-

Ngokwezifiso 0.5 2 5 10 micron insimbi engagqwali 316L powder sintered metal isihlungi for f...

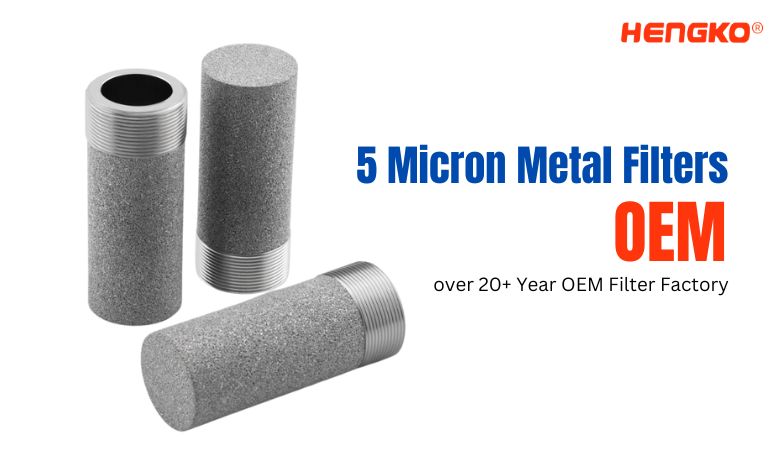

Izihlungi ze-HENGKO 5-micron sintered zenziwa ngokufaka i-sintering 316L powder material noma i-multilayer stainless stainless wire mesh emazingeni okushisa aphezulu ukuphoqa...

Buka imininingwane -

I-25 Micron Stainless Steel 316L I-Porous Metal Sintered Filter Cartridge ye-Gas Liquid Ngakho...

Chaza umkhiqizo we-HENGKO amashubhu okuhlunga ensimbi engenasici enziwa ngokufaka impahla engu-316L yempushana noma i-multilayer steel stainless wire mesh emazingeni okushisa aphezulu....

Buka imininingwane -

Ngokwezifiso 1 15 40 70 100 Microns Cylindrical Sintered Metal Stainless Steel 316L Porou...

Chaza umkhiqizo we-HENGKO izihlungi zensimbi engagqwali zenziwe ngokufaka impahla engu-316L yempushana noma i-multilayer steel stainless wire mesh at high temperatur...

Buka imininingwane -

Ukukhiqiza okudayisiwe kanye nentengo yefekthri 0.2 0.5 2 5 10 15 20 40 60 90 100 micron porosity ...

I-HENGKO i-stainless steel filter disc yenziwa nge-sintering 316L powder material noma i-multilayer stainless stainless wire mesh emazingeni okushisa aphezulu. Baye babanzi...

Buka imininingwane -

Impushana eyenziwe ngokwezifiso i-SS 316L ye-stainless steel filter disc, 0.2 5 7 10 30 40 50 70 ...

I-HENGKO i-stainless steel filter disc yenziwa nge-sintering 316L powder material noma i-multilayer stainless stainless wire mesh emazingeni okushisa aphezulu. Baye babanzi...

Buka imininingwane -

5 10 30 60 90 microns powder micro porous sintered metal sheet sheet

Amashidi okuhlunga ensimbi asetshenziswa kabanzi ukususa izinhlayiya zakwamanye amazwe ezinhlotsheni eziningi ezahlukene zokugeleza kwemidiya. Izinkambu ezisetshenziswa kakhulu: Amagesi ajwayelekile,...

Buka imininingwane -

I-Sintered 0.5 10 20 40 60 I-Micron Porous Metal Filter Assemblies Ye-Solid Liquid Gas Sep...

I-cartridge yensimbi engagqwali enezimbobo zensimbi isetshenziswa kakhulu ukuhlunga ukungcola nezinhlayiya oketshezini. Isibonelo, i-polyester resin: uku ...

Buka imininingwane -

316L SS insimbi engagqwali izihlungi sintered, ngokwezifiso microporous nickel monel inco...

