-

Ukuhlanzwa kwe-Biopharmaceutical kanye nokuhlunga ipuleti le-porous filter 10um 20um 50um

Ipuleti lesihlungi elinezimbobo wuhlobo olusha lwesihlungi esisebenza kahle kakhulu esinezimbobo esenziwe ngempushana yensimbi engagqwali ngesisefo sempushana, ukubumba, i-sinterin...

Buka imininingwane -

Imbiza ebanzi yomlomo obanzi ene-stainless sintered filter disc yokushisa okuphezulu...

Izinguquko ezincane, izinzuzo ezinkulu! Sigcina ubumba be-bentonite ngaphakathi kwembiza bese sibhaka kuhhavini ye-vacuum ukuze sisuse umswakama. Ngisho nesivalo sobumba siyaphuma o...

Buka imininingwane -

I-NW16 KF16 Flange-Centering O-Ring eneFine Fine

I-ISO-KF kanye ne-NW Sintered Metal Filter Centering Ring NW-16、NW-25、NW-40、NW-50 Umphakeli Onesihlungi esihle (isihlungi sensimbi esinezimbobo esinezimbobo noma khetha wire mesh f...

Buka imininingwane -

I-NW50 KF50 Vacuum Flange Centering ring ene-Sintered Metal Filter, insimbi engagqwali, 50 ...

I-NW50 KF50 Centreing ring ene-Sintered Metal Filter, insimbi engagqwali, 50 ISO-KF Izinto zomkhiqizo: insimbi engagqwali 304,316 Indlela yokufaka: sebenzisa ngembaza...

Buka imininingwane -

I-NW25 KF25 KF Indandatho Emaphakathi kusihlungi Sensimbi Esiyinsimbi

NW25 KF25 KF Centering Ring to Sintered Metal Filter • NW16 (KF16, QF16) Series• Viton (Fluorocarbon, FKM) O-Ring• Viton: 200°C Maximum• 0.2 µm Usayizi Wembotshana• F...

Buka imininingwane -

I-Monocrystalline silicon pressure transmitter sintered metal porous filter disc

Kusetshenziswa inzwa yokucindezela kobuchwepheshe eyodwa ye-crystal silicon piezoresistive, cubungula izinhlelo zokusebenza zokulinganisa izinga loketshezi embonini:...

Buka imininingwane -

Isihlungi sensimbi esinezimbotshana ze-ozone nomoya osemanzini

Inqubo yokukhiqiza yama-diameter amakhulu (80-300 mm) ama-sintered stainless stainless and corrosion-resistant steels ichazwa. Izici ze-i...

Buka imininingwane -

I-Sintered porous metal filter disc 20 micron yokuhlanza nokuhlaziya igesi

Zuza Ukwehlukana Okungenakuqhathaniswa Kwegesi/Izinsimbi NgamaDiski Okuhlunga Ensimbi Engagqwali e-HENGKO! Amasistimu ethu okuhlunga, afaka i-sintered stainless ...

Buka imininingwane -

i-sintered metal round deep filter sheets yokukhiqiza uwoyela we-cannabis

Ukuhlunga Ekukhiqizeni imikhiqizo ye-cannabinoid ezinzile ukuhlunga kuyisinyathelo esibalulekile. Ukuze ususe ama-wax, amafutha kanye namafutha e-winterization a multi...

Buka imininingwane -

I-Sintered metal Gas / Solids Venturi Blowback (GSV) GSP isihlungi se-OEM Services

I-Custom Sintered metal Gas/Solids Venturi Blowback (GSV) Isihlungi se-GSP se-Sintered metal sesetshenziselwe ukuhlunga igesi eshisayo ezitshalweni ezihlukahlukene...

Buka imininingwane -

I-Stainless Steel Porous Metal Sheets SS316 Isihlungi Sokusakazwa Kwegesi Ye-Hydrogen

I-Stainless Steel Porous Metal Sheets SS316 Isihlungi Sokusakazwa Kwegesi Ye-Hydrogen Vula Ukuhlukahluka Kwezinto Zensimbi Ezisikiwe nge-HENGKO! Imeta yethu ehlanganisiwe...

Buka imininingwane -

I-HENGKO Ivala Amagciwane Ibanga Lemidiya Lokuhlunga 0.2 5um Isihlungi Semidiya Sintered Porous...

Sethula Isihlungi Se-HENGKO Esenza Inzalo Yebanga Lensimbi Yezicelo Zesayensi Yezempilo Nezesayensi Yezempilo! Isihlungi sensimbi esisanda kwakhiwa sika-HENGKO si...

Buka imininingwane -

Isihlungi se-Porous Metal Metal Sintered Stainless Stainless Steel Disc Filter for Fiberf Yarn Production / P...

Izihlungi ze-Porous Metal Idizayini yesihlungi sensimbi ye-HENGKO enezimbobo ihlinzeka ngempilo eyengeziwe nokusebenza ekuhlungeni kwephakethe le-polymer spin. Isihlungi siyi-sintered,...

Buka imininingwane -

Isihlungi se-Porous Disc esingu-47mm 316L SS Sintered Metal Filter for Laboratory Bench Scale Testing

Isihlungi sebhentshi esiphezulu se-HENGKO (isihlungi sokuhlola idiski esingu-47mm), isihlungi sethu sediski esingu-47mm, siyindlela elula, engabizi kakhulu yokuhlukanisa uketshezi oluqinile futhi oluqinile nge-...

Buka imininingwane -

I-Industry Stainless Steel Powder Sintered Metal Filter Media Yokuvikela Umlilo

Izwa Ukuphepha Okungenakuqhathaniswa Nokusebenza Kahle Ngezindlu ze-HENGKO's Gas Sensor! Uma kuziwa ekuvikeleni izinzwa zakho zegesi nokuqinisekisa indawo evikelekile...

Buka imininingwane -

I-Sintered Stainless Stainless Stainless Sanitary Tri Clamp Filter Disc ene-Viton O-Ring frit Gasket f...

Kwa-HENGKO® sizama ukusiza amakhasimende ethu akhe imisebenzi yekhwalithi ephezulu, ephephile, nenembayo yokucubungula i-hemp. Izisetshenziswa ezinhle kakhulu ze-CBD esiziphindayo...

