-

Imelana Nezinga Lokushisa Eliphakeme Lensimbi Engagqwali Yesihlungi Sesihlungi se-cartridg...

I-Product Chaza Isihlungi se-Sintered powder filter esibuye siqanjwe ngensimbi eyisihlungi esinezimbotshana esenziwe nge-titanium noma impushana yensimbi engagqwali. Kuyisitayela esisha se-m...

Buka imininingwane -

I-Sintered Cartridge Filter ye-Polysilicon

Isihlungi se-cartridge ye-Sintered sokukhiqizwa kwe-polysilicon Izihlungi zensimbi ze-HENGKO sintered zinikeza umoya ohlanzekile, obuye uthuthukise impilo yabantu, uvikele umgxeki...

Buka imininingwane -

Isihlungi Esine-Acid Ne-Alkali Esiqinile Kakhudlwana esingu-316L Isihlungi Sensimbi Engenasici Esingenazimbobo...

Chaza umkhiqizo we-HENGKO isihlungi se-biomedical senziwe nge-316L yensimbi eyimpushana efakwe endaweni yokushisa ephezulu, ene-porosity efanayo engu-0.2-0.5 um, ukugqwala ukumelana...

Buka imininingwane -

20 Micron 316 Stainless Steel Wire Mesh Filter Cartridge Inner Core 32mm Ubude M4 Thread

Isihlungi se-wire mesh i-wire mesh enwetshwa ngokusebenzisa imicu yensimbi, enezimbobo ezinhle phakathi kwemicu yensimbi eyahlukene. Lapho amanzi angcolile empompa...

Buka imininingwane -

Reverse Osmosis Stainless Steel Isihlungi Samanzi Sesihlanzi Sesistimu Yokuhlunga SS 316 M...

I-Reverse Osmosis Stainless Steel Isihlungi Sesihlanzi Samanzi Uhlelo Lokuhlunga I-SS 316 Mesh Cartridge Filter Incazelo Yomkhiqizo Wonke umuntu ufuna i-n...

Buka imininingwane -

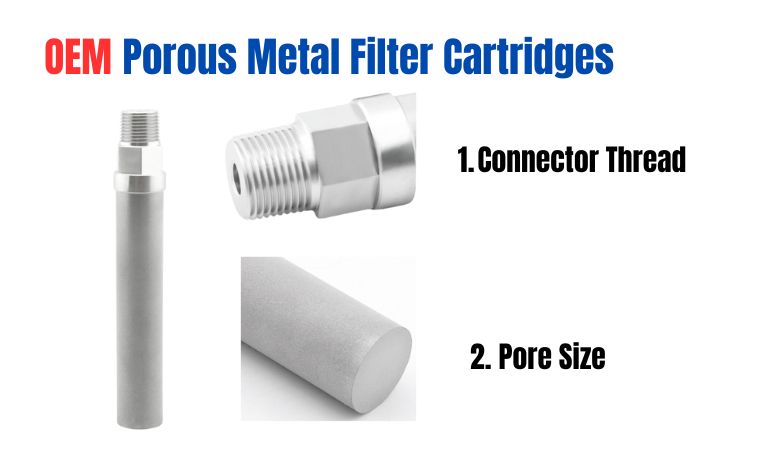

Amakhatriji Esihlungi Sensimbi Engagqwali e-Sintered Okuhlunga Inqubo Yokukhiqiza Izidakamizwa

Ama-cartridges ensimbi ane-porous sinter, ngokuvamile anezixhumi ezenziwe ngokwezifiso (Kwesinye isikhathi izixhumi azingezwa ezimweni ezithile zohlelo lokusebenza), zisetshenziselwa ukuhlukanisa ...

Buka imininingwane -

I-HENGKO Sintered Filter Cartridge for Process Gas and On-line Analysis

Ukuhlunga Kwegesi Nesampula Ukuze Kucutshungulwe Igesi Nokuhlaziywa Kwe-inthanethi Ukuhlungwa kwamagesi kubalulekile ezinhlobonhlobo zezicelo, nokho amamitha amathathu kuphela...

