulu kanye nezinga lokushisa eliphezulu, ihlinzeka ngegradient kumasayizi wembotshana ukuze kuhlungwe ngempumelelo ngezigaba eziningi.

Isetshenziswa ezimbonini ezifana ne-petrochemical, pharmaceutical, kanye nokucubungula ukudla.

3. Ishidi le-Sintered Wire Mesh

* Incazelo: Yenziwe ngezandlalelo zensimbi engagqwali ye-wire mesh ehlanganiswe ndawonye, enikeza ibhalansi yamandla nokuhlunga.

* Izicelo: Ivamise ukusetshenziswa ku-fluidization, ukuhlunga izinhlayiyana eziqinile, kanye nezinhlelo zokuwashwa ngemuva. Ifanele igesi kanye nokuhlunga okuwuketshezi

ezimbonini ezifana nokucubungula amakhemikhali nokuhlanza amanzi angcolile.

4. Ishidi le-Sintered Fiber Felt

* Incazelo: Idalwe ngokufaka imicu yensimbi engagqwali ibe ishidi elinezimbotshana. Inikeza indawo ephezulu kanye ne-porosity.

* Izicelo: Isetshenziswa ekuhlungeni okuhle kwamagesi noketshezi, ikakhulukazi ezindaweni ezidinga umthamo omkhulu wokubamba ukungcola kanye nokwehla komfutho ophansi.

Okujwayelekile ezimbonini ze-aerospace kanye nezimoto.

5. Ishidi Lensimbi Engenasici Elinezimbobo

* Incazelo: Amashidi ensimbi engagqwali anembobo abese efakwa i-sinter ukuze kuthuthukiswe ukuqina namandla okuhlunga.

* Izicelo: Iwusizo ezimbonini ezidinga kokubili ukuhlungwa nokusekelwa kwesakhiwo, njengokutholwa kwe-catalyst, ukusatshalaliswa koketshezi,

futhi njengosekelo lwemidiya yokuhlunga kangconywana.

6. Ishidi Lensimbi Engagqwali Eline-Sintered

* Incazelo: Inhlanganisela yamashidi amaningi ane-sintered ahlanganiswe ndawonye, ngokuvamile anamasayizi ahlukene wembotshana ukuze kwakheke ukuhlungwa kwegradient.

* Izicelo: Lawa mashidi asetshenziswa ezinhlelweni ezidinga ukunemba kokuhlunga okuphezulu namandla emishini, njengokuhlunga nge-hydraulic,

i-polymer filtration, nanjengama-cartridges okuhlunga oketshezi olune-viscosity ephezulu.

7. Ishidi le-Sintered Metal Powder

* Incazelo: Kwenziwe ngokufaka impushana yensimbi engagqwali efomini leshidi. Inikeza i-porosity efanayo kanye nokuhlunga okunembile.

* Izicelo: Ilungele izinhlelo zokusebenza ezibandakanya ukusabalaliswa kwegesi, ukuhlungwa koketshezi, nokuvikelwa kwezisetshenziswa ezibucayi ekungcoleni yizinhlayiya.

Isetshenziswa kaningi ezinhlelweni zezokwelapha, ze-aerospace, kanye nezibaseli.

8. Ishidi Lensimbi Engenasici elenziwe ngokwezifiso

* Incazelo: Lawa mashidi enziwe ngokwezifiso amasayizi athile, umumo, nezici zokuhlunga ngokusekelwe ezidingweni zomsebenzisi.

* Izicelo: Idizayinelwe izinhlelo zokusebenza ezihlukile zezimboni lapho izixazululo ezingekho eshalofini zingahlangabezani nezicaciso ezidingekayo, njengezikhethekile.

amasistimu okuhlunga ezitshalweni zamakhemikhali noma izinhlelo zokusabalalisa uketshezi lwangokwezifiso.

Uhlobo ngalunye lunikeza izinzuzo ezihlukile futhi lukhethwa ngokusekelwe ezimweni ezithile zokusebenza, njengokucindezela, izinga lokushisa, izinga lokuhlunga,

kanye nokuhambisana kwamakhemikhali.

Ishidi le-SS Lokusebenza :

Amashidi ensimbi engagqwali ye-Sintered (SS) ahlukahlukene kakhulu futhi athola izinhlelo zokusebenza kuzo zonke izimboni ezihlukahlukene ngenxa yokuqina kwawo, ukumelana nokugqwala, namandla anembile okuhlunga. Ngezansi izindawo zohlelo lokusebenza ezibalulekile:

1. Amasistimu Wokuhlunga

*Ukuhlungwa kwegesi: Isetshenziswa ekuhlungeni amagesi ezimbonini ezifana ne-petrochemical, imithi, kanye nokucubungula amakhemikhali, lapho ingahlunga khona izinhlayiya ezincane kanye nokungcola.

