-

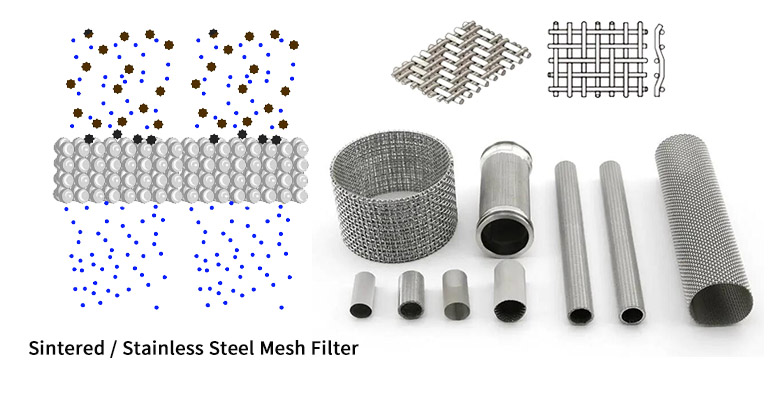

Ikhatriji yesihlungi sensimbi engenasici ecindezelwe yensimbi engenasici yenqubo eyinyumba yomoya kanye ne-g...

I-Sintering yinqubo ehlanganisa ukusetshenziswa kokushisa nengcindezi yokubopha izindawo zokuxhumana zazo zonke izintambo ndawonye ukuze kwakheke i-wire mesh ehlanganiswe ngokuvikelekile ...

Buka imininingwane -

Ishubhu yesihlungi yensimbi engenasici yensimbi engenasici (isilinda sokuhlunga) esetshenziswa ku-petroleum, ...

Izihlungi ze-Sinter wire mesh zivame ukusetshenziselwa ukuhlanzwa nokuhlunga uketshezi negesi, ukuhlukanisa kanye nokubuyiselwa kwezinhlayiya eziqinile, i-coolin yokuphefumula...

Buka imininingwane -

1.0-100um sintered metal porous stainless stainless cartridge filter mesh yenza oketshezi...

Izihlungi ze-Sinter wire mesh zivame ukusetshenziselwa ukuhlanzwa nokuhlunga uketshezi negesi, ukuhlukanisa kanye nokubuyiselwa kwezinhlayiya eziqinile, i-coolin yokuphefumula...

Buka imininingwane -

30 40 90 Microns Sintered SUS 304 SS 316L izihlungi zensimbi ezingenasici eziyinhlanganisela ye-c...

Izihlungi ze-Sinter wire mesh zivame ukusetshenziselwa ukuhlanzwa nokuhlunga uketshezi negesi, ukuhlukanisa kanye nokubuyiselwa kwezinhlayiya eziqinile, i-coolin yokuphefumula...

Buka imininingwane -

I-Sintered Filter Cartridges for Medical Filtration Applications -HENGKO

I-HENGKO isungule i-membrane yebanga lokufaka inzalo yensimbi yonke yezinhlelo zokusebenza zokuhlunga kwezokwelapha. Le nto ifaneleka kahle ekusetshenzisweni kwezokwelapha...

Buka imininingwane

Isici esiyinhloko sezihlungi ze-Stainless Steel Mesh :

1.uhlu Olubanzi lwezikolo zokuhlunga ukuze kugwenywe noma yimuphi usayizi wezinhlayiya

2.I-wire mesh ingenziwa ngokwezifiso kunoma yisiphi isimo noma isicelo ngokugxivizwa noma ukusikwa

3.Kulula Ukuhlanza nokugeza ngemuva

4Zisebenziseka kalula, Izitayela ezikhethekile zokuguquguquka emikhakheni yezimboni

5.Amandla emishini athuthukisiwe anokuqina okuhle kakhulu Ifanele ngaphansi kwe-thermal kanye

futhi inkinga edla kakhulu

6.I-Mesh ingamakwa noma yehliswe ibe usayizi

7.I-wire mesh ingagoqwa, ishiselwe, ifakwe i-sintered, futhi ithengiswe

8.Kulula ukuhlanza nokugeza ngemuva

4 - Umsebenzi Wezihlungi Zensimbi Engenasici

1. Ukususa izingcezwana ezingathandeki kanye nokungcola oketshezini oluhlukahlukene

2. Ukuqedela inqubo yokuhlunga kahle

3. Ukushintsha i-mesh yokuhlunga yendabuko ngaphansi kwemvelo enokhahlo

4. Vimbela ukulimala kwemishini

Ukusetshenziswa Kwesihlungi Se-Stainless Steel Mesh :

Izihlungi zensimbi engagqwali ziyizixazululo zokuhlunga eziguquguqukayo ezilungele uhla olubanzi lwezinhlelo zokusebenza. Ukwakhiwa kwazo okumelana nokugqwala kanye namaphethini anezikhala enziwa ngezifiso anika amandla ukuhlungwa okunembile kwezinhlayiya, ukungcola, nemfucumfucu.