Buka imininingwane -

I-Catalyst porous metal filter imvelo eyedlulele esebenzayo Isampula Lesampula Lokuhlola, ukugeleza okuphezulu ...

Izihlungi zokuhlaziya isampula yegesi neyoketshezi zivikela abahlaziyi ekungcoleni okuyisampula ngokususa inhlabathi noketshezi emagesini ngokusebenza kahle okungu-99.99999+% ku-0.1 m...

Buka imininingwane -

I-316L i-Sintered stainless steel filter cartridge yokuhlukaniswa kwezinto eziqinile zegesi

Amasistimu okuhlunga asebenzisa izakhi zokuhlunga zensimbi ezihlanganisiwe afakazele ukuthi ayindlela ephumelelayo neyongayo kwezinye izinto zokusebenza zokuhlukanisa...

Buka imininingwane -

esikhundleni se-sintered micron porous metal filter cartridges for grease/o...

Isihlungi esine-stainless steel sintered ikakhulukazi sakhiwe amashubhu, amasilinda, amakhatriji, izinkomishi ezine-flange, intambo, nezixhumi, njll... Kufakwe epayipini...

Buka imininingwane -

5 10 micron insimbi engagqwali 316L sintered isihlungi cartridge/isilinda

I-HENGKO inikezela ngezihlungi eziningi ze-cartridge zensimbi ezinezimbobo noma izinsiza eziklanywe ngokwezifiso zokuhlunga okuhle kakhulu ezinhlelweni ezibucayi (phoqelela ukuhlunga okusheshayo...

Buka imininingwane -

Isihlungi se-cartridge yekhwalithi ye-Sintered siqinisekisa isihlungi sensimbi engenamthungo esibandayo esidonsayo ...

Incazelo Yomkhiqizo I-HENGKO amashubhu okuhlunga ensimbi engagqwali enziwa ngokufaka i-sintering 316L powder impahla noma i-multilayer stainless stainless wire mesh emazingeni okushisa aphezulu....

Buka imininingwane -

I-Sintered metal powder steel stainless steel 316L i-industrial dust collector air cartridge

Amashubhu okuhlunga ensimbi engenasici e-HENGKO enziwa ngokufaka i-sintering 316L powder material noma i-multilayer stainless stainless wire mesh emazingeni okushisa aphezulu. Bake ba...

Buka imininingwane -

0.5 5 10 micron filter sintered cartridge for reflow-free oven engenamthofu

Isivikelo se-nitrogen endaweni ehlanganisiwe yomshini wokugcwalisa i-jet, eneshubhu yokuqala yokuhlakaza i-nitrogen enikezwe ngaphambi komlomo wokuqala wejethi ...

Buka imininingwane -

Ikhatriji yesihlungi yensimbi engenasici engu-316L ye-nitrogen ye-lead-free reflow ove...

I-HENGKO inikezela ngezixazululo zesicelo se-nitrogen gas soldering yokugeleza kabusha kanye ne-wave soldering, ukuxazulula izinkinga ezinkulu ezibhekene nomhlangano we-electronics kanye ...

Buka imininingwane -

I-Microporous sintered metal powder insimbi engagqwali ss 304 316L igobolondo lesihlungi

Ama-cartridge we-HENGKO ensimbi engagqwali anconyelwe insizakalo yesitimu futhi afaneleka kahle ukusetshenziswa koketshezi noma igesi okuhlanganisa izincibilikisi, i-chemical interm...

Buka imininingwane -

I-powder enekhono i-sintered micron metal bronze 316 inqola yokuhlunga igesi yemvelo yensimbi engagqwali...

Izimbobo zesihlungi se-cartridge yensimbi engagqwali ziyaphambana futhi amelana nezinga lokushisa eliphezulu nokubanda okusheshayo nokushisa. Imelana nokugqwala. Ifanele i...

Buka imininingwane -

Insimbi engagqwali eyenziwe ngokwezifiso engu-316L imelana nokushisa okuphezulu kwesihlungi somoya...