*Ukuhlunga okuwuketshezi: Kuqashwe ekuhlungeni uketshezi ezimbonini ezifana nokuhlanza amanzi, ukucubungula ukudla nesiphuzo, kanye nowoyela negesi. Ukuhlunga kwabo okunembayo kusiza ekususeni ukungcola emanzini, emafutheni, nakwezinye izinto eziwuketshezi.

2. I-Aerospace kanye Nezokuvikela

*Ukuhlungwa kwamafutha kanye neHydraulic: Sithiamashidi e-ered SS asetshenziselwa ukuhlunga ukungcola emigqeni kaphethiloli kanye nezinhlelo zokudonsa amanzi ezindizeni nasezinsizeni zezempi, ukuqinisekisa ukusebenza okuphephile nokuthembekile ngaphansi kwezimo ezimbi kakhulu.

*Izihlangu Zokushisa: Ukumelana nokushisa okuphezulu kwamashidi e-SS ane-sintered kuwenza afanelekele ukusetshenziswa njengezihlangu zokushisa noma izendlalelo zokuzivikela ezinhlelweni zokusebenza ze-aerospace.

3. Imboni yeKhemikhali nePetrochemical

*I-Catalyst Support: Amashidi ensimbi engagqwali e-Sintered asetshenziswa njengezakhiwo ezisekelayo kuma-reactors amakhemikhali lapho enikeza indawo ephezulu yokusabela kwamakhemikhali kuyilapho enikeza ukumelana nezinga lokushisa eliphezulu nokugqwala.

*Ukuhlunga Uketshezi Olugqwalile: Izakhiwo ezimelana nokugqwala zamashidi e-SS e-sintered ziwenza afaneleke ukuhlunga amakhemikhali aqala ukugqwala, ama-asidi, nezincibilikizo ezindaweni zokuhluza nasezitshalweni zamakhemikhali.

4. Imboni Yokudla Neziphuzo

*Ukuhlunga Okuyinyumba: Isetshenziswa ekuhlungeni imikhiqizo yokudla, iziphuzo, noketshezi lwemithi lapho ukuvala inzalo nokuhlunga okuqondile kuyadingeka. Isibonelo, amashidi e-SS ane-sintered asetshenziswa ezindaweni zokuphuza umoya oyinyumba kanye nokuhlunga kwe-CO₂ phakathi nenqubo yokuvutshelwa.

*I-Liquid Processing: Lawa mashidi asetshenziswa ekucubunguleni ubisi, ijusi, nokunye ukudla okuwuketshezi ukuze kukhishwe izinhlayiya kuyilapho kuqinisekiswa ubumsulwa nokuphepha komkhiqizo.

5. Ukuhlanza Amanzi Namanzi Angcolile

*Ukuhlanzwa kwamanzi: Amashidi ensimbi engagqwali e-sintered asetshenziswa ezinhlelweni zokuhlunga amanzi ukuze kukhishwe izinto eziqinile ezimisiwe kanye nokungcola emanzini okuphuza noma amanzi angcolile embonini.

*Ukuhlunga kwangaphambili kwe-Membrane: Ngokuvamile kusetshenziswa njengezihlungi zangaphambili ezinhlelweni zokuhlunga ulwelwesi ukuze kunwetshwe impilo yolwelwesi lokuhlunga olubiza kakhulu ngokususa izinhlayiya ezinkulu kuqala.

6. Imboni kawoyela negesi

*Ukulawulwa Kwesihlabathi Somgodi: Asetshenziswa ezikrinini zokulawula isihlabathi ekukhishweni kukawoyela negesi, amashidi e-SS acwilisiwe avimbela isihlabathi ukuthi singangeni emigqeni yokukhipha kuyilapho sivumela ukugeleza kukawoyela negesi.

*Izinhlelo Zokusabalalisa Uketshezi: Asetshenziselwa ukuhlunga nokusabalalisa uketshezi ezinqubweni ezibucayi zikawoyela negesi, lapho kukhona umfutho ophezulu kanye noketshezi olubolayo.

7. Imboni Yezokwelapha Neyemithi

*Izihlungi zokuvala inzalo: Amashidi ensimbi engagqwali e-Sintered asetshenziswa kakhulu ekukhiqizeni idivayisi yezokwelapha ngezinjongo zokuvala inzalo kanye nokukhiqizwa kwemithi ukuze kugcinwe indawo eyinyumba.