Buka imininingwane -

Umkhiqizi Wesihlungi Sesihlungi Se-Porous Metal Sintered Sintered Disc Strainers -HENGKO

I-HENGKO ikhiqiza amawasha ayisipele eVenus, Kitty, Class, kanye namabhodwe kaMusa Moka. Iphakheji ihlanganisa iwasha kanye nepuleti lesihlungi sekhofi. I-diameter ye-GasketSicela...

Buka imininingwane -

insimbi engagqwali eyi-sintered 316L yethusi enezimbotshana zokuhlunga umoya isilinda/ikhandlela

Sethula Izihlungi Zamakhandlela ze-HENGKO: Izixazululo Ezihlanganisiwe Zezidingo Zakho Zokuhlunga Kwezimboni! Izici Zomkhiqizo: - Ukuhlunga Okufanelekile: Izihlungi zethu zamakhandlela ziyi ...

Buka imininingwane -

I-Micron replacement sintered steel stainless porous metal filter disc

Sethula Izihlungi Zensimbi Engagqwali Yezinga eliphezulu ze-HENGKO ze-HENGKO I-HENGKO ingumkhiqizi oholayo wensimbi engagqwali enezimbobo zensimbi...

Buka imininingwane -

D6.1 * H1.6 20um sintered metal elinezimbobo zensimbi engagqwali isihlungi disc

Sethula Idiski Yesihlungi Se-HENGKO: Khipha Amandla Okuhlunga Okunembile! Ingabe ufuna i-sintered filter disc enikeza okuhlukile...

Buka imininingwane

Izici Eziyinhloko:

I-Sintered Stainless Steel Filter Disc iyaziqhenyaamandla aphezulu mechanical, ukuqina okuhle, futhiipulasitiki,

kanye neukumelana okuhle kakhulu to i-oxidationfuthiukugqwala. Akudingi skeleton eyengeziwe

ukuvikela ukusekela, ukwenza ukufakwa nokusebenzisa kulula futhi kulula ukuyinakekela. Le diski yokuhlunga ingaba

sintered nge 304 noma316izindlu, eziboshelwe, futhi zenziwe ngomshini ukuze zihlangabezane nezidingo ezithile zephrojekthi.

Amadiski okuhlunga ensimbi engagqwali ye-Sintered ayizici ezihlukahlukene ezisetshenziswa ezimbonini ezihlukahlukene ngezinjongo zokuhlunga. Lawa madiski akhiqizwa ngenqubo ebizwa ngokuthi i-sintering, lapho izinhlayiya zensimbi engagqwali zihlanganiswa futhi zishiselwe ukuze zakhe isakhiwo esinezimbotshana. Nazi ezinye izici nemisebenzi yamadiski okuhlunga ensimbi engagqwali ye-sintered:

Izici:

1. Izinto Zensimbi Engagqwali:Amadiski okuhlunga e-Sintered enziwe ngensimbi engagqwali yekhwalithi ephezulu, enikeza ukumelana nokugqwala okuhle kakhulu nokuqina.

2. Isakhiwo Sezimbotshana:Inqubo ye-sintering idala isakhiwo esinezimbotshana ezinobukhulu obufanayo bembotshana, okuvumela ukuhlungwa okusebenzayo nokuhlukaniswa kwezinhlayiya.

3. Ububanzi Obubanzi Bosayizi Bembotshana:Lawa madiski okuhlunga atholakala ngosayizi ohlukahlukene wezimbotshana, okuwenza afaneleke ukuhlunga izinto ezahlukahlukene ukusuka kokumahhadla kuya ezinhlayiyeni ezinhle.

4. Ukusebenza Okuphezulu Kokuhlunga:Ukusatshalaliswa kosayizi we-pore okufanayo kanye nokulawulwa kuqinisekisa ukusebenza kahle kokuhlunga ngenkathi kugcinwa ukwehla kwengcindezi ephansi.

5. Ukumelana Kwamakhemikhali Nokushisa:Amadiski okuhlunga ensimbi engagqwali e-Sintered angamelana nezinhlobonhlobo zamakhemikhali nezimo ezishisayo, awenze afanelekele ukusetshenziswa okuhlukahlukene.

6. Kulula Ukuhlanza Nokusebenzisa Kabusha:Lawa madiski okuhlunga angahlanzwa kalula futhi asetshenziswe kabusha, anciphise isidingo sokushintshwa njalo futhi kuncishiswe imfucuza.

7. Izimo Nosayizi Ongenziwa Ngezifiso:Abakhiqizi banikela ngezinketho zokwenza ngokwezifiso zomumo nosayizi ukuze kulingane imishini ethile yokuhlunga nezinhlelo zokusebenza.

8. Ukuqina kanye nokuzinza:Inqubo ye-sintering inikeza amadiski okuhlunga ngokuqina kwesakhiwo nokuzinza, ukuqinisekisa ukuthi agcina ukwakheka kwawo nokusebenza ngesikhathi sokusetshenziswa.

Imisebenzi:

1. Ukuhlunga:Umsebenzi oyinhloko wamadiski okuhlunga ensimbi engagqwali ukuhlunga ngokuphumelelayo nokususa ukungcola, ukungcola, noma izinhlayiya eziwuketshezi noma amagesi.

2. Ukwehlukana:Lawa madiski okuhlunga angasetshenziswa ukuhlukanisa izinto ezihlukene ngokusekelwe kusayizi wabo wezinhlayiyana, ukuqinisekisa ukuthi izingxenye ezifunwayo ziyagcinwa noma zisusiwe kungxube.

3. Ukuvikelwa:Amadiski okuhlunga ensimbi engagqwali e-Sintered asetshenziselwa ukuvikela okokusebenza okubucayi, amaphampu, nezinsimbi emonakalweni odalwe yizinhlayiya noma udoti.

4. Ukuhlanzwa:Baqashwe ezinqubweni zokuhlanza ukuze kucwengwe uketshezi namagesi, kuqinisekiswe imikhiqizo yokugcina yekhwalithi ephezulu.

5. Ukulawula Ukugeleza Komoya Nokungena komoya:Amadiski okuhlunga ane-porosity elawulwayo asetshenziselwa izinhlelo zokusebenza zokuvula umoya, okuvumela ukugeleza komoya noma igesi ngenkathi kuvimbela ukudlula kokungcola.

