-

I-Sintered micron steel stainless steel cylinder eyisihlungi sensimbi yokuhlunga igesi

I-Product Chaza I-Sintered Metal Filter Cartridges: Izihlungi zensimbi ezinama-Porous zinezinhlobonhlobo zokusetshenziswa kokuhlunga kwezimboni.Lezi zihlungi ezingasetshenziswa kabusha, zekhwalithi ephezulu...

Buka imininingwane -

Isihlungi Sensimbi Engagqwali Yezimboni Zemithi Yebanga Lezokwelapha Sintered Metal Stainless Steel

Izihlungi zensimbi ezi-sintered ezinezomisi nezigayo ngaphakathi kwemboni yezemithi.Uma lezi zakhi zisetshenziswa ngosomisi nezigayo, ziqukethwe ngaphakathi...

Buka imininingwane -

Imelana Nezinga Lokushisa Eliphakeme Lensimbi Engagqwali Yesihlungi Sesihlungi se-cartridg...

I-Product Chaza Isihlungi se-Sintered powder filter esibuye siqanjwe ngensimbi eyisihlungi esinezimbotshana esenziwe nge-titanium noma impushana yensimbi engagqwali.Kuyisitayela esisha se-m...

Buka imininingwane -

Izihlungi Zokuthola I-Catalyst Yensimbi Engagqwali Enezimbobo Zensimbi Ye-Catalyst Rec...

Isingeniso esifushane somgomo wokusebenza wesihlungi se-catalyst (izihlungi ze-sintered): Isihlungi se-HENGKO Sintered Metal Catalyst sisebenzisa ama-catalyst ukubuyisela...

Buka imininingwane -

Imbiza yomlomo obanzi / imbiza yomakhi ene-stainless sintered filter disc ye-high temperatu...

Izinguquko ezincane, izinzuzo ezinkulu!Sigcina ubumba be-bentonite ngaphakathi kwembiza bese sibhaka kuhhavini ye-vacuum ukuze sisuse umswakama.Ngisho nesivalo sobumba siyaphuma o...

Buka imininingwane -

Izihlungi Ze-Gasket Eziku-Line zokuhlunga amagesi

Isihlungi se-Gasket sokuhlunga amagesi Ukuze kuvikelwe izilawuli nama-MFC, sivikela izingxenye ezibalulekile emonakalweni wezinhlayiyana I-In-line Design Ukufaka Easy...

Buka imininingwane -

I-NW16 KF16 Flange-Centering O-Ring eneFine Fine

I-ISO-KF kanye ne-NW Sintered Metal Filter Centering Ring NW-16、NW-25、NW-40、NW-50 Umphakeli Onesihlungi esihle (isihlungi sensimbi esinezimbobo esinezimbobo noma khetha wire mesh f...

Buka imininingwane -

I-NW50 KF50 Vacuum Flange Centering ring ene-Sintered Metal Filter, insimbi engagqwali, 50 ...

I-NW50 KF50 Centreing ring ene-Sintered Metal Filter, insimbi engagqwali, 50 ISO-KF Izinto zomkhiqizo: insimbi engagqwali 304,316 Indlela yokufaka: sebenzisa ngembaza...

Buka imininingwane -

I-NW25 KF25 KF Indandatho Emaphakathi kusihlungi Sensimbi Esiyinsimbi

NW25 KF25 KF Centering Ring to Sintered Metal Filter • NW16 (KF16, QF16) Series• Viton (Fluorocarbon, FKM) O-Ring• Viton: 200°C Maximum• 0.2 µm Usayizi Wembotshana• F...

Buka imininingwane -

Isihlungi sangaphambili sesampula yesampula yegesi

Uphenyo lwesampula yegesi Isihlungi Sesihlungi sangaphambili Ukuhlukaniswa kothuli enqubeni Ukuze kugxiliswe uthuli kufika ku-3g/m3 Indawo enkulu esebenzayo Isikhathi eside sokuphila okuphansi umehluko...

Buka imininingwane -

Isilawuli sesihlungi sezinsiza ze-Diaphragm Pump

Isilawuli Sesihlungi Sezesekeli Zephampu Ye-Diaphragm Lapha ukuze ngikunikeze ithiphu lami le-cent tech lisebenzisa isilawuli sokuhlunga esinamavelu e-pneumatic actuator kuyinto enhle...

