-

I-Stainless Steel Sparger 2 I-Micron Stainless Steel Diffusion Diffusion Stone ye-Bacter...

Sethula ama-spargers a-sintered e-HENGKO - ikhambi lokugcina lokuxhumana okusebenzayo noketshezi lwegesi ezimbonini ezahlukahlukene. AbakwaSpager bethu basebenzisa wena...

Buka imininingwane -

Kufakiwe I-Directly Porous Metal In-Line Sparger Tube Khiqiza Amabhamuza Amancane

I-HENGKO sintered spagers yethula amagesi oketshezini ngezinkulungwane zezimbotshana ezincane, idala amabhamuza mancane kakhulu futhi maningi kakhulu kunamapayipi abhobhile ...

Buka imininingwane -

Sintered porous micron stainless steel spargers homebrew wine wort beer tool bar acces...

I-HENGKO sintered spagers yethula amagesi oketshezini ngezinkulungwane zezimbotshana ezincane, idala amabhamuza mancane kakhulu futhi maningi kakhulu kunamapayipi abhobhile ...

Buka imininingwane -

Ama-Micro Spargers Akhuphula Ukudluliswa Kwegesi futhi Athuthukise Isivuno Se-Reactor Ekhuphukayo Yezinto Eziphilayo

Sethula i-HENGKO sintered spagers - ikhambi lokugcina lokwethula amagesi oketshezini kalula! Ama-spager ethu afaka izinkulungwane zamapholi amancane...

Buka imininingwane -

I-Metal In-Tank Porous Spargers Yokwandisa Ukumuncwa Kwegesi

I-HENGKO sintered spagers yethula amagesi oketshezini ngezinkulungwane zezimbotshana ezincane, idala amabhamuza mancane kakhulu futhi maningi kakhulu kunamapayipi abhobhile ...

Buka imininingwane -

Amatshe ama-micro spargers bubble air aeration yomhlangano we-bioreactor

Ama-spager amancane avela kwa-HENGKO anciphisa usayizi webhamuza futhi andise ukudluliswa kwegesi ukuze kuncishiswe ukusetshenziswa kwegesi futhi kuthuthukiswe ukuvunwa kwe-reactor ekhuphukayo. HENGKO spagers can in...

Buka imininingwane -

Insimbi engagqwali engu-316L micro air sparger ne-brewing diffuser carbonation ozone ...

Ukucaciswa Kwegama Lomkhiqizo SFB01 D1/2''*H1-7/8'' 0.5um ne-1/4'' Barb SFB02 D1/2''*H1-7/8'' 2um ne-1/4'' Barb SFB03 D1 /2''*H1-7/8'' 0.5u...

Buka imininingwane -

I-316L yensimbi engagqwali enezimbotshana zeshubhu ye-sintered yezinsiza zomkhumbi wokuvutshelwa

Inamathisele ichopho leshubhu le-sparger, leli thiphu le-stainless steel sintered elingu-316L litholakala ngosayizi abahlukahlukene bezimbotshana. I-5 10 15 50 100 i-pore frit iyona ...

Buka imininingwane -

SFB02 2 microns sintered insimbi engagqwali micro porous air diffusers spargers asetshenziswa kimi...

Ukucaciswa Kwegama Lomkhiqizo I-SFB02 D1/2''*H1-7/8'' 2um ene-1/4'' Itshe le-Barb HENGKO carbonation lenziwe ngegrad yokudla...

Buka imininingwane -

Ithuluzi lewayini leNitrogenous Diffusion Professional Effective Aeration Stone Beer Brewage 316L...

Ukucaciswa Kwegama Lomkhiqizo SFB01 D1/2''*H1-7/8'' 0.5um ne-1/4'' Barb SFB02 D1/2''*H1-7/8'' 2um ne-1/4'' Barb SFB03 D1 /2''*H1-7/8'' 0.5um...