Izinto zensimbi ze-HENGKO ezinama-porous zikhiqizwa ngokwelashwa okushisa okuqinile kwe-multilayer yensimbi engagqwali wire mesh noma 316L powder emazingeni okushisa aphezulu. Ngoba...

Buka imininingwane -

2 5 50 100 150 300 Microns Porous 304 316L SS insimbi engagqwali wire sintered mesh isihlungi...

Insimbi engagqwali ene-sintered mesh yenziwe ngensimbi engagqwali elukiwe, futhi inqubo yokushisela i-argon-arc ijoyina izindawo zokuvala zesici sokuhlunga. ...

Buka imininingwane -

Round 25 50 100 micron sintered steel stainless wire mesh disc disc

Izihlungi ze-HENGKO sintered disc ziqukethe amanethiwekhi afanayo kakhulu, axhumene ezimbotshana anezindlela ezihlukumezayo ezibamba izinhlayiya eziqinile kugesi noma uketshezi. Exce...

Buka imininingwane -

Ukuhlanzeka okuphezulu 0.2 5 20 30 70 micron porosity metallic powder filter element kanye nengxenye...

Chaza umkhiqizo we-HENGKO izihlungi zensimbi engagqwali zenziwe ngokufaka i-sintering 316L powder impahla noma i-multilayer stainless steel stainless mesh in high temperatur...

Buka imininingwane -

I-Sintered 5 10 40 100 microns porous 316L insimbi engagqwali yokuhlunga wire mesh yesihlungi sothuli

Izihlungi ze-Sinter wire mesh zivame ukusetshenziselwa ukuhlanzwa nokuhlunga uketshezi negesi, ukuhlukanisa kanye nokubuyiselwa kwezinhlayiya eziqinile, i-coolin yokuphefumula...

Buka imininingwane -

5 40 micron sintered insimbi engagqwali uwoyela uphethiloli ezimbobokile / umoya / uthuli isihlungi wire mesh ca...

Izihlungi ze-Sinter wire mesh zivame ukusetshenziselwa ukuhlanzwa nokuhlunga uketshezi negesi, ukuhlukanisa kanye nokubuyiselwa kwezinhlayiya eziqinile, i-coolin yokuphefumula...

Buka imininingwane -

I-5 10 20 90 120 microns sintered metal porous bronze insimbi engagqwali 316L multi-purpose ...

I-HENGKO ikhiqiza izinto zokuhlunga ebangeni elibanzi lezinto, osayizi, nokufakwa ukuze kucaciswe kalula ngezici kanye nokucushwa...

Buka imininingwane -

Isihlungi sikaphethiloli esingu-35 50 microns esingokwezifiso sediski yediski yesihlungi sethusi somsebenzi osindayo kanye...

I-HENGKO ikhiqiza izinto zokuhlunga ebangeni elibanzi lezinto, osayizi, nokufakwa ukuze kucaciswe kalula ngezici kanye nokucushwa...

Buka imininingwane -

Ukwenza ngokwezifiso komuntu siqu 15 45 90 micron powder sintered zethusi zethusi ezinama-porous metal oil fi...

I-HENGKO ikhiqiza izinto zokuhlunga ebangeni elibanzi lezinto, osayizi, nokufakwa ukuze kucaciswe kalula ngezici kanye nokucushwa...

Buka imininingwane -

i-sintered metal filter disc yokwelashwa kwamanzi angcolile, i-5 20 micron 304 316L insimbi engenasici ...

Amashidi okuhlunga okujulile asetshenziselwa ukususa izinhlayiya oketshezini. Lokhu kusho ukuthi uketshezi lungacaca-, lucolise noma luhlungwe olwenziwa yinyumba. Amashidi okuhlunga alungele ...

Buka imininingwane -

I-5 10 micron sintered porosity powder insimbi engagqwali 316L yethusi/isilinda sokuhlunga ithusi

I-HENGKO ikhiqiza izinto zokuhlunga ebangeni elibanzi lezinto, osayizi, nokufakwa ukuze kucaciswe kalula ngezici kanye nokucushwa...