Buka imininingwane -

Amavavu Endlela eyodwa Okwehliswa kwevolumu yamaphaphu e-Bronchoscopic

Amavalvu Endlela Eyodwa Ye-Bronchoscopic Lung Volume Reduction Izindlela ezihlukile ze-bronchoscopic esikhundleni sokuhlinzwa kokunciphisa umthamo wamaphaphu (LVRS) zisanda kuhlongozwa;i...

Buka imininingwane -

I-Sintered Cartridge Filter ye-Polysilicon

Isihlungi se-cartridge esine-Sintered sokukhiqizwa kwe-polysilicon Ikhatriji enezimbobo ene-sintered yenziwe ngensimbi engagqwali, i-alloy powder, noma izinto ezikhethekile ezisindisiwe,...

Buka imininingwane -

Isihlungi Se-Steam Semboni Ye-Steam

Isihlungi Se-Steam Semboni Ye-Steam Ithuluzi elibalulekile elisendleleni yokuthutha imidiya.

Buka imininingwane -

I-Sintered Stainless Stainless Interchangeable Sensor Housing Yenzwa Yokucindezela

Izindlu zezinzwa zingahlakazwa ngokuguquguqukayo ukuze kuvikelwe inzwa ngokwayo ngempumelelo, futhi indlu yezinzwa inomsebenzi wokumuncwa ukushaqeka kanye ne-buf...

Buka imininingwane -

I-Wholesale Sintered Metal Filter, Intambo Yabesilisa i-G1-1/2 noma i-G2

3 5 I-Micron Sintered Pneumatic Exhaust Muffler Silencer/Diffuse air & Noise Reducer.Ama-muffler we-pneumatic enziwe nge-HENGKO yensimbi engagqwali ephezulu ahlangana ...

Buka imininingwane -

Isihlungi Sesihlungi Segesi Esisemgqeni Wezilawuli Zokucindezela Emuva

Izilawuli zisengozini yokulimala ezinhlayiyeni zesistimu.Ngakho-ke izilawuli ezehlisa ingcindezi zinikezwa i-20-100 µm press 316 SS eshintshwayo f...

Buka imininingwane -

Izindlu Zesihlungi Sensimbi Engagqwali I-Steam Zomoya Oyinyumba, I-Steam, kanye Nokuhlunga Kwe-Liquid

Izindlu Zesihlungi Sensimbi Engagqwali Zezicelo ZenhlanzekoIzindlu Zesihlungi Sensimbi Engagqwali ziklanyelwe ukuhlunga umusi endaweni yezemithi, i-biotechn...

Buka imininingwane -

Isihlungi sensimbi esinezimbotshana ze-ozone nomoya osemanzini

Inqubo yokukhiqiza yama-diameter amakhulu (80-300 mm) ama-sintered stainless stainless and corrosion-resistant steels ichazwa.Izici ze-i...

Buka imininingwane -

Isihlungi se-Sintered Porous Metal Leaf Disc Disc Semboni Ye-Polymer Melt

Izihlungi ze-Leaf Disc kanye ne-Solid Plate zezinhlelo zokusebenza zokuhlunga ze-polymer ezishisayo ezishisayo.Idiski leqabunga nezihlungi zepuleti eziqinile zenzelwe ukubalulekile...

Buka imininingwane

8 Izici Eziyinhloko Zokuhlunga Kwensimbi Yensimbi

Imikhiqizo yesihlungi sensimbi ye-HENGKO sintered ikakhulukazi iqukethe izihlungi zensimbi engenasici,izihlungi zethusi ezine-sintered,

izihlungi ze-sintered mesh, izihlungi ze-sintered titanium, izihlungi ze-metal powder, amadiski okuhlunga ensimbi ahlanganisiwe, kanye

amashubhu ensimbi engenasici.Bonke banokusebenza okuthembekile kwe-anti-corrosion, izinga lokushisa eliphezulu,

kanye nokunemba okuphezulu kwesicelo.