Chaza umkhiqizo we-HENGKO izihlungi zensimbi engagqwali zenziwe ngokufaka i-sintering 316L powder impahla noma i-multilayer stainless steel stainless mesh in high temperatur...

Buka imininingwane -

I-30-45 / 50-60um i-cartridge yensimbi engenasici ene-sintered yensimbi yokubopha ilangabi

Isibambisi somlilo iyisisetshenziswa esifakwe ekuvuleni kwendawo ebiyelwe, noma kumapayipi axhumayo ohlelweni lwezindawo ezivalekile. Bavumela amagesi noma umhwamuko ukuf...

Buka imininingwane -

micron porous powder sintered metal stainless steel filter cartridges

izihlungi zensimbi ezine-sintered kanye namashubhu anezimbotshana zizihlungi ezinde, eziyisilinda ezinezindonga ezincane, okungukuthi zinesilinganiso esiphakeme sobude ukuya kobubanzi. I-porous metal filter...

Buka imininingwane

Zisetshenziselwani izihlungi ze-Porous Sintered Metal?

Izihlungi zensimbi ezinezimbobo ezinezimbobo zinezimo ezihlukahlukene kakhulu futhi zithola izinhlelo zokusebenza kuwo wonke uhla lwezimboni

ngenxa yokuqina kwazo, ukumelana namazinga okushisa aphezulu nezingcindezi, kanye nokukwazi ukumelana nazo

izindawo ezonakalisayo. Nakhu okunye ukusetshenziswa okuvamile kwalezi zihlungi:

1. Izinhlelo zokusebenza zokuhlunga:

* Ukuhlunga igesi:

2. Ukubuyiselwa Kwe-Catalyst:

Kuma-reactor amakhemikhali, izihlungi zensimbi ezine-sintered zisetshenziselwa ukubuyisela ama-catalysts abizayo asetshenziswa enqubweni yokusabela

3. I-Sparing kanye Nokusabalalisa Igesi:

Lezi zihlungi zisetshenziswa kuma-bioreactors kanye nezinqubo zokuvutshelwa ukwethula amagesi kuketshezi ngendlela elawulwayo,

4. Izicelo Zokuvula umoya:

Ezimbonini zezimoto nezasemoyeni, izimbobo zensimbi ezine-sintered zivikela izinto ezibucayi ngokulinganisa izingcindezi

5. I-Fluidization:

Isetshenziswa ezimbonini zokubamba impushana ukuze ikhiphe izimpushana eziyinqwaba, iqinisekise ukugeleza okushelelayo nokuvimbela ukuvala

6. Aerosol Sampling:

Izihlungi zensimbi ezi-sintered zisetshenziswa emishinini yokuqapha imvelo ukuqoqa amasampula e-aerosol ukuze ahlaziywe,

7. Ukushintshaniswa Kokushisa:

Ngenxa ye-thermal conductivity ephezulu kanye nokumelana nokuguquka kwezinga lokushisa, lezi zihlungi nazo zisetshenziselwa

Izici Eziyinhloko Ze-Porous Metal Filter Cartridges:

1. Ukwakheka Kwezinto Ezibalulekile

Izihlungi zensimbi ezinezimbobo ngokuvamile zenziwa ngezinsimbi ezisikiwe njengensimbi engagqwali (304, 316L),

i-titanium, namanye ama-alloys afana ne-Hastelloy ne-Inconel. Lokhu kwakheka kunikeza okuhle kakhulu

amandla emishini nokumelana nokugqwala nokushaqeka okushisayo.

2. I-Porosity Elawulwayo

Inqubo yokukhiqiza ivumela ukulawula okunembile phezu kosayizi we-pore, kusukela ku-0.5 kuya ku-200 microns.

Lokhu kulawula kusiza ukuhlungwa kwezinhlayiya emazingeni ahlukahlukene, kuzenze zilungele ukuhlunga okuncane

yamagesi noketshezi ngaphansi kwengcindezi ephezulu kanye nezimo zokushisa.