Ukuhlunga Uketshezi

Izihlungi zensimbi engenasici zilungele ukuhlunga uketshezi olufana nalokhu:

- Iziphuzo - Vimbela inzika futhi uqinisekise ukucaca eziphuzweni zebhodlela, ijusi yezithelo, namanzi asemabhodleleni. • Hlanganisa uketshezi - Hlunga ukungcola kumakhemikhali, imithi, imikhiqizo yokudla, namanzi angcolile. • Amanzi echibi - Susa udoti, amaqabunga, nokunye ukungcola ukuze ugcine amanzi echibi ehlanzekile futhi ezungeza ngendlela efanele.

Ukuhlukaniswa kwe-Solids

Izihlungi zensimbi engenasici nazo ziyasebenza ekuhlukaniseni izinto eziqinile ezifana nalezi: • Izinhlayiya zokudla - Hlunga amagobolondo, imigodi, iziqu, nezinye izinhlayiya zokudla ngesikhathi sokucubungula nokulungisa. • Izinto Ezisetshenziswa Kabusha - Hlukanisa amaphepha, amapulasitiki, izinsimbi, nezingilazi ngesikhathi sokuhlelwa kabusha kokuhlelwa kabusha. • Ama-aggregate - Hlukanisa isihlabathi, amatshe amatshe, amatshe agayiwe, nezinye izilinganiso ngosayizi wokwakha nezimboni.

Izixazululo ezenziwe ngokwezifiso

Izihlungi zensimbi engagqwali ze-mesh zingenziwa ngendlela oyifisayo ngokohlobo lwe-mesh (okwelukiweyo uma kuqhathaniswa nokunwetshiwe), isibalo semeshi (imicu ngeyintshi ngayinye), nendawo yokuhlunga ukuze ivumelane nezidingo eziningi zokuhlunga. Izindawo zokuhlunga ezinkulu kanye nezibalo eziphansi ze-mesh ziholela ekuhlungeni okuqinile kuyilapho izibalo eziphezulu ze-mesh nezindawo zokuhlunga ezincane zihlinzeka ngokuhlunga okungcono.

Ngokumelana nokugqwala okuhle kakhulu, ukuqina, kanye nokuhlunga okwenziwa ngendlela oyifisayo, izihlungi zensimbi engagqwali zinekhambi zimelela ikhambi eliguquguqukayo nelichwepheshile lezinhlelo zokusebenza lapho kudingeka khona ukuhlunga okunembayo nokuthembekile.