Buka imininingwane -

3 5 18 30 60 90 I-Micron ene-porous sintered bronze air filter disc yokuhlunga kwezimboni...

I-HENGKO ikhiqiza izinto zokuhlunga ebangeni elibanzi lezinto, osayizi, nokufakwa ukuze kucaciswe kalula ngezici kanye nokucushwa...

Buka imininingwane -

Ngokwezifiso 3 5 10 20 90 micron porous sintered metal bronze isihlungi isilinda tube for izimboni...

I-HENGKO ikhiqiza izinto zokuhlunga ebangeni elibanzi lezinto, osayizi, nokufakwa ukuze kucaciswe kalula ngezici kanye nokucushwa...

Buka imininingwane

Izinhlobo zezihlungi ze-Metal 5 Micron

Kunezinhlobo ezimbalwa zezihlungi ze-Metal 5 Micron ezitholakalayo, ngayinye yakhelwe ukuhlangabezana nezidingo ezithile zokuhlunga:

*Izihlungi Zensimbi Ezihlanganisiwe:

Lezi zihlungi zidalwe ngokusebenzisa ainqubo sintering, lapho kukhona izinhlayiya zensimbi

kuhlanganiswe ndawonye emazingeni okushisa aphezulu ngaphandle kokuncibilika. Lokhu kubangela ukuthi aizimbotshananokho isihlungi esinamandla lokho

ingakwazi ukumelana namazinga okushisa aphezulu nezingcindezi, iyenze ilungele izinhlelo zokusebenza ezifunayo.

*Izihlungi Zensimbi Ezilukiwe:

Zenziwe ngezintambo zensimbi ezicolekile ezilukwe ndawonye, lezi zihlungi zihlinzeka ngokuqina futhi

isixazululo esisebenzayo sokuhlunga. Ziwusizo ikakhulukazi ekusetshenzisweni okudinga amazinga aphezulu okugeleza, njengokulukiweyo

isakhiwo sivumela uketshezi oluhamba kahle ngenkathi kuthunjwa ukungcola.

*Izihlungi Zensimbi Ezihlanganisiwe:

Ngokuhambisana nedizayini ecijile, lezi zihlungi zinikeza indawo enkulu yokuhlunga,

ukuthuthukisa amandla abo okubamba izinhlayiya. Isakhiwo se-pleated sibuye sibe nomthelela ekuphileni okude futhi

ukusebenza kahle kokuhlunga, okubenza bafanelekele izinhlelo zokusebenza ezidinga ukuhlungwa okuqinile.

Izinzuzo zezihlungi ze-Metal 5 Micron

Izihlungi ze-Metal 5 Micron zinikeza izinzuzo eziningi, zizenze zibe yinketho ekhethwayo ezimbonini ezahlukahlukene:

*Ukuhlunga Okuphakeme Ngempumelelo:

Iyakwazi ukuthwebula izinhlayiya ezincane njengama-microns angu-5, lezi zihlungi ziqinisekisa amazinga aphezulu okuhlunga, okubalulekile

izicelo ezifuna ubumsulwa nokunemba.

*Ukuqina:

Zakhiwe ngezinto eziqinile njengensimbi engagqwali, izihlungi zensimbi zingamelana nezindawo ezinokhahlo, okuhlanganisa

amazinga okushisa aphezulu nezingcindezi, okuqinisekisa ukusebenza okuthembekile.

*Isikhathi eside sokuphila:

Izihlungi zensimbi zenzelwe ukuphila isikhathi eside. Angahlanzwa futhi asetshenziswe kabusha izikhathi eziningi, ahlinzeke ngendlela eyongayo

isixazululo sokuhlunga phakathi nesikhathi sabo sokuphila.

*Ukumelana Kwamakhemikhali:

Imelana nezinhlobonhlobo zamakhemikhali, izihlungi zensimbi zilungele ukusetshenziswa okubandakanya izinto ezinolaka,

ukuqinisekisa ukusebenza okungaguquki ngaphandle kokucekelwa phansi.