3. Amandla Aphezulu Nokuqina

Lezi zihlungi zingakwazi ukumelana nezingcindezi eziphezulu ezihlukene (kufika ku-3000 psi) kanye nezimo zokusebenza ezinzima,

ukuqinisekisa impilo ende yesevisi kanye nokwethembeka ezinhlelweni ezifunayo.

4. Ukuhlanzeka kanye Nokusebenziseka Kabusha

Amakhatriji esihlungi sensimbi anezimbotshana aklanyelwe ukuhlanzwa futhi asetshenziswe kabusha, ngokuvamile ngezindlela ezinjengalezi

ukuhlanza i-backflushing noma i-ultrasonic. Lesi sici asinciphisi kuphela izindleko zokusebenza kodwa futhi

kuthuthukisa ukuphila kwabo isikhathi eside.

5. Ukumelana Nezishisayo Nezamakhemikhali

Lezi zihlungi zigcina ukusebenza emazingeni okushisa adlulele (kufika ku-930°C) futhi amelana nebanga elibanzi

zamakhemikhali, okuwenza alungele ukusetshenziswa ekusetshenzisweni kwamakhemikhali, kwezemithi, nokudla kanye

izimboni zeziphuzo.

6. Izinketho zokwenza ngokwezifiso

Abakhiqizi banikeza ukwenza ngendlela oyifisayo ngokuya ngezinto ezibonakalayo, usayizi wezimbotshana, nobukhulu ukuze kuhlangatshezwane nalokho

izidingo zohlelo lokusebenza.

Lokhu kuvumelana nezimo kuvumela ukusebenza kahle okuhambisana nezidingo zezimboni ezahlukene.

7. Ukwehla Kwengcindezi Ephansi

Idizayini yezihlungi zensimbi ezinezimbotshana ziqinisekisa ukwehla kwengcindezi ephansi endaweni yokuhlunga, okuthuthukisayo

amazinga okugeleza kanye nokusebenza kahle kohlelo lonke kuyilapho kunciphisa ukusetshenziswa kwamandla.

8. Izicelo Ezihlukahlukene

Lezi zihlungi zisetshenziswa emikhakheni eyahlukene, okuhlanganisa i-aerospace, izimoto, uwoyela negesi, namandla.

ukukhiqiza, kwezinhlelo zokusebenza ezifana nokuhlunga, ukulawula ukugeleza, nokunciphisa umsindo.

Kafushane, ama-cartridges okuhlunga ensimbi anezimbobo zenzelwe ukusebenza okuphezulu nokuguquguquka, ukwenziwa

yizici ezibalulekile ezinhlelweni eziningi zokuhlunga zezimboni.

Ukwakhiwa kwabo okuqinile kanye nekhono lokwenza ngokwezifiso izinhlelo zokusebenza ezithile kuqinisekisa ukuthi bayahlangabezana nezidingo

izimfuno ezinzima zezinqubo zesimanje zokukhiqiza.

Izinhlobo zama-Cartridges Wezihlungi Zensimbi ezinezimbotshana

Ama-cartridges okuhlunga ensimbi asetshenziswa kabanzi ezimbonini ezahlukahlukene ngenxa yezakhiwo zawo ezinhle kakhulu zokuhlunga,

ukuqina, nokumelana namakhemikhali. Imvamisa zakhiwe ngezimpushana zensimbi ezisinkiwe, njenge

insimbi engagqwali, ithusi, noma i-nickel.

Nazi ezinye izinhlobo ezivamile zama-cartridges okuhlunga ensimbi:

1.Ngokusekelwe kusayizi we-Pore:

*Kumahhadla:Osayizi abakhulu bembotshana, abalungele ukususa izinhlayiya ezinkulu njengokungcola, isihlabathi, nemfucumfucu.

*Kuhle:Osayizi bembotshana abancane, abalungele ukususa izinhlayiya ezicolekile njengamabhaktheriya, amagciwane, nama-colloid.

*I-Ultrafine:Osayizi bembotshana abancane kakhulu, abasetshenziselwa izinhlelo zokusebenza zokuhlunga kakhulu, njengokususa izinto eziqinile ezincibilikisiwe nokungcola.

