-

I-10Pcs/Lot HD Flat efakwe futhi enezimbobo ezinezimbobo zensimbi yethusi isithulisi se-M5 1/8"...

I-HD Exhaust Muffler Bronze Model G 1/8'' 1/4'' 3/8'' 1/2'' 3/4'' 1'' *Idatha ekulolu hlu ingeyereferensi kuphela ye-Pneumatic Sintered Muff...

Buka imininingwane -

I-Sintered Bronze Muffler 40 Micron Pressure Relief Valve Waterproof Breather Vent

Izihlungi ze-Pneumatic Sintered Mufflers zisebenzisa izici zesihlungi se-bronze esinezimbobo esivikelwe ekufakweni kwamapayipi okujwayelekile. Lawa ma-muffler ahlangene futhi angabizi ...

Buka imininingwane -

I-pneumatic exhaust muffler silencer isilawuli sokugeleza komoya esincishisiwe nge-slot cut 1/8 ...

Izihlungi ze-Pneumatic Sintered Mufflers zisebenzisa izakhi zokuhlunga zethusi ezinezimbobo ezivikelwe ekufakweni kwamapayipi okujwayelekile. Lawa ma-muffler ahlangene futhi angabizi...

Buka imininingwane -

I-HBSL-SEB I-Sintered Bronze Exhaust Filter Isithulisi 1/2 Indoda Ye-NPT Thread Pneumatic Mu...

I-HBSL-SEB Muffler Silencer Model M5 1/8'' 1/4'' 3/8'' 1/2'' 3/4'' 1'' 1 1/4'' 1 1/2'' 2'' Izihlungi ze-Pneumatic Sintered Mufflers zisetshenziswa...

Buka imininingwane -

HENGKO Impushana eyimpushana ethengekayo yensimbi ene-ax100 yomoya womoya

Izihlungi ze-Pneumatic Sintered Mufflers zisebenzisa izakhi zokuhlunga zethusi ezinezimbobo ezivikelwe ekufakweni kwamapayipi okujwayelekile. Lawa ma-muffler ahlangene futhi angabizi...

Buka imininingwane -

I-HB Micron Stainless steel Bronze Sintered Filter Element 1/4" Air Pneumatic Flow S...

I-HD Exhaust Muffler Bronze Model 1/8'' 1/4'' 3/8'' 1/2'' 3/4'' 1'' Izihlungi Ze-Pneumatic Sintered Mufflers zisebenzisa isihlungi se-bronze esinezimbobo...

Buka imininingwane -

Izimbobo zokuphefumula ezinentambo yowesilisa, ithusi lethusi lensimbi engagqwali SS 316 ASP-1/2/3/4/6/8 BV

Izihlungi ze-Pneumatic Sintered Mufflers zisebenzisa isici sesihlungi se-bronze esinezimbobo esivikelwe ekufakweni kwamapayipi okujwayelekile. Lawa ma-muffler ahlangene futhi angabizi ...

Buka imininingwane -

I-HBSL-MA V i-sintered brass pneumatic flat silencer isithulisi somoya esikhipha umoya esinciphisa umsindo futhi...

I-Muffler Silencer Model G M5 1/8'' 1/4'' 3/8'' 1...

Buka imininingwane -

I-Brass air eliminator ye-pneumatic muffler breather vent eno-1/8” 1/4” 3/8R...

Izihlungi ze-Pneumatic Sintered Mufflers zisebenzisa izici zesihlungi se-bronze esinezimbobo esivikelwe ekufakweni kwamapayipi okujwayelekile. Lawa ma-muffler ahlangene futhi angabizi ...

Buka imininingwane -

I-HENGKO Sintered Porous Metal Pneumatic components/ muffler return valve oil filter that...

Isihlungi Se-Oil Valve Bronze Model M5 M5 M5 1/8'' 1/4'' Izihlungi Ze-Pneumatic Sintered Mufflers zisebenzisa isihlungi sethusi esinezimbobo esinezimbobo...

Buka imininingwane -

Izesekeli ze-ECMO System Breathing ze-ECMO "amaphaphu okufakelwa" okokusebenza

I-ECMO, noma i-extracorporeal membrane pulmonary oxygenation, iyindlela esekela ukuphila esebenzisa idivayisi yokwenziwa ekhethekile ukukhipha igazi enhliziyweni, ngaphandle...