6. I-Fluidization:Kwezinye izinhlelo zokusebenza, amadiski okuhlunga asiza ezinqubweni zokukhipha amanzi, okusiza ukulawula ukugeleza nokusabalalisa kwamagesi noma uketshezi ngombhede wezinhlayiya.

7. Ukulawula Uthuli Nokungcolisa:Amadiski okuhlunga ensimbi engagqwali e-Sintered asetshenziswa kuzilungiselelo zezimboni ukulawula ukukhishwa, ukuthwebula uthuli nezinhlayiya ukuze kuhambisane nemithetho yemvelo.

8. Usekelo lwe-Catalyst:Kwezinye izimo, lawa madiski okuhlunga asebenza njengezakhiwo zokusekela i-catalyst ezinqubweni zamakhemikhali, athuthukise ukusebenza kahle kokusabela futhi enze kube lula ukuhlukana ngemva kokusabela.

Lezi zici nemisebenzi zigqamisa ukubaluleka kanye nokuguquguquka kwamadiski okuhlunga ensimbi engagqwali e-sintered kuzinhlelo zokusebenza eziningi zezimboni lapho ukuhlunga nokwehlukanisa kudlala indima ebalulekile.

Uma unezidingo eziphakeme zendawo yokuhlunga kanye nezidingo zedatha yokulawula ukugeleza, ithimba lonjiniyela be-HENGKO

izoklama izixazululo ezinhle kakhulu zeisihlungi sensimbi esine-sinteredi-disc ukuze uhlangabezane nezidingo zakho eziphakeme kanye namaphrojekthi wamazinga.

Kungani i-HENGKO Sintered Filter Disc

I-HENGKO ingumkhiqizi owaziwayo wezihlungi ze-porous stainless steel disc eziklanyelwe ukuhlangabezana nezidingo ezihlukahlukene zohlelo lokusebenza.

Imikhiqizo yethu yakhelwe ngendlela emisha nokwenza ngokwezifiso ukuze kuqinisekiswe ukuthi uthola umkhiqizo ofanele izidingo zakho.

Siyaziqhenya ngomlando wethu omdala wokuhlinzeka ngemikhiqizo yekhwalithi ephezulu, evame ukusetshenziswa ekuhlungeni okuphakeme kwezimboni,

ukudambisa, i-sparger, ukuvikela inzwa, ukulawula ingcindezi, nezinye izinhlelo zokusebenza eziningi. Imikhiqizo yethu yenzelwe ukuhlangabezana ne-CE

amazinga futhi aziwa ngokuzinza nokuphila isikhathi eside.

Kwa-HENGKO, sinikeza ukwesekwa okuphelele, kusukela kwezobunjiniyela kuya ezinsizeni ze-aftermarket, siqinisekisa ukuthi uthola usizo oludingayo.

kuwo wonke umjikelezo wokuphila womkhiqizo. Ithimba lethu lochwepheshe linolwazi olunzulu kumakhemikhali ahlukahlukene, ukudla, nesiphuzo

izicelo, okusenza sibe uzakwethu ophelele wezidingo zakho zokuhlunga.

✔ Umkhiqizi owaziwayo embonini ye-PM wezihlungi zediski yensimbi engenazimbobo

✔ Imiklamo eyenziwe ngokwezifiso ehlukile njengosayizi ohlukile, izinto zokwakha, izendlalelo kanye nokwakheka

✔ Imikhiqizo yekhwalithi ephezulu ngokuqinile njenge-CE standard, ijamo elizinzile

✔ Isevisi esuka kubunjiniyela kuze kufike ekusekelweni kwemakethe yangemuva

✔ Ingcweti ekusetshenzisweni okuhlukahlukene ezimbonini zamakhemikhali, zokudla neziphuzo

Ukusetshenziswa Kwediski Yesihlungi Sensimbi Engagqwali :

Kokuhlangenwe nakho kwethu, sithole ukuthi ama-disc okuhlunga ensimbi ayimpushana asebenza kahle kakhulu ezinhlelweni ezihlukene zezimboni.

Lawa madiski okuhlunga alungele ukusetshenziswa ku-distillation, ukumuncwa, ukuhwamuka, ukuhlunga, nezinye izinqubo ezimbonini ezifana ne-petroleum,

ukucwenga, amakhemikhali, imboni elula, imithi, insimbi, imishini, umkhumbi, ugandaganda wezimoto, nokunye. Ziyasebenza ngokukhethekile

ekukhipheni amaconsi kanye negwebu eliwuketshezi elifakwe kusitimu noma igesi, okuholela ekuphumeni kwekhwalithi ephezulu.

Ukuhlunga Uketshezi

Insimbi engagqwali isihlungi discs kabanzi for liquid filtration izicelo. Angasetshenziselwa ukuhlunga amanzi, amakhemikhali, amafutha, nolunye uketshezi. I-wire mesh iklanyelwe ukubamba izinhlayiya ezinosayizi abahlukene, ukuqinisekisa ukuthi uketshezi oluhlungiwe alunakho ukungcola.

Ukuhlunga Kwegesi

Amadiski okuhlunga ensimbi engagqwali nawo angasetshenziselwa izinhlelo zokusebenza zokuhlunga igesi. Asetshenziswa kakhulu embonini yezimoto ukuhlunga umoya ngaphambi kokuthi ungene enjinini. Angasetshenziswa futhi kuzilungiselelo zezimboni ukuhlunga amagesi afana ne-nitrogen, umoya-mpilo, ne-hydrogen.

Ukuhlunga Ukudla Neziphuzo

Amadiski okuhlunga ensimbi engagqwali aphephile ukusetshenziswa ezinhlelweni zokuhlunga ukudla nesiphuzo. Angasetshenziselwa ukuhlunga uketshezi olufana newayini, ubhiya, namajusi ezithelo. I-wire mesh yakhelwe ukubamba izinhlayiya nokungcola, iqinisekise ukuthi umkhiqizo ohlungiwe umsulwa futhi uphephile ukusetshenziswa.