*Amadivayisi Afakelwayo: I-biocompatibility yensimbi engagqwali yenza amashidi e-SS ane-sintered afanele ukusetshenziswa kuzimila zezokwelapha namathuluzi okuhlinza adinga ukuhlungwa nokuqina.

8. Amandla kanye Nokukhiqiza Amandla

*Fuel Cells: Amashidi e-SS ane-Sintered asetshenziswa njengezakhiwo zokusekela ezinezimbotshana nezendlalelo zokusabalalisa igesi kumaseli kaphethiloli ukuze kuthuthukiswe ukusebenza kahle nokuthembeka kwezinqubo zokuguqulwa kwamandla.

*Izicelo Zenuzi: Ezimbonini zamandla enuzi, lawa mashidi asetshenziselwa ukuhlunga nokulawula uketshezi olukhipha imisebe namagesi, njengoba ekwazi ukumelana nemisebe eyingozi kakhulu kanye nezinga lokushisa.

izimo.

9. Imboni Yezimoto

*I-Exhaust Filtration: Amashidi ensimbi engagqwali e-Sintered asetshenziswa ezinhlelweni zokukhipha umoya wezimoto ukuze kuhlungwe izinhlayiya, okusiza ukunciphisa ukungcola nokuthobela imithetho yemvelo.

*Ukuhlungwa kwamafutha: Lawa mashidi asetshenziswa ezinhlelweni zokuhlunga uphethiloli ukuze kuqinisekiswe ukulethwa kukaphethiloli okuhlanzekile enjinini, ukuthuthukisa ukusebenza nokusebenza kahle.

10.Amasistimu we-HVAC kanye Nokuhlunga Komoya

*Ukuhlunga komoya: Amashidi ensimbi engagqwali e-Sintered asetshenziswa ezinhlelweni zokuhlunga komoya zokungenisa umoya ezimbonini, amakamelo ahlanzekile, nezinhlelo ze-HVAC, ezihlinzeka ngokuhlunga komoya okusebenza kahle kakhulu (i-HEPA) nokugcina ikhwalithi yomoya.

*Ukulawula Umswakama Nokushisa: Kuqashwe kumakhava okuvikela ezinzwa zomswakama nezinga lokushisa, okuqinisekisa ukufundwa okunembile kanye nokwelula impilo yezinzwa.

11.I-Fluidization Systems

*Ukukhipha igesi: Amashidi e-SS ahlanganisiwe asetshenziselwa izinhlelo zokusebenza ze-gas sparging ezinqubweni zamakhemikhali nezemithi, lapho asiza ngokulinganayo ukusabalalisa igesi ibe uketshezi noma impushana yokusabela, ukuvutshelwa, noma izinqubo zokuxutshwa.

*I-Powder Fluidization: Ezinhlelweni lapho izimpushana zidinga ukugcwaliswa ngegesi ukuze zicutshungulwe, amashidi e-SS ane-sintered anikezela ngokusatshalaliswa kwegesi okufanayo nokusebenza kahle.

12.I-Electronics kanye ne-Semiconductor Manufacturing

*Ukuhlanza okunembayo: Isetshenziswa ekuhlungeni okuhle kakhulu embonini ye-semiconductor, lapho izindawo ezingenakungcola zibalulekile. Amashidi e-SS ahlanganisiwe asiza ekuhlungeni amakhemikhali nokucubungula amagesi asetshenziswa ekukhiqizeni ama-chip.

*EMI/RFI Shielding: Amashidi ensimbi engagqwali e-Sintered kwesinye isikhathi asetshenziselwa ukuphazamisa kuka-electromagnetic (EMI) noma ukuvikela i-radio-frequency interference (RFI), ukuvikela izinto zikagesi ezibucayi ekuphazamisekeni.

Lezi zinhlelo zokusebenza ezihlukile zigqamisa ukuguquguquka nokusebenza kwamashidi ensimbi engagqwali e-sintered kuwo wonke umkhakha obanzi wezimboni, okuwenza abaluleke ekuhlungeni okubalulekile, ezinhlelweni zokusebenza, nasekusabalaliseni uketshezi.

I-FAQ Kumashidi Ensimbi Engagqwali e-Sintered

1. Iyini inqubo yokukhiqiza amashidi ensimbi engenasici?

Amashidi ensimbi engenasici akhiqizwa ngenqubo enezinyathelo eziningi:

Ukulungiswa Kwempushana:I-powder yensimbi engagqwali ikhethwa ngokucophelela futhi isayizi.