Buka imininingwane -

I-SFC02 2 micron MFL Carbonation Sparger Inline Diffusion Stone yamanzi agelezayo/Ibhamuza...

Amanzi e-hydrogen ahlanzekile, anamandla, futhi ane-hydron. Kuyasiza ukuhlanza igazi futhi kwenza igazi lihambe. Ingavimbela izinhlobo eziningi zezifo futhi ithuthukise...

Buka imininingwane -

Insimbi engagqwali engu-316L micro air sparger ne-brewing carbonation ozone bubble st...

I-Sintered air stone diffuser ivamise ukusetshenziselwa ukujova igesi enezimbotshana. Zinobukhulu obuhlukene bezimbotshana (0.5um kuya ku-100um) okuvumela amabhamuza amancane ukuthi ageleze phakathi ...

Buka imininingwane -

Insimbi engagqwali ye-Sintered 316L aeration carbonation stone air stone i-ozone air sparger 0....

Itshe le-HENGKO carbonation lenziwe ngebanga lokudla lensimbi engagqwali engcono kakhulu engu-316L, enempilo, esebenzayo, ehlala isikhathi eside, ukumelana nokushisa okuphezulu, kanye ne-anti-co...

Buka imininingwane -

Ikhithi kabhiya wasekhaya i-carbonation stone air sparger aeration stone diffusion esetshenziselwa i-hydr...

I-Sintered air stone diffuser ivame ukusetshenziselwa ukusatshalaliswa kwegesi nokufaka umoya. Zinohlu olubanzi lwamasayizi wembotshana ukusuka ku-0.2 microns kuya kuma-microns ayi-120 avumela...

Buka imininingwane -

Amatshe e-air sparger bubble diffuser carbonation ahlinzeka ngendlela eshesha kakhulu yokufaka...

I-HENGKO Diffusion Stones, noma 'i-Carbonations Stones', ijwayele ukusetshenziselwa ukufaka umoya ku-wort ngaphambi kokuvutshelwa, okusiza ukuqinisekisa isiqalo esinempilo ku-fermen...

Buka imininingwane -

Insimbi engagqwali 316L SFC04 iphisa lasekhaya 1.5 ″ i-Tri Clamp ifaka i-2 micron diffusion itshe ai...

I-HENGKO sintered spagers yethula amagesi oketshezini ngezinkulungwane zezimbotshana ezincane, idala amabhamuza mancane kakhulu futhi maningi kakhulu kunamapayipi abhobhile ...

Buka imininingwane -

amaqoqo amakhulu i-hydrogen permeation micro bubble ozone sparger diffuser ye-diy home brewin...

1. Kungcono Kunokunyakazisa Ibheji! 2. Ingabe ukhathele ukuphuza ubhiya wakho ngendlela engalindelekile? Ukhuphula i-PSI ku-keg, unyakazise, bese ulinda nge ...

Buka imininingwane -

Izihlungi zenqubo yensimbi enezimbotshana, ama-spager amancane okukhiqiza uwoyela we-hydrogenated

Incazelo Yomkhiqizo Iziphazamisi zamatshe omoya we-Sintered zivame ukusetshenziselwa ukujova igesi enezimbotshana. Zinobukhulu obuhlukahlukene be-pore (0.5um kuya ku-100um) okuvumela i-bub encane ...