Ukuhlunga Kwemithi

Amadiski okuhlunga ensimbi engagqwali avame ukusetshenziswa ezinhlelweni zokuhlunga kwezemithi. Angasetshenziswa ukuhlunga uketshezi namagesi ekukhiqizeni izidakamizwa neminye imikhiqizo yemithi. I-wire mesh yakhelwe ukucupha amagciwane nokunye ukungcola, kuqinisekiswe ukuthi umkhiqizo wokugcina uphephile futhi uyasebenza.

Ngokuzibophezela kwethu emikhiqizweni yekhwalithi ephezulu, ukwesekwa kochwepheshe, nemiklamo emisha, i-HENGKO ikulungele

uzakwethu kuzo zonke izidingo zakho zediski lokuhlunga.

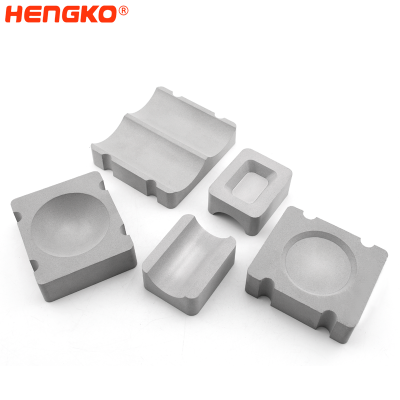

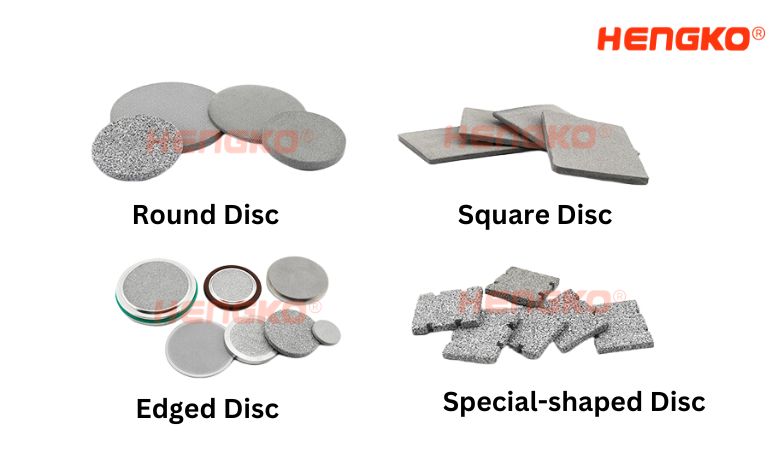

Izinhlobo ze-Sintered Metal Filter Disc

Amadiski okuhlunga ensimbi anezinhlobo ezehlukene, ngalinye lakhelwe ukubhekelela izidingo ezithile zokuhlunga nezinhlelo zokusebenza. Lezi zinhlobo zihlukaniswa ngokusekelwe ekwakhekeni kwazo okubalulekile, usayizi wezimbotshana, kanye nokusetshenziswa okuhlosiwe. Nazi ezinye izinhlobo ezijwayelekile zamadiski okuhlunga ensimbi:

1. I-Stainless Steel Sintered Filter Disc:Uhlobo oluvame kakhulu, olwenziwe ngensimbi engagqwali, lunikeza ukumelana nokugqwala okuhle kakhulu nokuqina. Isetshenziswa kabanzi ezimbonini ezahlukahlukene zokuhlunga okujwayelekile kwezicelo.

2. Idiski Yesihlungi Sethusi:Amadiski esihlungi esine-bronze aziwa ngokuqina kwawo okuphezulu futhi avame ukusetshenziselwa ukuhlunga uketshezi namagesi ezinhlelweni ezidinga ukuhlungwa okuhle.

3. I-Nickel Sintered Filter Disc:Amadiski okuhlunga ane-nickel asetshenziswa ezindaweni ezinamazinga okushisa aphezulu nezimo zamakhemikhali ezinolaka, ngenxa yokumelana okukhethekile kwe-nickel nokugqwala.

4. I-Copper Sintered Filter Disc:Amadiski okuhlunga e-Copper sintered athola ukusetshenziswa ekuhlungeni amagesi noketshezi kuyilapho enikeza ukuguquguquka okuhle kokushisa.

5. I-Titanium Sintered Filter Disc:Amadiski okuhlunga e-Titanium sintered akhethwa ezinhlelweni lapho amandla aphezulu, isisindo esiphansi, nokumelana nokugqwala okuhle kakhulu kubalulekile.

6. I-Inconel Sintered Filter Disc:Amadiski esihlungi se-Inconel sintered asetshenziswa kuzinga lokushisa elidlulele kanye nezindawo ezonakalisayo, okuwenza afanelekele imisebenzi yokuhlunga eyinselele.

7. I-Monel Sintered Filter Disc:Amadiski okuhlunga e-Monel sintered amelana kakhulu nokugqwala, okuwenza alungele ukuhlungwa ezindaweni zasolwandle nokucutshungulwa kwamakhemikhali.

8. I-Hastelloy Sintered Filter Disc:Amadiski okuhlunga e-Hastelloy sintered asetshenziswa ezinhlelweni ezidinga ukumelana nenhlobonhlobo yemidiya egqwalayo.

9. I-Tungsten Sintered Filter Disc:Amadiski okuhlunga e-Tungsten asetshenziswa emazingeni okushisa aphezulu kanye nokuhlunga amakhemikhali anolaka.

10. I-Porosity-graded Sintered Filter Disc:Lawa madiski okuhlunga anosayizi abahlukahlukene bembotshana kwidiski yonkana, okuvumela ukuhlunga okunembe kakhudlwana ezigabeni ezihlukene.

11. I-Sintered Fiber Metal Filter Disc:Yenziwe ngemicu yensimbi, lolu hlobo lwesihlungi sediski lunikeza i-porosity ephakeme nendawo engaphezulu, olwenza ukuhlunga okusebenzayo kwezinhlayiya ezinhle.

12. I-Multi-Layer Sintered Filter Disc:Ihlanganisa izendlalelo eziningi ezinama-porosities ahlukene, lolu hlobo lwediski lokuhlunga luhlinzeka ngomthamo othuthukisiwe wokuhlunga futhi

ingasetshenziselwa imisebenzi yokuhlunga eyinkimbinkimbi.