▪ Ukuminyana:Impushana ihlanganiswe ibe isikhunta ngaphansi kwengcindezi ephezulu, yakha umzimba oluhlaza.

▪ Ukucula:Isikhunta esihlanganisiwe sishiswa esithandweni sokushisa esingaphansi kwendawo yokuncibilika, okuvumela izinhlayiya ukuba zihlangane.

▪ Ukupholisa:Ishidi lipholiswa kancane kancane ukuze lithuthukise izakhiwo zalo.

2. Yiziphi izinzuzo zamashidi ensimbi engenasici?

▪Ukumelana Nokugqwala:Ukusebenza okuhle kakhulu ezindaweni ezinokhahlo.

▪Amandla:Amandla aphezulu emishini uma kuqhathaniswa nezinye izinto ezimbotshana.

▪Ukusebenza kahle kokuhlunga:Ilungele ukuhlunga amagesi noketshezi ngenxa ye-porosity yawo efanayo.

▪Ukwenza ngokwezifiso:Ingalungiselelwa izinhlelo zokusebenza ezithile ezinobukhulu obuhlukahlukene bezimbotshana nobukhulu.

3. Ingabe kukhona okungalungile ekusebenziseni amashidi ensimbi engagqwali e-sintered?

▪Izindleko:Ukutshalwa kwezimali kokuqala okuphezulu uma kuqhathaniswa nezinto ezingezona izimbotshana.

▪Imikhawulo ye-Porosity:Ingase ingalungeli izinhlelo zokusebenza ezidinga ukungathobeki ngokuphelele.

▪Ukuqina:I-brittleness engaba khona ngaphansi kwezimo ezimbi kakhulu uma ingaklanywanga kahle.

4. Kungani usebenzise izihlungi zensimbi engenasici?

▪Ukusebenza kahle kokuhlunga:Isebenza kahle ekususeni izinhlayiya nokungcola.

▪Ukuqina:Ingakwazi ukumelana namazinga okushisa aphezulu nezingcindezi.

▪Ukulungisa Okulula:Ingahlanzwa futhi isetshenziswe kabusha, inciphise izindleko zokusebenza.

▪Ukuhlukahluka:Ifanele ukusetshenziswa okuhlukahlukene, okuhlanganisa uketshezi nokuhlunga kwegesi.

5. Yimaphi amamaki ensimbi angcono kakhulu amashidi ensimbi engenasici?

▪Uhlobo 304:Ukumelana nokugqwala okuhle nokushisela; ilungele izicelo eziningi.

▪Uhlobo 316L:Inikeza ukumelana okuphezulu nokugqwala nokugqwala, ikakhulukazi ezindaweni ezine-chloride.

▪Uhlobo 310:Izicelo ezisezingeni eliphezulu ngenxa yokumelana ne-oxidation okuhle kakhulu.

6. Ungakwazi yini umshini amashidi ensimbi engenasici?

▪Yebo, kodwa:Idinga amasu namathuluzi akhethekile.

▪Okucatshangwayo:Sebenzisa isivinini esiphansi kanye noketshezi oluningi lokupholisa ukuze uvimbele ukushisa ngokweqile.

▪Izindlela:Izindlela zokugaya ezijwayelekile zihlanganisa ukugaya, ukubhoboza, nokugaya.

7. Uwenza kanjani umshini amashidi ensimbi engenasici?

▪Ukulungiselela:Qinisekisa ukuthi ishidi liboshwe ngokuvikelekile ukuze ugweme ukunyakaza.

▪Ukukhetha Ithuluzi:Sebenzisa i-carbide noma amathuluzi ensimbi anesivinini esikhulu.

▪Ukupholisa:Faka uketshezi lokusika ukuze ugcine izinga lokushisa eliphansi ngesikhathi somshini.

▪Amasu:Sebenzisa amasu anembayo ukuze uthole ukubekezelelana oyifunayo.

8. Yimiphi imikhiqizo engenziwa ngamashidi ensimbi engagqwali e-sintered?

▪Izihlungi:Izihlungi zegesi neziwuketshezi zezinhlelo zokusebenza ezihlukene zezimboni.

▪Ama-Spargers:Okokufaka umoya ezinqubweni zokuvutshelwa.

▪Izingxenye ezinezimbotshana:Isetshenziswa kuzinzwa kanye nezingxenye ezikhethekile mechanical.