Yini Engenziwa Izihlungi Ze-Metal 5 Micron?

Izihlungi ze-Metal 5 micron zingenza izinto ezahlukahlukene, kuye ngohlelo lokusebenza. Nazi ezinye ezivame kakhulu:

1. Khipha inzika, ukungcola, nokunye ukungcola oketshezini:

Avame ukusetshenziswa ezinhlelweni zokuhlunga amanzi ukuze asuse intlenga, ukungcola, ukugqwala nokunye ukungcola emanzini.

Lokhu kungasiza ekuthuthukiseni ukunambitheka kanye nekhwalithi yamanzi, futhi kungavikela nezinto ezisebenza ngogesi ukuthi zingalimali

ngalawa magciwane.

2. Susa uthuli, impova, nezinye izinhlayiya ezihamba emoyeni:

3. Susa ukungcola, udoti, nokunye ukungcola kuphethiloli:

Angasetshenziswa ezinhlelweni zokuhlunga uphethiloli ukususa ukungcola, udoti, nokunye ukungcola kuphethiloli.

Lokhu kungasiza ukuvikela izinjini ekugugeni futhi kuthuthukise ukusebenza.

4. Khipha izinhlayiya kumakhemikhali nolunye uketshezi:

Angasetshenziswa ezinhlelweni zokuhlunga amakhemikhali ukuze asuse izinhlayiya kumakhemikhali, izinyibilikisi, nolunye uketshezi.

Lokhu kungasiza ekuthuthukiseni ikhwalithi yoketshezi futhi kuvikele izinto zokusebenza ukuthi zingalimali.

Kubalulekile ukuqaphela ukuthi ukusebenza kahle kwesihlungi sensimbi esingu-5 micron kuzoncika kuhlelo lokusebenza oluthile.

Isibonelo, isihlungi se-micron esingu-5 singase singasebenzi ekukhipheni wonke amagciwane emanzini, ngakho-ke kubalulekile

sebenzisa ezinye izindlela zokwelapha ngokuhambisana nokuhlunga uma kunesidingo.

Nazi ezinye izinto ezengeziwe okufanele uzikhumbule mayelana nezihlungi ze-metal 5 micron:

* Atholakala ngamasayizi ahlukahlukene kanye nokucushwa ukuze alingane nezidingo ezahlukene.

* Zingenziwa ngezinhlobo ezahlukene zensimbi, njengensimbi engagqwali, ithusi ne-nickel.

* Angaphinda asetshenziswe noma alahlwe.

* Zidinga ukushintshwa noma zihlanzwe ngezikhathi ezithile ukuze zigcine ukusebenza kwazo ngempumelelo.

Izici Eziyinhloko Zezihlungi Ze-Sintered Metal 5 Micron ?

Izihlungi ze-Sintered metal 5 micron ziziqhayisa ngezici ezimbalwa ezibalulekile ezizenza ukukhetha okuthembekile

ngezicelo ezahlukahlukene zezimboni:

1. Ukusebenza Kahle Kokuhlunga:

Tizihlungi ze-hese, ngenxa yesakhiwo sazo sezimbotshana ezilawulwa ngokuqinile, zinekhono lokuthwebula ezincane

izinhlayiya nokungcola okuncane okungama-microns angu-5 kusuka kugesi noma imifudlana ewuketshezi.

Lokhu kuhumushela kuketshezi oluhlanzekile nolucoliseke kakhulu noma emoyeni kuye ngohlelo lokusebenza.

2. Indawo Enkulu:

Izihlungi zensimbi ezine-sintered zinendawo enkulu yangaphakathi naphezu kosayizi wazo ohlangene.

Lokhu kuvumela:

Amazinga okugeleza aphezulu: Lokhu kusho ukuthi angakwazi ukuphatha umthamo omkhulu woketshezi noma amagesi ngaphandle

ukwehla kwengcindezi enkulu, ukugcina ukuhlunga okusebenzayo ngaphandle kokuba nomthelela ekusebenzeni kwesistimu.