Buka imininingwane

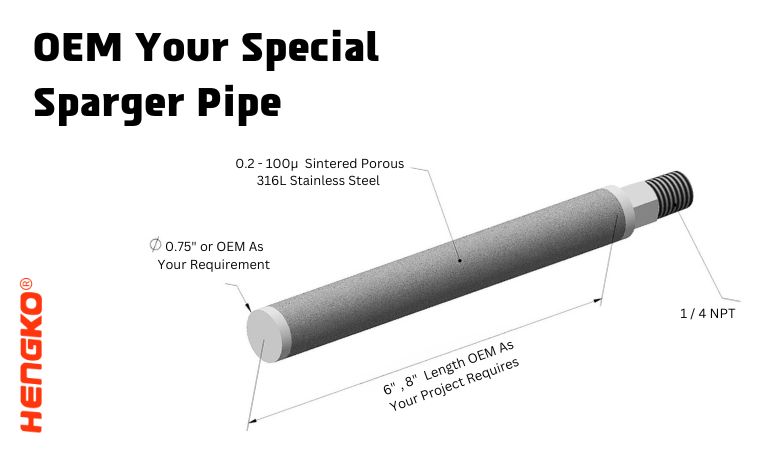

Izici Eziyinhloko ze-Sparger Pipe

Ipayipi le-sparger wuhlobo lwepayipi elisetshenziswa ezinhlobonhlobo zezimboni, ikakhulukazi ezimbonini zamakhemikhali ne-petrochemical.

Isetshenziselwa kakhulu ukujova igesi oketshezini, ngokuvamile ukusiza ukusabela kwamakhemikhali noma kwezinye izidingo zenqubo.

Njengoba okulandelayo ezinye zezici ze-sparger tube, sicela ulihlole.

1. Izinto:

Amapayipi e-Sparger ngokuvamile enziwa kusukelainsimbi engagqwalinoma okunyeukumelana nokugqwalaizinto zokwakha.

Lokhu kubalulekile ngoba avame ukusetshenziswa namakhemikhali anolaka futhi kumele amelane nezimo zokusebenza ezinzima.

2. Idizayini:

Ukuklanywa kwepayipi le-sparge kubalulekile ekusebenzeni kwayo.

Ngokuvamile kufaka phakathi uchungechunge lwezimbobo ezincane noma izimbobo ngobude bepayipi ukuvumela igesi ukuba iphume futhi ihlakazeke oketshezini.

Isikhala kanye nosayizi izimbobo kungenziwa egcizelele ngezidingo ezithile inqubo.

3. Usayizi:

Ubukhulu bepayipi le-sparger bungahluka kuye ngokuthi isicelo, kodwa ngokuvamile bancane ngobubanzi kunezinye izinhlobo zamapayipi asetshenziswa kwinqubo efanayo.

Lokhu kungenxa yokuthi igesi ejovwe ngeshubhu le-sparger kufanele ihlakazwe kahle oketshezini ukuze kube nemiphumela emihle.

4. Ukuxhumana:

Amapayipi e-Sparger angaxhunywa kwezinye izinto ezihlukahlukene kanye nezinhlelo zamapayipi.

Angase acushwe, ashiselwe, noma axhunywe ngama-flange, kuye ngezidingo zenqubo.

5. Ukuhlanza:

Ngenxa yokuthi amapayipi e- sparger asetshenziswa ezinqubweni ezihilela amakhemikhali nezinye izinto, kumelwe ahlanzwe njalo ukuze avimbele ukunqwabelana nokugqwala.

Angahlanzwa ngemishini, njengokuxubha noma ukuqhunyiswa, noma ngezixazululo zamakhemikhali.

Sekukonke, amashubhu e-sparger adlala indima ebalulekile ezinqubweni eziningi zezimboni, futhi ukwakheka nokwakhiwa kwawo kufanele kube

iqondiswe ngokucophelela kuhlelo lokusebenza ngalunye ukuze kuqinisekiswe ukusebenza kahle nokusebenza kahle.