Buka imininingwane -

I-HSC Pneumatic Sintered Stainless Steel Brass Exhaust Muffler Silencer Ifaka Ifayela Lomsindo...

I-HD Exhaust Muffler Bronze Model 1/8'' 1/4'' 3/8'' 1/2'' 3/4'' 1'' 1-1/4'' Izihlungi ze-Pneumatic Sintered Mufflers zisebenzisa i-porous...

Buka imininingwane -

3 70 micron sintered micropore izimbotshana zethusi zethusi exhaust izingxenye zokuhlunga

Izihlungi ze-Pneumatic Sintered Mufflers zisebenzisa izici zesihlungi se-bronze esinezimbobo esivikelwe ekufakweni kwamapayipi okujwayelekile. Lawa ma-muffler ahlangene futhi angabizi ...

Buka imininingwane -

Ukulawula ukugeleza kokukhipha umsindo wezithulisi zezithuli zensimbi enezimbotshana zensimbi engenasici...

Izihlungi ze-Pneumatic Sintered Mufflers zisebenzisa izici zesihlungi se-bronze esinezimbobo esivikelwe ekufakweni kwamapayipi okujwayelekile. Lawa ma-muffler ahlangene futhi angabizi ...

Buka imininingwane -

I-Microns Pneumatic Plus Sintered Metal Bronze Breather Vent - Umzimba Wethusi 1/4″...

Izihlungi ze-Pneumatic Sintered Mufflers zisebenzisa izici zesihlungi se-bronze esinezimbobo esivikelwe ekufakweni kwamapayipi okujwayelekile. Lawa ma-muffler ahlangene futhi angabizi ...

Buka imininingwane -

I-HBSL-SSDM Male Breather Vent Flat Sintered Mesh Pneumatic Air Silencer Muffler Solenoi...

Izihlungi ze-Pneumatic Sintered Mufflers zisebenzisa isici sesihlungi se-bronze esinezimbobo esivikelwe ekufakweni kwamapayipi okujwayelekile. Lawa ma-muffler ahlangene futhi angabizi ...

Buka imininingwane -

I-sintered porous metal powder bronze exhaust filter izithulisi ezifaka isihlungi somsindo...

Izihlungi ze-Pneumatic Sintered Mufflers zisebenzisa isici sesihlungi se-bronze esinezimbobo esivikelwe ekufakweni kwamapayipi okujwayelekile. Lawa ma-muffler ahlangene futhi angabizi ...

Buka imininingwane -

I-HSP sintered insimbi engagqwali 304/316L yemithombo ye-porous filter yokuvikelwa kwemvelo,...

Izihlungi ze-Pneumatic Sintered Mufflers zisebenzisa izici zesihlungi se-bronze esinezimbobo esivikelwe ekufakweni kwamapayipi okujwayelekile. Lawa ma-muffler ahlangene futhi angabizi ...

Buka imininingwane

Izici Eziyinhloko Zesihlungi Sensimbi Yensimbi

Izihlungi zensimbi ze-Sintered zinezici ezimbalwa ezibalulekile, ezihlanganisa:

1. Ukusebenza kahle kokuhlunga:

Isihlungi sensimbi esine-sintered sinosayizi omncane wezimbotshana kanye nendawo enkulu engaphezulu, engasusa ngempumelelo ukungcola kumagesi ahlukahlukene noketshezi.

2. Ukuhambisana kwamakhemikhali okubanzi:

Lezi zihlungi zenziwe ngezinto ezinokumelana namakhemikhali aphezulu, okuzenza zifaneleke emithonjeni eminingi ebolayo.

3. Ukumelana nezinga lokushisa eliphezulu:

Izihlungi zensimbi ezine-sintered zinokuzinza okuhle kakhulu kokushisa, okuzivumela ukuthi zisebenze kahle emazingeni okushisa aphezulu.

4. Ukuqina:

Lezi zihlungi ziqinile, zinamandla amakhulu okusebenza kanye nokumelana nokuhuzuka, ukuguguleka kanye nomthelela.