-

I-Aerospace

-

Izimboni zamakhemikhali nezimboni zikawoyela/zegesi

-

Imboni kawoyela edliwayo

-

Imboni yezinsimbi nezimayini

-

Izincibilikisi, Amapende

-

Imboni yezemithi

-

Ukuphathwa Kwamanzi Nemfucuza

-

High viscosity uketshezi

-

amanzi olwandle desalination

-

Ukudla Nesiphuzo

-

Ukuhlunga, Ukuhlunga, Ukulinganisa

-

Izimbobo

-

Obhasikidi

-

Izihlunu

-

Izikrini ze-Faucet

-

Izikrini Zezinambuzane

-

Ama-grilles okuhlobisa ama-wire mesh

-

Onogada

-

Izinhlelo zokusebenza zokuhlobisa/izikebhe

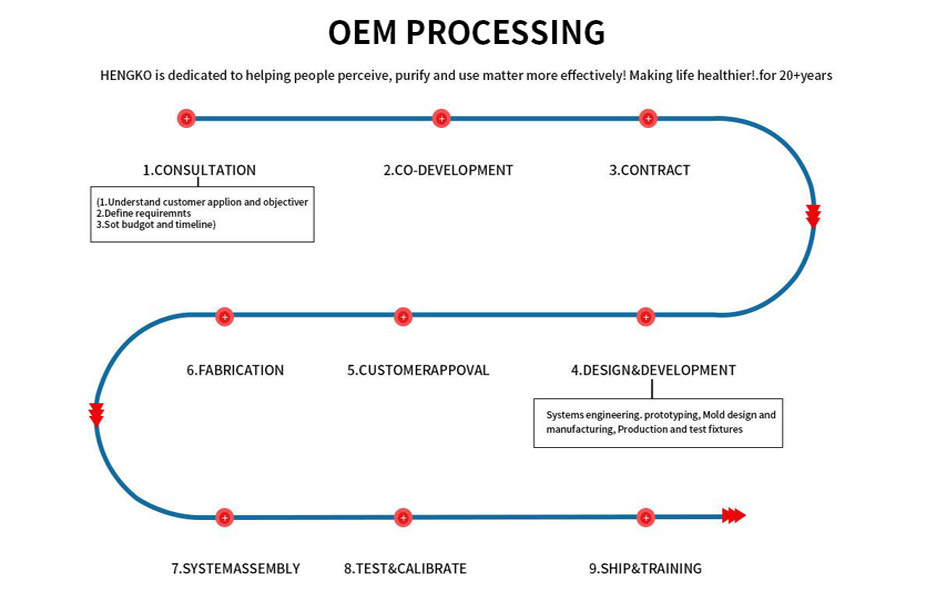

Usenza kanjani ngokwezifiso isihlungi se-Stainless Stainless Steel Mesh

uma unezidingo ezikhethekile zesihlungi se-Stainless Stainless Steel samaphrojekthi akho futhi ungakwazi ukukuthola okufanayo noma

imikhiqizo efanayo Yesihlungi, Siyakwamukela ukuthintana no-HENGKO ukuze nisebenze ndawonye ukuze nithole isisombululo esingcono kakhulu, futhi nakhu

inqubo yesihlungi se-OEM Sintered Stainless Steel Mesh,

I-HENGKO ingumkhiqizi ochwepheshe wezihlungi ze-stainless steel mesh. Singahlinzeka nge-sintered eyenziwe ngokwezifiso

izihlungi zensimbi engenasici ngokwezidingo zakho ezikhethekile uma imikhiqizo ejwayelekile ingakwazi ukuhlangabezana nezidingo zakho.

Inqubo yesihlungi se-OEM sintered steel stainless mesh ihlanganisa:

1.Ukubonisana ngobuchwepheshe:

Onjiniyela bethu bazobonisana nawe ngezidingo ezithile zamaphrojekthi akho ukuthola izinto ezifanele,

usayizi wemeshi, ukujiya, njll. kwesihlungi se-mesh yensimbi engagqwali.

2. Ukwenza amasampula:

Sizokwenza amasampula asekelwe emiphumeleni yokubonisana futhi sikuthumele kuwe ukuze ahlolwe futhi aqinisekiswe.

Uma amasampula ehlangabezana nezidingo zakho, sizoqala ukukhiqiza ngobuningi bezihlungi zensimbi engenasici.

4.Ukuhlola:

Yonke imikhiqizo izodlula ekuhlolweni okuqinile ukuze kuqinisekiswe ukuthi iyahlangabezana namazinga ngaphambi kokulethwa.

5. Ukupakisha nokuthunyelwa:

Imikhiqizo ehloliwe izopakishwa futhi ithunyelwe kuwe ngendlela yokuthumela oyishilo.

Sinemishini ethuthukisiwe nochwepheshe bokukhiqiza izihlungi zensimbi engenasici zekhwalithi ephezulu.

Siphinde sibe nesistimu yokuphatha ikhwalithi eqinile ukuze siqinisekise ikhwalithi yomkhiqizo ezinzile nethembekile. Uma unezinye izidingo,

sicela usithinte nganoma yisiphi isikhathi. Sizibophezele ekukunikezeni izixazululo namasevisi angcono kakhulu.

Uhlu Lwenqubo Yoku-oda kwe-OEM

1.Ukubonisana futhi Xhumana HENGKO Ekuqaleni

2.Ukuthuthukiswa ngokubambisana

3.Yenza Inkontileka

4.Idizayini Nokuthuthukiswa

5.Ukuvunyelwa Kwekhasimende

6. Ukukhiqiza/Ukukhiqiza Okuningi

7. Umhlangano wesistimu

8. Hlola & Linganisa

9. Ukuthumela nokufakwa

Yini I-HENGKO Engakunikeza Ngesihlungi Se-Stainless Steel Mesh

I-HENGKO Sekela Izicelo Ezihlukahlukene ezidingweni zakho ezihlukene zesihlungi se-Stainless Stainless Steel Mesh

enemiklamo engokwezifiso nemisha njengezidingo zamakhasimende Isihlungi sethu se-Stainless Mesh sinesikhathi eside saba khona

umlando wokusetshenziswa kakhulu ekuhlungeni okuphakeme kwezimboni, ukuthambisa, i-sparger, ukuvikela inzwa, ingcindezi

umthethonqubo nezinye izinhlelo zokusebenza eziningi.