Sparger Pipe Classify

Amapayipi we-sparger ensimbi angahlukaniswa ngokusekelwe ezicini ezihlukahlukene. Nazi ezinye izigaba ezingaba khona:

-

Ngokusekelwe Ohlotsheni Lwegesi Olwethuliwe:

- Umoya-mpilo

- I-nitrogen

- I-Carbon dioxide

- I-Argon

- Okunyeamapayipi wegesi sparger

-

Ngokusekelwe Kumumo noma Idizayini:

- Umklamo oqondile

- Ipayipi elimise okwe-U

- I-tube ehlanganisiwe

- Amanye amapayipi amise

-

Ngokusekelwe ku-Porosity:

- I-porosity sparger tube ephansi (ngaphansi kuka-30%)

- Ipayipi le-porosity elimaphakathi (30-50%)

- Ipayipi le-sparge eline-porosity ephezulu (ngaphezu kuka-50%)

-

Ngokusekelwe kuhlelo lokusebenza:

- Ipayipi le-sparger yokuhlanza amanzi angcolile

- Ukuvutshelwa sparger tube

- Chemical processing sparge pipe

- Ipayipi le-sparger elikhiqiza imithi

- Olunye uhlelo lwe-spager yezimboni

-

Ngokusekelwe ezintweni:

- Stainless steel sparger pipe

- I-Hastelloy sparger tube

- Ipayipi le-Inconel sparge

- Amanye amapayipi we-alloy sparger

Qaphela ukuthi lezi zigaba aziphelele futhi ezinye izindlela zingasetshenziswa futhi ukuhlukanisa amapayipi ensimbi ane-sintered sparger.

Isicelo

Amapayipi e-sparger ensimbi anezinhlobonhlobo zezicelo ezimbonini ezahlukahlukene, kufaka phakathi:

1. Ukuhlanza Amanzi Angcolile:

2. Ukuvutshelwa:

3. Ukucubungula Amakhemikhali:

4. Ukukhiqizwa Kwemithi:

5. Ukukhiqizwa Kokudla Neziphuzo:

6. Ukuqapha Imvelo:

7. Ukukhiqizwa Kwephethiloli Negesi:

8. Ukucwengisiswa kwensimbi:

FAQ for Sparger Pipe

1. Yini i-Sparger Pipe?

Kafushane, i-A Sparger Pipe iyipayipi lensimbi elinezimbobo elisetshenziselwa ukwethula amagesi oketshezini lwezinhlelo zokusebenza ezihlukene zezimboni.Ipayipi ngokuvamile lenziwa ngensimbi engagqwali e-Sintered Porous noma enye insimbi efana nama-alloys, futhi inesakhiwo esinezimbotshana ezivumela amagesi ukuthi asakazeke ngokulinganayo oketshezini. futhi kungaba lula ku-OEM usayizi we-pore wensimbi, ukuhlangabezana nezidingo zesistimu ye-sparger.

2. Yiziphi ezinye izinhlelo zokusebenza ezivamile ze-sparger tube?

Amapayipi e-Sparger avame ukusetshenziswa ekusetshenzisweni okufana nokuhlanza amanzi angcolile, ukuvutshelwa, ukucutshungulwa kwamakhemikhali, nokukhiqizwa kwemithi. Angasetshenziselwa ukwethula umoya-mpilo noma amanye amagesi oketshezini, futhi angasetshenziselwa ukuxuba nokuhlakazeka.

3. Yiziphi izinhlobo zamagesi ezingangeniswa kusetshenziswa ipayipi le-sparge lensimbi yensimbi?

I-sintered metal sparge pipe iyisisetshenziswa esisetshenziselwa ukwethula amagesi oketshezini oluwuketshezi noma oluqinile. Yenziwe ngezinhlayiya zensimbi ezihlanganiswe ndawonye, zakha isakhiwo esinezimbotshana esivumela igesi ukuthi igeleze kuyo. Lokhu kungasetshenziswa ezinhlelweni ezehlukene njengasezimbonini zokuphisa, ezemithi, zamakhemikhali, nezokuhlanza amanzi angcolile. Nazi ezinye izinhlobo ezivamile zamagesi ezingase zethulwe kusetshenziswa ipayipi le-sparge lensimbi ene-sintered:

1. Umoya:Ngokuvamile isetshenziswa ezinqubweni zokungenisa umoya ukukhuthaza umsebenzi webhayoloji noma ukuxuba izinto.

2. Umoya-mpilo:Isetshenziswa ezinqubweni zokwelapha zebhayoloji, ukuvutshelwa, nezinye izinhlelo zokusebenza lapho amazinga komoya-mpilo engeziwe edingeka.