Kubalulekile ukukhetha uhlobo olufanele lwediski yesihlungi sensimbi e-sintered ngokususelwe kuzimfuneko ezithile zohlelo lokuhlunga, njengosayizi wezinhlayiyana, ukuhambisana kwamakhemikhali, izinga lokushisa, nezimo zokucindezela. Uhlobo ngalunye lwediski yokuhlunga lunikeza izinzuzo eziyingqayizivele kanye nemikhawulo, ngakho ukukhetha elungile kuqinisekisa ukusebenza kahle kokuhlunga nokuqina.

I-Sintered Filter Engineered Solutions Umhlinzeki Wakho Ongcono Kakhulu

Eminyakeni engu-20+ edlule, i-HENGKO inikeze izixazululo zokuhlunga okuningi okuyinkimbinkimbi nokulawula ukugeleza

izidingo zamakhasimende kuzo zonke izinhlobo zezimboni emhlabeni jikelele. Ithimba lethu lochwepheshe lingakwazi ngokushesha

hlinzeka ngezixazululo ezihambisana nezinhlelo zakho zokusebenza zobunjiniyela eziyinkimbinkimbi.

Xhumana nathi namuhla ukuze uxoxe ngephrojekthi yakho nethimba le-HENGKO R&D, futhi sizothola uchwepheshe ongcono kakhulu

isixazululo sediski sesihlungi sensimbi sephrojekthi yakho phakathi nesonto elilodwa.

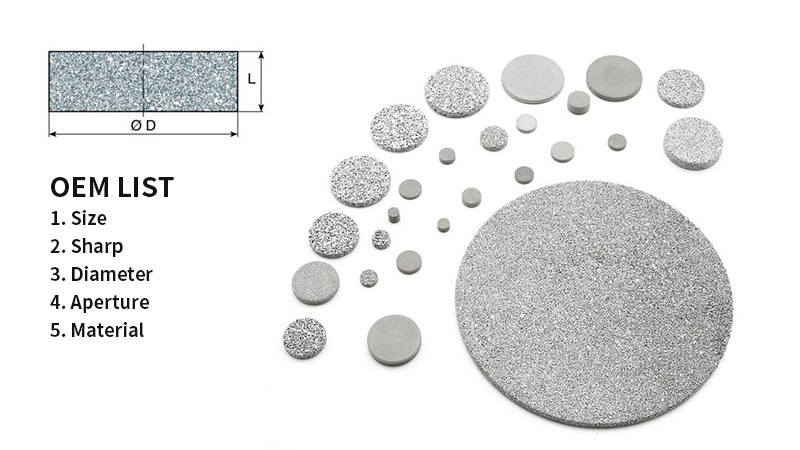

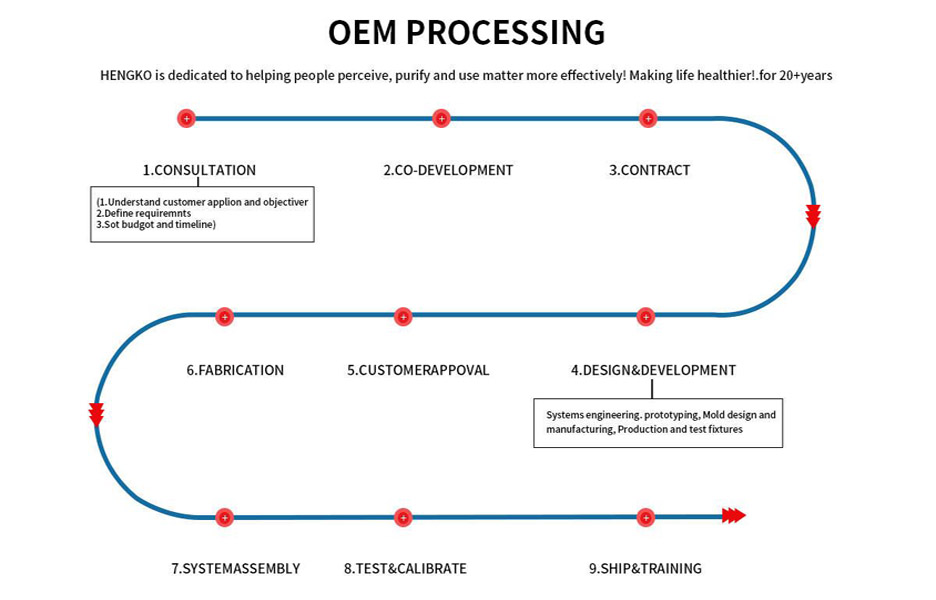

Ulenza kanjani ngokwezifiso i-Metal Sintered Stainless Steel Filter Disc

Uma unedizayini ethile yamaphrojekthi akho futhi ungakwazi ukuthola umkhiqizo ofanayo noma ofana nawo wokuhlunga insimbi engagqwali,

wamukelekile ukuthintana noHENGKO. Sizosebenzisana ukuze sithole isixazululo esingcono kakhulu. Nansi inqubo ye-OEM sintered

i-stainless steel filter disc:

1. Ukubonisana futhi Xhumana HENGKO

2. Ukuthuthukiswa ngokubambisana

3. Yenza Inkontileka

4. Design & Development

5. Ukuvunyelwa Kwekhasimende

6. Ukukhiqiza / Ukukhiqizwa Okuningi

7. Umhlangano Wesistimu

8. Hlola & Linganisa

9. Ukuthumela Nokuqeqeshwa

I-HENGKO izinikele ekusizeni abantu babone, bahlanze futhi basebenzise indaba ngempumelelo, okwenza impilo ibe nempilo iminyaka engaphezu kwengu-20.

Sicela uhlole inqubo futhi usithinte ukuze nixoxe ngemininingwane eyengeziwe.

I-HENGKO iyimboni enolwazi ehlinzeka ngokuyinkimbinkimbiisihlungi sensimbi engagqwali sinteredizakhi zezinhlelo zokusebenza eziningi.

Sisebenze nezinkulungwane zamalebhu, amanyuvesi, kanye neminyango ye-R&D yezinkampani zomkhiqizo emhlabeni jikelele. Amanyuvesi amaningi,

njengalokhu okulandelayo, bebengabalingani bethu besikhathi eside. Wamukelekile ukuthi usithinte futhi usebenze nethimba le-HENGKO.

Uzothola izixazululo zakho ngokushesha.