✔Imboni Yezihlungi Ze-Sintered Mesh Umkhiqizi Ophezulu Weminyaka Engaphezu Kwengu-20

✔Imiklamo Ehlukile Njengosayizi Ohlukene, Ncibilikisa, Izendlalelo kanye Nokwakheka

✔Ikhwalithi ephezulu ye-CE Izinga lokukhiqiza, ukwakheka okuzinzile, Umsebenzi Ocophelelayo

✔Isixazululo Esisheshayo sesevisi yangemuva kokuthengisa

✔Abanolwazi Oluningi Kuzinhlelo Zokuhlunga Ezihlukahlukene Ezimbonini Zamakhemikhali, Zokudla, Neziphuzo njll

Eminyakeni engu-20 edlule, u-HENGKO usebenzela amanyuvesi amaningi adumile emhlabeni wonke, ikakhulukazi ilebhu yasenyuvesi,

I-Physics and Chemistry Laboratory, i-R&D laboratories yamakhemikhali ahlukahlukene, i-petroleum, nemikhiqizo yokudla, i-R&D kanye

iminyango yokukhiqiza yamabhizinisi okukhiqiza, sithole isipiliyoni samaphrojekthi amaningi kusihlungi sensimbi engenasici,

isihlungi se-sintered mesh, ukuze sikwazi ukukunikeza ngokushesha isixazululo esiphelele samadivayisi akho nephrojekthi.

I-FAQ Yesihlungi Se-Stainless Steel Mesh

1. Ungakwazi yini ukwenza isihlungi se-mesh yensimbi engagqwali engu-5?

Yebo, singakwazi i-OEM noma yimuphi usayizi nanoma yikuphi ukushuba kwe-5 micron yensimbi engagqwali yokuhlunga,

noma 5 Micron 3 Layer Sintered Stainless Mesh, 5 Micron 5 Layer Sintered Stainless Mesh

Futhi, singakwazi ukwenza ngokwezifiso noma yimuphi usayizi wembotshana, njenge-0.2 - 200 micron Stainless Steel Mesh Filter for

amaphrojekthi akho.

2. Yenzani I-Stainless Steel Mesh?

Insimbi engagqwali inezikhala isikrini sensimbi esenziwe kusetshenziswa insimbi engagqwali noma amanye ama-alloys. Ikona

evame ukusetshenziswa ezinhlelweni ezahlukahlukene, kufaka phakathi ukuhlunga, ukusefa, ukuhluza, nokuhlola.

I-mesh ivame ukusetshenziswa ezimbonini ezifana nokucubungula ukudla, imithi, amakhemikhali

ukucubungula, izimayini, kanye nemikhiqizo yabathengi. Ngoba insimbi engagqwali imelana nokugqwala

futhi inenani eliphezulu lamandla-kuya-isisindo, iyinto efanelekile ukuthi isetshenziswe kumanetha. Imeshi

ingenziwa ngosayizi nobujamo obuhlukahlukene, kuye ngohlelo oluthile oluhloselwe lona.

3. Kungani I-Mesh Wire Ibaluleke Kangaka?

I-wire mesh ibalulekile ezimbonini nasezisetshenziswa eziningi ngenxa yokuguquguquka kwayo, amandla,

kanye nokuqina. Isetshenziswa ezinhlelweni eziningi, kufaka phakathi ukuhlunga, ukusefa, ukuhluza, nokuhlola,

futhi ivame ukusetshenziswa ekucubunguleni ukudla, kwezemithi, ekucubunguleni amakhemikhali, nasezimayini.

I-mesh wire iphinde isetshenziswe emikhiqizweni yabathengi, njengezikrini zeminyango namafasitela.

4. Isebenza Kanjani I-Wire Mesh?

I-wire mesh iyigridi noma isikrini esenziwe ngezintambo ezixhumene. Isetshenziswa ezinhlobonhlobo

izinhlelo zokusebenza, okuhlanganisa ukuhlunga, ukusefa, ukuhluza, nokuhlola. Okwemeshi, isampula lempahla

ibekwe phezu kwemeshi, futhi inetha liyanyakaziswa noma linyakaziswe. Impahla izodlula

izimbobo ezisenetheni, kodwa noma yiziphi izinhlayiya noma izinto ezinkulu kakhulu ukuthi zingadlula

i-mesh izogcinwa phezu kwe-mesh. Ivumela impahla ukuthi ihlukaniswe ngokwehlukana

ububanzi besayizi noma izingxenye.