2. Ngokusekelwe Kumumo:

*Isilinda:Umumo ovame kakhulu, onikeza indawo enkulu engaphezulu yokuhlunga.

*Kufakiwe:Idizayini egoqiwe noma ecijile, ikhulisa indawo yokuhlunga futhi ithuthukise ukusebenza kahle.

*Idiski:Amakhatriji ayisicaba, amise okwediskhi, alungele izinhlelo zokusebenza ezithile noma amathuluzi.

3. Ngokusekelwe kokubalulekile:

*Insimbi engagqwali:Izinto ezivame kakhulu ngenxa yokumelana nokugqwala okuhle kakhulu, amandla, nokubekezelela izinga lokushisa eliphezulu.

*Ithusi:Inikeza ukumelana nokugqwala okuhle kanye ne-thermal conductivity, evame ukusetshenziswa ezinhlelweni zokushintshanisa ukushisa.

*I-Nickel:Inikeza ukumelana kwamakhemikhali okuhle kakhulu nokusebenza kwezinga lokushisa eliphezulu, kulungele izindawo ezinokhahlo.

*Ezinye Izinsimbi:Ngokuya ngezidingo ezithile, ezinye izinsimbi ezifana ne-titanium, i-aluminium, noma i-tungsten zingasetshenziswa.

4. Ngokusekelwe ku-Filtration Mechanism:

*Ukuhlunga Ukujula:Izinhlayiya zivaleleke ngaphakathi kwesakhiwo esinezimbotshana sesihlungi.

*Ukuhlunga Okungaphezulu:Izinhlayiya zithwetshulwa ebusweni besihlungi.

*Ukuhlunga kweSieve:Izinhlayiya zivinjwe usayizi wembotshana.

Izinto Ezibalulekile Okufanele Zicatshangelwe Lapho Ukhetha I-Porous Metal Filter Cartridge:

*Usayizi Wengxenye:Usayizi wezinhlayiya ezizokhishwa.

*Izinga lokugeleza:Izinga lokugeleza elidingekayo ngesihlungi.

*Ukwehla Kwengcindezi:Ukucindezela okuvunyelwe kwehlela kuso sonke isihlungi.

*Ukuhambisana Kwekhemikhali:Ukuhambisana kwezinto zokuhlunga noketshezi oluhlungwayo.

*Izinga lokushisa:Izinga lokushisa lokusebenza lesihlungi.

*Ukuhlanza nokuvuselela kabusha:Indlela kanye nemvamisa yokuhlanza noma ukukhiqiza kabusha isihlungi.

Ngokuqonda lezi zinhlobo nezici ezihlukile, ungakhetha i-cartridge yesihlungi sensimbi efanelekile kakhulu ngezidingo zakho zokuhlunga.

Ungawakhetha Kanjani Amakhatriji Esihlungi Sensimbi Alungile?

Kunezici eziningi okufanele uzicabangele lapho ukhetha amakhatriji esihlungi sensimbi alungile

okwakhookokuhlunga noma iphrojekthi. Lapha sibala amaphuzu angu-8 abalulekile okufanele uwahlole.

1. Usayizi Wezinhlayiyana:

*Nquma usayizi wezinhlayiya okudingeka uzisuse.

*Khetha i-cartridge enosayizi wembotshana encane kunezinhlayiya okufanele zihlungwe.

2. Izinga lokugeleza:

*Cabangela izinga lokugeleza elidingekayo ngesihlungi.

*Khetha i-cartridge enendawo engaphezulu kanye nosayizi wembotshana engakwazi ukuphatha izinga lokugeleza olifisayo

ngaphandle kokwehla kwengcindezi ngokweqile.

3. Ukwehla Kwengcindezi:

*Hlola ukwehla kwengcindezi okuvunyelwe kuso sonke isihlungi.

*Khetha i-cartridge enengcindezi ephansi ukuze unciphise ukusetshenziswa kwamandla futhi uqinisekise ukusebenza kahle.