Ukwanda komthamo wokubamba ukungcola: Indawo enkulu engaphezulu ivumela isihlungi ukuthi sibambe uhla olubanzi lwalo

ukungcola ngaphambi kokudinga ukushintshwa noma ukuhlanzwa.

3. Ukuqina Nokuphila Isikhathi Eside:

Lezi zihlungi zaziwa ngokuhlukile:

Ukumelana nezinga lokushisa: Bangakwazi ukumelana namazinga okushisa aphezulu okusebenza, okubenza bafaneleke

ezindaweni ezidinga kakhulu.Ukumelana nokucindezela: Bangakwazi ukubhekana nokucindezela okukhulu ngaphandle

ukuyekethisa ubuqotho babo besakhiwo.

-

Ukumelana nokugqwala: Izinto zokuhlunga, ngokuvamile insimbi engagqwali, zinikeza ukumelana okuhle kakhulu

-

ukugqwala okuvela kuketshezi namakhemikhali ahlukahlukene, okuqinisekisa ukusebenza okuhlala isikhathi eside.

4. Ukuhlukahluka:

Izihlungi ze-Sintered metal 5 micron zihambisana nohlu olubanzi loketshezi, okuhlanganisa:

Amanzi: Awusizo ezinhlelweni zokuhlunga amanzi ekukhipheni ukungcola njengenhlabathi nokugqwala.Umoya:

Kuqashwe ezinhlelweni zokuhlunga komoya ukuze kuthwebule uthuli, impova, nezinye izinhlayiya ezihamba emoyeni.

*Amafutha: Asetshenziswa ezinhlelweni zokuhlunga uphethiloli ukususa ukungcola nemfucumfucu, ukuvikela izinjini.

*Amakhemikhali: Isebenza ezinhlelweni zokuhlunga amakhemikhali ukuze kuqedwe izinhlayiya ezinhlobonhlobo

amakhemikhali nezincibilikisi.

5. Ukuhlanzeka Nokusebenziseka Kabusha:

Ngokungafani nezinye izihlungi ezilahlwayo, izihlungi zensimbi ezine-sintered zivame ukuhlanzeka futhi zisebenziseke kabusha.

Lokhu kusho ukwehlisa izindleko zesikhathi eside kanye nokuncipha komthelela kwezemvelo.

Izindlela zabo zokuhlanza zingabandakanya ukuwashwa emuva, ukugeleza okubuyela emuva, noma ukuhlanza nge-ultrasonic,

kuye ngohlelo oluthile kanye nezincomo zomkhiqizi.

Kafushane, izihlungi zensimbi ezine-sintered 5 micron zinikeza inhlanganisela ephoqelelayo yokuhlunga okuphezulu

ukusebenza kahle, indawo enkulu, ukuqina okukhethekile, ukuguquguquka, nokuhlanzeka/ukusebenziseka kabusha,

ukwenza kube ukukhetha okubalulekile kwezidingo ezahlukahlukene zokuhlunga kwezimboni.

Ukwengeza, lezi zihlungi zingasebenza njengesixazululo sokuvikela ukuvikela isistimu yokuhlunga

izinsongo ezingaba khona.

FAQ

1. Siyini isihlungi sensimbi esingu-5 micron, futhi sisebenza kanjani?

Isihlungi sensimbi esingu-5 micron siyidivayisi yokuhlunga eklanyelwe ukususa izinhlayiya ezinkulu kuno-5 micrometer.

kusuka kuketshezi oluhlukahlukene noma amagesi ezimbonini, ezentengiselwano, noma izilungiselelo zaselabhorethri.