3. I-Carbon Dioxide:Okuvame ukusetshenziswa embonini yesiphuzo ye-carbonation, kanye nokulawula i-pH ezinqubweni ezihlukahlukene zamakhemikhali.

4. I-nitrogen:Isetshenziswa ezinhlelweni lapho kudingeka khona umoya ongasebenzi, njengalapho kulondolozwe ukudla noma kwezinye izimo zamakhemikhali.

5. I-Hydrogen:Ingasetshenziswa kuzinqubo ze-hydrogenation embonini yamakhemikhali.

6. I-Steam:Nakuba kungeyona igesi ngokwayo, isitimu singangeniswa ngamapayipi ensimbi ane-sintered ukuze kushiswe noma ezinye izidingo zenqubo.

7. I-Chlorine:Isetshenziswa ezinqubweni zokwelashwa kwamanzi ukuze kukhishwe amagciwane.

8. I-Argon:Enye igesi ye-inert, esetshenziswa ezinhlelweni lapho ukusabela nezinto ezizungezile kufanele kuncishiswe.

9. I-Helium:Isetshenziswa ekutholeni ukuvuza nezinye izinhlelo zokusebenza ezikhethekile.

10. Amagesi Akhethekile:Amanye amagesi ahlukahlukene aklanyelwe izidingo ezithile zezimboni nawo angethulwa ngamapayipi ensimbi ane-sintered sparge, kuye ngokuhambisana nezinto kanye nezidingo ezithile zenqubo.

Kubalulekile ukuqaphela ukuthi ukuhambisana kwegesi nezinto zepayipi le-sparge lensimbi ehlanganisiwe kufanele kucatshangelwe, njengoba amanye amagesi angase asabele ngezinsimbi ezithile. Idizayini, okuhlanganisa usayizi wembotshana nokusabalalisa, kufanele futhi ifanele igesi ethile kanye nesicelo ukuze kuqinisekiswe ukusatshalaliswa okuphumelelayo nokuvimbela ukuvala noma ezinye izinkinga zokusebenza.

4. Iyini i-porosity yepayipi ye-sparger yensimbi evamile?

I-porosity yepayipi ye-sparger yensimbi ene-sintered ingahluka kuye ngohlelo oluthile kanye nezidingo zomsebenzisi. Ngokuvamile, ama-porosities avela ku-20 kuya ku-60% ngevolumu.

5. Yenziwa kanjani i-Sparger Pipe?

Sintered metal sparger tube enziwa kusetshenziswa inqubo ebizwa ngokuthi i-powder metallurgy, ehlanganisa ukucindezela impushana yensimbi

ibe yisimo esithile bese uyishisisa ekushiseni okuphezulu ukuze udale isakhiwo esiqinile, esinezimbotshana.

Ipayipi le-sparger iyisisetshenziswa esisetshenziselwa ukwethula amagesi oketshezini, ngokuvamile asetshenziswa ezimbonini ezifana nokuvutshelwa, ukucutshungulwa kwamakhemikhali, noma ukuhlanzwa kwamanzi angcolile. Inqubo yokukhiqiza yepayipi le-sparger ingahluka kuye ngomklamo othize kanye nokusebenza, kodwa nansi umbono ojwayelekile wokuthi ipayipi le-sparger lingenziwa kanjani:

1. Ukukhethwa Kwezinto:Impahla kufanele ikhethwe ngokusekelwe ekusetshenzisweni kanye nohlobo lwegesi noketshezi oluhilelekile. Izinto ezijwayelekile zifaka insimbi engagqwali, i-titanium, noma ama-alloys akhethekile amelana nokugqwala.