5. Ingabe Izihlungi Zensimbi Zensimbi Zilungile?

Izihlungi ze-metal mesh ziwuhlobo lwesihlungi esisebenzisa i-mesh eyenziwe ngocingo lwensimbi noma amanye ama-alloys kuwo

khipha izinhlayiya noma ezinye izinto oketshezini noma igesi. Zivame ukusetshenziswa ezindaweni ezihlukahlukene

izimboni, okuhlanganisa ukucubungula ukudla, ezemithi, ukucubungula amakhemikhali, nezimayini,

kanye nasemikhiqizweni yabathengi. Izihlungi ze-metal mesh ngokuvamile zibhekwa njengezisebenzayo futhi

okuthembekile ezinhlelweni eziningi zokuhlunga. Ziqinile, zinesilinganiso esiphakeme samandla nesisindo,

futhi imelane nokugqwala, izenze zikufanelekele ukusetshenziswa ezindaweni eziningi.

Ngaphezu kwalokho, izihlungi ze-mesh zensimbi zingahlanzwa kalula futhi zisetshenziswe kabusha, okuzenza

engabizi futhi enobungani nemvelo.

6. Ingabe Ukudla Kwe-Stainless Steel Mesh Kuphephile?

Isihlungi sensimbi engagqwali esikhethekile se-316L sensimbi engenasici sivame ukucatshangelwa

ephephile ekulungiseni nasekuphatheni ukudla. Insimbi engagqwali ayinobuthi futhi ayinabuthi

impahla, okusho ukuthi ayikhiphi noma yiziphi izinto ekudleni ezingase zilimaze

impilo yomuntu. Ngaphezu kwalokho, insimbi engagqwali ayikwazi ukugqwala futhi kulula ukuyihlanza,

ukwenza kube yimpahla efanelekile yokucubungula ukudla kanye nokuphatha izinhlelo zokusebenza.

Usihlanza kanjani isihlungi se-mesh yensimbi engagqwali?

Kunezindlela eziningana zokuhlanza isihlungi sensimbi engenasici, kuye ngokuthi

uhlobo oluthile lwesihlungi kanye nenani lokuhlanza elidingekayo. Nazi izinyathelo ezijwayelekile

ongayilandela ekuhlanzeni isihlungi se-mesh yensimbi engagqwali:

1.Hlanza isihlungi ngamanzi ukuze ususe noma iyiphi imfucumfucu exekethile noma izinhlayiya.

2.Uma isihlungi singangcole kakhulu, ungasebenzisa ibhulashi elithambile noma indwangu ethambile ukuze ukhuhle kahle.

susa noma yikuphi ukungcola noma insila esele.

3.Uma isihlungi singcolile kakhulu, ungasicwilisa emanzini afudumele kanye nesihlanzi esithambile imizuzu embalwa

ukukhulula noma yikuphi ukungcola okunenkani noma insila.

4.Hlanza isihlungi kahle ngamanzi ukuze ususe noma iyiphi insipho noma isisombululo sokuhlanza.

5.Sula isihlungi ngokuphelele ngaphambi kokusisebenzisa futhi.

Kubalulekile ukugwema ukusebenzisa ama-abrasive cleaners noma amabhulashi, njengoba lokhu kungalimaza

mesh futhi unciphise ukusebenza kwayo. Ukomisa isihlungi ngaphambi kokusisebenzisa futhi kubalulekile,

njengoba umswakama ungenza ukuthi inetha ligle noma ligle.

6. Yiziphi izinzuzo zezihlungi zensimbi engenasici?

Izihlungi zensimbi engenasici zinikeza izinzuzo ezibalulekile ezimbalwa ngaphezu kwezinye izinto zokuhlunga. Ziqinile kakhulu futhi zihlala isikhathi eside, zikwazi ukumelana nezingcindezi eziphezulu namazinga okushisa ngaphandle kokulimala. Futhi azikwazi ukumelana nokugqwala, azinzi ngamakhemikhali, futhi azisebenzi ngakho zingasetshenziswa nohlu olubanzi loketshezi. Izihlungi zensimbi engagqwali nazo zilungile kakhulu, ziyakwazi ukuhlunga ngisho nezinhlayiya ezincane nama-microorganisms.