Isebenza ngokusekelwe kumgomo wokuhlunga ngomshini, lapho ainsimbi enezimbotshanaimidiya isebenza njengesithiyo lokho

ihlukanisa ngokomzimba futhi icuphe izinhlayiya ezivela ekugelezeni okudlula kuyo. Lezi zihlungi zenziwe

izinto zensimbi eziqinile njengensimbi engagqwali, ekwazi ukumelana nezingcindezi eziphezulu, amazinga okushisa, kanye

izindawo ezonakalisayo. Ukukhethwa kwensimbi kanye nomklamo wemidiya yokuhlunga

(okubandakanya ukusatshalaliswa kosayizi wembobo kanye nendawo engaphezulu) kulungiselelwe ukuze kuzuzwe ukusebenza kahle kokuhlunga, ukuqina,

kanye nokumelana nokuvala.

2. Kungani izihlungi zensimbi eziyi-5 micron zikhethwa kunezinye izinhlobo zezihlungi?

Izihlungi ze-Metal 5 micron zikhethwa ngenxa yezizathu ezimbalwa:

* Ukuqina Nokuthembeka:

Izihlungi zensimbi zinikeza amandla okusebenza aphakeme futhi zingamelana nezimo ezimbi kakhulu, okuhlanganisa amazinga okushisa aphezulu,

izingcindezi, nezinto ezonakalisayo, eziqinisekisa ukwethembeka nokusebenza kwesikhathi eside.

* Ukusebenziseka kabusha kanye nokusebenza kahle kwezindleko:

Ngokungafani nezihlungi ezilahlwayo, izihlungi zensimbi zingahlanzwa futhi zisetshenziswe kabusha izikhathi eziningi, zinciphise kakhulu

imfucuza kanye nezindleko zokusebenza esikhathini sokuphila kwabo.

* Ukuhlunga Okunembayo:

Ukulawulwa okunembile kosayizi wembotshana ezihlungi zensimbi kuvumela ukusebenza kokuhlunga okungaguquki nokubikezelwa,

kubalulekile ezinhlelweni ezidinga amazinga aphezulu okuhlanzeka.

* Ukuhlukahluka:

Izihlungi zensimbi zingaklanywa ukuthi zivumelane nezinhlelo zokusebenza eziningi, ngezinketho zokwenza ngokwezifiso zezinto ezibonakalayo, usayizi,

umumo, kanye nosayizi wembotshana ukuze kuhlangatshezwane nezidingo ezithile.

3. Yiziphi izinhlelo zokusebenza ezivame ukusetshenziswa kuzo izihlungi zensimbi ezingu-5 micron?

Izihlungi ze-Metal 5 micron zithola ukusetshenziswa kuhlu lwezimboni ezihlukene, ezihlanganisa:

* Ukucubungula Amakhemikhali:

Ukuhlunga ama-catalysts, ama-particle, nama-sediments kumakhemikhali nezincibilikisi.

* Imithi:

Okweukuhlanzwa kwamagesikanye noketshezi, okuqinisekisa ubumsulwa bomkhiqizo nokuhambisana nezindinganiso zokulawula.

* Ukudla nesiphuzo:

Ekuhlungeni amanzi, amafutha, nezinye izithako ukususa ukungcola nokuthuthukisa ikhwalithi yomkhiqizo.

* Uwoyela Negesi:

Ukuze kuhlukaniswe izinhlayiya kumafutha nezinto zokugcoba ukuze kuvikelwe imishini futhi kunwetshwe ukuphila kwayo. Lezi zihlungi zingasiza futhi ukuvikela imishini ekuhlaselweni okungaba khona ku-inthanethi.

* Ukwelashwa kwamanzi:

Ekuhlungeni amanzi angcolile ezimbonini namanzi aphuzwayo ukuze kukhishwe izinhlayiya nokuqinisekisa ukuphepha nokuhambisana nezindinganiso zemvelo.

4. Izihlungi zensimbi eziyi-5 micron zigcinwa futhi zihlanzwa kanjani?

Ukugcinwa nokuhlanza izihlungi zensimbi ezingama-micron angu-5 kubalulekile ekusebenzeni kahle nokuphila isikhathi eside. Inqubo ngokuvamile ihlanganisa:

* Ukuhlola Okuvamile:

Ukuhlola ngezikhathi ezithile izimpawu zokuguga, ukulimala, noma ukuvaleka kubalulekile ukuze kutholwe isidingo sokuhlanza noma ukushintshwa.