5. Ukusebenziseka kabusha:

Ngokungafani nezihlungi ezilahlwayo, izihlungi zensimbi ezine-sintered zingahlanzwa futhi ziphinde zisetshenziswe izikhathi eziningi, zizenze isixazululo esingabizi kakhulu ezinhlelweni zokuhlunga.

Ukusetshenziswa Kwesihlungi Esikhethekile Sensimbi Yensimbi

Empeleni Izihlungi Ezikhethekile Zihlala Zisetshenziswa Kuhlelo Olujwayelekile, Uhlelo oluthile Nje Oluzosetshenziswa

Ngezinga Lokushisa Elikhethekile Kakhulu,Ingcindezi Ephezulu, KakhuluUkukhiqizwa Okucekelayo kanye

Izindawo zokuhlola. Futhi Abanye Badinga I-Special Design Shape, Ngakho Ungathintana

I-HENGKO yokuxazulula Izidingo Zakho Zesihlungi Sensimbi ye-OEM.

1. Ukuhlunga Okuwuketshezi

2. Fluidizing

4. Ukusabalalisa

6. Ukuhlunga Kwegesi

7. Ukudla Nesiphuzo

Izihlungi ze-Sintered metal zinemisebenzi eminingi futhi zingasetshenziswa ezinhlobonhlobo zezinhlelo zokusebenza.

Ezinye izinhlelo zokusebenza ezijwayelekile zezihlungi zensimbi ezine-sintered yilezi:

1. Ukuhlungwa Koketshezi:

Izihlungi zensimbi ezine-sintered zisetshenziswa kakhulu ekuhlungeni uketshezi olunjengamanzi, amakhemikhali, nezincibilikisi.

Lezi zihlungi ziyakwazi ukususa i-particle, ukungcola, nokungcola oketshezini, okwenza

zilungele ukusetshenziswa ezimbonini zemithi, zokudla neziphuzo, kanye namakhemikhali.

Zibuye zisetshenziswe ezindaweni zokuhlanza amanzi angcolile ukuze kukhishwe ukungcola kanye nokungcola emanzini.

2. Ukuhlunga Kwegesi:

Izihlungi zensimbi ezine-sintered nazo zisetshenziswa ekuhlungeni amagesi anjengomoya, igesi yemvelo, namanye amagesi ezimboni.

Angakwazi ukususa izinhlayiya, uwoyela, nokunye ukungcola emagesini, okuwenza afanelekele ukusetshenziswa kuwo

izilungiselelo zezimboni nezohwebo njengamapayipi egesi kanye nezinhlelo zomoya ezicindezelwe.

3. Iziguquli ze-Catalytic:

Izihlungi zensimbi ezine-sintered zisetshenziswa kuziguquli ze-catalytic ukuze zisuse ukungcola okuyingozi kumagesi akhipha umoya wezimoto.

Bangakwazi ukucupha futhi bahlunge i-particle, kuyilapho bevumela ukusabela kwamakhemikhali okwenzeka ku-catalytic.

converters ukuba kwenzeke. Lokhu kusiza ukunciphisa ukukhishwa kwekhabhoni ezimotweni futhi kuthuthukise izinga lomoya.

4. I-Fluidization:

Izihlungi zensimbi ezi-sintered zisetshenziswa ezinqubweni zokukhipha amanzi, lapho zisetshenziselwa ukusabalalisa igesi noma uketshezi embhedeni we

izinhlayiya eziqinile. Isakhiwo esinezimbotshana sezihlungi zensimbi ezine-sintered sivumela ukusatshalaliswa okulinganayo koketshezi, okubalulekile

izinqubo ezisebenzayo ze-fluidization.

5. Ukuhlunga Amafutha:

Izihlungi zensimbi ezine-sintered zisetshenziswa ezinhlelweni zokuhlunga uwoyela ukususa ukungcola, ukungcola, kanye nezinhlayiya.

Indaba kawoyela wenjini, uwoyela wehydraulic, namanye amafutha ezimboni. Lezi zihlungi ziyakwazi ukumelana namazinga okushisa aphezulu

kanye nezingcindezi, okuzenza zilungele ukusetshenziswa ezinhlelweni zezimboni.