4. Ukuhambisana Kwamakhemikhali:

*Hlola ukuhambisana kwekhemikhali kwezinto zokuhlunga ngoketshezi oluhlungwayo.

*Khetha i-cartridge eyenziwe ngezinto ezikwazi ukumelana nokugqwala nokuhlaselwa ngamakhemikhali uketshezi.

5. Izinga lokushisa:

*Nquma izinga lokushisa lokusebenza kwesihlungi.

*Khetha i-cartridge engamelana nebanga lokushisa elilindelekile ngaphandle kokuphazamisa ukusebenza kwayo noma ubuqotho.

6. Ukuhlanza Nokuvuselela:

*Cabangela indlela nokuvama kokuhlanza noma ukukhiqiza kabusha isihlungi.

*Khetha i-cartridge okulula ukuyihlanza noma ukuyikhiqiza kabusha, kuye ngohlelo oluthile kanye nezidingo zokuhlanza.

7. Hlunga Imidiya:

*Hlola uhlobo lwesihlungi semidiya esetshenziswa kukhatriji.

*Cabangela izinketho ezifana nezimpushana zensimbi ezisikiwe, izintambo zocingo ezilukiwe, noma ezinye izinto ezimboza izimbotshana, ngokusekelwe ezidingweni zakho ezithile.

8. Idizayini yeCartridge:

*Hlola idizayini ye-cartridge, efana ne-cylindrical, pleated, noma umumo wediski.

*Khetha idizayini ehambisana nezisetshenziswa zakho futhi enikeza ukusebenza kokuhlunga okufunayo.

9. Umkhiqizi kanye Nekhwalithi:

*Cwaninga abakhiqizi abathembekile bamakhatriji esihlungi sensimbi anezimbobo.

*Khetha i-cartridge kumkhiqizi onerekhodi eliqinisekisiwe lekhwalithi nokuthembeka.

FAQ

1. Ayini ama-cartridges ensimbi anezimbotshana futhi asebenza kanjani?

Amakhatriji esihlungi sensimbi anezimbotshana angamathuluzi okuhlunga enziwe ngezinsimbi ezisikiwe ezinokwakheka okuqinile, okuyizimbotshana.

Lawa ma-cartridges ngokuvamile akhiwa ngokuhlanganisa izimpushana zensimbi ngaphansi kwamazinga okushisa aphezulu nezingcindezi ukuze zakhe okuqinile,

nokho izimbotshana, impahla. I-porosity ingalawulwa ngokunembile ukukhomba osayizi bezinhlayiyana ezithile.

Njengoba uketshezi noma amagesi edlula esihlungini, izinhlayiya ezinkulu kunosayizi wembotshana ziyavaleka, zizikhiphe ngempumelelo emfudlaneni.

Lo mshini ubalulekile ezinhlelweni ezidinga ukuhlanzeka okuphezulu nokusebenza kahle, njengasekwenziweni kwemithi,

ukucubungula kwamakhemikhali, kanye nezinhlelo zokulawula uketshezi olubalulekile.

2. Yiziphi izinto ezisetshenziswayo ezivame ukusetshenziswa ekukhiqizeni amakhatriji esihlungi sensimbi anezimbotshana?

Izinto ezisetshenziswa kakhulu ukwenza amakhatriji okuhlunga ensimbi anezimbobo zifaka insimbi engagqwali, i-titanium, nama-nickel alloys.

Lezi zinto zikhethwa ngenxa yezakhiwo zazo eziqinile zemishini, ukumelana nokugqwala okuhle kakhulu, kanye nekhono lokumelana nokweqisa

amazinga okushisa nezingcindezi. Insimbi engagqwali ithandwa kakhulu ekusetshenzisweni okujwayelekile ngenxa yokuqina kwayo nokusebenza kahle kwezindleko,

kuyilapho ingxubevange ye-titanium ne-nickel ikhethwa ezindaweni ezonakalisa kakhulu noma ezidinga izilinganiso ezinkulu zamandla nesisindo.