2. Ukuklama nokuhlela:Ukwakhiwa kwepayipi le-sparger kuzoxhomeka kuhlelo lokusebenza oluthile. Ingase ifake izimbobo ezincane eziningi noma imibhobho ukuqinisekisa nokusatshalaliswa kwegesi. Umklamo uvame ukwenziwa kusetshenziswa isofthiwe ye-CAD (Computer-Aided Design).

3. Ukusika nokubunjwa:Impahla ekhethiwe iyasikwa futhi ibunjwe ngendlela oyifunayo. Lokhu kungase kuhlanganise izinqubo ezifana nokusika i-laser, ukusika i-plasma, noma ukusika ijethi yamanzi ukuze kwakhiwe indikimba eyinhloko yepayipi.

4. Ukubhoboza noma Ukubhoboza Izimbobo:Izimbobo ezincane noma imibhobho kwakhiwa epayipini ukuvumela igesi ukuba iphumele oketshezini. Lokhu kungenziwa ngokubhoboza, ukubhoboza, noma amanye amasu akhethekile.

5. Ukushisela nokuhlanganisa:Uma ipayipi le-sparger liqukethe izingxenye eziningi, zihlanganiswa futhi zihlanganiswe ndawonye. Lokhu kungase kuhlanganise ukunamathisela ama-flange, okokufakwayo, noma ezinye izingxenye.

6. Ukwelashwa kwendawo:Kuye ngesicelo, ingaphezulu lepayipi le-sparger lingaphathwa ukuze kuthuthukiswe izakhiwo zalo. Lokhu kungase kuhlanganise ukupholisha ukuze udale indawo ebushelelezi noma ukusebenzisa okokunamathela ukuze kwandiswe ukumelana nokugqwala.

7. Ukuhlola Nokulawula Ikhwalithi:Ipayipi le-sparger eliqediwe liyahlolwa ukuze kuqinisekiswe ukuthi lihlangabezana nezimfuneko ezidingekayo. Lokhu kungase kuhlanganise ukuhlolwa kwengcindezi, ukuhlolwa kokuvuza, nokuhlolwa kokukhubazeka.

8. Ukupakisha Nokuthumela:Uma ipayipi le-sparger seliphumelele kukho konke ukuhlolwa kokulawulwa kwekhwalithi, liyapakishwa futhi lilungiselelwe ukuthunyelwa ekhasimendeni.

9. Ukufakwa:Kuye ngobunkimbinkimbi, ipayipi le-sparger lingadinga ukufakwa kochwepheshe. Lokhu kungase kuhlanganise ukukuhlanganisa ezinhlelweni zamapayipi ezikhona, ukuqinisekisa ukuhleleka okufanele, nokwenza ukuxhumana okudingekayo.

10. Ukunakekela kanye Nokuqapha:Ukugcinwa njalo nokuqapha kungase kudingeke ukuze kuqinisekiswe ukuthi ipayipi le-sparger liyaqhubeka nokusebenza ngempumelelo. Lokhu kungase kuhlanganise ukuhlanzwa njalo, ukuhlolwa, nokushintshwa kwezingxenye ezigugile.

Inqubo eqondile ingahluka kakhulu kuye ngokuthi umklamo othize wepayipi le-sparger kanye nezidingo zohlelo lokusebenza. Amapayipi e-sparger angokwezifiso angase adinge amasu okukhiqiza akhethekile kanye nezinyathelo ezengeziwe ukuze ahlangabezane nezicaciso eziyingqayizivele.

6. Ingakanani izinga lokushisa eliphezulu lokusebenza kwe-Sparger Tube?

Ukushisa okuphezulu kokusebenza kweshubhu ye-sparger yensimbi ene-sintered kuncike ku-alloy ethile esetshenziselwa ukwakhiwa kwepayipi. Ngokuvamile, zingasebenza emazingeni okushisa afinyelela ku-800°C (1472°F).