Izihlungi zensimbi ezenziwe nge-sintered zenziwe ngezimpushana zensimbi ezicindezelwa futhi zifakwe i-sintered (fused) ukuze zakhe i-porous,

isakhiwo esiqinile.Lezi zihlungi zaziwa ngamandla azo aphezulu, ukuqina, kanye namandla okuhlunga amancane kakhulu

izinhlayiya.Nazi izici eziyisishiyagalombili zezihlungi zensimbi ezine-sintered:

1. Amandla Aphezulu:Izihlungi zensimbi ze-sintered zenziwe ngezimpushana zensimbi, ezibanika amandla aphezulu

kanye nokuqina.

2. Ukumelana nezinga lokushisa eliphezulu:Izihlungi zensimbi ezine-sintered zingamelana namazinga okushisa aphezulu, zizenze

ilungele izindawo ezinokushisa okuphezulu.

3. Ukumelana Nokugqwala:Izihlungi zensimbi ezine-sintered zimelana nokugqwala futhi zingasetshenziswa ekonakalini

izindawo.

4. Ukumelana Namakhemikhali:Izihlungi zensimbi ezine-sintered zimelana namakhemikhali amaningi, okuwenza afanelekele amakhemikhali

ukucubungula izinhlelo zokusebenza.

5. Ukusebenza kahle kokuhlunga:Izihlungi zensimbi ezine-sintered zinesakhiwo esihle kakhulu se-pore, esivumela ukuba

hlunga izinhlayiya ezincane kakhulu ngempumelelo.

6. Amandla aphezulu okubamba ukungcola:Izihlungi zensimbi ezine-sintered zinamandla aphezulu okubamba ukungcola, okusho ukuthi zingakwazi

hlunga umthamo omkhulu woketshezi ngaphambi kokuthi kushintshwe.

7. Kulula Ukuhlanza:Izihlungi zensimbi ezine-sintered zingahlanzwa kalula futhi ziphinde zisetshenziswe, kuzenze zingabizi

ohambeni olude.

8. Ukuhlukahluka:Izihlungi zensimbi ezi-sintered zingenziwa ngezindlela ezihlukahlukene nosayizi ukuze zihlangabezane nezidingo ezithile

kwezinhlelo zokusebenza ezahlukene.

Ngesihlungi sensimbi esinezimbotshana, insimbi engagqwali iyisinqumo esihle sokuhlunga ekucutshungulweni kwamakhemikhali, ukucwengisiswa kwe-petroleum,

ukukhiqiza amandla, ukukhiqizwa kwemithi, njll.

Zonke izici zesihlungi esine-sintered ezivela ku-HENGKO zidinga ukuhlolwa kwekhwalithi eqinile ngaphambi kokuthunyelwa ngaphandle, okuhlanganisa nokuhlunga

ukusebenza kahle nokuhlola okubukwayo.Uma kuqhathaniswa nabanye abahlinzeki besihlungi sensimbi, isihlungi sensimbi se-HENGKO esinaso

ukusebenza kahle kokususwa kwezinhlayiyana okuphezulu, ukumelana nokugqwala, ukwehla kwengcindezi encane, ukuhlanzwa okulula, kanye nezinzuzo ze-backwash.

I-HENGKO inolwazi lokuzinza kwemishini ezinqubweni ezibandayo zokucindezela isostatic kanye ne-sintering.Kungakhathaliseki ukuthi uketshezi noma

ukuhlunga kwegesi, i-HENGKO ihlale ihlinzeka ngezixazululo ezithembekile nezihlala isikhathi eside.Ukwenza i-Sintered MetalIzihlungi zilula futhi kulula.

Namanje awukwazi ukuhlangabezana nezidingo zakho zokuhlunga, SicelaThumela izidingo zakhookokusebenza, ubukhulu, nokusebenzisa.

Isicelo seIsihlungi se-SinteredImikhiqizo

1. Ukuhlunga Okuwuketshezi

2. Fluidizing

3. Ukubhuqa

4. Ukusabalalisa

5. I-Flame Arrestor

6. Ukuhlunga Kwegesi

7. Ukudla Nesiphuzo

Kungani HENGKO Sintered Metal Filter

I-HENGKO ingabakhiqizi abahamba phambili bezihlungi zensimbi

, enikeza imiklamo eyingqayizivele futhi engenziwa ngezifiso ukuhlangabezana nezidingo eziqinile zezinhlelo zokusebenza ezihlukahlukene.Eyethu

imikhiqizo isetshenziswa kabanzi ekuhlungeni okuphakeme kwezimboni, ukudambisa, ukubola, ukuvikelwa kwezinzwa, ingcindezi

umthethonqubo, nokunye.