* Izindlela zokuhlanza:

Ngokuya ngohlobo lokungcoliswa kanye nempahla yesihlungi, ukuhlanza kungenziwa kusetshenziswa i-backflushing, ukuhlanza nge-ultrasonic, ukuhlanza amakhemikhali, noma amajethi amanzi anomfutho ophezulu. Kubalulekile ukukhetha indlela yokuhlanza ehambisana nezinto zokuhlunga ukuze ugweme ukulimala.

* Ukushintshwa: Nakuba izihlungi zensimbi ziklanyelwe ukuqina, kufanele zishintshwe uma zibonakalisa izimpawu zokuguga okungenakulungiseka noma umonakalo, noma uma zingasakwazi ukuhlanzwa ngokuphumelelayo.

5. Umuntu angakhetha kanjani isihlungi esifanele sensimbi esingu-5 micron sohlelo lwakhe lokusebenza?

Ukukhetha isihlungi esifanele sensimbi esingu-5 micron kuhilela izinto ezimbalwa:

* Ukuhambisana Kwezinto:

Into yokuhlunga kufanele ihambisane noketshezi noma amagesi ezohlangana nayo, kucatshangelwa izici ezifana nokungagqwala kanye nokuzinza kwezinga lokushisa.

* Izimo zokusebenza:

Isihlungi kufanele sikwazi ukuphatha ukucindezela okulindelekile, izinga lokushisa, nezimo zesilinganiso sokugeleza ngaphandle kokuphazamisa ukusebenza noma ubuqotho.

* Ukusebenza kahle kokuhlunga:

Cabangela izidingo ezithile zokuhlunga zohlelo lwakho lokusebenza, okuhlanganisa uhlobo nosayizi wezinhlayiya ezizosuswa, ukuze uqinisekise ukuthi isihlungi esikhethiwe sihlangabezana nezidingo zakho.

* Ukunakekela nokuhlanza:

Linganisa ukunethezeka kokulungiswa nokuhlanza ngokusekelwe emandleni akho okusebenza kanye nohlobo lokungcola okulindelekile.

Sengiphetha, izihlungi ze-metal 5 micron ziyizingxenye ezibalulekile ezinhlelweni ezihlukene zezimboni, ezinikeza ukuqina, ukunemba, kanye nokuhlukahluka. Ukuqonda izidingo zabo zokuklama, ukusetshenziswa, kanye nokugcinwa kwazo kubalulekile ekukhetheni isihlungi esifanele nokuqinisekisa ukusebenza kahle nokuphila isikhathi eside.

Xhumana nezihlungi ze-HENGKO OEM Stainless Steel 5 Micron

Ukuze uthole izixazululo eziqondene nawe kanye nesiqondiso sochwepheshe ekukhetheni izihlungi ezifanele zensimbi ezingu-5 micron

ngezidingo zakho ezithile, ungangabazi ukuxhumana nethimba le-HENGKO.

Kungakhathaliseki ukuthi ufuna izinketho zokwenza ngokwezifiso, iseluleko sobuchwepheshe, noma unemibuzo mayelana nemikhiqizo yethu,

ochwepheshe bethu abazinikele balapha ukuze bakusize zonke izinyathelo zendlela.

Xhumana nathi ngqo kuka@hengko.comukuthola ukuthi singakuthuthukisa kanjani ukusebenza kahle nokuthembeka kwakho

ukusebenza ngezixazululo zethu zokuhlunga zekhwalithi ephezulu. Vumela u-HENGKO abe umlingani wakho ekuzuzeni impumelelo

ukusebenza kokuhlunga. Sithumele i-imeyili namuhla - imibuzo yakho iyisinyathelo sokuqala sokubambisana ngempumelelo.