I-FAQ Edumile mayelana Nediski Yesihlungi Sensimbi Engagqwali

1. Iyini i-Stainless Steel Filter Disc?

Obeye aziwe njengoinsimbi engagqwali isihlungi discskanye namadiski anezikhala ezincane, lawa madiski anezimbobo ezincane ezinosayizi wembotshana

bamba izinhlayiya ezincane kakhulu.

Okuvamile Amadiski anezikhala zocingo avame ukusetshenziswa kumalabhorethri nasezinhlelweni zokubhubhuza igesi (sparging).

Zenziwe ngo-316L ezingenasiciinsimbi ngenxa yokugqwala okuhle kakhulu nokumelana nemihuzuko.

Amadiski okuhlunga anensimbi engagqwali asetshenziswa kakhulu ukuhlunga ezinjinini zikadizili, isihlungi somfutho, imicu yamakhemikhali kanye

i-plastic extruder, i-textile dope filtration, imayini, amanzi, ukudla, nezinye izimboni.I-Sintered metal 316l engenasici

i-steel filter disc isiza ukuhlola noma ukuhlukaniswa kwento eyodwa kwenye,ukwenza kube nokwenzeka kuwe

khipha ukungcola okungadingekile kokuqinile noma oketshezini.

Inqubo yokukhiqiza yeisihlungi sensimbi engagqwalii-disc ihlanganisa izinyathelo ezintathu eziyinhloko.

Isinyathelo sokuqala sihlanganisa ukukhethwa kwentambo yensimbi engenasici yekhwalithi ephezulu, kamuva ephonswa ngesibhakela noma yelukwe.

Kudingeka futhi uthole impahla efanelekile yokugoqa unqenqema lwediski enezikhala zocingo.

Futhi, khetha osayizi abahlukene bezimbotshana zempushana yensimbi engagqwali engu-316L ukuze uhlanganise phakathi nendawo kanye ne-sintering.

Amadiski anensimbi engagqwali angaklama futhi enze izimo ezihlukene, amasu okuluka, ukunemba kwesihlungi, kanye

izinto zokugoqa ezinqenqemeni, phakathi kwezinye izici.Ngakho ungakwazi ukuklama lolu hlobo metal isihlungi disc ukufeza yakho

idinga njengezinga lokugeleza, usayizi wezinhlayiyana zokuhlunga, ukulinganiselwa kwesikhala somzimba, noketshezi lokuxhumana.

Njengomunye wochwephesheinsimbi engagqwali isihlungi disc umphakeli, Wamukelekile ukuthi uvakashele Imboni yethu ubuso nobuso

ukukhuluma imininingwane eyengeziwekumaphrojekthi akho, sinesivumelwano sokusayina sokungavezi sokuhlunga okuningi

iphrojekthi yamakhasimende ethu.

2. Yiziphi Izici Eziyinhloko Ze-Sintered Filter Disc?

1. Amandla aphezulu kanye nokuzinza kohlaka lwempilo ende yesevisi.

2. Ukumelana okuhle kakhulu nokugqwala, i-asidi, i-alkali, nokuhuzuka.

3. Ingasebenzisa ukumelana nokushisa okuphezulu ngaphansi kwamazinga okushisa asukela ku -200 °C kuya ku-600 °C.

4. Izilinganiso ezihlukahlukene zokuhlunga ongakhetha kuzo noma wenze ngendlela oyifisayo kanye nokunemba okukhulu kwesihlungi sezinhlelo zokusebenza ezahlukene.

5. Umthamo omuhle wokubamba ukungcola.

6. Kulula ukuhlanza nokusebenziseka kabusha, kunciphisa isikhathi sokuphumula nokonga izindleko.

7. Ngokwezidingo ezihlukahlukene zephrojekthi, i-Sintered Metal Filter Disc ingalolongwa ibe yindilinga, isikwele,

unxande, okusaqanda, indandatho, nokunye. Kungakhethwa ungqimba olulodwa noma ungqimba oluningi.

Ngakho-ke, ukusebenza okuthembekile okunesikhathi esiphezulu se-inthanethi nokugcinwa okuphansi; Bonisa nubuchwepheshe ew

ngezinga lezentengiselwano.

3.Izihlungi ze-Sintered zisetshenziselwa ini?

Izihlungi ze-Sinteredyakhelwe futhi yasetshenziswa njengento entsha yokuhlunga yokudla, isiphuzo,

Ukwelashwa kwamanzi, ukususwa kothuli, izimboni zemithi, kanye ne-polymer ngenxa yobuhle obuhle kakhulu

ukusebenza kwezihlungi ezi-sintered, okuhlanganisa amandla aphezulu emishini yezihlungi ezi-sintered kanye nobubanzi

ububanzi bamabanga okuhlunga.

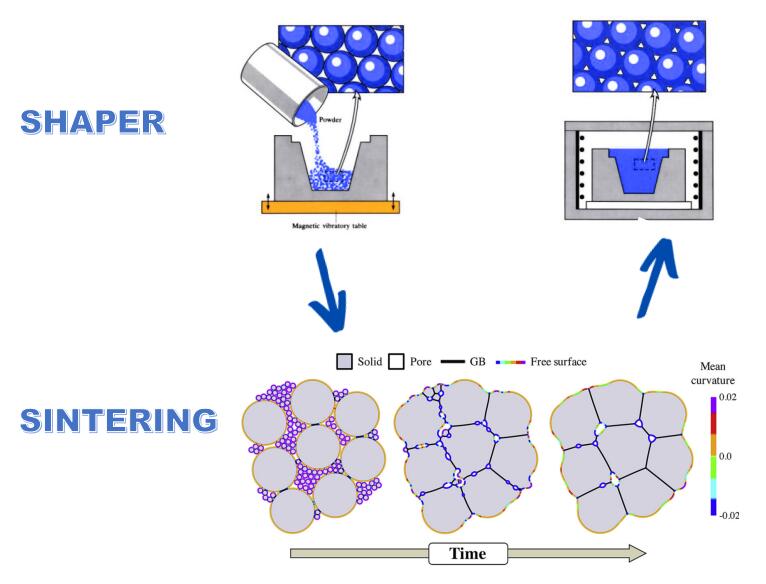

4. Lisebenza kanjani Idiski Lokuhlunga Le-Sinered?

Kafushane, inqubo yokukhiqiza yezihlungi ezi-sintered iqukethe izinyathelo ezi-2

1. Ukubumba

2. Ukucula

Kodwa-ke, ngaphambi kokubunjwa nokucwiliswa, kufanele siqinisekise nekhasimende umklamo, usayizi, i-porosity,

izimfuneko zokugeleza, okokusebenza, kanye nokuthi isihlungi sinezindlu ezinentambo ukuze zifakwe kalula.