Siyaziqhenya ngokuhlinzeka ngemikhiqizo yekhwalithi ephezulu enamathela ngokuqinile kumazinga we-CE, iqinisekisa ukwakheka okuzinzile

kanye nomsebenzi.Onjiniyela bethu abanolwazi bahlale bekulungele ukunikeza ubuchwepheshe babo nokusekelwa, kusukela ku-

isiteji sokuklama kusevisi ye-aftermarket.Ngesipiliyoni seminyaka embonini yamakhemikhali, yokudla, neziphuzo,

I-HENGKO inomlando ofakazelwe wokuxazulula izinkinga zokuhlunga kanye nokulawula ukugeleza kwamakhasimende emhlabeni jikelele.

Izihlungi zensimbi ze-Sintered zivame ukusetshenziswa ezimbonini ezihlukahlukene zokuhlunga nokuhlukanisa izinhlelo zokusebenza.Bona

enziwa ngokuhlanganisa futhi ashisise izimpushana zensimbi ukuze zakhe isakhiwo esiqinile, esinezimbotshana ezinosayizi wembotshana ochaziwe,

ukuvumela uketshezi noma amagesi ukuba kudlule kuyilapho kugcinwe izinhlayiya eziqinile noma ukungcola.

Lapho uklama futhi ukhetha izihlungi zensimbi ezingama-316L, kunezici ezimbalwa okufanele uzicabangele, njengohlobo lwe

insimbi ezosetshenziswa, usayizi wembotshana kanye nokuma, ukujiya kwemidiya yesihlungi, nezimo zokushisa nezingcindezi ngaphansi

esizosetshenziswa isihlungi.Kubalulekile futhi ukucabangela uhlobo loketshezi noma igesi ehlungwayo kanye nosayizi

kanye nohlobo lokungcola okufanele kususwe.

Ukusekelwa Kwezixazululo Zonjiniyela

Ukuqinisekisa ukuklama okungcono kakhulu nokukhetha okubalulekile kwezidingo zakho zohlelo lokusebenza, kungase kusize uku

thintana nonjiniyela onolwazi noma uchwepheshe wezobuchwepheshe kulo mkhakha.Bangakuqondisa ohlelweni lokukhetha

futhi unikeze ulwazi olubalulekile olusekelwe kumazinga emboni kanye nokushicilelwe kobuchwepheshe.

I-HENGKO ezinikele ekunikezeni izixazululo ezingcono kakhulu zezidingo zakho zokuhlunga.Yabelana nathi ngephrojekthi yakho,

futhi sizosebenzisana nawe ukuze sikunikeze isisombululo sesihlungi sensimbi ngokushesha ngangokunokwenzeka.