7. Iyini ingcindezi ephezulu yokusebenza yepayipi le-sparger lensimbi ye-sintered?

Ukucindezela okukhulu kokusebenza kwepayipi le-sparger kuncike ekuklanyeni okuqondile kwepayipi kanye nezinto ezisetshenziswayo. Ngokuvamile, bangasebenza ngezingcindezi ezifika ku-10 bar (145 psi).

8. Ishubhu ye-sparger yensimbi ene-sintered ngokuvamile ihlala isikhathi esingakanani?

Ukuphila kwepayipi ye-sparger yensimbi ene-sintered kuncike ekusetshenzisweni okuqondile kanye nezimo lapho isetshenziswa khona. Ngaphansi kwezimo ezijwayelekile zokusebenza, zingahlala iminyaka eminingana.

9. Ingabe amapayipi ensimbi ane-sintered angahlanzwa?

Yebo, ishubhu ye-sparger yensimbi ene-sintered ingahlanzwa kusetshenziswa izindlela ezahlukahlukene, okuhlanganisa i-backwashing, ukuhlanzwa nge-ultrasonic, nokuhlanza amakhemikhali.

10. Ingabe ishubhu ye-sparger yensimbi ene-sintered ingafakwa inzalo?

Yebo, amapayipi ensimbi afakwe inzalo angenziwa inzalo kusetshenziswa izindlela ezihlukahlukene, ezihlanganisa i-autoclaving, i-gamma irradiation, nokuvalwa kwamakhemikhali.

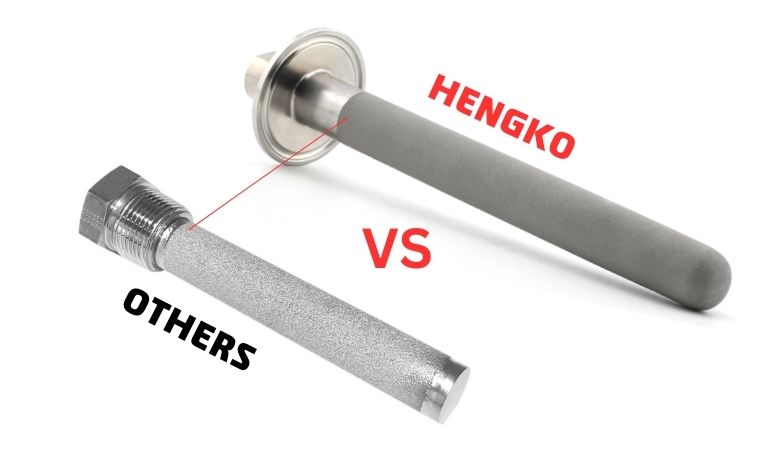

11. Yiziphi izinzuzo zokusebenzisa amapayipi e-stainless steel sparger?

Amapayipi e-stainless steel sparger asetshenziswa kakhulu ezimbonini ezahlukahlukene zokwethula amagesi kuketshezi noma ezinye izinto. Banikeza izinzuzo ezimbalwa ezibenza bafanelekele izinhlelo zokusebenza ezahlukene:

1. Ukuqina:Insimbi engagqwali yaziwa ngokumelana nokugqwala nokuguga. Lokhu kwenza amapayipi e-sparger ensimbi engagqwali e-sintered ahlale isikhathi eside futhi afanele ukusetshenziswa namakhemikhali ahlukahlukene kanye nezimo ezihlukene zemvelo.

2. Ukusatshalaliswa Kwegesi Okufanayo:Isakhiwo esinezimbotshana sensimbi engagqwali ene-sintered sivumela ukusatshalaliswa okufanayo kwegesi. Lokhu kungaholela ekuxubeni okuhle noma ekuphenduleni, kuye ngohlelo lokusebenza.

3. Ukumelana Nezinga lokushisa:Insimbi engagqwali ingamelana namazinga okushisa aphezulu, okwenza la mapayipi e-sparger afanele izinqubo ezidinga ukushisa noma eziqhutshwa emazingeni okushisa aphakeme.