7. Yiziphi izilinganiso ze-micron ezitholakalayo?

Izihlungi ze-mesh yensimbi engagqwali ziyatholakala kuhlu lwezilinganiso zama-micron, ukusuka kuma-microns angu-0.5 kufika kuma-microns angu-100. Isilinganiso se-micron sibhekisela kusayizi wezinhlayiya ezizodlula esihlungini. Izilinganiso ezincane zama-micron ezifana nama-micron angu-0.5-5 zilungele ukuhlunga izinhlayiya nama-microorganisms, kuyilapho izilinganiso ezinkulu zama-micron ezingama-20-100 microns zingcono ekuhlungeni imfucumfucu emikhulu kanye nenhlabathi.

8. Zisetshenziswa kanjani izihlungi zensimbi engenasici?

Izihlungi ze-mesh yensimbi engenasici zinezinhlobonhlobo zezinhlelo zokusebenza futhi zisetshenziswa ezimbonini eziningi. Okunye ukusetshenziswa okuvamile kubandakanya: • Ukuhlunga uketshezi namagesi ekucutshungulweni kwamakhemikhali, emithini yemithi, ekudleni naseziphuzweni, nakwi-biotechnology. • Ukuvalwa komoya, amagesi, noketshezi ngokuhlunga amagciwane. • Ukucaciswa koketshezi ngokukhipha izinhlayiya, izinhlayiya, nokungcola. • Ukuhlunga kwangaphambili kwezihlungi ze-membrane ukuvimbela ukuvaleka. • Ukuhlukaniswa kwezinhlayiya zesampula nokuhlaziya. • Ukuhlunga uketshezi olunamanzi nama-slurries. • Ukuhlunga uketshezi olubolayo namagesi. • Ukuhlunga uketshezi olunezinga lokushisa eliphezulu namagesi.

9. Siyini isihlungi sensimbi engenasici?

Izihlungi zensimbi engagqwali ziyizihlungi ezibunjwe ngokunemba ezenziwe ngensimbi engagqwali engagqwali. Zakhelwe ukuhlunga izinhlayiya, ukungcola, kanye nemfucumfucu oketshezini namagesi kuyilapho zivumela okuphakathi ukuba kudlule.

10.Iziphi izinzuzo zezihlungi zensimbi engenasici?

Izihlungi zensimbi engenasici zinikeza izinzuzo ezibalulekile ezimbalwa ngaphezu kwezinye izinto zokuhlunga. Ziqinile kakhulu futhi zihlala isikhathi eside, zikwazi ukumelana nezingcindezi eziphezulu namazinga okushisa ngaphandle kokulimala. Futhi azikwazi ukumelana nokugqwala, azinzi ngamakhemikhali, futhi azisebenzi ngakho zingasetshenziswa nohlu olubanzi loketshezi. Izihlungi zensimbi engagqwali nazo zilungile kakhulu, ziyakwazi ukuhlunga ngisho nezinhlayiya ezincane nama-microorganisms.

11.Iziphi izilinganiso ze-micron ezitholakalayo?

Izihlungi ze-mesh yensimbi engagqwali ziyatholakala kuhlu lwezilinganiso zama-micron, ukusuka kuma-microns angu-0.5 kufika kuma-microns angu-100. Isilinganiso se-micron sibhekisela kusayizi wezinhlayiya ezizodlula esihlungini. Izilinganiso ezincane zama-micron ezifana nama-micron angu-0.5-5 zilungele ukuhlunga izinhlayiya nama-microorganisms, kuyilapho izilinganiso ezinkulu zama-micron ezingama-20-100 microns zingcono ekuhlungeni imfucumfucu emikhulu kanye nenhlabathi.

12.Zisetshenziswa kanjani izihlungi zensimbi engenasici?

Izihlungi ze-mesh yensimbi engenasici zinezinhlobonhlobo zezinhlelo zokusebenza futhi zisetshenziswa ezimbonini eziningi. Okunye ukusetshenziswa okuvamile kubandakanya: • Ukuhlunga uketshezi namagesi ekucutshungulweni kwamakhemikhali, emithini yemithi, ekudleni naseziphuzweni, nakwi-biotechnology. • Ukuvalwa komoya, amagesi, noketshezi ngokuhlunga amagciwane. • Ukucaciswa koketshezi ngokukhipha izinhlayiya, izinhlayiya, nokungcola. • Ukuhlunga kwangaphambili kwezihlungi ze-membrane ukuvimbela ukuvaleka. • Ukuhlukaniswa kwezinhlayiya zesampula nokuhlaziya. • Ukuhlunga uketshezi olunamanzi nama-slurries. • Ukuhlunga uketshezi olubolayo namagesi. • Ukuhlunga uketshezi olunezinga lokushisa eliphezulu namagesi.