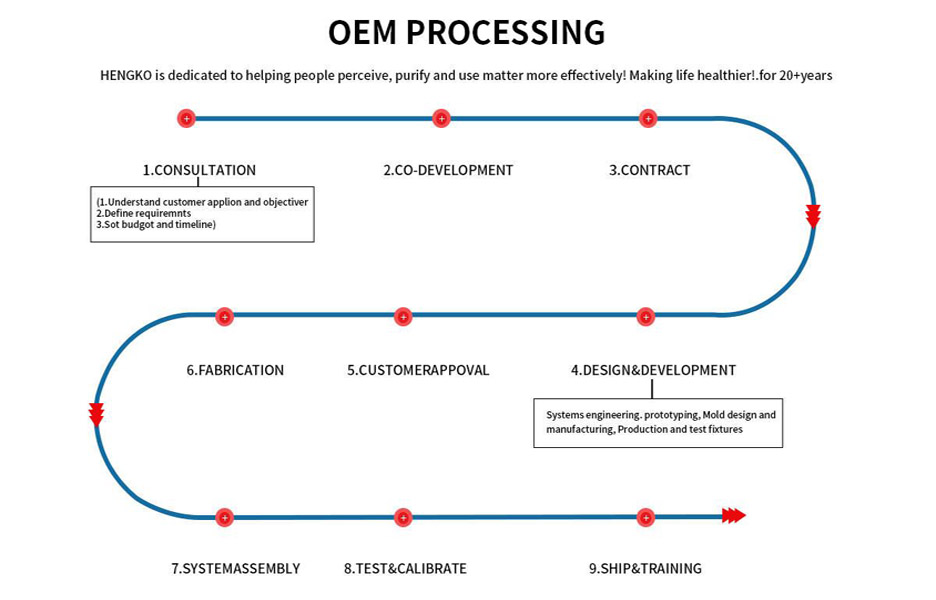

Enza ngendlela oyifisayo Inqubo yesihlungi se-Sintered Metal

Lapho UnakhoIdizayini ekhethekilekumaphrojekthi akho futhi awukwazi ukuthola imikhiqizo yesihlungi efanayo noma efanayo, Siyakwamukela

ukuze uxhumane no-HengKo ukuze basebenzisane ukuze bathole isisombululo esingcono kakhulu, futhi nansi inqubo yeIzihlungi ze-OEM Sintered Metal,

Sicela uyihlole futhiXhumana nathiukukhuluma imininingwane eyengeziwe.

I-HENGKO Izinikele Ekusizeni Abantu Babone, Bahlanze futhi Basebenzise Izinto Ngempumelelo Kakhudlwana!Ukwenza Impilo Iphile Kahle Ngaphezu kweminyaka engama-20.

1. Ukubonisana futhi Xhumana HENGKO

2. Ukuthuthukiswa ngokubambisana

3. Yenza Inkontileka

4. Design & Development

5. Ikhasimende Appova

6. Ukukhiqiza/Ukukhiqiza Okuningi

7. Umhlangano wesistimu

8. Hlola & Linganisa

9. Ukuthumela nokufakwa

I-HENGKO, Enye yezimboni ezinokuhlangenwe nakho, ihlinzeka ngezinga eliphezuluumkhiqizi wesihlungi sensimbi e-sintered e-China.

Sinethimba lezobuchwepheshe eligxile ekuthuthukiseni nasekukhiqizeni insimbi engagqwali edingeka kakhulu edingeka kakhulu

kanye nezinto ezinama-porous.Kukhona amabhizinisi obuchwepheshe obuphezulu, i-Key Laboratory, kanye nesikole semfundo ephakeme enyuvesi ekhaya naphesheya e-HENGKO.

Amathiphu angu-4 Uma Ukhetha & Isihlungi Sensimbi Se-OEM Sintered Okufanele Unakekele

Kunezindlela ezimbalwa zokwenza ngokwezifiso izihlungi zensimbi ezisikiwe ukuze zihlangabezane nezidingo ezithile zohlelo lokusebenza.

Ezinye izindlela ezijwayelekile zihlanganisa:

1. Ukukhetha insimbi efanele:Izinsimbi ezahlukene zinezakhiwo ezahlukene ezingathinta iukusebenza kwe

isihlungi sensimbi esine-sintered.Isibonelo, insimbi engagqwali imelana nokugqwala futhi inephuzu eliphezulu lokuncibilika, kuyilapho

i-aluminium ayisindi futhi inokuhamba kahle kukagesi.

2. Icacisa usayizi wembotshana nokuma:Izihlungi zensimbi ze-Sintered zingaklanywa ngama-pores osayizi abahlukene futhi

bobunjwa ukuze ivumelane nezidingo ezahlukene zokuhlunga.Isibonelo, isihlungi esinezimbotshana ezincane sizosebenza kangcono ekukhipheni

izinhlayiya ezincane, kuyilapho isihlungi esinezimbotshana ezinkudlwana singase sifaneleke kakhulu kumazinga aphezulu okugeleza.

3. Ukushintsha ukujiya kwemidiya yesihlungi:Ugqinsi lwemidiya yokuhlunga lungabuye lulungiswe ukuze luvumelane nokuthile

izidingo zohlelo lokusebenza.Imidiya ewugqinsi ingahlinzeka ngokusebenza kahle kokuhlunga kodwa ingase ibangele ukuphakama

ukwehla kwengcindezi nokuncipha kwamazinga okugeleza.

4. Ukulungisa izinga lokushisa nengcindezi:Izihlungi zensimbi ezi-sintered zingaklanywa ukuthi zimelane nokukhethekile

izinga lokushisa kanye nezimo zokucindezela, kuye ngokuthi isicelo.Kubalulekile ukucabangela lezi zici lapho

ukukhetha isihlungi ukuqinisekisa ukuthi singakwazi ukumelana nezimo zokusebenza zesistimu.