6. Amadivayisi Ezokwelapha:

Izihlungi zensimbi ezi-sintered zisetshenziswa emishinini yezokwelapha njengama-nebulizer kanye nezinhlelo zokulethwa kwezidakamizwa. Lezi

izihlungi ziyakwazi ukuhlunga amagciwane, amagciwane, nokunye ukungcola emithini namagesi ezokwelapha, okuthi

kusiza ukuqinisekisa ukuphepha kwesiguli.

7. I-Aerospace kanye Nokuvikela:

Izihlungi zensimbi ze-Sintered zisetshenziswa ezimbonini ze-aerospace nezokuvikela ngezinhlelo zokusebenza ezahlukahlukene,

okuhlanganisa ukuhlungwa kukaphethiloli, ukuhlunga uketshezi olunamanzi, nokuhlunga komoya negesi. Lezi zihlungi kufanele zihlangabezane nokusebenza okuqinile nokuphepha

amazinga, okwenza izihlungi zensimbi ezine-sintered zibe yisinqumo esihle kulezi zimboni.

Ukusekelwa Kwezixazululo Zonjiniyela

Ngokuhamba kweminyaka, i-HENGKO ixazulule izidingo zedatha yokuhlunga nokulawula ukugeleza okuyinkimbinkimbi kakhulu

izinhlobonhlobo zezimboni emhlabeni wonke.Ukuxazulula ubunjiniyela obuyinkimbinkimbi obuhambisana nesicelo sakho kuyinhloso yethu futhi

Futhi kuwumgomo wethu ovamile ukugcina okokusebenza namaphrojekthi akho esebenza kahle nangokuzinza njengoba kuhleliwe , Ngakho-ke

Kungani singasebenzi ngokubambisana ukuze siqedele le miklamo ndawonye futhi sinqobe ubunzima, sithuthuke

izihlungi ezikhethekile zamaphrojekthi akho akhethekile namuhla.

Siyakwamukela Ekwabelaneni Ngephrojekthi Yakho futhi Sebenza no-HENGKO, Sizohlinzeka Ngesihlungi Esikhethekile Sensimbi Engcono Kakhulu

Isixazululo Semiklamo Yakho.

Isinyathelo Ngesinyathelo Umhlahlandlela Wokwenza Ngokwezifiso Isihlungi Sensimbi Ye-Sintered

Ifekthri yakho engcono kakhulu yokuklama isihlungi samaphrojekthi akho akhethekile anezidingo eziphezulu, uma ungakwazi ukuthola okufanayo noma okufanayo

Imikhiqizo yokuhlunga, Siyakwamukelaukuze uxhumane no-HENGKO ukuze basebenzisane ukuze bathole isisombululo esingcono kakhulu, futhi nansi inqubo ye

Izihlungi ezikhethekile ze-OEM,Sicela uyihlole futhiXhumana nathikhuluma ngemininingwane eyengeziwe.