3. Yiziphi izinzuzo eziyinhloko zokusebenzisa i-cartridge ye-metal filter ye-porous ngaphezu kwezinye izinhlobo zezihlungi?

I-porous metal filter cartridges inikeza izinzuzo eziningana ezihlukene:

*Ukumelana Nokushisa Okuphezulu: Angasebenza kahle ngaphansi kwezimo zokushisa okuphezulu, okubalulekile kuzinqubo ezifana nokuhlunga kwegesi eshisayo kanye ne-catalysis.

*Ukumelana Kwamakhemikhali: Izihlungi zensimbi azisebenzi kumakhemikhali amaningi, okuwenza afanelekele izindawo zamakhemikhali ezinokhahlo lapho izihlungi ze-polymer zingehlisa khona.

*Amandla Nokuqina: Izihlungi zensimbi zingamelana nokucindezela okuphezulu kanye nokucindezeleka okunzima kwemishini ngaphandle kokukhubazeka noma ukuphuka.

*Ivuselelwe futhi Isebenziseka Kabusha: Angahlanzwa futhi asetshenziswe kabusha izikhathi eziningi, anikeze impilo ende yesevisi futhi anciphise izindleko zokushintshwa kanye nokumosha.

*Kungenziwa ngendlela oyifisayo: I-porosity ne-geometric design ingenziwa ngezifiso ukuze ihlangabezane nezidingo ezithile zokuhlunga, inikeze ukuguquguquka kuzo zonke izinhlelo zokusebenza ezihlukahlukene.

4. Yiziphi izinhlelo zokusebenza lapho amakhatriji okuhlunga ensimbi anezimbotshana asetshenziswa kakhulu?

Ama-cartridges okuhlunga ensimbi asetshenziswa kakhulu ezinhlelweni ezimbalwa ezibalulekile, kufaka phakathi:

*Imboni Yamakhemikhali: Ukuze kuhlungwe amakhemikhali ahlanzeke kakhulu nokuvikela imibhede ye-catalyst ekungcoleni yizinhlayiya.

*Imithi: Ekukhiqizweni kwama-API (Izithako Zekhemisi Ezisebenzayo) lapho ukulawula ukungcoliswa kubalulekile.

*Ukudla nesiphuzo: Ngezinqubo zokuhlunga eziyinyumba zokuqinisekisa ukuphepha komkhiqizo kanye nekhwalithi.

*Uwoyela Negesi: Ekucutshungulweni okukhuphuka nomfula ukuze kukhishwe izinhlayiya kumafutha nokuvikela okokusebenza okubucayi.

*I-Aerospace nezimoto: Ukuze kuhlungwe uketshezi olusebenzisa amanzi kanye nezibaseli ngaphansi kwezimo zokusebenza ezinzima.

5. Amakhatriji esihlungi sensimbi anezimbobo agcinwa futhi ahlanzwe kanjani?

Ukugcinwa nokuhlanzwa kwama-cartridges ensimbi anezimbotshana zokuhlunga kuncike kakhulu ohlotsheni lokungcoliswa kanye nokomzimba

izakhiwo zezinto zokuhlunga. Izindlela zokuhlanza ezijwayelekile zihlanganisa:

*Ukubuyela emuva: Ukubuyisela emuva isiqondiso sokugeleza ukuze kukhishwe izinhlayiya.

*Ukuhlanza kwe-Ultrasonic: Ukusebenzisa amaza omsindo wemvamisa ephezulu ukuze kukhishwe izingxenye ezincane.

*Ukuhlanza Amakhemikhali: Ukusebenzisa izincibilikisi noma ama-asidi ukuncibilikisa ukungcola.

*Ukushiswa Kwezinga Lokushisa Eliphezulu: Ukusebenzisa ukushisa ukwenza i-oxidize izinto eziphilayo.

Ukugcinwa okuvamile nokuhlanza okufanele kungandisa kakhulu impilo yama-cartridges okuhlunga, okwenza kube yisixazululo esingabizi kakhulu ezinhlelweni eziningi zezimboni.