Ukuze wenze ngendlela oyifisayo isihlungi sensimbi esinezinsimbi ukuze sihlangabezane nezimfuneko zakho ezithile, thintana nonjiniyela onolwazi

noma uchwepheshe wezobuchwepheshe kulo mkhakha angase abe usizo.Bangakwazi ukuqondisa umklamo ofanele kanye nokukhethwa kwezinto ezibonakalayo ngokusekelwe

ezidingweni ezithile zohlelo lokusebenza.

Izihlungi Zensimbi Ezihlanganisiwe: EzipheleleFAQUmhlahlandlela

A:IziciYesihlungi Sensimbi Sintered

1. Iyini Isihlungi Sensimbi Ye-Sintered?

Incazelo emfushane yesihlungi se-sintered metal:Kuyisihlungi sensimbi esisebenzisa izinhlayiya zempushana zensimbi ezinosayizi wezinhlayiyana ezifanayo

ukuze ibunjwe ngokugxiviza, inqubo yokushisa ephezulu yokushisa i-Sintering inqubo yokusansimbi kusetshenziswa usayizi oyimpushana.

imizimba yezinsimbi ezahlukene nama-alloys ngemva kokunyathela.

I-Metallurgy yenzeka ngokusabalalisa emazingeni okushisa angaphansi kwendawo yokuncibilika yezithando zokushisa eziphezulu.Izinsimbi nama-alloys

okuvame ukusetshenziswa namuhla kuhlanganisa i-aluminium, ithusi, i-nickel, ithusi, insimbi engagqwali, ne-titanium.

Kunezinqubo ezahlukene ongazisebenzisa ukwenza impushana.Kuhlanganisa ukugaya, ukuzenzela, nokubola kwamakhemikhali.

2. Kungani usebenzise iStainless Steel Metal ukwenza Isihlungi?

Ukukhetha i-Stainless Steel Metal njengezinto eziyinhloko, ngenxa nje yokuthi kunezinzuzo eziningi zensimbi engagqwali

1. Akulula ukugqwala

2. Izinga lokushisa le-sintering akudingeki libe phezulu kakhulu

3. Izimbotshana kulula ukulawula ngesikhathi sintering

4. Ukubunjwa kwe-Sintered kuhlala isikhathi eside futhi akulula ukukonakalisa

5. Kulula ukuhlanza

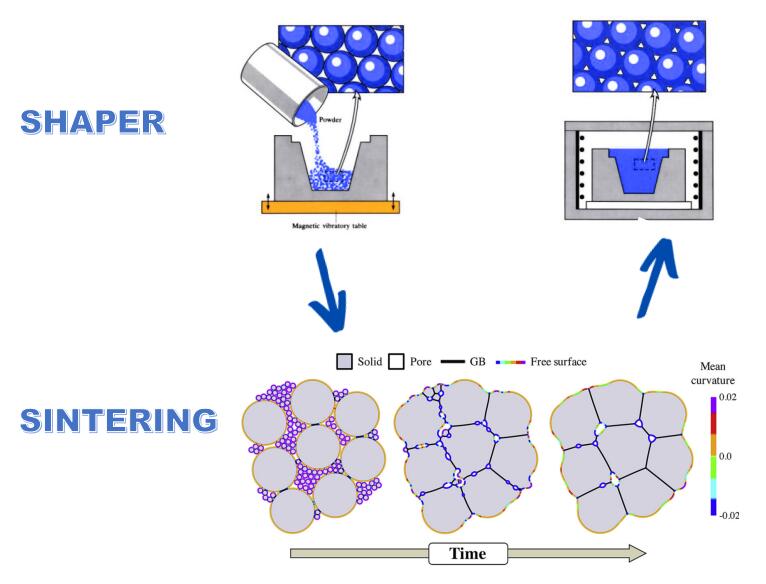

3. Senziwa kanjani isihlungi se-Sintered Metal?

Ngenqubo yokukhiqiza yesihlungi se-Sintered metal, main inezinyathelo ezi-3 kanje:

A: Isinyathelo sokuqala ukuthola insimbi yamandla.