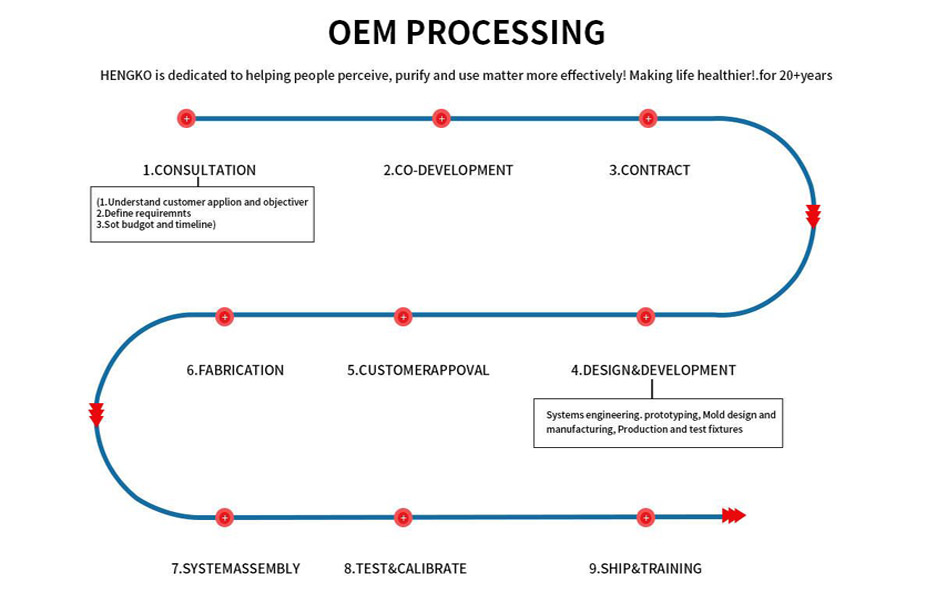

I-HENGKO Izinikele Ekusizeni Abantu Babone, Bahlanze futhi Basebenzise Izinto Ngempumelelo Kakhudlwana! Ukwenza Impilo Iphile Kahle Ngaphezu kweminyaka engama-20.

1.Ukubonisana futhi Xhumana HENGKO

2.Ukuthuthukiswa ngokubambisana

3.Yenza Inkontileka

4.Idizayini Nokuthuthukiswa

5.I-Customerpoval

6. Ukukhiqiza/Ukukhiqiza Okuningi

7. Systemassembly

8. Hlola & Linganisa

9. Ukuthumela Nokuqeqesha

Usenemibuzo futhi uthanda ukwazi eminye imininingwane yeIsihlungi Esikhethekile se-OEM, Sicela uzizwe Ukhululekile Ukuxhumana Nathi Manje.

Futhi UngakwaziSithumele I-imeyiliNgokuqondile Ngokulandelayo:ka@hengko.com

Sizothumela Emuva Ngamahora angu-24, Siyabonga Ngesiguli Sakho !

I-FAQ mayelana nezihlungi ze-Sintered Metal :

1. Yini isisefo sensimbi esine-sintered?

A: Aisihlungi sensimbi esine-sinteredisisefo esenziwe ngokuhlanganisa izimpushana zensimbi ukuze zakhe aimpahla enezimbotshana

evumela uketshezi noma amagesi ukuthi ageleze ngenkathi ibamba izinhlayiya noma ukungcola.

2. Yiziphi izinzuzo zokusebenzisa izihlungi zensimbi ezine-sintered?

Izihlungi zensimbi ze-Sintered zinikeza inhlanganisela eyingqayizivele yezakhiwo ezizenza zibe nenzuzo ezinhlelweni ezihlukahlukene. Nazi ezinye zezinzuzo ezibalulekile:

1. Amandla nokuqina:

Ngokungafani nezihlungi zephepha noma zendwangu, izihlungi zensimbi ezine-sintered ziqine ngendlela emangalisayo futhi zingamelana nezingcindezi eziphezulu namazinga okushisa. Lokhu kubenza bafaneleke ekufuneni izicelo zezimboni ezifana nokucubungula amakhemikhali, ukucwengwa kwe-petrochemical, kanye nokukhiqizwa kwamandla.

2. I-porosity ephezulu kanye nokuhlunga okunembile:

I-porosity elawulwayo yezihlungi zensimbi e-sintered ivumela ukuhlungwa okunembile kwezinhlayiya kuze kufike kumasayizi amancane kakhulu. Lokhu kufezwa ngokulawula ngokucophelela ubukhulu nokusabalalisa kwama-pores ngesikhathi senqubo yokucwilisa.

3. Ukumelana nokugqwala:

Izihlungi eziningi zensimbi ezine-sintered zenziwe ngensimbi engagqwali noma ezinye izinsimbi ezikwazi ukumelana nokugqwala, okuzenza zifanelekele ukusetshenziswa namakhemikhali anokhahlo noketshezi. Lokhu kunciphisa isidingo sokushintshwa nokugcinwa njalo.

4. Ukuhlanzeka nokusebenziseka kabusha:

Ngokungafani nezihlungi ezilahlwayo, izihlungi zensimbi ezine-sintered zingahlanzwa kalula futhi ziphinde zisetshenziswe, zizenze zibe inketho engabizi kakhulu futhi evumelana nemvelo ngokuhamba kwesikhathi.