4. Ukumelana Namakhemikhali:Insimbi engagqwali imelana nezinhlobonhlobo zamakhemikhali, okwenza la mapayipi e-sparger afanele ukusetshenziswa ezinqubweni zamakhemikhali ezihlukahlukene ngaphandle kwengozi yokugqwala noma okunye ukusabela ngento.

5. Usayizi Wembotshana Ongawenza ngokwezifiso:Inqubo ye-sintering ivumela ukulawula usayizi wembotshana nokusatshalaliswa kokubalulekile. Lokhu kusho ukuthi amapayipi e-sparger angenziwa ngendlela oyifisayo ukuze avumelane nezinhlelo zokusebenza ezithile, kungakhathaliseki ukuthi lokho kudinga amabhamuza amahle ukuze kuxutshwe kahle noma amabhamuza amakhulu ukuze kube nokuyaluza okunamandla.

6. Ukuhlanza Kalula:Indawo ebushelelezi yensimbi engagqwali yenza kube lula ukuyihlanza, okubaluleke kakhulu ezimbonini ezifana nokucubungula ukudla noma ezokuthaka imithi lapho ukuhlanzeka kuyinto ebaluleke kakhulu.

7. Ukumelana Nokucindezela:Amapayipi e-stainless steel sparger angamelana nezingcindezi eziphezulu, awenze afanelekele izinhlelo zokusebenza ezisebenza ngaphansi kwengcindezi enkulu ngaphandle kwengozi yokwehluleka.

8. Ukuhambisana namagesi ahlukahlukene:Njengoba kushiwo ngaphambili, la mapayipi e-sparger angasetshenziswa nezinhlobo eziningi zamagesi, kusukela emoyeni nomoya-mpilo kuya kumagesi akhethekile noma asebenzayo.

9. Ukusebenza Kwezindleko:Nakuba izindleko zokuqala zingase zibe phezulu uma kuqhathaniswa nezinye izinto zokwakha, ukuqina kanye nezidingo eziphansi zokugcinwa kwensimbi engagqwali e-sintered kungenza kube ukukhetha okungabizi kakhulu ngokuhamba kwesikhathi.

10. Ayinandaba nemvelo:Insimbi engagqwali iyakwazi ukugaywa kabusha, futhi isikhathi eside sokuphila kwalawa mapayipi e-sparger nawo anomthelela ekusimameni kwawo kwemvelo.

11. Ukuqina:Amapayipi e-stainless steel sparger ensimbi angenziwa ngobukhulu nobujamo obuhlukahlukene, awenze afanelekele kokubili izicelo zaselabhorethri ezincane kanye nezinqubo zezimboni ezinkulu.

Kafushane, amapayipi e-stainless steel sparger ensimbi anikezela ngenhlanganisela yokuqina, ukusebenza kahle, kanye nokuguquguquka okuwenza afanelekele uhla olubanzi lwezinhlelo zokusebenza. Ukumelana kwabo nokugqwala, amandla okumelana namazinga okushisa aphezulu nezingcindezi, kanye nezakhiwo ezenziwe ngokwezifiso kunomthelela ekudumeni kwazo ezimbonini ezahlukahlukene.

12. Yibuphi ububi bokusebenzisa amapayipi e-sparge ensimbi ane-sintered?

Okunye okungalungile kokusebenzisa amashubhu e-sparger ensimbi ane-sintered kufaka phakathi izindleko zawo zokuqala eziphezulu, ukuba sengozini yokuvaleka noma ukonakala, kanye namandla okugqwala uma kungenziwanga ngengxubevange efanele.

More questions about the sintered metal sparger pipes, you are welcome to contact us by email ka@hengko.com, we are pleasure to supply

isixazululo esingcono kakhulu sephrojekthi yakho ekhethekile nezinhlelo zokusebenza.