Izinyathelo zokukhiqiza ze-cartridge e-sintered zimi kanje.

5. Iluphi uhlobo Lwensimbi Engagqwali olusetshenziswa kakhulu I-Filter Disc?

Amamaki ayisihluthulelo e-stainless steel powder afanele ukukhiqizwa kohlobo lwensimbi engagqwali

I-sintered filter disc ihlanganisa:

1.) Insimbi engagqwali 316, ehlanganiswe ne-manganese, i-silicon, i-carbon,izakhi ze-nickel ne-chromium.

2.) Insimbi engagqwali316L, Inenani eliphansi lokuqukethwe kwekhabhoni uma kuqhathaniswa nensimbi engagqwali 316.

amamaki okudla ezinhlelo zokusebenza eziningi ahlanganisa Ukudla nokudla kanye nokuhlunga kwezokwelapha njll

3.) Insimbi engagqwali 304, Ihlanganisa insimbi ye-nickel ne-chromium okuyizinto ezingezona ayoni.

4.) Insimbi engagqwali engu-304L, Inenani eliphezulu lokuqukethwe kwekhabhoni uma kuqhathaniswa nensimbi engagqwali engu-304.

ngokuqinisekile intengo izoba ngaphansi kuka-316L, 316, njll

6. Ulihlanza Kanjani Idiski Lokuhlunga Insimbi Engenasici?

Kunezindlela eziningana zokuhlanza amadiski okuhlunga ensimbi engagqwali, ngokukhetha indlela ngayinye

kuye ngohlobo lwakho kanye nezinga lokusebenza.

Ake sibheke ezinye zezindlela ezivamile zokuhlanza izihlungi zensimbi.

1) I-Blowback kanye ne-Backwash Flushing

Ingenye yezindlela ezilula zokuhlanza amadiski okuhlunga.

Ukuze i-backwash isebenze ngempumelelo, kuncike ekugelezeni okubuyela emuva koketshezi oluzophuma

futhi uphathe izinhlayiya kude nesakhiwo semidiya.

Uketshezi olusetshenziswayo ngokuvamile luyahlungwa noma olunye uketshezi oluhambisana nenqubo.

Inqubo ye-blowback ne-backwashing incike ekunamathiselwe okuxekethile kwezinhlayiya noma

ngaphakathi kwezimbobo ze-mesh yokuhlunga.

Ukusebenzisa igesi njengomthombo wengcindezi esikhundleni soketshezi kudala isiyaluyalu njengoba kukhiqizwa

ingcindezi iphoqa ingxube yegesi/uketshezi nge-filter disc mesh.

2) Gcoba bese ugeza

Ukuhlanza amadiski okuhlunga ensimbi engagqwali kubhekisela ekusebenziseni isisombululo sokuhlanza.

Kule nqubo, uvumela i-disc yokuhlunga ukuthi icwiliswe ngokwanele ukuze kwenziwe okokuhlanza

khulula izinhlayiya futhi uzikhiphe ngaphandle kwemidiya yesihlungi.

Elabhorethri, ungenza le nqubo ekucubunguleni amadiski okuhlunga ensimbi engagqwali noma ngamancane

izingxenye.

3) Ukugeleza Kwegazi

Kule ndlela yokuhlanza i-disc yokuhlunga i-wire mesh, udinga uhlelo lokuhlanza ukusiza ukupompa kanye

zungeza ikhambi lokuhlanza kuyo yonke i-mesh yokuhlunga ize ihlanzeke.

Ukusakazwa kuvame ukubheke kolunye uhlangothi lapho i-mesh yesihlungi yediski ibingcoliswe khona.

Kufanele uhlunge isisombululo sokuhlanza ngaphambi kokusibuyisela kumidiya yesihlungi.

4) Amabhavu e-Ultrasonic

Le nqubo idinga imishini ekhethekile esebenzisa amaza omsindo we-ultrasonic ukuze icuphe

izinhlayiya bese uzikhipha ku-mesh yokuhlunga.

Ungasebenzisa amamodeli aselabhorethri alo mshini ukuze uhlanze kalula amadiski okuhlunga ensimbi engagqwali,

kanti ezinkulu zidinga okokusebenza kwethangi elikhulu elinamandla amakhulu.

Ukuhlanza kwe-ultrasonic, ngokuhambisana nesisombululo esifanele sokuhlanza, kuyindlela ephumelela kakhulu

ukuhlanza amadiski okuhlunga, ikakhulukazi endabeni yezinhlayiya ezishunyekiwe ngokujulile.

5) Ukuhlanza Isithando somlilo

Futhi kuyindlela elula yokuhlanza amadiski okuhlunga ensimbi ngokushisa noma ngokushisa i-biological noma

ama-organic compounds.Isebenza kahle kakhulu ekususeni izinto ze-polymer.

Isithando somlilo sensimbi engagqwali yokuhlanza idiski ifanele izinto ezingashiyi umlotha osele.

Uma kungenjalo, uzodinga indlela yokuhlanza eyengeziwe ukuze ususe izinsalela zomlotha.

6) I-Hydro Blasting

Amasu okuhlanza i-Hydro blasting ngokuvamile adlula amanye amasu okuhlanza lapho izinhlayiya

zivimbe izimbobo ze-mesh yokuhlunga.

Ungasebenzisa le ndlela ukuhlanza, isibonelo, ukuhlunga amadiski kumashubhu agelezayo.

Ijethi lamanzi elinengcindezi ephezulu isusa izinhlayiya eziboshiwe ngokusebenzisa amandla aphezulu.

Ayingeni ijule kakhulu kwi-mesh yokuhlunga; Nokho, ezimweni eziningi, ukuvinjelwa kungase kube kuphela

endaweni yesihlungi semidiya.