5. Ukumelana nokushaqeka okuphezulu kokushisa:

Izihlungi zensimbi ezine-sintered zingamelana noshintsho olusheshayo kuzinga lokushisa ngaphandle kokuqhekeka noma ukugoba, zizenze zifanelekele ukusetshenziswa ezindaweni ezinezinga lokushisa eliphezulu njengezinjini zomoya nezinjini.

6. Ukuhlukahluka:

Izihlungi zensimbi ezi-sintered zingenziwa ngendlela oyifisayo ukuze zihlangabezane nezidingo eziningi ngokuya ngosayizi wembotshana, umumo, nezinto ezibonakalayo. Lokhu kubenza bavumelane nezimo kuzinhlelo zokusebenza ezahlukahlukene kuzo zonke izimboni ezahlukahlukene.

Nazi ezinye izinzuzo ezengeziwe okufanele zishiwo:

* Ukwakhiwa kwe-welded:

Izihlungi zensimbi ezine-sintered zinesakhiwo esingenamthungo, ezisusa ubungozi bokuvuza okuhambisana nezihlungi ezinamathiselwe noma ezithungiwe.

* Impilo ende yesevisi:

Ngenxa yokuqina nokuhlanzeka kwazo, izihlungi zensimbi ezine-sintered zinesikhathi eside sempilo uma ziqhathaniswa nezinye izinhlobo zezihlungi.

* I-Biocompatibility:

Izinsimbi ezithile ezine-sintered ezifana ne-titanium ziyavumelana ne-biocompatible, zizenza zifanelekele ukusetshenziswa kwezokwelapha kanye nemithi.

Sekukonke, izinzuzo zokusebenzisa izihlungi zensimbi ezine-sintered zizenza ukukhetha okuphoqayo kwezinhlelo zokusebenza ezifunayo lapho ukusebenza okuphezulu, ukuqina, nokusebenziseka kabusha kubalulekile.

3. Yiziphi ezinye izinhlelo zokusebenza ezivamile zezihlungi zensimbi ezine-sintered?

A: Izihlungi zensimbi ze-Sintered zisetshenziswa ezimbonini ezahlukahlukene ezihlanganisa ukudla nesiphuzo,

imithi, amakhemikhali, i-petrochemical, ukwelashwa kwamanzi kanye nezimoto.

Ngokuvamile zisetshenziselwa ukuhlunga uketshezi noma amagesi afana nowoyela, uphethiloli, igesi noma amanzi.

4. Yini okufanele inakwe lapho ukhetha umenzi we-sintered metal filter?

IMP: Uma ukhetha umkhiqizi wesihlungi sensimbi, bheka inkampani enolwazi nobungcweti kuyo

ukukhiqiza izihlungi zekhwalithi ephezulu, isebenzisa izinqubo ezithuthukisiwe zokukhiqiza kanye nobuchwepheshe, inikeza ukwenza ngokwezifiso

izinketho nokusekelwa kwezobuchwepheshe, futhi inedumela lenkonzo yamakhasimende kanye nokulethwa Inkampani enegama elihle.

5. Zenziwa kanjani izihlungi zensimbi ezine-sintered?

Izihlungi zensimbi ezine-sintered zenziwa ngenqubo ethakazelisayo ehilela ukuguqula impushana yensimbi ibe isakhiwo esiqinile, esinezimbotshana. Nakhu ukuhlukaniswa kwesinyathelo ngesinyathelo:

1. Ukulungiswa kwempushana yensimbi:

Uhambo luqala ngezimpushana zensimbi, ngokuvamile ezenziwe ngensimbi engagqwali, ithusi, i-nickel, noma i-titanium. Lezi zimpushana zingatholakala ngezindlela ezihlukahlukene ezifana nokugaya, i-atomization, noma ukubola kwamakhemikhali.

2. Ukuxuba nokubumba:

Impushana yensimbi ixubene nezibophezelo kanye nezinto zokugcoba ukuze kuthuthukiswe ukugeleza kwayo nezici zokucindezela. Le ngxube ibe isicindezelwa esimeni esifiswayo sesici sokuhlunga kusetshenziswa ingcindezi ephezulu iyafa. Amajamo angaba amadiski alula, amashubhu ayinkimbinkimbi, noma amajiyometri ayinkimbinkimbi kuye ngohlelo lokusebenza.