Impushana yensimbi, Ungathola izimpushana zensimbi ngokugaya, ukuzishintshanisa, noma ukubola kwamakhemikhali.Ungakwazi ukuhlanganisa insimbi eyodwa

impushana nenye insimbi ukwenza ingxubevange ngesikhathi senqubo yokwenziwa, noma ungasebenzisa impushana eyodwa kuphela.Inzuzo yokucula yilokho

ayiguquli izinto ezibonakalayo zensimbi.Inqubo ilula kangangokuthi izakhi zensimbi aziguqulwa.

B: Ukunyathela

Isinyathelo sesibili ukuthululela i-powder yensimbi ibe isikhunta esilungiselelwe ngaphambili lapho ungabumba khona isihlungi.Ukuhlanganiswa kwesihlungi kwakhiwa ekamelweni

izinga lokushisa nangaphansi kokugxivizwa.Inani lokucindezela elisetshenzisiwe lincike ensimbi oyisebenzisayo, njengoba izinsimbi ezihlukene zinokunwebeka okuhlukile.

Ngemuva komthelela wengcindezi ephezulu, impushana yensimbi ihlanganiswa esikhunjeni ukuze yakhe isihlungi esiqinile.Ngemuva kwenqubo yomthelela wengcindezi ephezulu, ungakwazi

beka isihlungi sensimbi esilungisiwe esithandweni sokushisa okuphezulu.

C: I-sintering eshisa kakhulu

Enqubweni ye-sintering, izinhlayiya zensimbi ziyahlanganiswa ukuze zakhe iyunithi eyodwa ngaphandle kokufinyelela endaweni yokuncibilika.Le monolith iqine ngendlela efanayo,

iqinile, futhi inezimbotshana zokuhlunga njengensimbi.

Ungakwazi ukulawula i-porosity yesihlungi ngenqubo ngokusho kwezinga lokugeleza komoya noma uketshezi okufanele luhlungwe.

4. Iyini Inqubo Ye-Sintering?

Isinyathelo esisodwa esibalulekile i-Sintering, ngakho-ke iyini inqubo yokucwenga kanye nokuba izihlungi zensimbi ?

Ungahlola njengeshadi lokulandela ukuze uqonde ngokucacile.

5. Yiziphi Izicaciso Eziyinhloko Zesihlungi Sensimbi Ye-Sintered?

Ngemuva kwenqubo yokugxiviza kanye nokushisa okuphezulu kwe-sintering, singathola izihlungi zensimbi ezihlanganisiwe, bese singena

ukuze sazi ikhwalithi yezihlungi ezifakiwe, ngokuvamile, sizohlola idatha ethile yezihlungi, uma idatha ifinyelela

izidingo njengoba amakhasimende ecelile, bese singakhulula ukuze sihlele ukuthunyelwa ngaphandle.

1. I-Porosity

2. Ukuhlolwa kokucindezelwa

3. Ukuhlolwa kokugeleza (igesi noketshezi)

4. Ukuhlolwa kwesifutho sikasawoti (isivivinyo sokulwa nokugqwala)

5. Ukulinganisa ukubukeka kwe-Dimensional

Uma usathanda ukwazi okwengeziweumgomo wokusebenza kwesihlungi se-sintered, sicela uhlole imininingwane yethu yokuhlola le bhulogi.

B:IsiceloYesihlungi Sensimbi Sintered

6. Kukuphi Ukusetshenziswa Kwezihlungi Zensimbi Ze-Sintered?

Njengoba amaklayenti ethu ebhekisela ekusetshenzisweni okuyinhloko kwesihlungi se-sintered kanje:

1.) Ukuhlunga Okuwuketshezi2. Fluidizing

3. Ukubhuqa4. Ukusabalalisa

5. I-Flame Arrestor6. Ukuhlunga Kwegesi

7. Ukudla Nesiphuzo

7. Ngingakwazi Ukusebenzisa Izihlungi Zensimbi Ezisiyingi ezinezinhlobo Eziningi Zamafutha?

Yebo, kodwa udinga ukwenza ngokwezifiso usayizi wembotshana okhethekile njengamafutha, futhi nemfuneko yokulawula ukugeleza, ngakho

ungakwamukela kuXhumana nathiukuze usazise imininingwane yakho.