Isetshenziswa kakhulu ezitshalweni, futhi imvamisa isetshenziselwa ukuhlanza amashubhu okushintsha ukushisa.

7. Yiziphi Izinto Okufanele Uzicabangele Lapho Ukhetha Idiski Yesihlungi Sensimbi Engagqwali?

Lapho Ukhetha idiski yesihlungi sensimbi esilungile ukuze uqinisekise ukusebenza kahle kohlelo lwakho lokuhlunga,

Ngakho-ke, kufanele ucabangele izici ezilandelayo lapho ukhetha i-disc yokuhlunga yensimbi engagqwali:

-

Uhlobo Lwemidiya Yesihlungi

Kunezinhlobo ezahlukene zemidiya yokuhlunga, njengefayibha yensimbi engahleliwe, eqoshiwe, ne-sintered

imidiya yokuhlunga, ngayinye inezinzuzo zayo kanye nokubi.

Ngakho-ke, kufanele ukhethe i-disc yokuhlunga engagqwali enemidiya yokuhlunga efanele yezinhlelo zakho zokusebenza.

-

Uhlobo Lwensimbi Engagqwali Esetshenziswayo

Insimbi engagqwali iza ngezinhlobo ezahlukene, ngohlobo ngalunye lunezinzuzo ezifanele izinhloso ezahlukene.

Ngaphambi kokuyithenga, kubalulekile ukuthola izici ngazinye zezinto ezisetshenziselwa ukwenza idiski yokuhlunga.

Izici ezinjalo zihlanganisa ingcindezi, imikhawulo yokushisa, nokusabela kwezinye izinhlanganisela nezimo.

-

Inombolo ye-Mesh

Yinombolo yezimbobo iyintshi ngayinye yemeshi yesihlungi sensimbi engagqwali.

Uma inombolo yemeshi inkulu, ikhombisa izimbobo eziningi iyintshi ngayinye ye-filter disc mesh.

Kuphinde kusho ukuthi izimbobo ngazinye zincane futhi ngokuphambene nalokho.

-

Usayizi We-Mesh

Usayizi wemeshi uchaza usayizi wezimbobo ngazinye kumeshi wediski yesihlungi sensimbi engagqwali.

Ihlala ikalwa ngamamilimitha, ama-microns, noma ama-intshi angama-fractional.

-

I-Strand Diameter

Kuwukucatshangelwa okubalulekile lapho ukhetha idiski yesihlungi sensimbi engagqwali.

Uma ucingo lunobubanzi bomucu obanzi, kusho ukuthi linezimbobo ezincane ezinezikhala.

Ngamafuphi, uma ubukhulu be-strand buba bukhulu, bukhulu inombolo ye-mesh yediski yokuhlunga e-sintered.

Ububanzi bomucu iphesenti lendawo yonke yendawo yesihlungi sensimbi engagqwali, okungukuthi,

iphesenti lendawo evulekile.Ngakho-ke, ukuba nephesenti elikhulu lendawo evulekile kubonisa

ukuthi i-disc yokuhlunga inokugeleza okuphezulu.

-

I-Filament Diameter

Le pharamitha ithinta ukuvuleka kwemeshi kanye nephesenti lendawo evulekile yemeshi yesihlungi.

-

Ukuhambisana Kwe-Fluid

Kufanele uqinisekise ukuthi idiski yesihlungi sensimbi engagqwali ihambisana kahle noketshezi ofuna ukuluhlunga.

Kuyasiza ukugwema noma yikuphi ukusabela phakathi kwediski yokuhlunga kanye noketshezi oluhilelekile njengoba noma yikuphi ukusabela kuyokwenza

kunomthelela omubi kwikhwalithi yenqubo yokuhlunga.

8. Ingabe kukhona Umkhawulo Womumo Wediski Yesihlungi Socingo Lwensimbi Engagqwali?

Cha, ungaklama njengoba iphrojekthi yakho idinga. yabelana ngosayizi wakho, usayizi wembotshana, isilawuli sokugeleza njll kanye

Xhumana nathingemininingwane.

9. Yiziphi Izinzuzo zama-Sintered Filter Discs?

Izinzuzo Ezine Eziyinhloko zihlanganisa:

1.) Ukuqina

I-Sintered Stainless Stainless filter disc iqinile kakhulu, iyenza ibe yinketho efanelekile yezinhlelo zakho zokusebenza.

Ihlala isikhathi eside njengoba ingasabeli ngoketshezi oluningi.

Iqinisekisa ukuthi unamandla aphelele ediski yakho yesihlungi sensimbi engenasici sintered mesh.

Ngenxa yokuphila isikhathi eside, kuzonciphisa izindleko zakho zokusebenza esikhathini eside.

2. ) Ukuhlukahluka

Insimbi engagqwali sintered isihlungi discs akunikeza inkululeko ukusebenzisa izicelo ezahlukene ngenxa

izakhiwo eziyingqayizivele zamakhemikhali nezomzimba zamadiski okuhlunga ensimbi engagqwali.

Lezi zici zihlanganisa ukugqwala, ukumelana ne-asidi ne-alkali, ingcindezi yokusebenza kanye nezinga lokushisa,

kanye nokuhambisana noketshezi oluhlukahlukene.

3.) Ukusebenza kahle

Uhlobo lwediski yesihlungi sensimbi siqinisekisa ukusebenza kahle ekusebenzeni kwayo.

Ukusebenza kahle kwe-sintered stainless steel filter disc kuqinisekisa ukuthi ungakwazi ukufinyelela kalula okufunayo

izinga lokuhlunga.

4.) Ukuhlanza Kalula

Amadiski okuhlunga enziwe ngensimbi engagqwali izinga eliphezulu lenhlanzeko njengoba kulula ukuwahlanza.

Ukuzisebenzisa ezinhlelweni ezizwelayo kwenhlanzeko njengomkhakha wokudla neziphuzo kwenza kwenzeke.

Ngaphezu kwalokho, ukubukeka okusiliva kwensimbi engagqwali kukhulisa ukukhanga kobuhle bediski lokuhlunga ngenkathi

ukuqinisekisa ukuhlanzeka jikelele kokusebenza kwakho.

Xhumana nathi uma Ufuna Ukuxazulula Imininingwane Yediski Yesihlungi Sensimbi Engagqwali.