13.Iziphi izinzuzo zezihlungi zensimbi engenasici?

Izihlungi zensimbi engenasici zinikeza izinzuzo ezibalulekile ngaphezu kwezinye izinto. Zihlala isikhathi eside kakhulu futhi zihlala isikhathi eside, zikwazi ukumelana nezingcindezi eziphezulu, amazinga okushisa, namazinga aphezulu okugeleza ngaphandle kokulimala. Akwazi ukumelana nokugqwala futhi angasebenzi ngamakhemikhali, alungele ukusetshenziswa noketshezi oluningi oluhlanganisa ama-asidi, izisekelo, nezincibilikisi. Izihlungi zensimbi engenasici zilungile kakhulu, ziyakwazi ukuhlunga ngisho nezinhlayiya ezincane, ama-microorganisms, kanye nokungcola. Angaphinda afakwe ngokuzenzakalelayo ukuze avale inzalo futhi aphinde asetshenziswe.

14.Siyini isihlungi sensimbi engenasici?

Izihlungi zensimbi engagqwali ziyizihlungi ezibunjwe ngokunemba ezenziwe ngensimbi engagqwali engagqwali. Zakhelwe ukuhlunga izinhlayiya, ukungcola, kanye nemfucumfucu oketshezini namagesi kuyilapho zivumela okuphakathi ukuba kudlule.

15.Iziphi izinzuzo zezihlungi zensimbi engenasici?

Izihlungi zensimbi engenasici zinikeza izinzuzo ezibalulekile ezimbalwa ngaphezu kwezinye izinto zokuhlunga. Ziqinile kakhulu futhi zihlala isikhathi eside, zikwazi ukumelana nezingcindezi eziphezulu namazinga okushisa ngaphandle kokulimala. Futhi azikwazi ukumelana nokugqwala, azinzi ngamakhemikhali, futhi azisebenzi ngakho zingasetshenziswa nohlu olubanzi loketshezi. Izihlungi zensimbi engagqwali nazo zilungile kakhulu, ziyakwazi ukuhlunga ngisho nezinhlayiya ezincane nama-microorganisms.

16.Iziphi izilinganiso ze-micron ezitholakalayo?

Izihlungi ze-mesh yensimbi engagqwali ziyatholakala kuhlu lwezilinganiso zama-micron, ukusuka kuma-microns angu-0.5 kufika kuma-microns angu-100. Isilinganiso se-micron sibhekisela kusayizi wezinhlayiya ezizodlula esihlungini. Izilinganiso ezincane zama-micron ezifana nama-micron angu-0.5-5 zilungele ukuhlunga izinhlayiya nama-microorganisms, kuyilapho izilinganiso ezinkulu zama-micron ezingama-20-100 microns zingcono ekuhlungeni imfucumfucu emikhulu kanye nenhlabathi.

17.Zisetshenziswa kanjani izihlungi zensimbi engenasici?

Izihlungi ze-mesh yensimbi engenasici zinezinhlobonhlobo zezinhlelo zokusebenza futhi zisetshenziswa ezimbonini eziningi. Okunye ukusetshenziswa okuvamile kubandakanya: • Ukuhlunga uketshezi namagesi ekucutshungulweni kwamakhemikhali, emithini yemithi, ekudleni naseziphuzweni, nakwi-biotechnology. • Ukuvalwa komoya, amagesi, noketshezi ngokuhlunga amagciwane. • Ukucaciswa koketshezi ngokukhipha izinhlayiya, izinhlayiya, nokungcola. • Ukuhlunga kwangaphambili kwezihlungi ze-membrane ukuvimbela ukuvaleka. • Ukuhlukaniswa kwezinhlayiya zesampula nokuhlaziya. • Ukuhlunga uketshezi olunamanzi nama-slurries. • Ukuhlunga uketshezi olubolayo namagesi. • Ukuhlunga uketshezi olunezinga lokushisa eliphezulu namagesi.