▪Izingxenye Ngokwezifiso:Ingalungiselelwa izidingo ezithile zobunjiniyela.

9. Ingabe uyawabona amashidi ensimbi engagqwali eshiselwe sintered?

▪Yebo, kodwa:Idinga indlela ecophelelayo ukugwema ukulimaza isakhiwo esinezimbotshana.

▪Ukulungiselela:Hlanza izindawo ezizoshiselwa ukuze zinamathele kangcono.

▪I-Welding Technique:Sebenzisa izilungiselelo zokushisa okuphansi kanye nohlelo lokusebenza olusheshayo ukuze unciphise ukucindezelwa kokushisa.

10. Yimaphi amasayizi adumile amashidi ensimbi engenasici?

▪Osayizi Abajwayelekile:Ngokuvamile isukela ku-100mm x 100mm kuya kubukhulu obukhulu obususelwe ezindingweni.

▪Osayizi Bangokwezifiso:Ingenziwa ukuze ihlangabezane nezidingo ezithile zephrojekthi, okuhlanganisa ukuhlukahluka kokuqina.

11. Ingakanani inombolo enkulu yezimbobo ongazibhoboza eshidini lensimbi engagqwali e-sintered?

▪Incike kakhulu kwi:Ugqinsi nosayizi wezimbotshana zeshidi.

▪Isiqondiso Esijwayelekile:Ukubhoboza kufanele kukhawulwe ukuze kugcinwe ubuqotho besakhiwo; izimbobo ngokweqile kungaba buthaka impahla.

12. Ulicacisa kanjani ipuleti lensimbi engagqwali elinezimbobo?

▪Ukucaciswa Okubalulekile:Faka usayizi wezimbotshana, ukujiya, izinga lezinto ezibonakalayo, kanye nokusetshenziswa okuhlosiwe.

▪Ukubonisana:Sebenzisana nabakhiqizi ukuqinisekisa ukuthi izidingo ziyahlangabezana nezindinganiso zokusebenza ezifiselekayo.

13. Yiziphi izinzuzo ezibalulekile zokuklama zezingxenye zensimbi engagqwali ezinezimbobo?

▪Ukonga Isisindo:Ilula uma iqhathaniswa nezinto eziqinile.

▪I-Fluid Dynamics:Izici zokugeleza ezithuthukisiwe ngenxa ye-porosity efanayo.

▪Ukuzivumelanisa nezimo:Ingadizayinelwa imisebenzi eyahlukene, njengokuhlunga nokusekelwa kwesakhiwo.

14. Iyini i-axial compaction ekukhiqizeni insimbi engagqwali e-sintered?

▪Incazelo:Indlela yokusebenzisa ingcindezi eduze kwe-axis ye-powder ukufeza ukuminyana okufanayo.

▪Izinzuzo:Ithuthukisa izakhiwo zemishini namandla ayo wonke omkhiqizo wokugcina.

15. Uyenza kanjani insimbi engagqwali e-sintered usebenzisa ubuchwepheshe bamandla adonsela phansi?

▪Inqubo:Amandla adonsela phansi asiza ekugcwaliseni isikhunta ngempushana ngokufanayo.

▪Izinzuzo:Iqinisekisa ukuminyana okungaguquki futhi inciphisa ukuhlukaniswa kwezinhlayiya.

16. Uwenza kanjani amashidi ensimbi engenasici usebenzisa indlela yokufutha?

▪Icebo:Gcoba impushana yensimbi engagqwali ibe amaconsi amahle bese uwabeka ku-substrate.

▪I-Sintering:Isendlalelo esifakiwe sibe sintered ukuze kwakhiwe ishidi eliqinile.

▪Izicelo:Ilungele ukudala i-coatings noma izakhiwo ezigqinsiwe.

17. Yiziphi izici zohlobo 316L zamashidi ensimbi engenasici?

▪Ukumelana Nokugqwala:Ukumelana okukhethekile nama-chloride nezinye izindawo ezonakalisayo.

▪Okuqukethwe Kwekhabhoni Ephansi:Yehlisa ubungozi bemvula ye-carbide, ithuthukisa ukushisela.

▪Amandla:Igcina amandla emazingeni okushisa aphezulu, iyenze ifaneleke izinhlelo zokusebenza ezinzima.

Uma ungathanda ukufunda okwengeziwe noma udinga izihlungi zeshidi lensimbi engagqwali ye-OEM ekhethekile,

finyelela kithi kuka@hengko.comngosizo lochwepheshe kanye nezixazululo ezenziwe ngezifiso!