8. Ingabe Isihlungi Sensimbi Esiyinsimbi Singaqhubeka Sisebenza Ngisho Nalapho Izimo Kubanda?

Yebo, nge-sintered metal finter, njenge-316Lisihlungi sensimbi engagqwali sinteredingasebenza ngaphansi

-70 ℃~ +600℃ , ngakhongoba isihlungi esiningi se-sintered singasebenza ngaphansi kwe-freezong.kodwa kudingeka uqinisekise

Uketshezi negesi kungageleza ngaphansi kwesimo sokubanda.

9. Iluphi Uhlobo Lwamakhemikhali Olungakwazi Ukuhlunga Ngezihlungi Zensimbi Ezisiyingi Nangaphandle Kokulimaza Umzimba Wesihlungi?

Sihlola amakhemikhali amaningi angahanjiswa ngalo mkhiqizo ngaphandle kokuwulimaza,

njenge-phenol enikezwe ukuthi zenziwa kusetshenziswa izinto eziqinile ezimelana namakhemikhali.

1. ) I-Acid

Ama-asidi aqinile: afaka i-sulfuric acid (H2SO4), i-nitric acid (HNO3), ne-hydrochloric acid (HCl).

Ama-acids abuthakathaka ekugxilweni okuphezulu, njenge-acetic acid

B Izixazululo ze-Lewis acid ezinezakhiwo zamakhemikhali ezikhethekile, njenge-zinc chloride

2.) Izisekelo Eziqinile:kufaka phakathi i-sodium hydroxide (NaOH) ne-potassium hydroxide (KOH)

Izinsimbi ze-alkali (njenge-sodium) esimweni sazo sensimbiI-alkali kanye ne-alkaline Earth metal hydrides

Ukugxila okuphezulu kwezisekelo ezibuthakathaka njenge-ammonia

3.) I-Dehydrating agents,kuhlanganise high-concentration sulfuric acid, phosphorus pentoxide, calcium oxide,

i-zinc chloride (okungeyona isixazululo), kanye nezakhi zensimbi ze-alkali

4.) Ama-oxidizing agents aqinile, okuhlanganisa i-hydrogen peroxide, i-nitric acid, ne-concentrated sulfuric acid.

5.)Ama-halogen kagesinjenge-fluorine, i-chlorine, i-bromine, ne-iodine (ama-ion of halides awagqwali),

kanye nosawoti we-electrophilic njenge-sodium hypochlorite.

6.) I-Organic halides noma i-halides yama-organic acid, njenge-acetyl chloride ne-benzyl chloroformatei-anhydride

7.)Ama-alkylating agentsnjenge-dimethyl sulfate

8.) Ezinye izinhlanganisela eziphilayo

C:Oda UlwaziI-Sintered Metal Filter

10. Ngingakwazi yini Ukwenza ngokwezifiso isihlungi sensimbi e-sintered lapho ngi-oda kwa-HENGKO?

Yebo, Ngokuqinisekile.

Singakwazi Izihlungi ze-OEM Sintered Metal njengohlu lwakho lwezidingo zokucaciswa okulandelayo:

1. Usayizi Wembotshana

2. Isilinganiso seMicron

3. Isilinganiso sokugeleza

4. Hlunga imidiya ozoyisebenzisa

5. Noma yimuphi usayizi njengomklamo wakho

11. Iyini i-MOQ kuya ku-Wholesale sintered metal filter from HENGKO?

Njengomkhiqizi Wezihlungi Ochwepheshile, sinohlobo oluthile esingalukhetha olufana ne-Sintered Filters Disc,

I-Sintered Filters Tube,I-Sintered Filters Plate, i-Sintered Filters Cup,I-Sintered Filters Mesh, Mayelana ne-MOQ

izosuselwe kuweusayizi wokuklama nosayizi we-pore njll, okuvamile i-MOQ yethu imayelana nama-200 -1000pcs / into esekelwe ekwakhiweni.

Usenemibuzo futhi uthanda ukwazi eminye imininingwane yeI-Sintered Metal Filter, Sicela uzizwe Ukhululekile Ukusithinta Manje.

Futhi UngakwaziSithumele I-imeyiliNgokuqondile Ngokulandelayo:ka@hengko.com

Sizothumela Emuva Ngamahora angu-24, Siyabonga Ngesiguli Sakho !