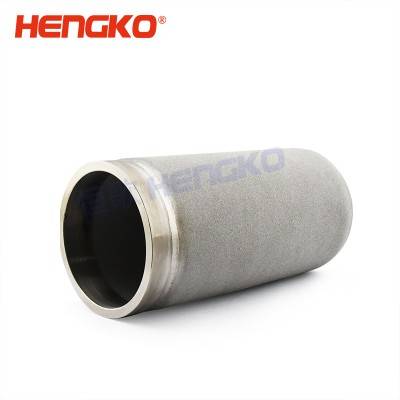

Izihlungi ze-porous metal sintered stainless steel catalyst recovery for catalyst recovery process

Izihlungi ze-porous metal sintered stainless steel catalyst recovery for catalyst recovery process,

I-Porous Metal, isihlungi sensimbi esinezimbotshana, Isihlungi Sensimbi Engagqwali ye-Sintered, Isihlungi Sensimbi Engagqwali,

I-Micron porous metal filtration system isetshenziswa ku-petroleum kanye nenqubo yokukhiqiza amakhemikhali kukho konke ukwahlukanisa okuqinile kwe-liquid-solid kanye ne-gas-solid high, umnyombo wawo okuyingxenye yesihlungi se-metal powder sintered microporous metal, ngokuvamile eyenziwe316L insimbi engagqwali powder, I-Hastelloy, i-titanium, njll. Lesi sihlungi sensimbi esinezimbotshana singakwazi ukuzivumelanisa nezinga lokushisa lenqubo ephakeme kanye nokucindezela kwezinto zokuhlanza nezitshalo zamakhemikhali, futhi siqinisekise umphumela wokuhlunga ngenkathi sifinyelela ukwehla kwengcindezi encane kanye nesilinganiso esiphezulu sokubuyisela i-backwashing.

I-Micron porous metal filtration system ekukhiqizeni i-petrochemical inezici zokumelana nokushisa okuphezulu, ukwehla kwengcindezi ephezulu, ukusebenza kokuqukethwe okuphezulu okuqinile;uketshezi (igesi) kanye nokuhlukaniswa okuqinile okuphezulu nokusebenza kahle;i-backwashing yangaphakathi yesistimu ukususa izinto eziqinile;ukusebenza okuzenzakalelayo okuqhubekayo;futhi ingagwema ukushintshwa njalo kanye nokulahlwa kwezinto zokuhlunga imfucuza ekungcoleni kwemvelo.

Izicelo:

Ukutholwa kwempushana yensimbi eyigugu kanye ne-catalyst yensimbi eyigugu

I-CTA, i-PTA kanye nohlelo lokuvuselela i-catalyst ekukhiqizeni kwe-PTA

I-Coal to olefin (MTO) uhlelo lokuvuselela i-catalyst

Ukuhlunga kwe-oyela slurry namafutha ajikelezayo kuyunithi yokuqhekeka kwe-catalytic

I-Catalyst regeneration flue gas purification kanye neyunithi yokulawula uthuli

Uhlelo lokuhlunga uwoyela we-Feedstock lokuhlanza i-hydrogenation/inqubo yokupheka

I-Catalyst filtration system ye-Raney Nickel (Raney Nickel) inqubo ye-hydrogenation

Isihlungi segesi esihlanzekile esiphezulu se-wafer, imidiya yokugcina, inqubo yokukhiqiza isekethe ehlanganisiwe