3. Ukucula:

Lena inhliziyo yenqubo lapho kwenzeka khona umlingo. Izimo ezicindezelwe zishiswa endaweni elawulwayo ezingeni lokushisa elingaphansi kwendawo yokuncibilika yensimbi. Lokhu kushisa kubangela izinhlayiya zensimbi ukuthi zihlangane ndawonye ezindaweni zazo zokuxhumana, kwakheka inethiwekhi eqinile, exhumene kuyilapho kusashiya isikhala esanele esingenalutho sokuqina kwesihlungi.

4. Ukuqeda nokuhlanza:

Uma i-sintered, i-elementi yokuhlunga icutshungulwa okwengeziwe njengokupholisa, ukuvala ukubopha (ukususwa kwezinto ezibophayo), nokuqedwa kwendawo. Ezinye izihlungi zingase zidinge ukwenziwa kwemishini eyengeziwe noma ukuhlanganisa ukuze kuzuzwe ifomu lokugcina elifiswayo.

5. Ukulawulwa kwekhwalithi nokuhlola:

Isigaba sokugcina sibandakanya ukuhlolwa kokulawulwa kwekhwalithi okuqinile ukuqinisekisa ukuthi isihlungi sihlangabezana nezicaciso ezidingekayo ze-porosity, ukusatshalaliswa kosayizi wezimbotshana, amandla, neminye imingcele. Lokhu kuvame ukubandakanya ukuhlola okubonakalayo, izilinganiso zobukhulu, kanye nokuhlolwa kokusebenza ngoketshezi.

Futhi voila! Impushana yensimbi ethobekile iguqulwa ibe isici sokuhlunga esiqinile, esisebenziseka kabusha esilungele ukubhekana nemisebenzi ehlukahlukene yokuhlunga kuzo zonke izimboni.

Kubalulekile ukuqaphela ukuthi kukhona ukuhluka kwenqubo ngqo kuye ngohlobo lwensimbi, izakhiwo ezifiselekayo, nomkhiqizi othize. Amanye amasu ahlanganisa ukusebenzisa imicu yensimbi eyakhiwe ngaphambilini esikhundleni sezimpushana, noma ukusebenzisa izindlela zokushisisa ezihlukene ezifana nokucwiliswa kwe-microwave.

Kafushane, inqubo ye-sintering idala isakhiwo sensimbi esiqinile kodwa esinezimbotshana esihlunga kahle uketshezi kuyilapho sigcina izinto ezifiselekayo ezifana nezinga lokushisa eliphezulu nokumelana nokucindezela. Lokhu kwenza izihlungi zensimbi ezine-sintered zibe ithuluzi elibalulekile emikhakheni eyahlukene, kusukela kumishini yezokwelapha kuye kubunjiniyela bezimoto.

6. Yiziphi izinto ezijwayelekile ezisetshenziselwa ukwenza izihlungi zensimbi ezine-sintered?

A: Izihlungi zensimbi ezine-sintered zingenziwa ngezinto ezihlukahlukene ezihlanganisa insimbi engagqwali, ithusi, i-nickel, i-titanium.

namanye ama-alloys. Ukukhethwa kwezinto kuncike ekusetshenzisweni okuqondile kanye nezakhiwo ezifiswayo zesihlungi.

7. Ingabe i-sintered metal filter ingenziwa ngezifiso?

A: Yebo, izihlungi zensimbi ezine-sintered zingenziwa ngendlela oyifisayo ukuze zihlangabezane nezidingo ezithile zezinhlelo zokusebenza ezahlukene. Abakhiqizi

ingalungisa usayizi wembotshana, ukujiya, umumo neminye imingcele ukuze ithuthukise ukusebenza kokuhlunga.

8. Ngizihlanza futhi ngizigcine kanjani izihlungi zensimbi ezine-sintered?

A: Izihlungi zensimbi ezine-sintered zingahlanzwa ngokuwashwa ngamanzi noma ngomoya ocindezelwe noma ngokucwiliswa emanzini.

isixazululo sokuhlanza. Kubalulekile ukulandela izincomo zokuhlanza nokugcinwa komkhiqizi ukuze

qinisekisa ukusebenza kahle kwesihlungi nempilo yesevisi.