18. Yiziphi izinzuzo zezihlungi zensimbi engenasici?

Izihlungi zensimbi engenasici zinikeza izinzuzo ezibalulekile ngaphezu kwezinye izinto. Zihlala isikhathi eside kakhulu futhi zihlala isikhathi eside, zikwazi ukumelana nezingcindezi eziphezulu, amazinga okushisa, namazinga aphezulu okugeleza ngaphandle kokulimala. Akwazi ukumelana nokugqwala futhi angasebenzi ngamakhemikhali, alungele ukusetshenziswa noketshezi oluningi oluhlanganisa ama-asidi, izisekelo, nezincibilikisi. Izihlungi zensimbi engenasici zilungile kakhulu, ziyakwazi ukuhlunga ngisho nezinhlayiya ezincane, ama-microorganisms, kanye nokungcola. Angaphinda afakwe ngokuzenzakalelayo ukuze avale inzalo futhi aphinde asetshenziswe.

19.Iziphi izimboni ezisebenzisa izihlungi zensimbi engenasici?

Izihlungi zensimbi engenasici zisetshenziswa ezimbonini eziningi ezihlanganisa:

• Ukucutshungulwa kwamakhemikhali nokwemithi - Okokuhlunga nokuhlukaniswa kwamakhemikhali, izincibilikisi, nezithako zemithi.

• Ukudla nesiphuzo - Ukuze kucaciswe, ukuvala inzalo, nokuhlunga uketshezi namagesi.

• I-Biotechnology - Ngokuvalwa inzalo, ukucaciswa, nokuhlukaniswa kwamasampula ebhayoloji namasiko.

• I-Microbiology - Ngokuvalwa inzalo nokuhlunga komoya, amagesi, noketshezi olusetshenziswa ekuhlolweni kwe-microbiology nocwaningo.

• Ukunakekelwa kwezempilo - Ukuvalwa inzalo kwamagesi ezokwelapha, ukuhlungwa koketshezi lwe-IV, nokucaciswa kwamasampuli aselabhorethri.

• Ukukhiqizwa kwe-semiconductor - Okokuhlunga amakhemikhali agqwalayo kanye nama-slurries abrasive asetshenziswa ekwenzeni ama-chip.

• Izimboni ze-nuclear - Okokuhlunga uketshezi olukhipha imisebe kanye nesitimu esishisa kakhulu.

• Ukukhiqiza ugesi - Okokuhlunga amagesi ashisayo, izinhlayiya eziabrasive, nokungcola ezimbonini zamandla kaphethiloli.

• Ukusebenza kwensimbi - Okokuhlunga uketshezi olusikiwe, izinto ezipholile, nezinhlayiya zensimbi.

• I-Pulp nephepha - Ukuze kucaciswe futhi kukhishwe uyinki we-pulp kanye nokuhlunga kwamanzi okucubungula.

20. Yiziphi izinhlobo zezihlungi zensimbi ezingenasici ezitholakalayo?

Izinhlobo eziyinhloko zezihlungi zensimbi engenasici zihlanganisa:

• Izihlungi zemeshi ezilukiwe - Zenziwe nge-electroforming intambo yensimbi engagqwali ibe yinetha. Imeshi eqinile yokuhlunga okuphezulu.

• Izihlungi ze-Sintered mesh - Zenziwe ngokufaka insimbi engagqwali eyimpushana ibe yinetha. I-porosity ephezulu yokwehla kwengcindezi ephansi.

• Izihlungi zamapuleti anezimbobo - Amapuleti ensimbi engagqwali anezimbobo ezibhontshiwe noma asikwe nge-laser ngamaphethini athile.

• Izihlungi zezikhwama - Izikhwama zensimbi engagqwali ezinezikhala noma imikhono esetshenziswa njengesihlungi esilahlwayo noma esisebenziseka kabusha.

• Izihlungi eziyi-cylindrical - Insimbi engagqwali enezikhala ezisongelwe ngaphandle kweshubhu lokusekela noma ikheji.

• Izihlungi zephaneli - Amashidi anezikhala ensimbi engagqwali anohlaka ukuze akhe izihlungi zamaphaneli ayisicaba.

• Izihlungi zesikhwama/eziphuma esikhwameni - Izihlungi zezikhwama zensimbi engenasici ezilahlwayo ezingakhishwa futhi zishintshwe kuyilapho isihlungi sezindlu sihlala sisemgqeni.

Usenemibuzo futhi uthanda ukwazi eminye imininingwane yesihlungi se-Stainless Stainless Steel Mesh, Sicela ukhululeke

Xhumana nathi Manje.Futhi UngakwaziSithumele I-imeyiliNgokuqondile Ngokulandelayo:ka@hengko.com

Sizothumela Emuva Ngamahora angu-24, Siyabonga Ngesiguli Sakho !